Used LAM RESEARCH A6 9600 PTX #201020 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 201020

Etcher

Process: metal

SMIF type: API

Chamber type: PTX

Chambers: (2) PM, (2) Strip

Automation online component: SECS I/II, SECSGEM

Chamber config

Process module 1:

Focus ring: 716-460216-002

Quartz plate: 716-000941-001

Process module 2:

Esc: 718-094523-281

Liner, chamber, vat 65, Trnsn manf: 839-495013-002

Liner, chamber, trnsn manf, adptr: 715-495014-001

Liner, chamber, trnsn manf: 714-495015-001

Liner, chamber, al, alli, bsr, 9600XX: 715-330825-007

Top quartz: 716-330891-002

Insul, esc, 9600XX: 716-330915-001

Pl, sh hd, cer, 21 hole, 9600PTX: 716-330892-007

Ring, gnd, chamber, bsr, ac cpld: 715-330889-002

Edge ring: 716-330045-281

Uniformity ring: 716-331051-002

Process module 3:

Esc: 718-094523-281

Liner, chamber, vat 65, Trnsn manf: 839-495013-002

Liner, chamber, trnsn manf, adptr: 715-495014-001

Liner, chamber, trnsn manf: 714-495015-001

Liner ,chamber, al, alli, bsr, 9600XX: 715-330825-007

Top quartz: 716-330891-002

Insul, esc, 9600XX: 716-330915-001

Pl, sh hd, cer, 21 hole, 9600PTX: 716-330892-007

Ring, gnd, chamber, bsr, ac cpld: 715-330889-002

Edge ring: 716-330045-281

Uniformity ring: 716-331051-002

Process module 4:

Focus ring: 716-460216-002

Quartz plate: 716-000941-001

EPD

Channel: end point filter box for PM 1 and PM 2

Channel (nm): 853-540066-011 703/261nm, 853-540066-011 703/261nm

Gas and B/H module (PM 1, 2, 3, 4 respectively)

Gas line qty (analog): 3, 8, 8, 3

Gas box model (analog): all universal

Gas 1: O2 5000, BCl3 200, BCl3 200, O2 5000

Gas 2: N2 1000, O2 1000, O2 1000, N2 1000

Gas 3: H2O 1000, Cl2 400, Cl2 400, H2O 1000

Gas 4: n/a, N2 200, N2 200, n/a

Gas 5: n/a, CF4 100, CF4 100, n/a

Gas 6: n/a, Ar 200, Ar 200, n/a

Gas 7: n/a, N2 20, N2 20, n/a

Gas 8: n/a, CHF3 50, CHF3 50, n/a

Helium pressure control unit: n/a, UPC-1300, UPC-1300, n/a

VAC (PM 1, 2, 3, 4 respectively)

Turbo pump: n/a, ATH-1600, ATH-1600, n/a

Turbo pump controller: n/a, ACT1300M/1600M, ACT1300M/1600M, n/a

Dry pump (TM and VCE): all single pump

Chamber manometer: MKS 10Torr, MKS 0.1Torr, MKS 0.1Torr, MKS 10Torr

Turbo manometer: n/a, MKS 10Torr 625A, MKS 10Torr 625A, n/a

Foreline manometer: all MKS 10Torr 625A

Pressure control valve: VAT64, Pendulum VAT65, Pendulum VAT65, VAT64

VAT controller: all software 65PM.3E.20

Temperature control (PM 1, 2, 3, 4 respectively)

Temperature control system: all 16 channel

Chiller type: 1 CH TCU, n/a, n/a, 1 CH TCU

RF generator: UPPER:RFDS1250/LOW:RFDS1250-HALO, n/a, n/a, UPPER:RFDS1250/LOW:RFDS1250-HALO

Match: (L-853-330951-021)/(U-853-032294-002), Stripper SmatchMatch, Stripper SmatchMatch, (L-853-330951-021)/(U-853-032294-002)

TR system

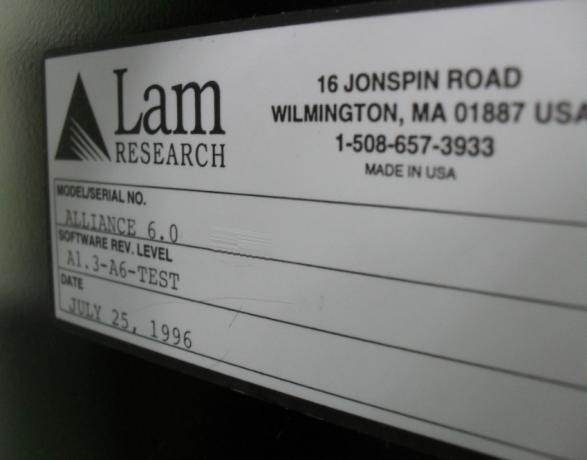

Platform: A6

Light tower: standard 4 light

Robot type: Brooks Mag-7

Arm type: dual arm

Wafer handling interface: Kalrze end effector

TM cover lift arm with PRK function

VCE inspection: lip seal

Computer system:

PC

Software version 2.2

Remote UI

Standard power

1996 vintage.

LAM RESEARCH A6 9600 PTX is an etcher / asher equipment that is used for etching and ashing processes in the production of microelectronic devices, such as semiconductor ICs and transistors. The system is designed to produce high-resolution results with excellent uniformity and minimal damage to the device layers during the etch and ash process. The unit consists of a number of components that work together to provide the user with an efficient etching / ashing process. The main components of the machine are the plasma source assembly, external process chamber, vacuum pump, and its related control electronics. These components work together to create a chemically reactive environment, allowing the user to control the reaction and conditions necessary for successful etching and ashing processes. The plasma source assembly is designed to generate a high-density plasma beam that will react with the materials contained within the process chamber. The process chamber is designed to house the sample materials and is filled with a reactive gas mixture. The vacuum pump is used to evacuate the process chamber as well as exhaust any byproducts generated by the etch and ash process. The tool is controlled by the control electronics, which includes a frequency synthesizer, an amplitude modulator, and an event control interface. The frequency synthesizer is responsible for providing the user with the ability to accurately adjust the plasma parameters for optimal throughput and uniformity during the process. The amplitude modulator is used to adjust the RF input power resulting in the desired plasma beam density and profile. The event control interface allows users to set up multistage processes, such as etch and ash. A6 9600 PTX is capable of handling production sizes ranging from wafers less than 3" through 12". The asset is capable of etching a variety of materials such as metals, polymers and dielectrics. The model is also capable of highly anisotropic etching processes. The equipment's uniformity and reproducibility capabilities make it well suited for use in the production of integrated circuits and transistors.

There are no reviews yet