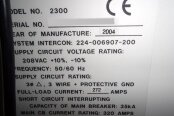

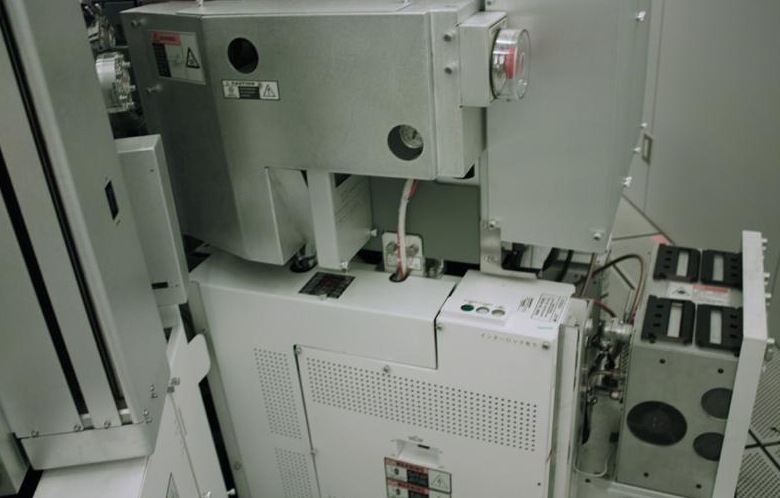

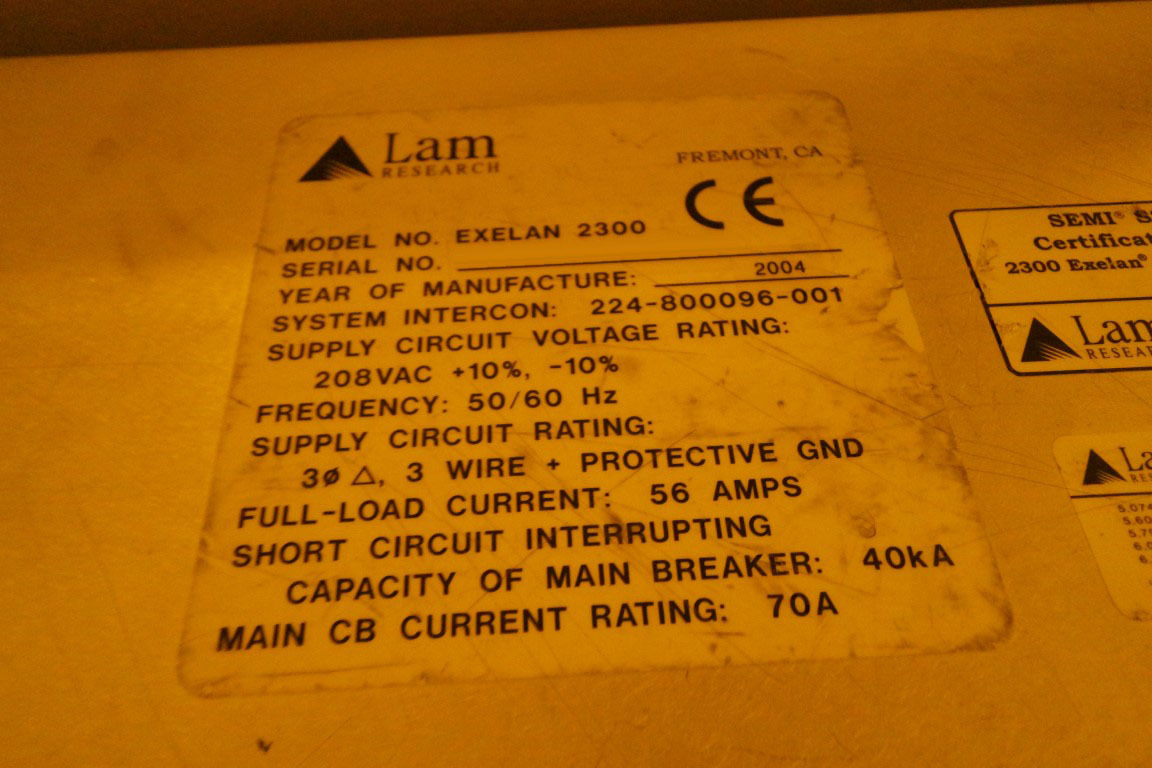

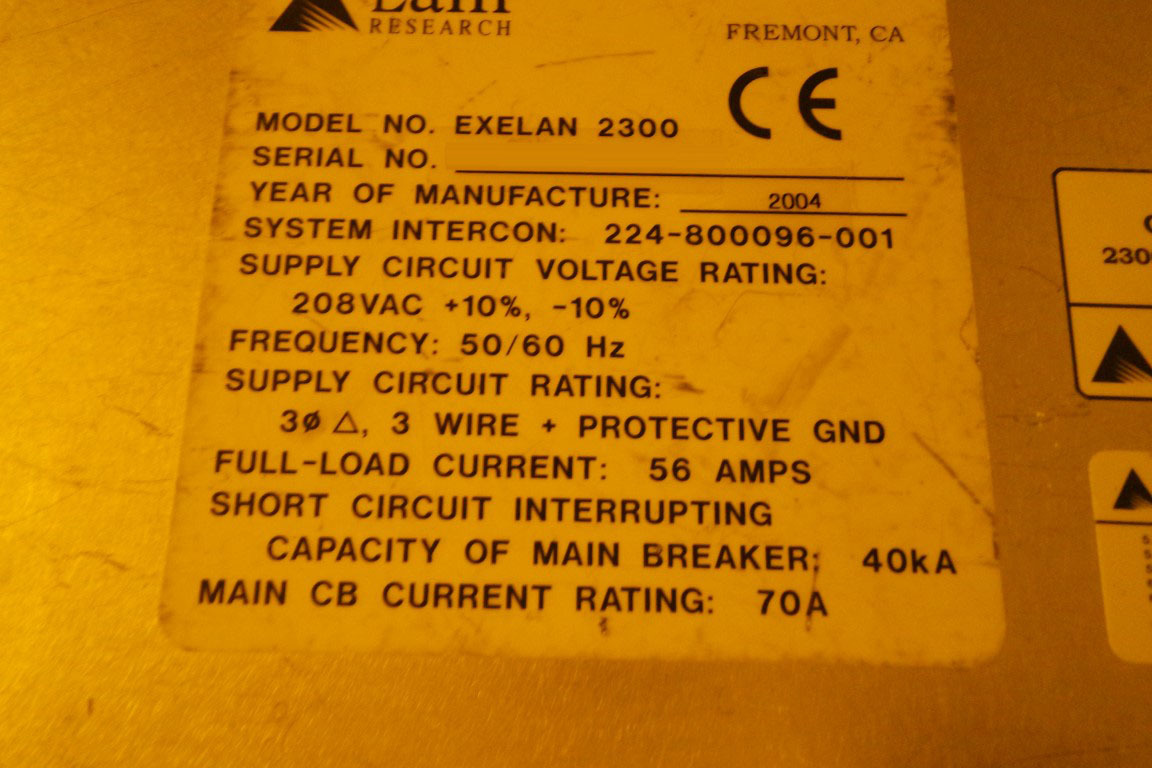

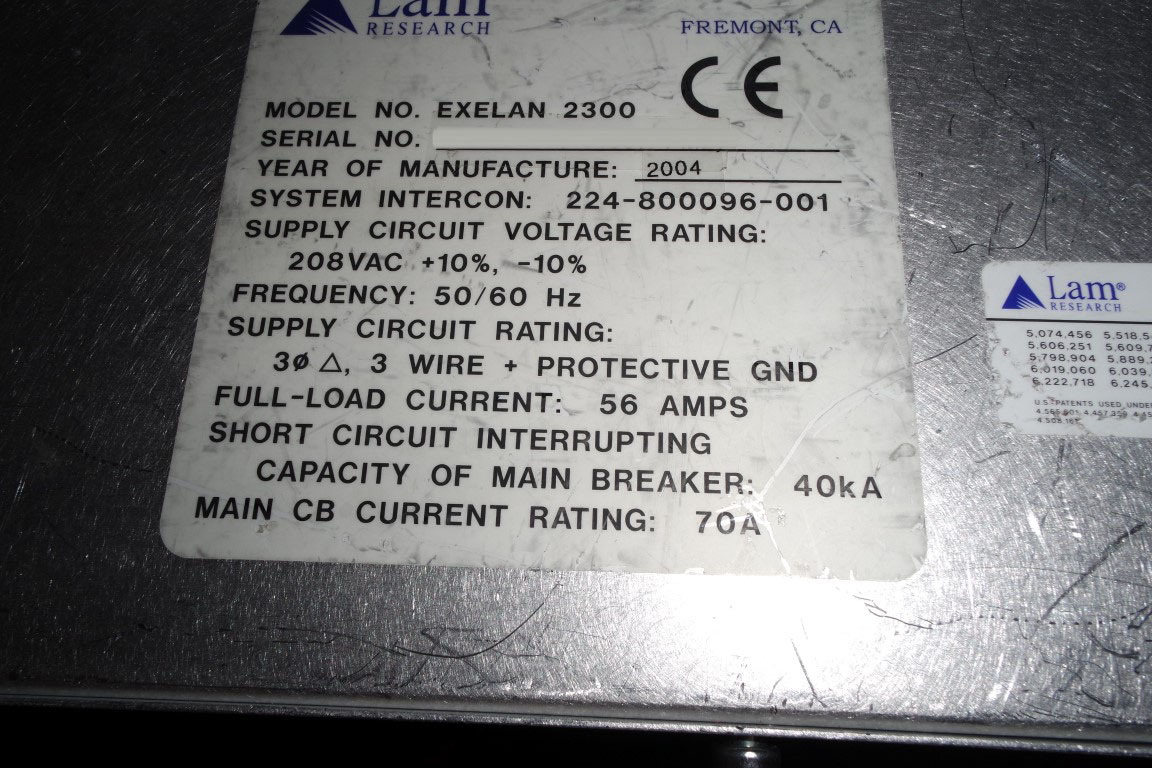

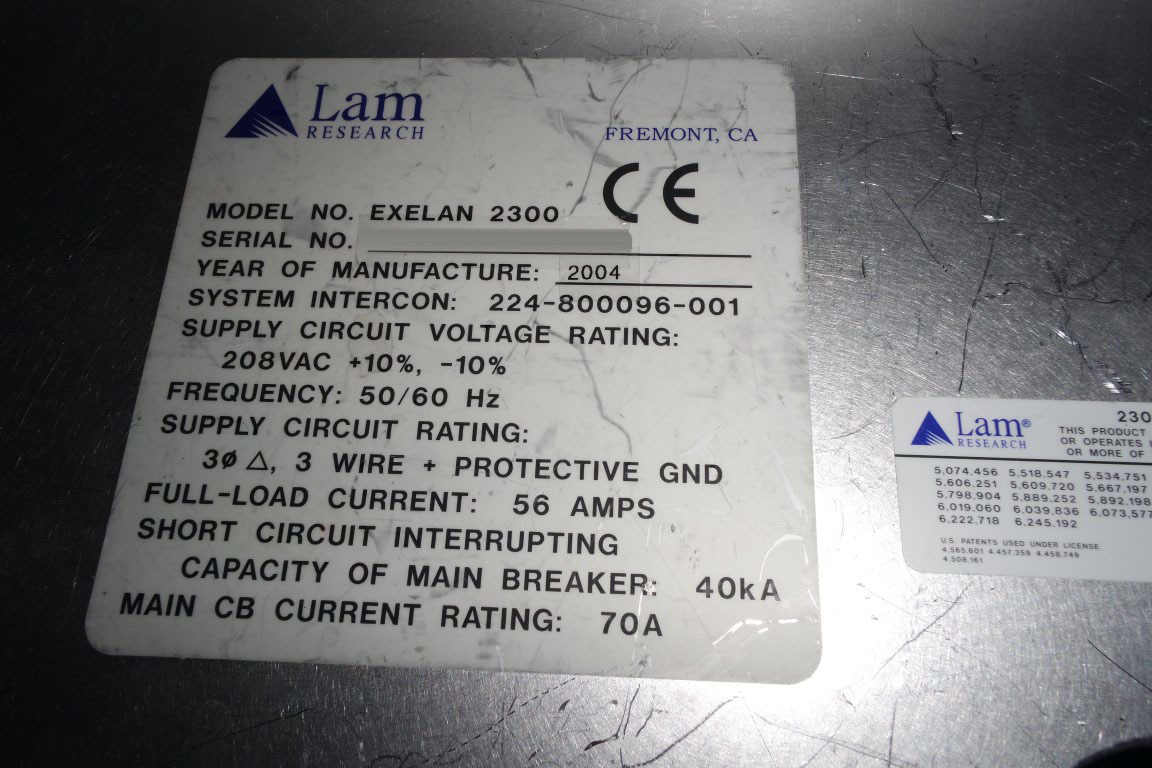

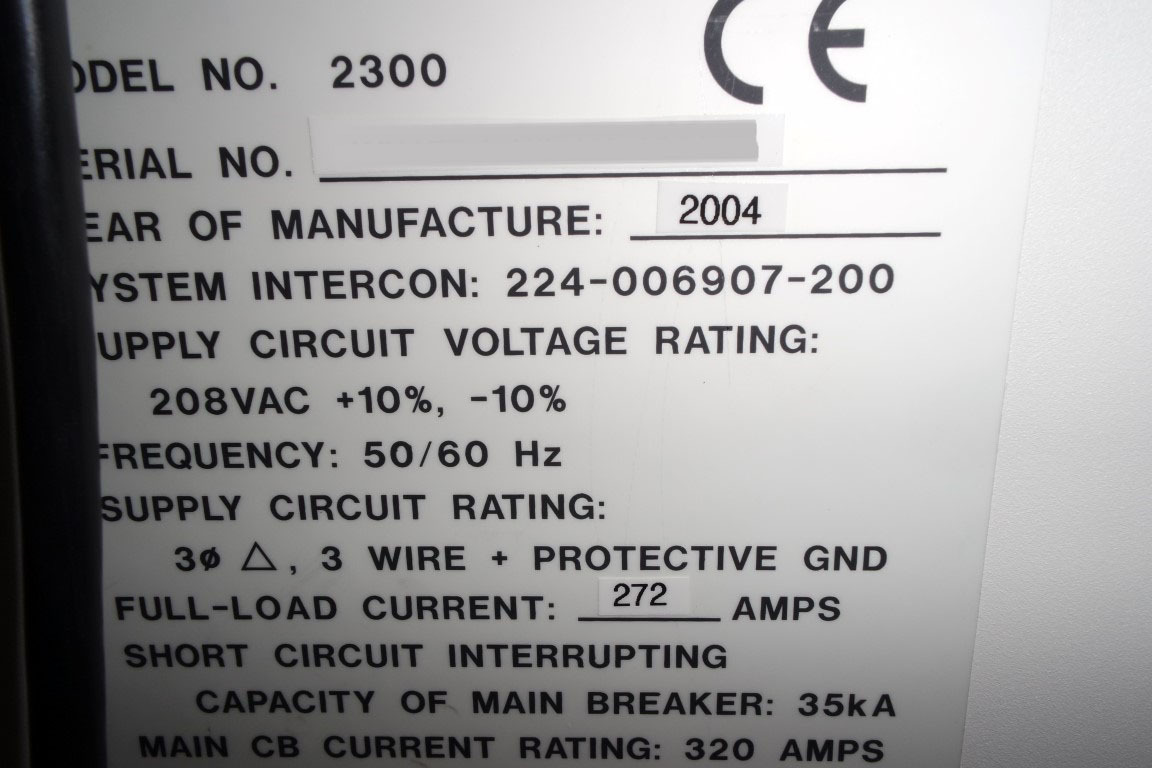

Used LAM RESEARCH 2300 #9083803 for sale

URL successfully copied!

Tap to zoom

ID: 9083803

Wafer Size: 8"

Vintage: 2004

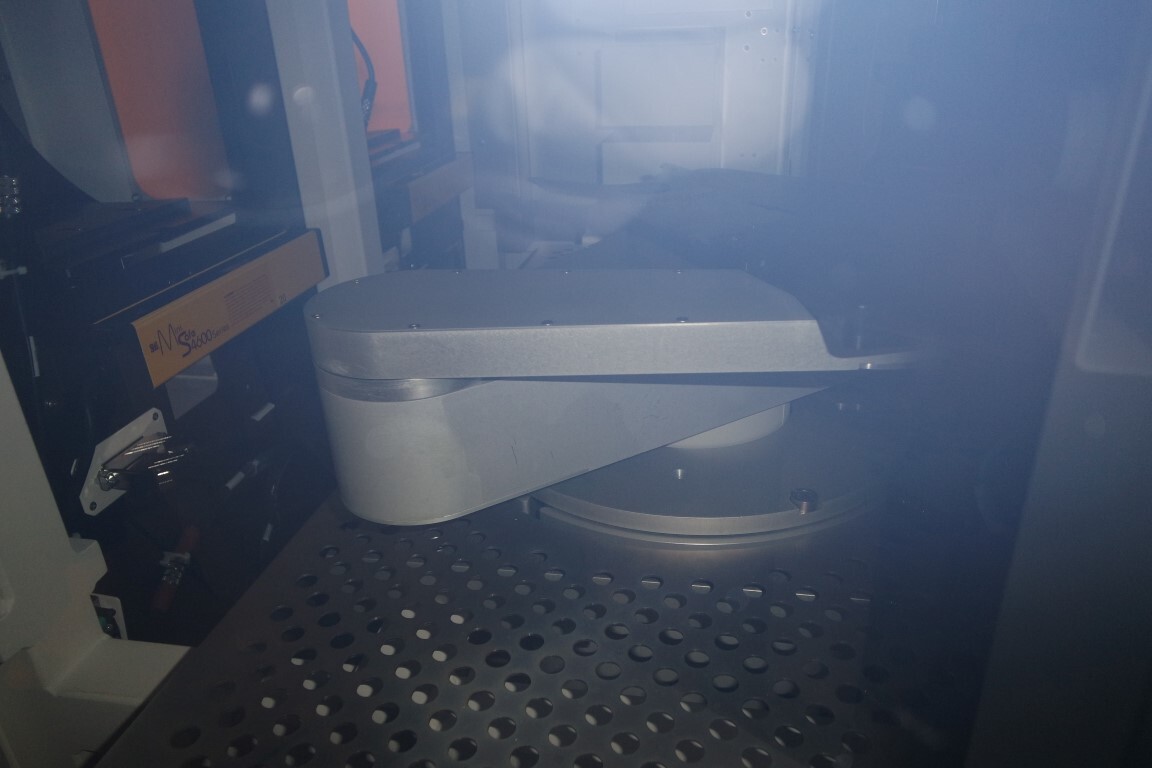

Oxide etcher, 8"

Cass nest plastic, 8"

Wafer shape: SNNF (Semi notch no flat)

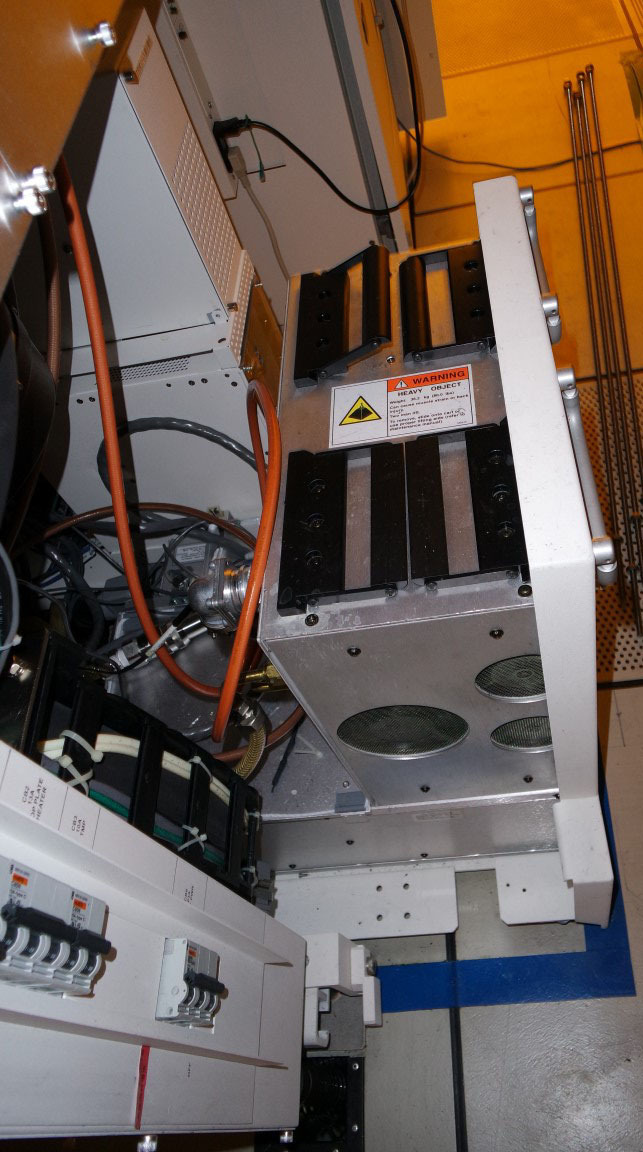

(4) Process chambers:

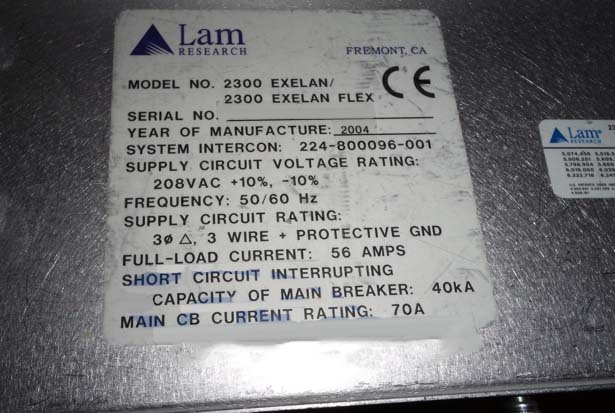

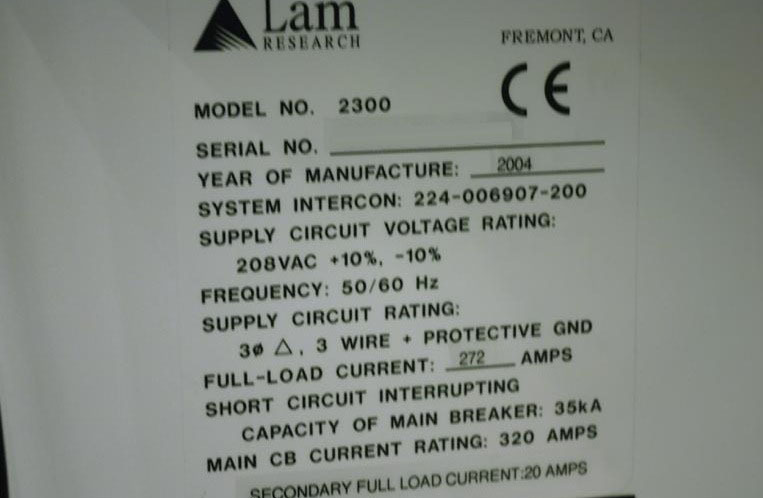

Position 1: 2300 Exelan

Position 2: 2300 Exelan

Position 3: 2300 Exelan

Position 4: 2300 Exelan

Front end load port cassette:

(3) Open cassettes iPX

Backing pumps for TM iPX

User interface option: Side and front monitor UI

Earth leakage breaker ELB

Signal tower

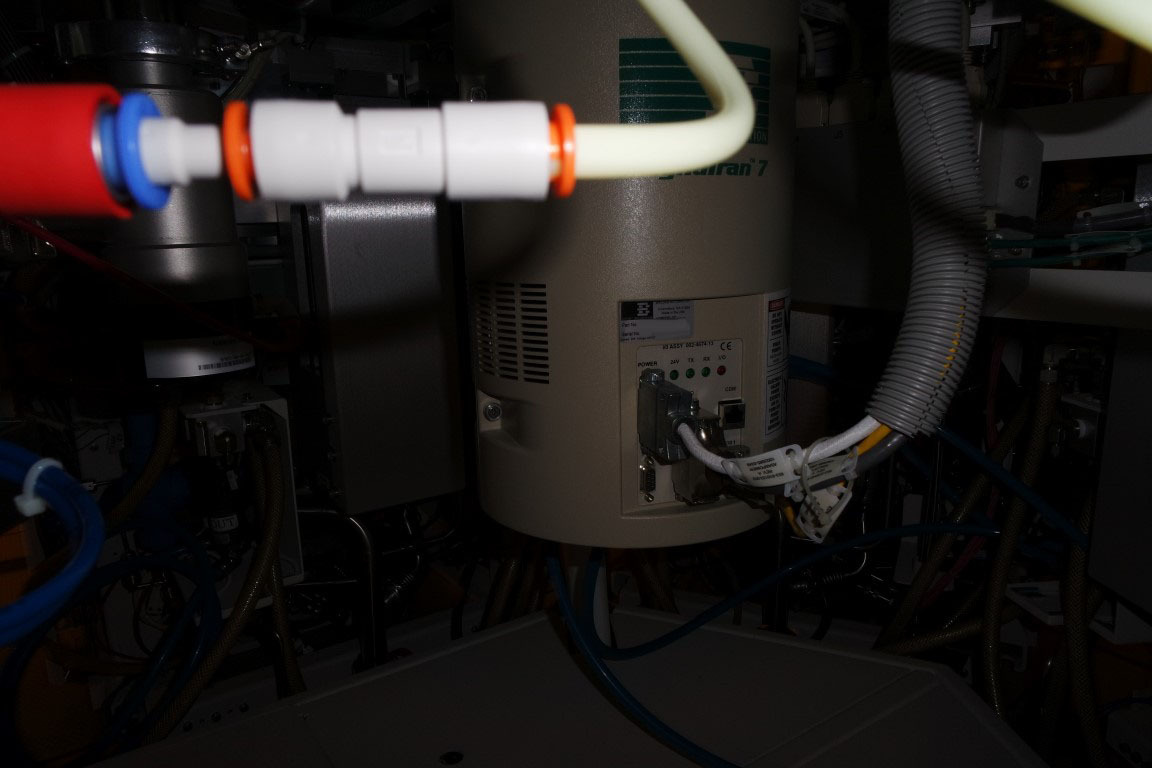

SECS / GEM

Plat from type: Version 2

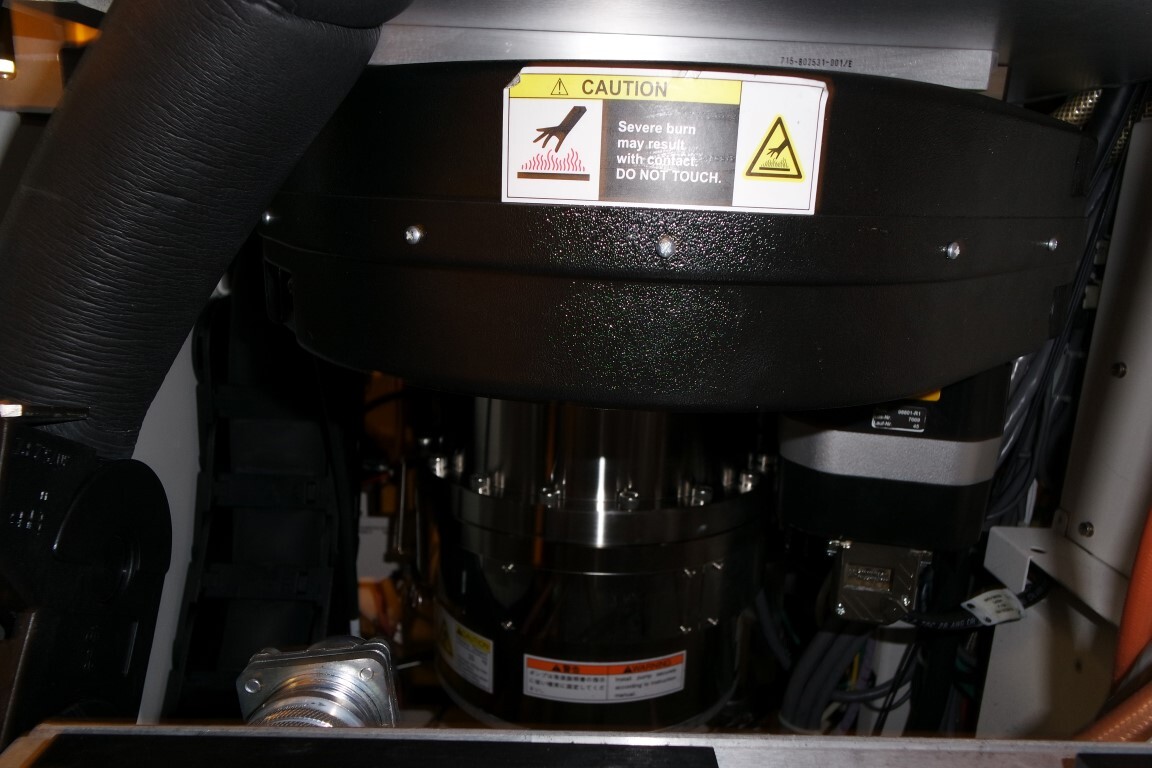

2300 Exelan options:

Chamber type: 2300 Exelan CFE

Upper electrode heated

ESC Cooling dual zone

1600 L/S EDWARDS Turbo pump, 8"

Endpoint detection optical emission spectroscopy

Chamber isolation valve rocker gate valve

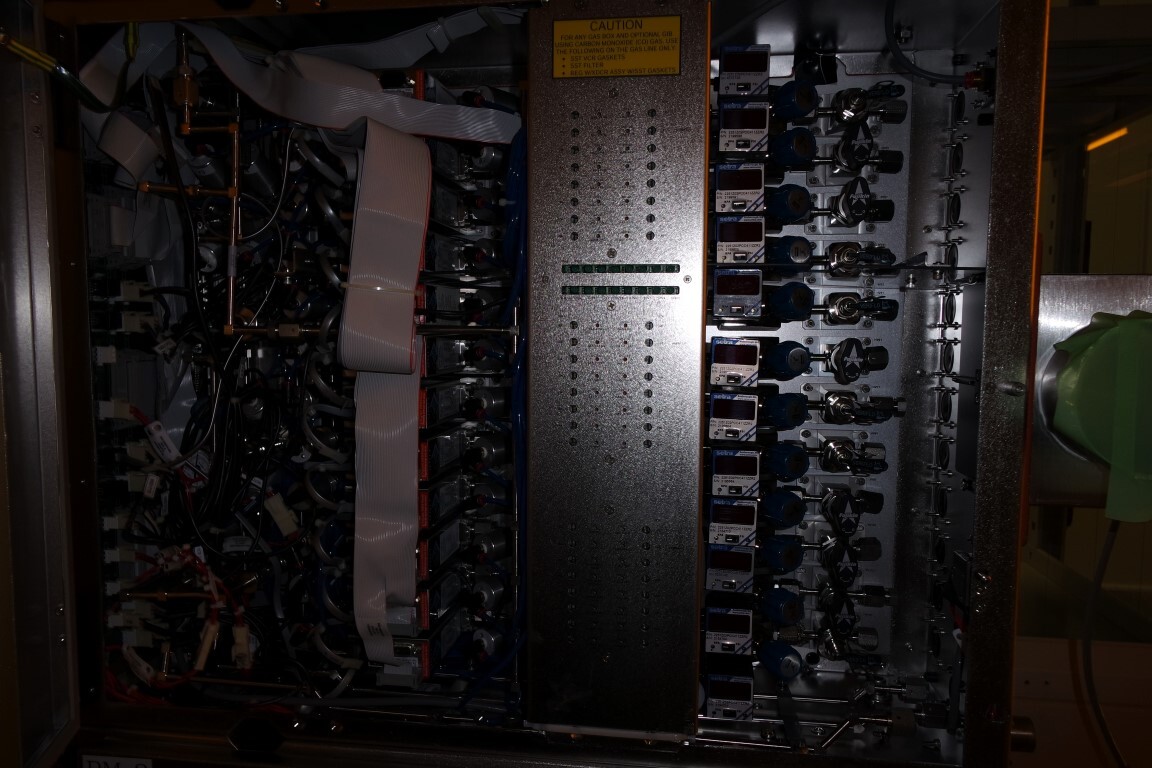

2300 Gas box:

Gas system type: Enhanced gas box II

Std stacking kits: 4 PM stacking kit

Gas line 12 gas configuration

Gas box inlet option: Regulated inlet gas panel

Gas filters: Standard filter

Gas box configuration:

PM1 MFC Type: Unit 1661 metal, digital

Line 1 Ar 1000 sccm

Line 2 O2 50 sccm

Line 3 N2 200 sccm

Line 4 O2 2000 sccm

Line 5 CHF3 100 sccm

Line 6 C4F8 20 sccm

Line 7 CH2F2 50 sccm

Line 8 C4F8 50 sccm

Line 9 CF4 100 sccm

Line 10 NSR70%He/30%O2100 sccm

Line 11 C4F6 20 sccm

Line 12 NSR Xe 300 sccm

Line 13 HeO2 20 sccm (Tuning gas)

PM2 MFC Type: Unit 1661 metal, digital

Line 1 Ar 1000 sccm

Line 2 O2 50 sccm

Line 3 N2 200 sccm

Line 4 O2 2000 sccm

Line 5 CHF3 100 sccm

Line 6 C4F8 20 sccm

Line 7 CH2F2 50 sccm

Line 8 C4F8 50 sccm

Line 9 CF4 100 sccm

Line 10 NSR70%He/30%O2100 sccm

Line 11 C4F6 20 sccm

Line 12 NSR Xe 300 sccm

Line 13 HeO2 20 sccm(Tuning gas)

PM3 MFC Type: Unit 1661 metal, digital

Line 1 Ar 1000 sccm

Line 2 O2 50 sccm

Line 3 N2 200 sccm

Line 4 O2 2000 sccm

Line 5 CHF3 100 sccm

Line 6 C4F8 20 sccm

Line 7 CH2F2 50 sccm

Line 8 C4F8 50 sccm

Line 9 CF4 100 sccm

Line 10 NSR70%He/30%O2100 sccm

Line 11 C4F6 20 sccm

Line 12 NSR Xe 300 sccm

Line 13 HeO2 20 sccm(Tuning gas)

PM4 MFC Type: Unit 1661 metal, digital

Line 1 Ar 1000 sccm

Line 2 O2 50 sccm

Line 3 N2 200 sccm

Line 4 O2 2000 sccm

Line 5 CHF3 100 sccm

Line 6 C4F8 20 sccm

Line 7 CH2F2 50 sccm

Line 8 C4F8 50 sccm

Line 9 CF4 100 sccm

Line 10 NSR70%He/30%O2100 sccm

Line 11 C4F6 20 sccm

Line 12 NSR Xe 300 sccm

Line 13 HeO2 20 sccm (Tuning gas)

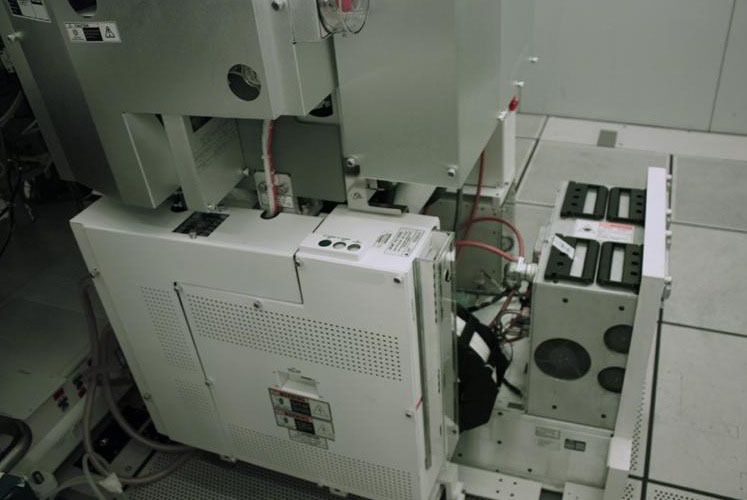

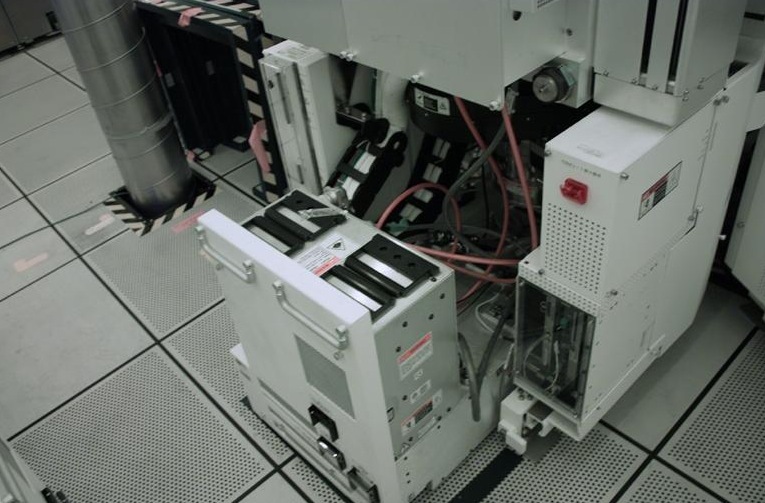

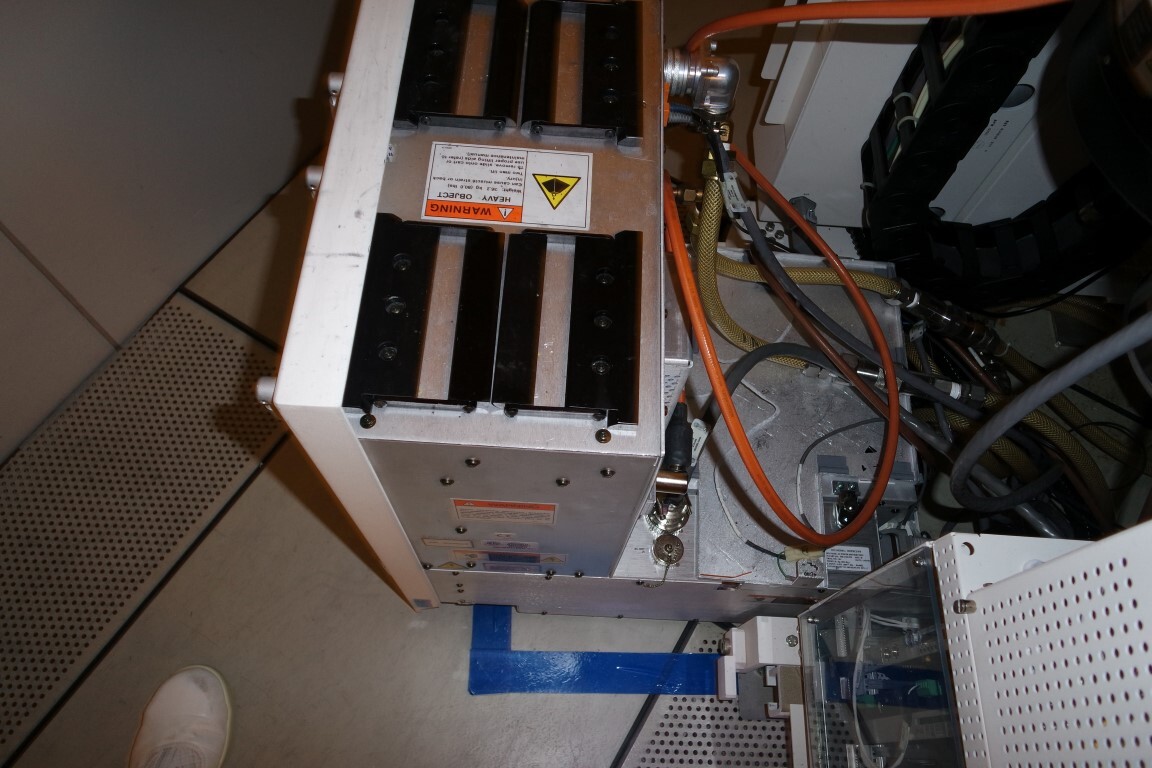

2300 Peripherals:

DFC Backing pumps cust supply

DFC TCU Config lam supply: (4) 4080 Plus

Gas scrubber: EBARA GTE-3-0WVT

Power distribution module: RPDB

Dry pumps:

TM EDWARDS iPX 100A

PM1 EBARA AA100W

PM2 EBARA AA100W

PM3 EBARA AA100W

PM4 EBARA AA100W

No SMIF interface

2004 vintage.

LAM RESEARCH 2300 Exelan is a technologically advanced etcher and asher specifically designed for high-volume production of semiconductor devices. The Exelan is capable of etching and ashing at high speeds while still providing extremely precise results. Its unique semi-aqueous chemical process ensures a consistently uniform structure and surface quality. The equipment is capable of performing high-throughput etching and ashing of silicon wafers, and can handle a maximum of three 200-mm (8-inch) wafers at a time. The Exelan is equipped with advanced process control and integration capabilities for process-automated operations. Its high-precision optical white light system enables the unit to perform etching and ashing with precision and accuracy. Its advanced automation machine provides a localized and flexible control strategy that allows simultaneous control of various process parameters. The integrated robotic arm helps minimize the cycle time, while providing repeatable results. The machine's software controls provides a complete range of process control and integration capabilities.t includes a wide range of variables such as high-precision optical registration systems, auto-stabilization control systems, precision wafer orientation systems, and integrated robotic arms. The tool is equipped with an extensive library of recipes that can be accessed and reused for applications with similar set of processing requirements. The Exelan also offers a comprehensive suite of process, diagnostic and data analysis functions. The asset features a process minirobot with automatic wafer loading and unloading. Additionally the model has built-in diagnostic tools which allows monitoring and analysis of the etching and ashing process. The equipment also offers process control software that enables engineers to tune their processes for optimal performance and efficiency. The Exelan's modular design enables customization for additional features such as nitrogen inerting systems, recirculation systems, and additional chemical deliverance systems. The system is compliant with various safety and environmental standards and has passed various safety checks throughout various testing regimes. The unit has been proven to help reduce the cost of ownership and provide a low total cost of operation. Overall, 2300 Exelan is an advanced machine capable of high-performance etching and ashing tasks. The tool is ideal for high-volume production applications such as semiconductor device manufacturing as it enables time- and cost-efficient operations. The asset's integrated process control and automation capabilities provide a consistent and repeatable performance, while its wide range of process, diagnostic, and data analysis functions ensures process optimization and efficiency.

There are no reviews yet