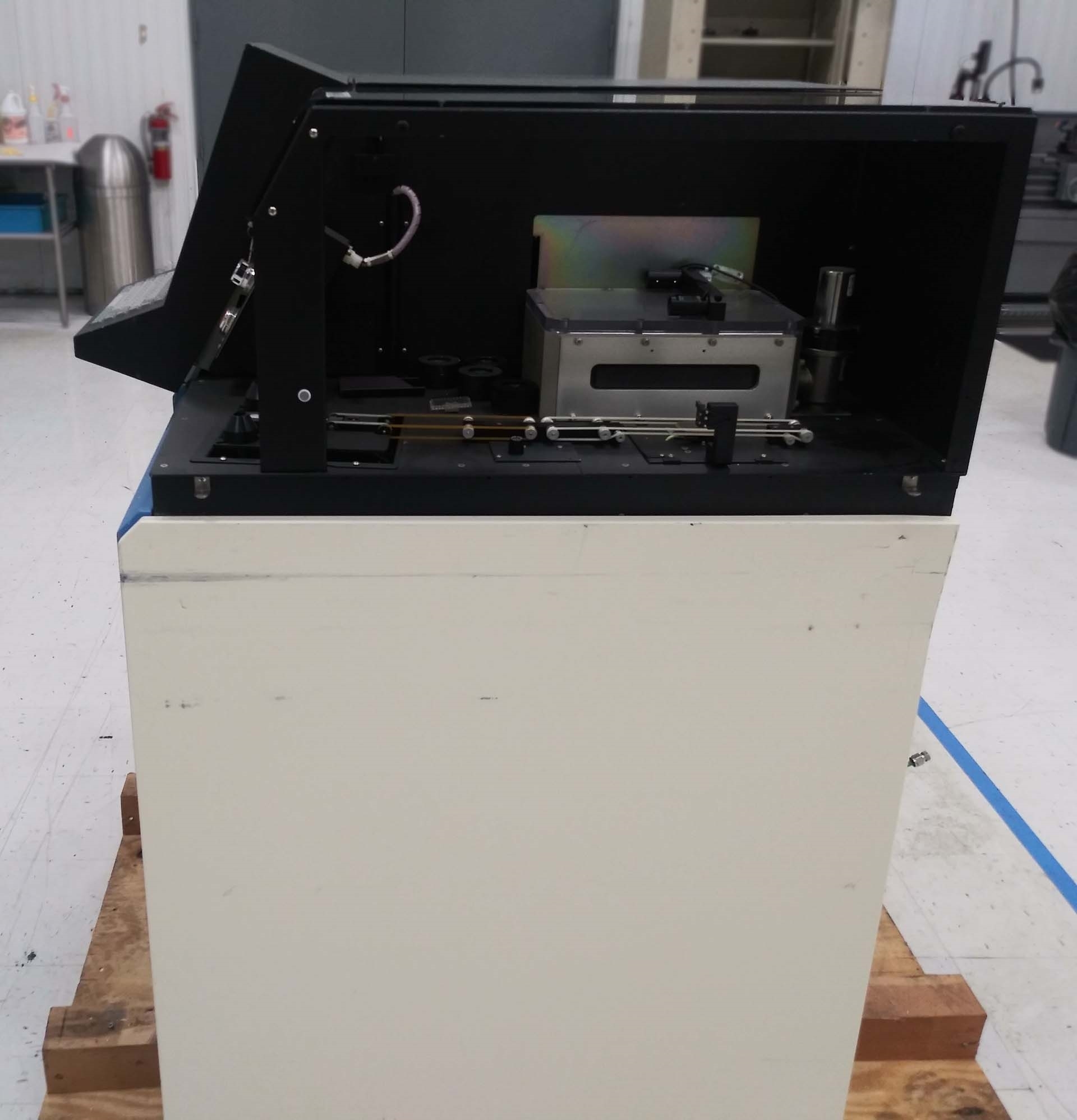

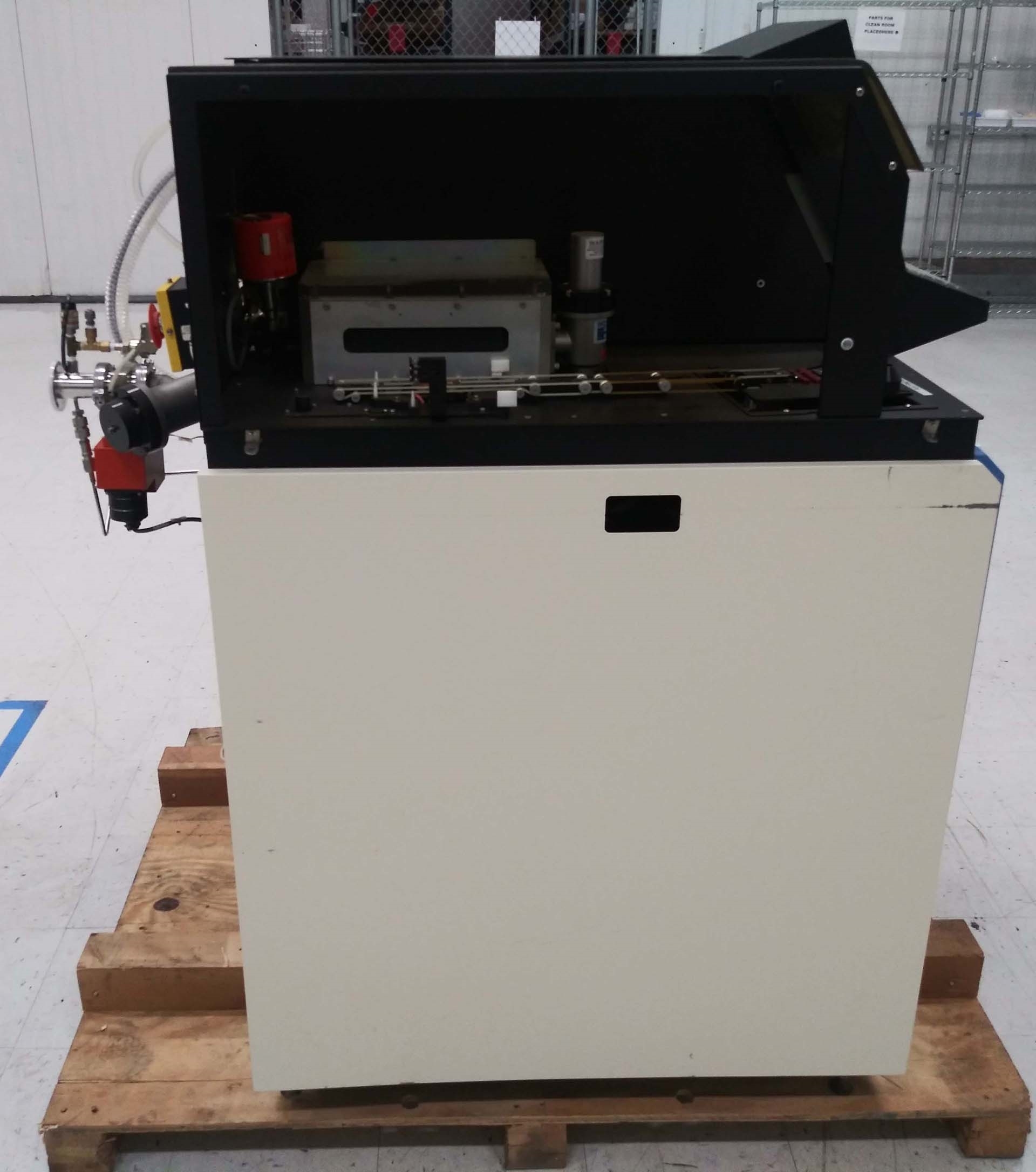

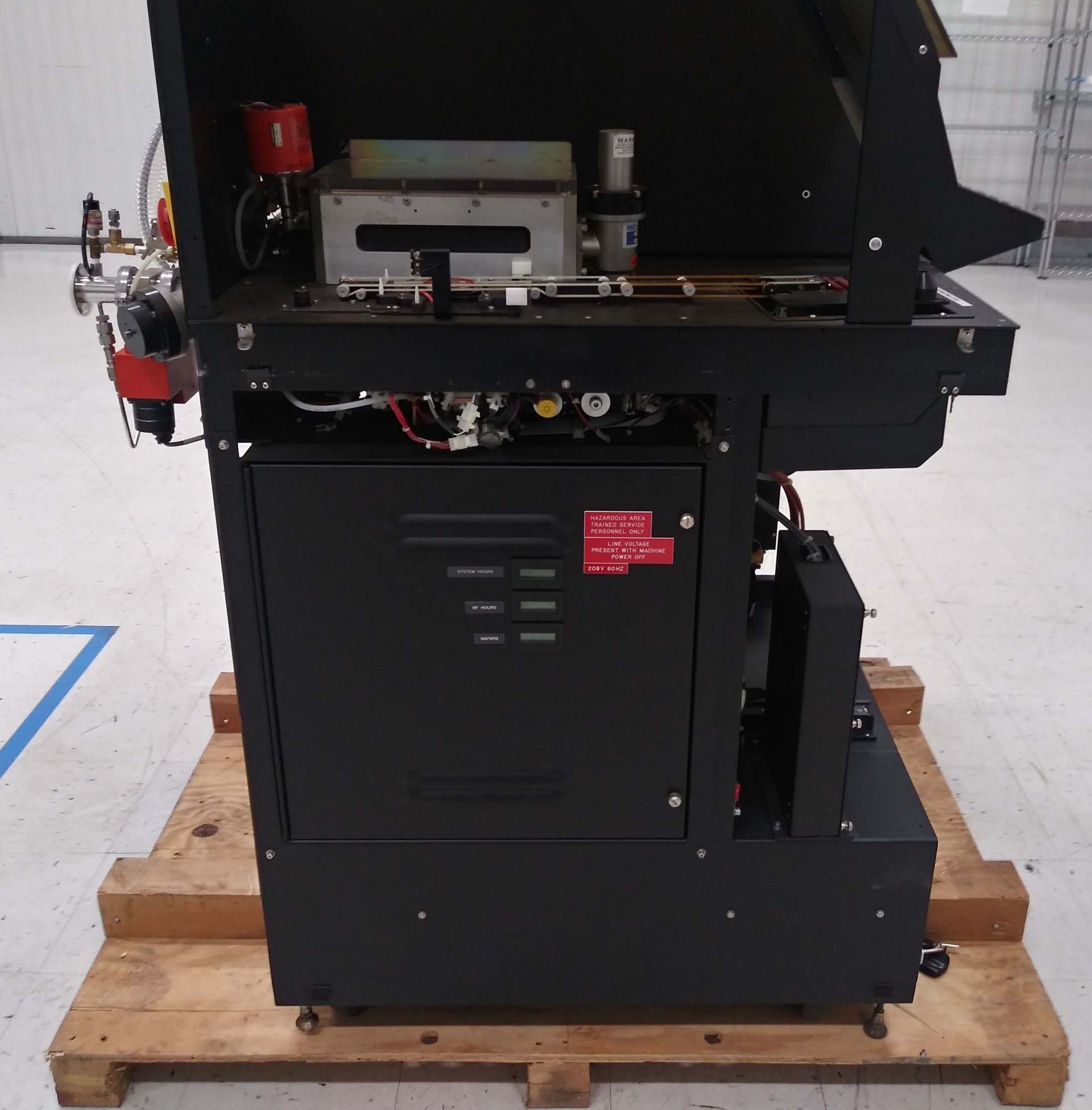

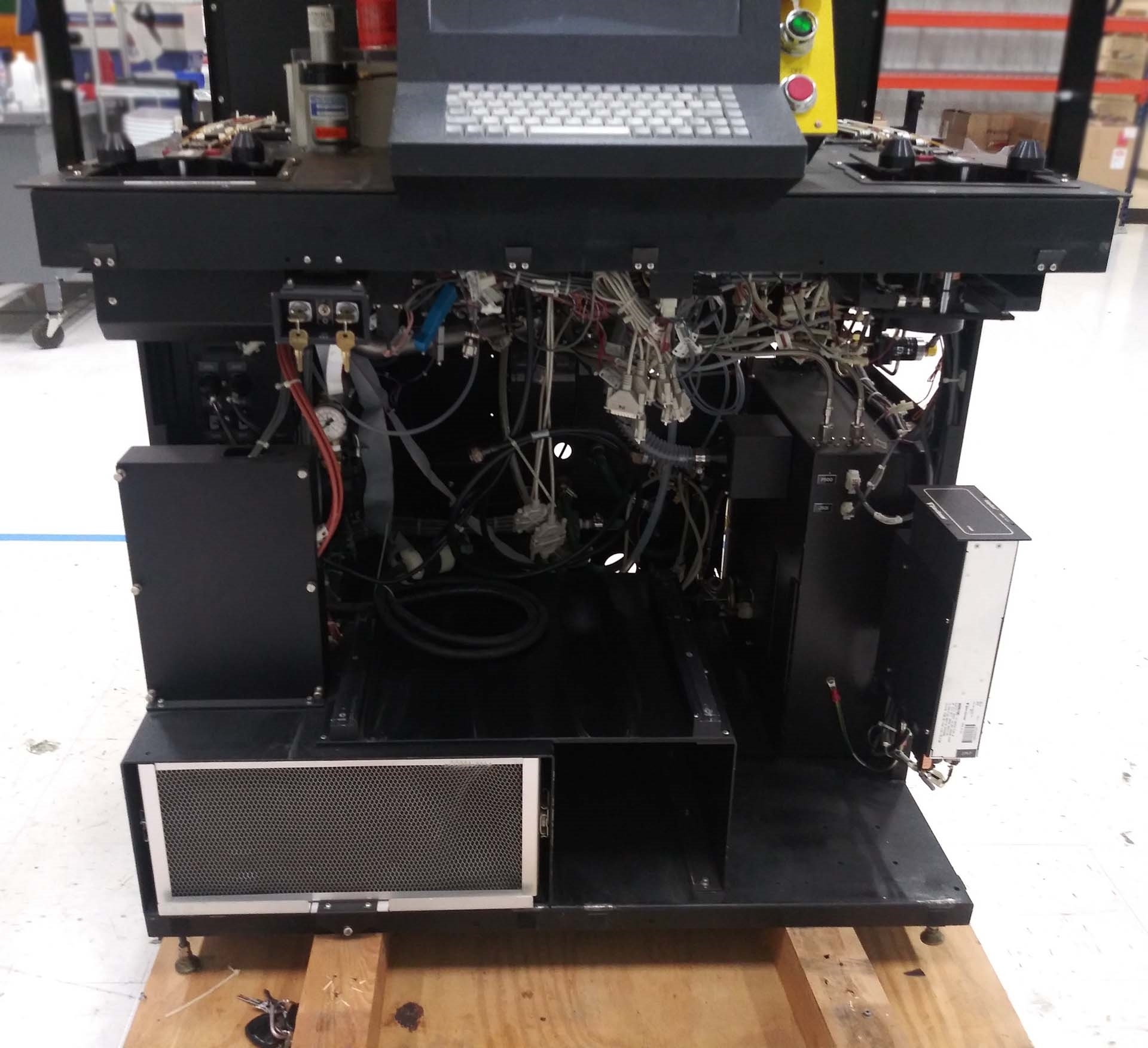

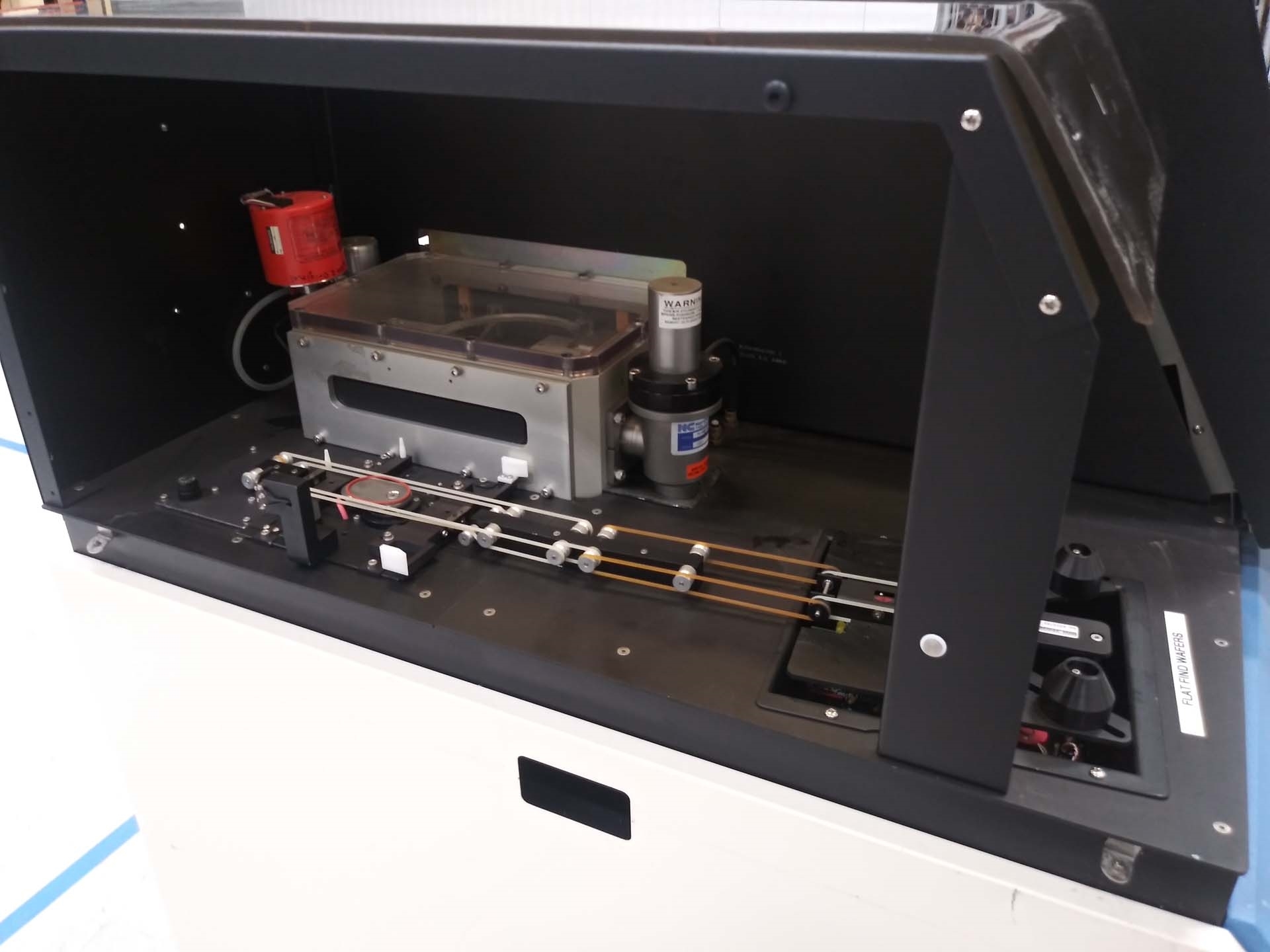

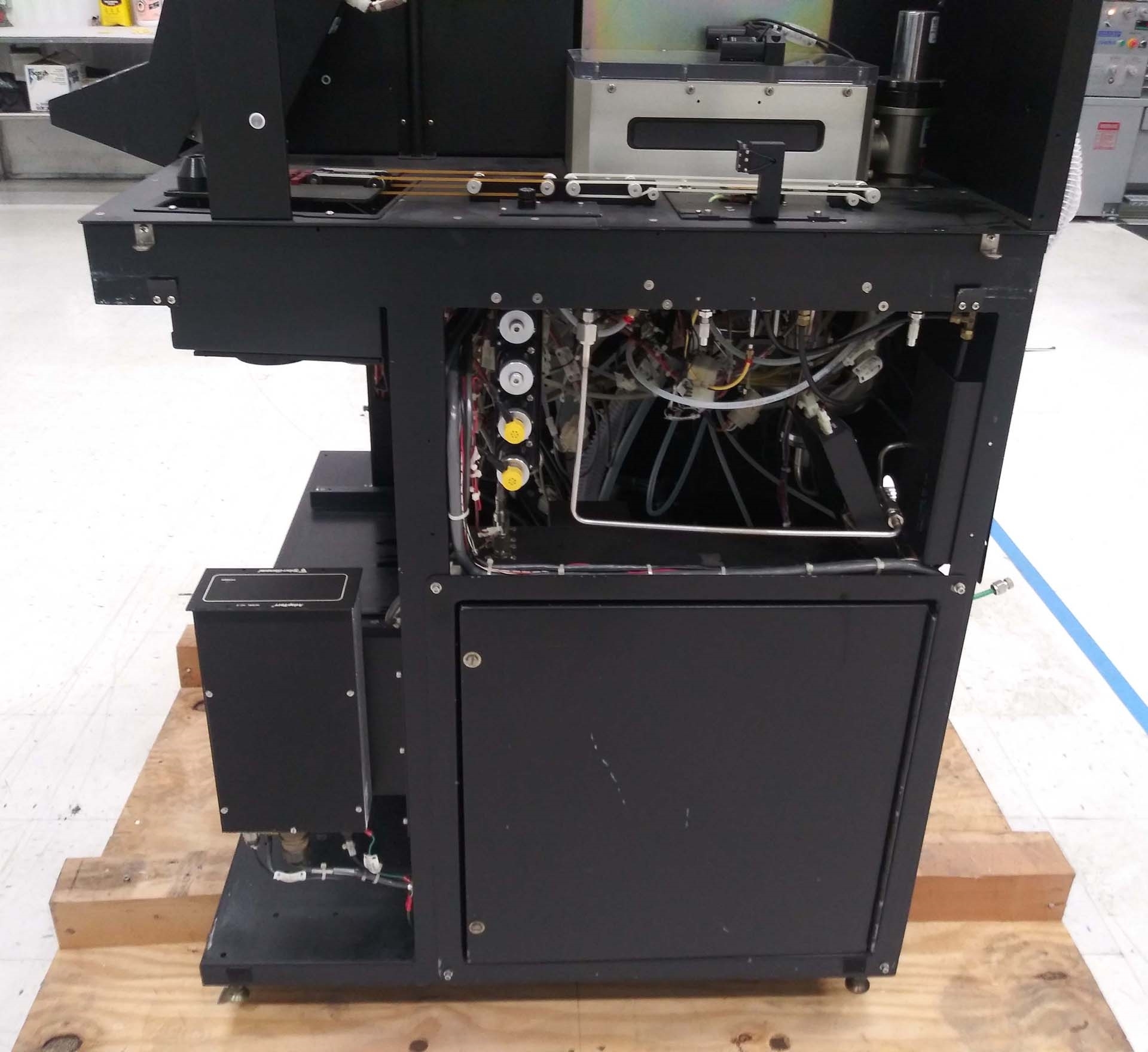

Used LAM RESEARCH 490 #9262879 for sale

URL successfully copied!

Tap to zoom

LAM RESEARCH 490 is a medium-vacuum etcher / asher designed for a broad range of deposition and etching processes in the semiconductor manufacturing industry. The etcher / asher utilizes multiple high-pressure, low-temperature gas sources which allow for precise control of the process parameters. 490 features precise gas delivery, precise pressure and temperature control, and precise control of source power. LAM RESEARCH 490 can be used with a variety of different gases, including FEP (Fluorinated Ethylene Propylene), CF4 (Carbon Tetrafluoride), CHF3 (Chlorotrifluoromethane), Ar (Argon), and other gases. 490 has a two stage vacuum equipment which includes a vacuum pump chamber, and a 2-beam ion beam chamber. The vacuum pump chamber has a 10mT ultimate vacuum level and is equipped with a MechanicalTurbo-Molecular pump to sustain this vacuum level. The two-beam ion beam chamber contains a diffusion pump, which provides a stable, uniform distribution of ions to the sample. The ion beam chamber also contains a high-energy ion source, which is capable of generating ions of up to 50keV. LAM RESEARCH 490 also features a custom-designed Gas Management System (GMS), which provides precise control of the gas composition and flow rate in the vacuum process chamber. The GMS allows for a wide range of process parameters, from low-pressure to atmospheric pressure. The GMS also includes a unique feature, called the Power Control Interface (PCI) which allows direct control of the source power, independent of the gas flow rate. 490 is rated for use with a variety of substrates, including silicon, quartz, and ceramic. It is also capable of accommodating a variety of sample sizes and shapes. LAM RESEARCH 490 has a wide range of available process flow rates, from low to high. In conclusion, 490 is a medium-vacuum etcher / asher that provides precise control of process parameters with its two-stage vacuum unit, custom-designed Gas Management Machine, and Power Control Interface. It is capable of processing a wide range of substrates and offers a wide range of available process flow rates.

There are no reviews yet