Used LAM RESEARCH 490 / 590 #9077769 for sale

URL successfully copied!

Tap to zoom

ID: 9077769

Etcher

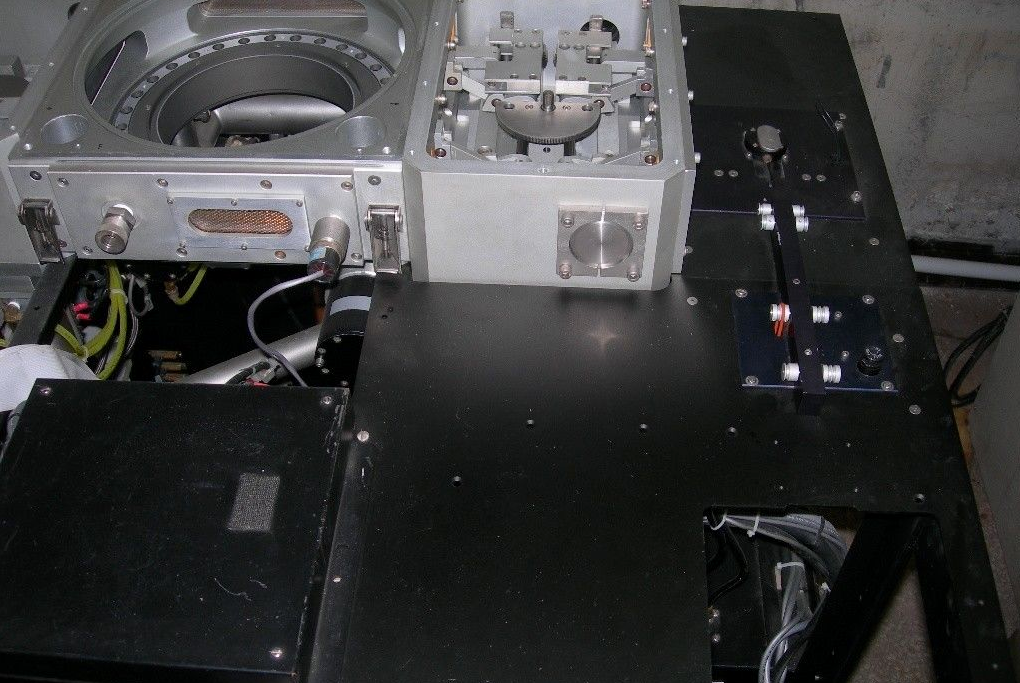

Main Chamber:

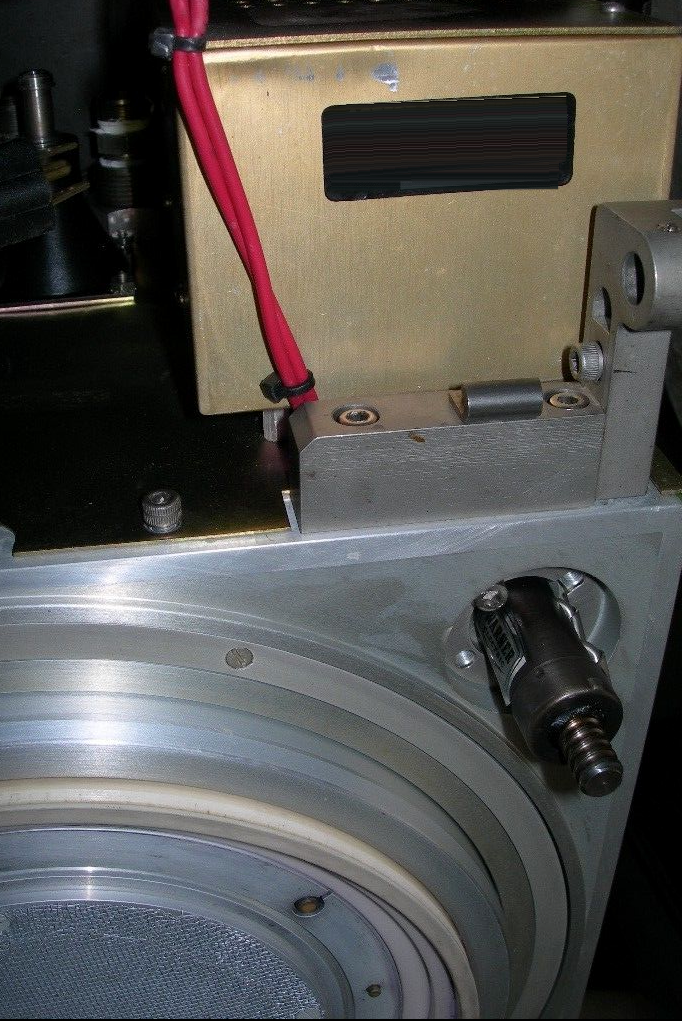

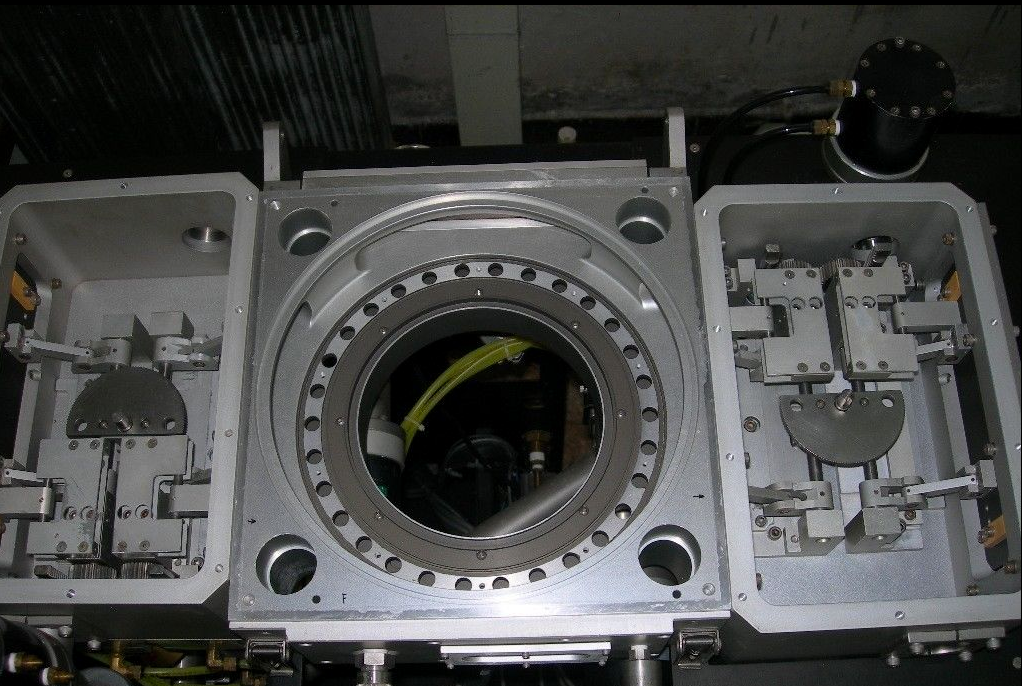

Chamber

Bottom chamber and exhaust ring

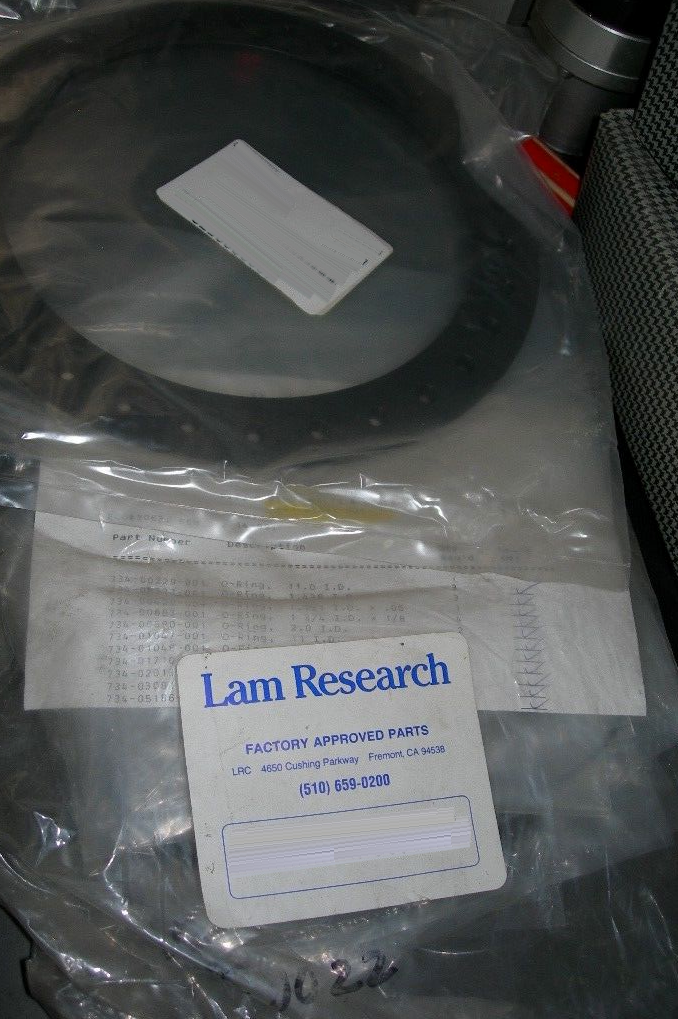

Lower electrode assembly with focus ring style electrode (Boxed separately)

Vacuums

Rotary O-rings

Seals

Pneumatic tubing and fittings

Pneumatic cylinders

Upper electrode is process dependent and not supplied

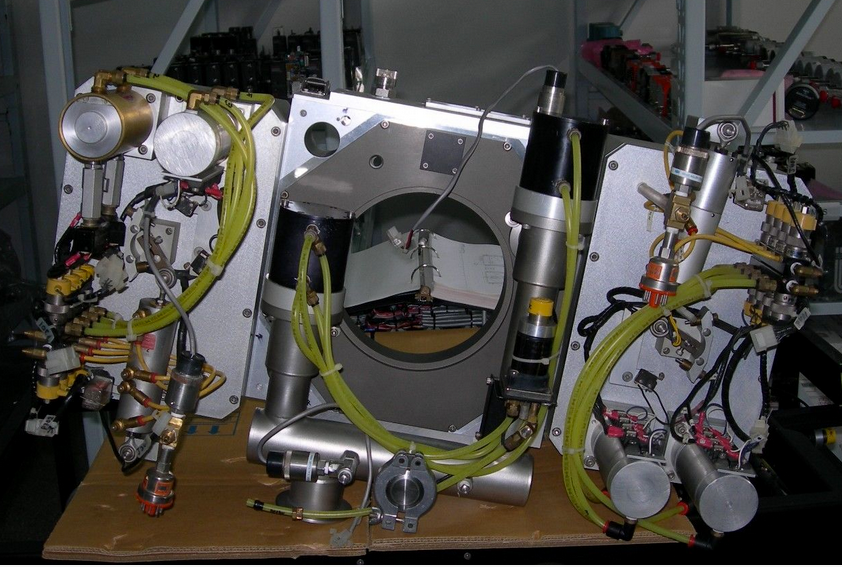

Load Locks:

Vacuums

Rotary O-rings

Seals

Pneumatic tubing and fittings

Pneumatic cylinders

Wafer arms and wafer guides are size dependent and not supplied

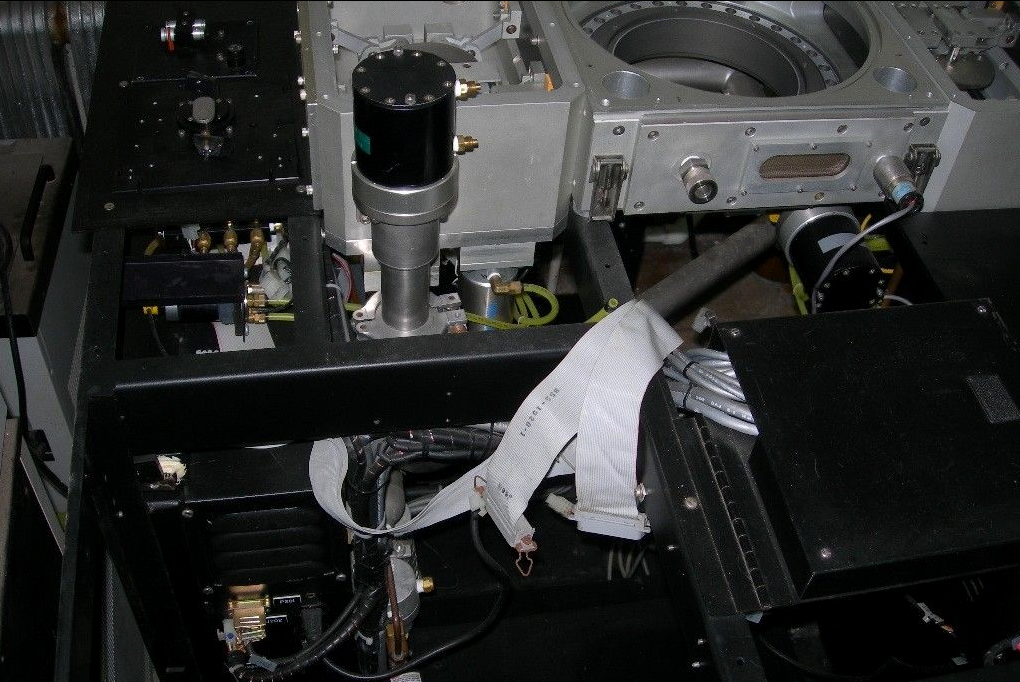

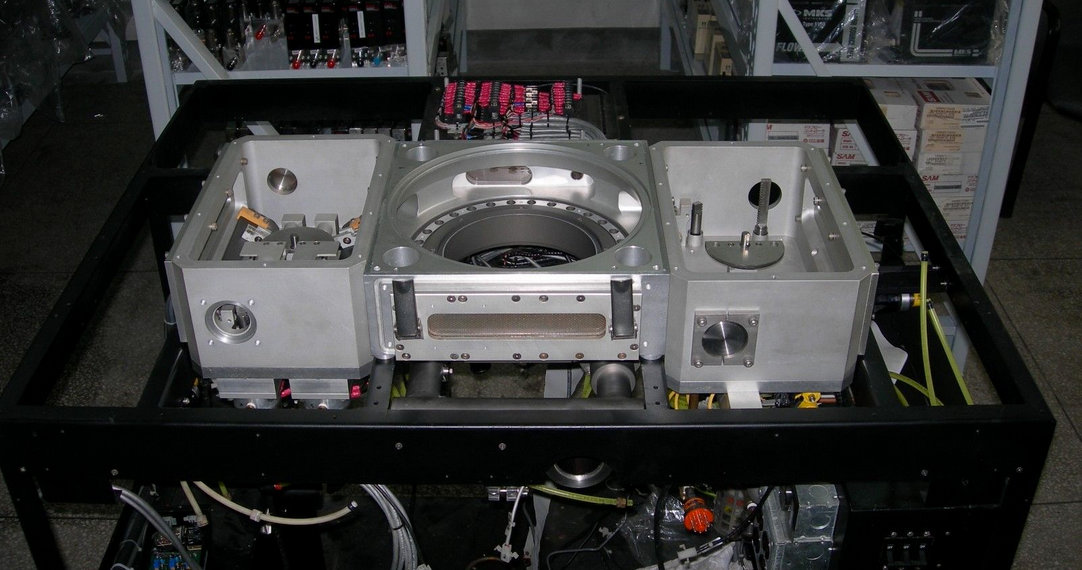

Machine Mainframe:

Pneumatic tubing

Connectors and fittings

Cables re-bundled and ty-wrapped

Frame

Top panels

Front and side panels

Elevators: (Packed separately)

Top plastic dust covers not supplied

Baratron head not supplied

Gap Drive head and Automatch: (Packed separately)

Front display panel and operator interface

Electronics drawer (Packed separately)

Factory manuals are included

Complete frame

RF Power supply is not supplied nor are any external cables, gas lines, throttle valve, or vacuum fittings.

LAM RESEARCH 490 / 590 is an etcher/asher equipment ideal for a variety of substrate materials. Designed to be versatile, it supports the use of reactive ion etching and resist ashing techniques. This system includes a fully computer-controlled etch chamber, enabling precise control and repeatability of the etching process. The etch chamber has a chamber volume of 40 liters and is capable of reaching vacuum levels down to 1x10-5 torr. It houses a dual-frequency RF source power supply and a ceramic turbo-molecular pump. The chamber boasts a standard 12"x12" substrate support that can be configured to allow for up to 8" wafers. It also features a process monitoring window allowing for the monitoring of the etch process in real-time. Reactive ion etching (RIE) is a key capability of this unit, allowing for the etching of substrates made of materials including silicon, polyimides, polycarbosilanes, and even metal alloys. It allows for the formation of complex patterns with sharp edges. It is also capable of performing on both positive and negative resists ashing. The machine also features a selection of gas chemical vapor deposition (CVD) capabilities. This includes pulsing mode CVD, dual frequency CVD, and dual power CVD, which can be used to deposit materials such as SiO2, SiN, and Al2O3 on the wafer. 490 / 590 etcher/asher tool is a powerful etching tool that provides a variety of functions and capabilities to process various substrates. It features user-friendly interfaces, flexible configurations, and an integrated RF source to allow for precise control of the etching process. It is capable of safely and reliably producing high-quality etch results while reducing production times and costs.

There are no reviews yet