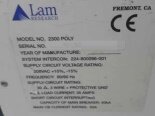

Used LAM RESEARCH 2300 #9176731 for sale

URL successfully copied!

Tap to zoom

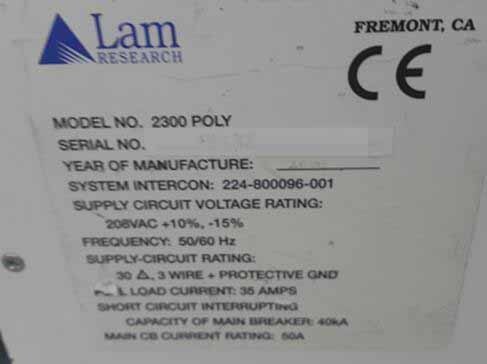

ID: 9176731

Wafer Size: 12"

Vintage: 2002

Poly etcher, 12"

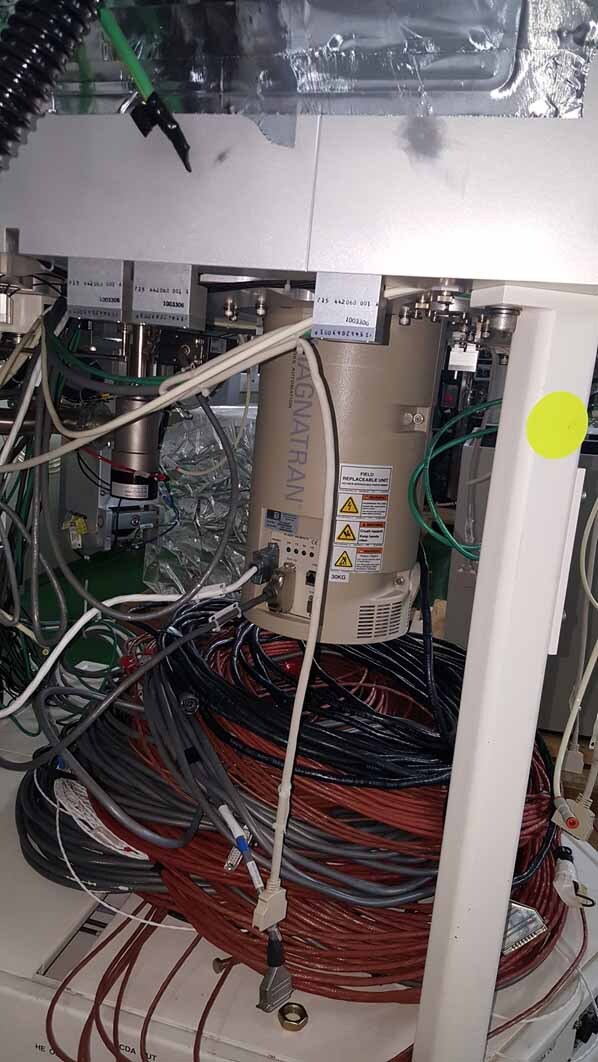

(2) Chambers

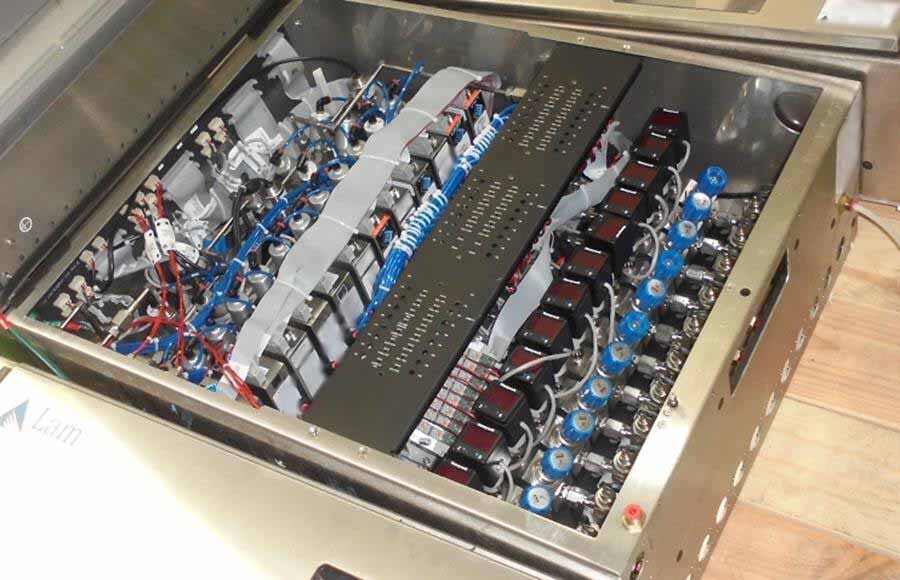

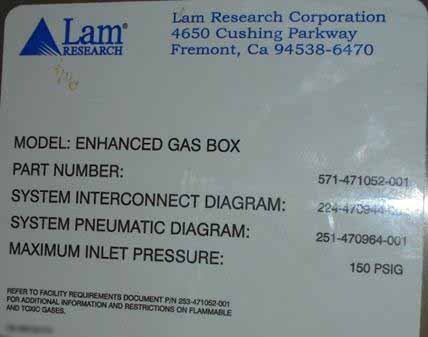

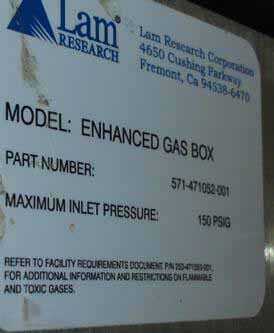

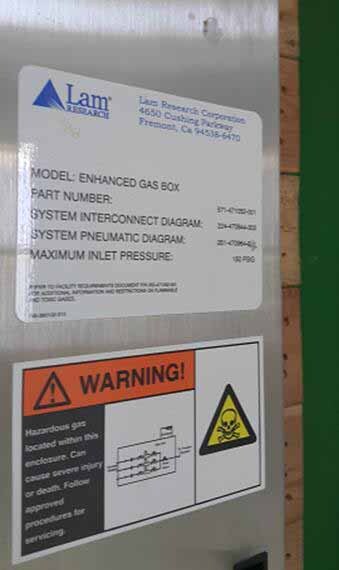

(12) Enhanced poly gas boxes:

(12) Unit 1660 and 1661 MFCs:

Unit 1661 tbd

Unit 1661 tbd

Unit 1661 CL2 250 sccm

Unit 1661 Tbd

Unit 1661 CF4 200 sccm

Unit 1661 tbd

Unit 1661 NF3 300 sccm

Unit 1660 He 200 sccm

Unit 1660 HBr 200 sccm

Unit 1661 N2 250 sccm

Unit 1660 Ar 100 sccm

Unit 1660 O2 200 sccm

P/N: 571-471052-001

Currently de-install and warehoused

2002 vintage.

LAM RESEARCH 2300 is an advanced, large capacity plasma etcher / asher. It is designed to etch/etch process a wide range of substrates in a highly integrated, fully automated equipment. The system features state-of-the-art process control, with a full suite of sensors, controllers and software to enable users to process their substrates in the most efficient and cost effective manner. 2300 is capable of delivering high-quality etching / ashing applications for a range of substrates, including CMOS and MEMS devices, photoresist, lead-free alloys, and pharmaceutical substrates, as well as common metals such as copper, aluminum, nickel, and titanium. LAM RESEARCH 2300 provides high aspect ratio etching and cleaning over large substrate areas, and also has the flexibility to process substrates of different shapes and sizes. 2300 uses a unique low-voltage etching process that eliminates excessive metal sputtering, providing superior etching performance and uniformity, longer pump life and reduced residues on the substrate. The process can be tuned to meet the specific requirements of the substrate and application, while also providing high selectivity, repeatability and reproducibility. The unit comes equipped with an array of advanced features, including a fully automated chamber-to-chamber flow control machine, a highly configurable recipe-driven tool with flow and pressure control, real-time process monitoring, and a wide selection of process gases with controllable flows. Additionally, LAM RESEARCH 2300 has an automated gas mixing asset that allows operators to control the gas mixture, which is a key parameter for etching efficiency and process control. The model is also equipped with advanced safety features, providing secure containment of the process gases, protection against too high process ranges, and automated shut off in the event of a process malfunction. Overall, 2300 provides a highly reliable, flexible and cost-effective etching solution for a wide range of substrates and applications.

There are no reviews yet