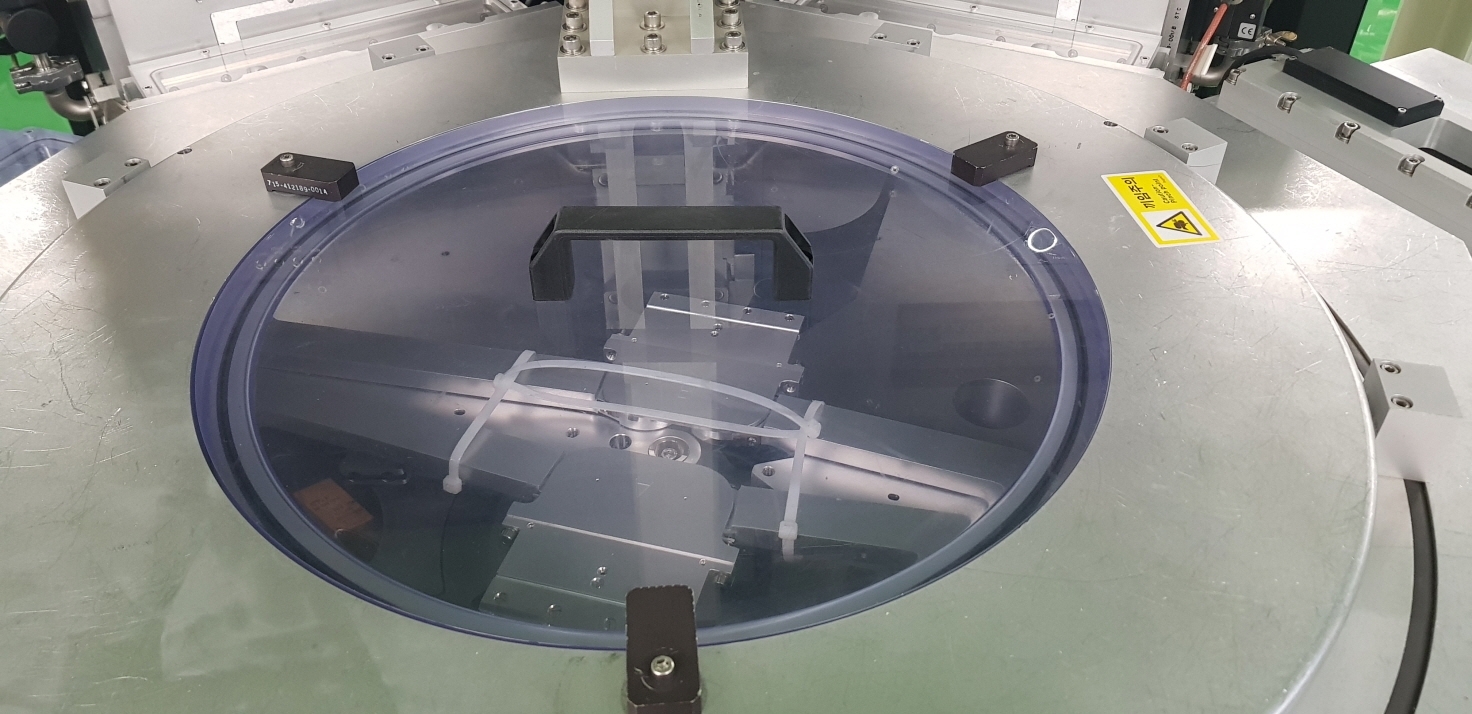

Used LAM RESEARCH A 9608 PTX #9217816 for sale

URL successfully copied!

Tap to zoom

ID: 9217816

Wafer Size: 8"

Vintage: 1998

Metal etcher, 8"

Integrated gas panel

Mainframe:

Alliance 6 rainbow standalone

TCP Standalone

Alliance A2

Alliance A4

Alliance A6

Chamber:

PM 1 / Microwave

PM 2 / 9600PTX

PM 3 / 9600PTX

PM 4 / Microwave

PM 5 / Aligner

PM 6 / Cool station

Box 4:

Electrostatic chuck

Turbo pump on process chamber

VAT65 Turbo gate valve

Endpoint detection system

Endpoint type: Photodiode

CD Rom manuals included

Alliance:

MAG7 Robot

Dual blade

VCE6

VCE: Rotation

VCE Seal: Dynamic seal

Signal lamp tower

Heated gate valve (PM2, PM3)

Turbo pump:

PM 2 / SEIKO SEIKI / H1303CV3

PM 3 / SEIKO SEIKI / H1303CV3

RF / Microwave generator:

PM 1 Top / MKS / CPS

PM 2 Top / ADVANCED ENERGY / RFG 1250

PM 2 Bottom / ADVANCED ENERGY / RFG1250 HALO

PM 3 Top ADVANCED ENERGY / RFG 1250

PM 3 Bottom / ADVANCED ENERGY / RFG 1250 HALO

PM 4 Top / MKS / CPS

GAS:

Make / Model / Gas / Flow

TYLAN / FC-2950MEP5 / N2 / 1000

TYLAN / FC-2950MEP5 / O2 / 5000

STEC / - / BCL3 / -

STEC / - / CL2 / -

TYLAN / FC-2950MEP5 / N2 / 200

TYLAN / FC-2950MEP5 / O2 / 200

TYLAN / FC-2950MEP5 / CHF3 / 100

TYLAN / FC-2950MEP5 / AR / 50

TYLAN / FC-2950MEP5 / BCL3 / 200

TYLAN / FC-2950MEP5 / CL2 / 200

TYLAN / FC-2950MEP5 / N2 / 200

TYLAN / FC-2900M / O2 / 200

TYLAN / FC-2950MEP5 / CHF3 / 100

TYLAN / FC-2950MEP5 / AR / 50

TYLAN / FC-2950MEP5 / N2 / 1000

TYLAN / FC-2950MEP5 / O2 / 5000

1998 vintage.

LAM RESEARCH A 9608 PTX is an anisotropic etcher/ asher designed to provide exact plasma chemical vapor deposition (CVD) etching. It has become a highly sought-after tool for advanced lithography and plasma-enhanced chemical vapor deposition (PECVD) processes. It is used for high-quality etching of wafers with extraordinary precision, repeatability, and uniformity for feature sizes down to nanometers. LAM RESEARCH A9608 PTX is the industry-standard for in-house Production Tool Exchange (PTX) etch process. It offers the same process control and repeatability as production tool exchange (PTX) and provides superior etching characteristics with the most stringent process conditions. The equipment provides an exceptionally wide process window to etch a variety of substrate materials, including silicon, metal alloys, nitrides, and oxides. A 9608 PTX supports advanced wet chemistry etching of metals without a vacuum system. It offers precision dry plasma etch capabilities, including isotropic, directional, and non-directional etching. A9608 PTX features a high power RF generator, variable frequency generator, programmable multi-axis gas delivery subsystem, and advanced thermal uniformity subsystem. This allows for precise control and tuning of the process parameters, such as etching selectivity and step coverage, to achieve superior feature control. It also has a high-resolution inspection unit with multiple image-capture optics and video options. LAM RESEARCH A 9608 PTX is highly reliable, efficient, and is endowed with a wide array of configurations to satisfy customers regardless of their process requirements. Its integrated process control software package allows for monitoring of all process parameters during real-time etching, and it has a low-maintenance operation. The machine can also support batch processing for up to eight substrates. LAM RESEARCH A9608 PTX is easy to install and versatile in application, supporting a variety of etch processes, including anisotropic dry etching, wet-chemistry, and difusion oxidation. It is highly reliable and capable of batch etching up to eight measurements. The plasma source features an automatic end point detection tool to ensure that there is no over etching of the substrate. The adjustable gas flow ensures uniformity of etch rates regardless of substrate type, leading to fewer reworks, higher yields, and reduced cycle time. It is a powerful and highly efficient etching tool for the nanotechnology industry that can be utilized in a wide variety of applications.

There are no reviews yet