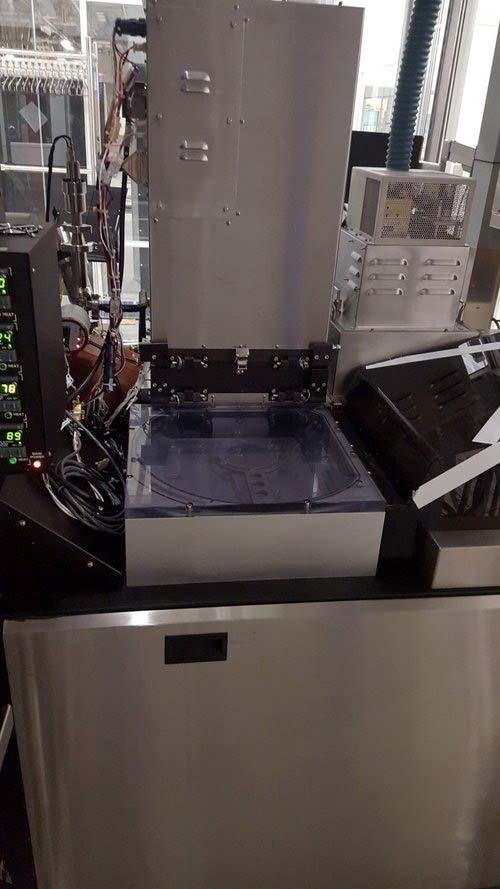

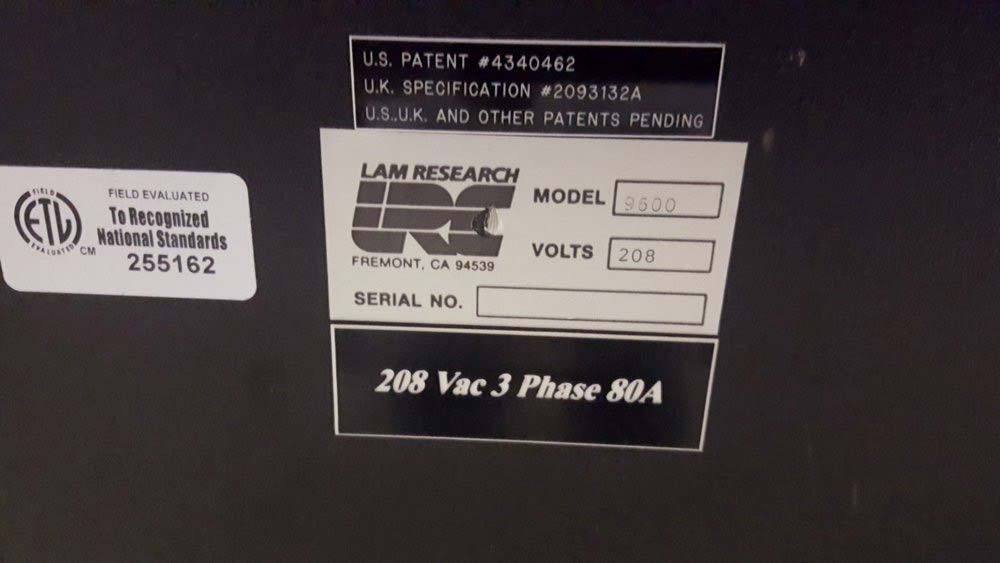

Used LAM RESEARCH 9600 #9354013 for sale

URL successfully copied!

Tap to zoom

ID: 9354013

Etcher

Etch aluminum metal and TiW layers

With vertical sidewalls suitable: 0.35 um line width

Plasma medium-high density transformer coupled plasma

Top electrode power and platen lower electrode power

Water cooled platen

Backside gas: He

C12/BC13 Chemistry used for Al and SF6 for TiW Layers

TiW Etching

Cl-Passivation step

Cl-Chemistry: AI203 Layers and silicon trenches

With minimum undercut

Process gases: CI2, BCI3, HBr, SF6, CF4, Ar, N2, 02, He

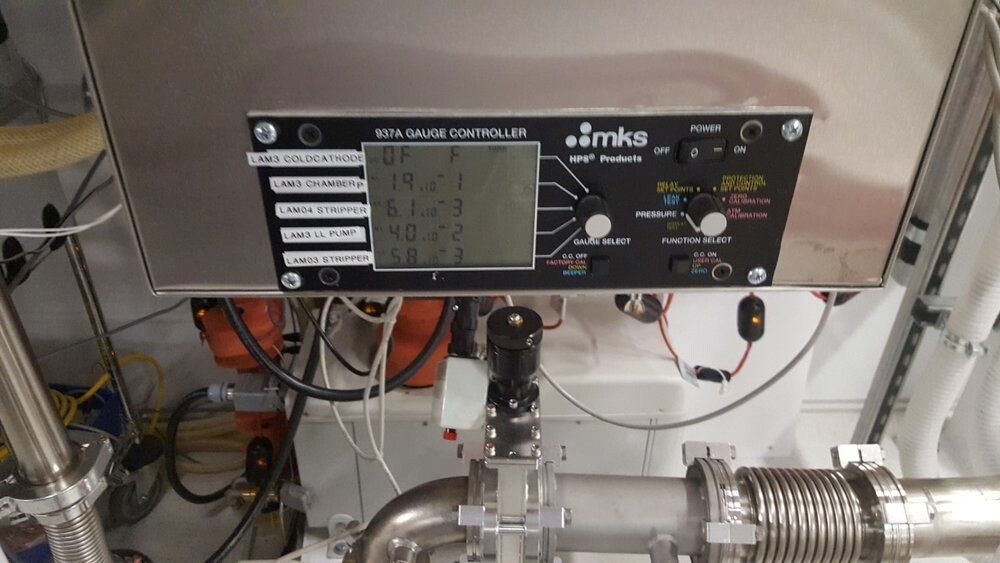

Process pressure: 0-100 mTorr

Top electrode power: 0-1250 W

Lower electrode power 0-1200 W

Process temperature: 55°C

Adjustable monochromator

Endpoint detection

With Decoupled Source Quartz (DSQ) strip module

AI Etching:

Standard recipe: 600/601

Etch rate: 800 nm/min

Photoresist etch rate: 400 nm/min

AI203 Etching:

Standard recipe: 640

Etch rate: 100-120 nm/min

Substrate, 6" diameter

Materials:

AI

AI203

Ti02

poly Si

Nb

Nitrides .

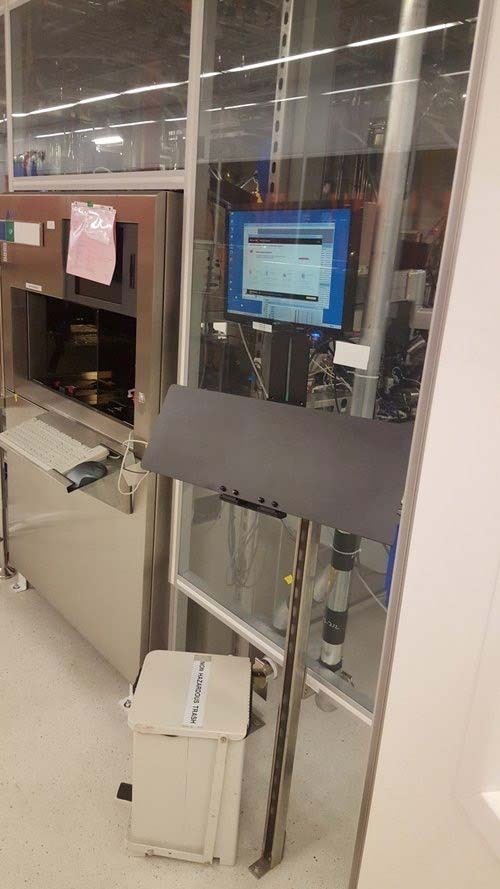

LAM RESEARCH 9600 Etcher/Asher is a fully automated, ultra high-throughput, state-of-the-art etcher and asher. It is a multi-chambered equipment that can process a wide range of substrates. The production of intricate and precise features is what 9600 is built to do extremely well, while maintaining a long process unattended run time. LAM RESEARCH 9600 is designed to support multiple recipe dependent processes simultaneously. This is extremely useful in a manufacturing environment where variable or different processes may need to be run consecutively. 9600 offers users flexibility to choose between three primary processes such as etching, passivation and annealing. This flexibility is enabled by its four integrated process chambers, each capable of performing individual processes for up to 4 wafers. The etch chamber is unique, in that it allows for the use of multiple chemistry gases, such as fluorine, boron trichloride, oxygen, nitrogen trifluoride, sulfur hexafluoride and nitrogen dioxide. The passivation chamber is designed to perform a vapor chemical process, which treats the wafer with a layer of protection from heat, humidity, and chemical contamination. In order to provide the highest possible throughput, LAM RESEARCH 9600 is equipped with both vertical and horizontal transfer mechanisms. The horizontal transfer option is an automated load/unload platform, allowing for high-speed movement of materials between process chambers. This is especially useful when dealing with large batch sizes. 9600 offers ultra precision control over temperature, pressure, and gas flows throughout each process chamber. This precise control enables the creation of extremely precise features, with precise depth and width tolerances. The integrated metrology monitor tracks process parameters throughout the entire system, allowing for higher yield, reduced cycle time, and better process optimization. LAM RESEARCH 9600 runs off a powerful x86-based CPU with industry proven Linux® operating unit, capable of managing up to 200 recipes. Stable, repeatable results help ensure the highest etch and passivation quality, with minimal manual intervention. 9600 is a robust solution for those in need of a reliable and efficient etcher/asher. Its multi-chambered machine, precision control, and automated load/unload platform, give it the capabilities necessary to meet the demands of today's complex etching and passivation processes.

There are no reviews yet