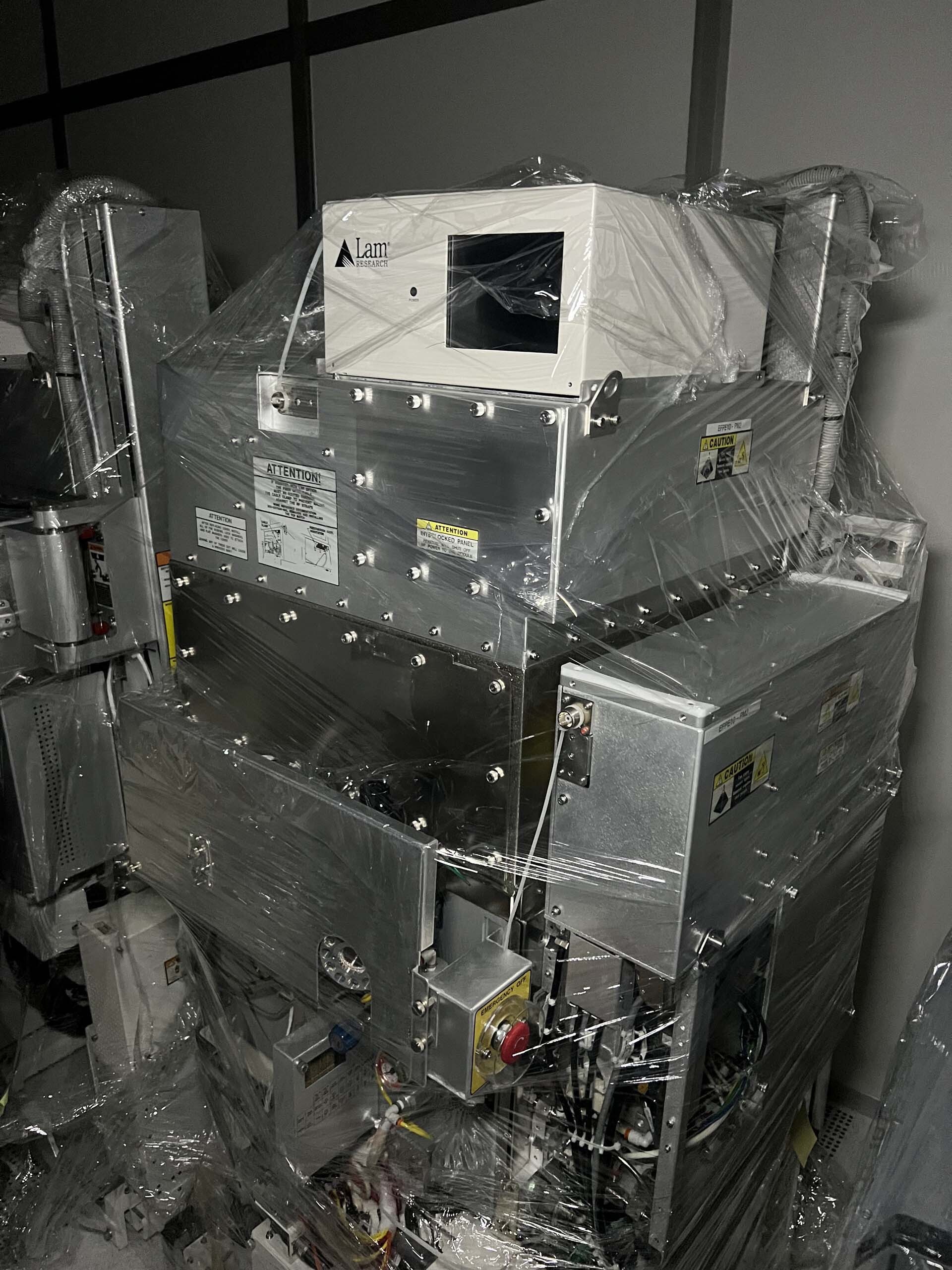

Used LAM RESEARCH 2300 #293654544 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

LAM RESEARCH 2300 is an industry-leading reactive ion etcher and asher operating in a process chamber. This fully automated system is capable of achieving precise linearity, uniformity, and repeatability in an etch and ashing process. Designed for use in the semiconductor and research and development industries, 2300 offers flexibility and accuracy that can meet the demands of a wide variety of processes. LAM RESEARCH 2300 creates a uniform etch profile by utilizing sophisticated showerhead design. This incorporated design creates a more efficient, uniform etch process that ultimately results in a more accurate etch depth and uniformity throughout the wafer. 2300 is also designed as a full one-piece system, granting better accessibility and enhance servicing. With one-piece installation, the overhead track outside of the wafer protection area is kept to a minimum overall space requirement. LAM RESEARCH 2300 is equipped with the latest process technologies, including high frequency and power modulation, the ability to choose between either gas flow or pressure for etching, variable on-board gas composition, variable gas flow control, and variable power control. These features can be used together to optimize etching processes tailored to the needs of a specific application type. In addition, 2300 also offers temperature control and uniformity, providing a highly precise process control and even temperature distribution over the entire wafer, contributing to reliable and repeatable processes. LAM RESEARCH 2300 features advanced safety features in addition to highly precise processes. These features include Virtual Guard Technology (VGT), a system of embedded sensors that continuously monitors the protective shield relative to the wafer protection area, protecting the equipment and the user from any potential hazards caused by improper use. In conclusion, 2300 provides a precise, reliable, and automatic process that is capable of meeting the demands of a wide variety of processes, including semiconductor and research and development industries. Its one-piece design and virtual guard safety technology make it the ideal solution for all etching and ashing needs, no matter the application type.

There are no reviews yet