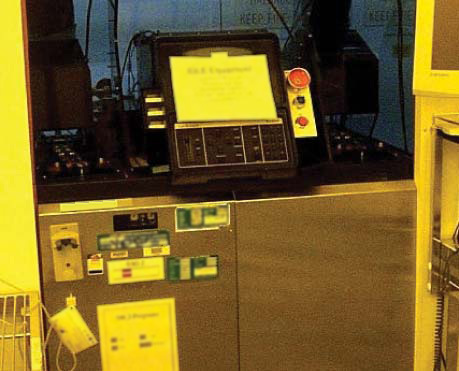

Used LAM RESEARCH 590 #9027423 for sale

URL successfully copied!

Tap to zoom

ID: 9027423

Wafer Size: 6"

Oxide etcher, 6"

Fully automated microprocessor control

High-throughput vacuum loadlocked

Programmable, variable electrode spacing

End point detection

Cassette to cassete

Can accommodate 3" to 6" wafers

(5) Gas channels max

RF power: 1,250 W @ 13.56 MHz

208 VAC, 3 phase, 60 Hz.

LAM RESEARCH 590 is an etcher / asher equipment used for semiconductor device fabrication. It is capable of processing wafers up to 300 mm in diameter. 590 features a dual cavity "UniClave" design which helps improve productivity by allowing double the number of wafers to be processed at once. The system also offers superior thermal performance and low deposition rates thanks to its distributed heating unit, advanced chamber geometry, and high-efficiency pumping design. In addition, LAM RESEARCH 590 utilizes electropheretic deposition (epd) technology, which allows for precise control of etch patterns and thickness during process cycles. With its advanced features, it is an ideal machine to handle advanced technology nodes and applications. The tool features automated loading and unloading and is capable of being loaded in both single- and multi-wafer configurations. 590 also incorporates an advanced wafer mapping asset which allows for precise process control. A vacuum level monitor is configured to alert the operator of potential damage to the surface of the substrate. In addition, LAM RESEARCH 590 includes dual in-line programing and diagnostics, enabling fast and precise process cycle setup and adjustments. 590 etcher is also equipped with an integrated high-performance GaAs etcher for both blanket and line-ending processes, with minimal damage to the surface of the device. Finally, LAM RESEARCH 590 Etcher/Asher model utilizes a wet/dry process cycle which helps reduce thermal stress and results in a higher overall yield. This makes it an ideal candidate for advanced technology nodes and applications. It also offers a robust solution to deliver precise, high-quality etches at a high throughput rate, providing users the accuracy and productivity they need to remain competitive in the semiconductor fabrication industry.

There are no reviews yet