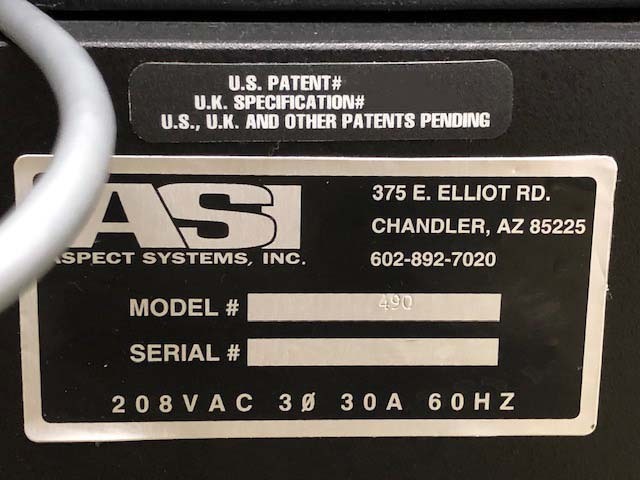

Used LAM RESEARCH 490 #9089389 for sale

URL successfully copied!

Tap to zoom

ID: 9089389

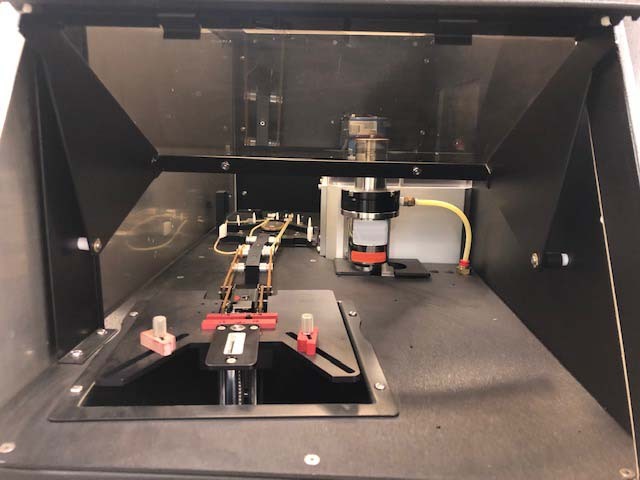

Etcher

Polyimide plasma

(6) Gas inputs

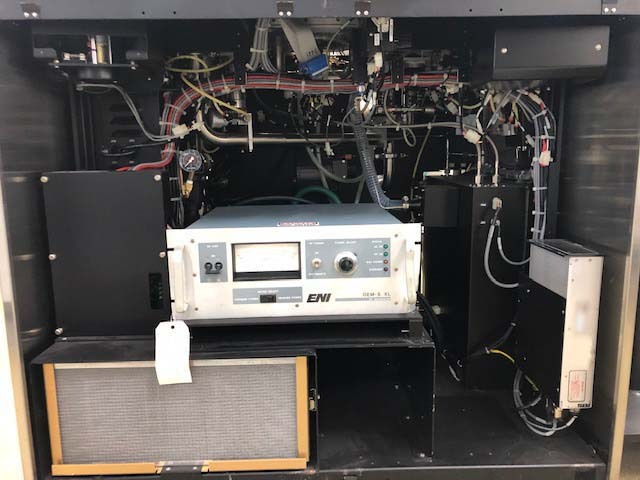

ENI OEM6-XL power supply

EDWARDS Drystar DP80 Dry pump

With EH-500 Booster and 1400 Controller.

LAM RESEARCH 490 is a wet etching and ashing equipment designed to be used in industrial manufacturing processes. It is capable of handling a variety of etching and ashing applications and is compatible with a range of materials. Utilizing a combination of solvents and catalysts, 490 can etch or ashing materials such as silicon, glass, metals, plastics, and ceramics with high precision. It offers advanced etching and ashing processes including deep reactive ion etch (DRIE), a process which utilizes one or more reactive gas plasmas to create an etching profile with a high-aspect ratio and anisotropic etch patterns. LAM RESEARCH 490 has a maximum operating temperature of 800ºF (427ºC) and a maximum pressure of 40 PSI, making it suitable for a wide range of hard materials. It includes a self-contained substrate heater that offers batch processing of up to six substrates at one time and features a fast response, low background environment. A built-in cupric-chloride bath maintains the correct etch chemistry, reducing the chance of contamination to the surrounding environment. The etch chamber of 490 is constructed of stainless steel and features a large viewport allowing loading and unloading of substrates as well as monitoring of operations during the etch and ashing process. This viewport also allows operators to determine the degree of etching or ashing complete with excellent clarity. Further, the system includes a multistep process controller and a versatile end point monitoring unit that ensures optimized etching and ashing results. The computer controlled machine of LAM RESEARCH 490 allows for precise control of etching and ashing cycles that are customized for a particular material and application. The user interface of the tool is easy to use and offers a variety of advanced features for efficient operation of the asset. Additionally, the model includes a large library of operational parameters and recipes, making experiments easy to setup and perform. With its high process yield, precision, and repeatability, 490 is an ideal equipment for etching and ashing applications in the industrial sector.

There are no reviews yet