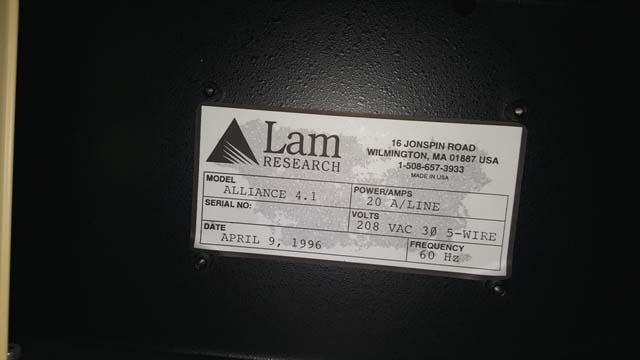

Used LAM RESEARCH Alliance 4.1 #9182310 for sale

URL successfully copied!

Tap to zoom

ID: 9182310

Wafer Size: 6"

Vintage: 1996

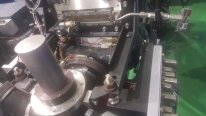

Etcher, 6"

(3) System monitors

TM LID: Cylinder open / Close (Manual type)

Wafer present sensors (WPS)

TM & VCE Pump option: Single pump type

Fab clean room configuration: Bulkhead

Robot:

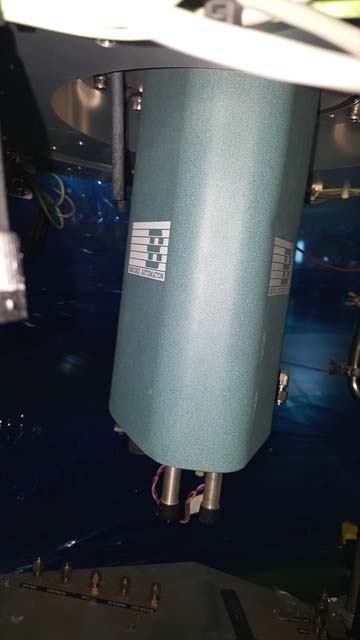

BROOKS / MTR 5 / (2) Blades

Load lock:

Manual door

VCE Elevator: Bellows seal

Mapping sensor included

Cassette type: 25 Slot cassette

VCE Vacuum isolation valves

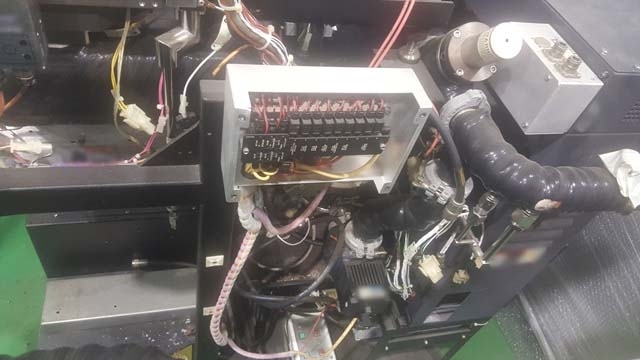

TM Vacuum isolation valves

TM Pneumatic valves

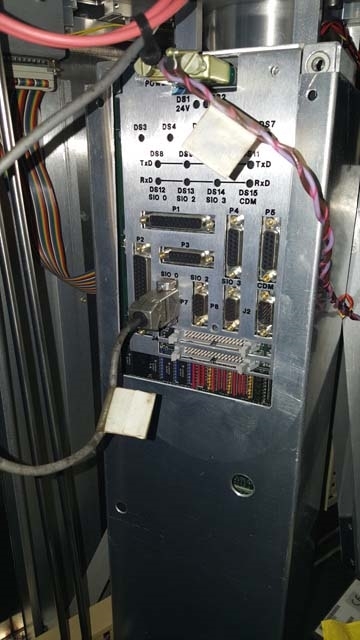

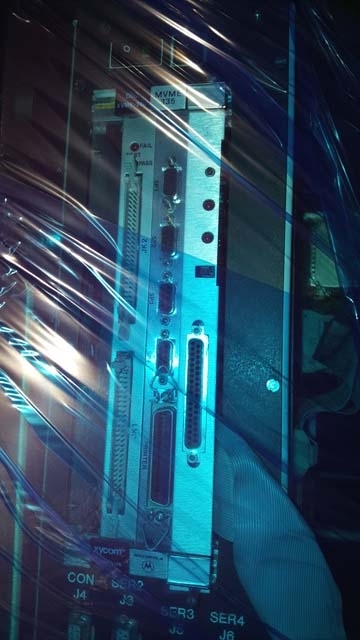

Transport system control:

Transport VME

Multiplexer PCB

Aux position 1: Aligner

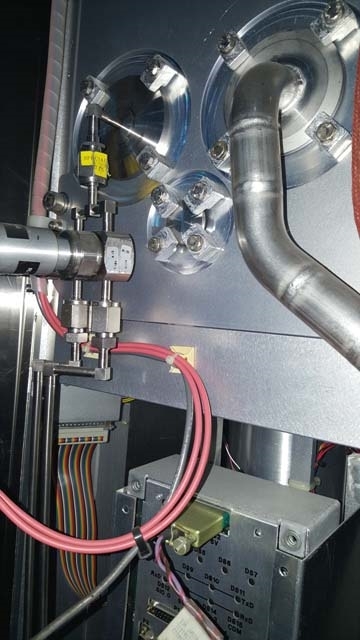

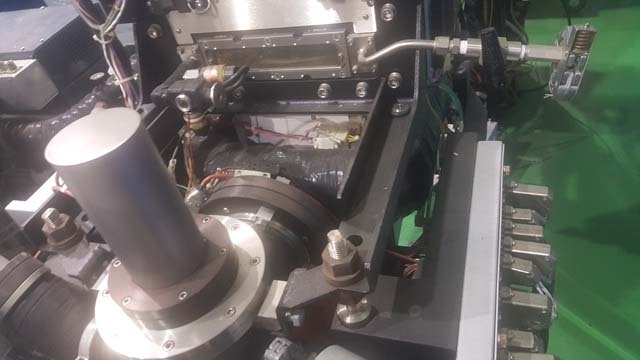

Chamber position 2:

4420XL, 6"

Chamber process: Poly

Endpoint type: Photo diode

Turbo pump: SEIKOSEIKI STP-H200C

RF Generator TCP: ADVANCED ENERGY RFG1250 13.56 MHz

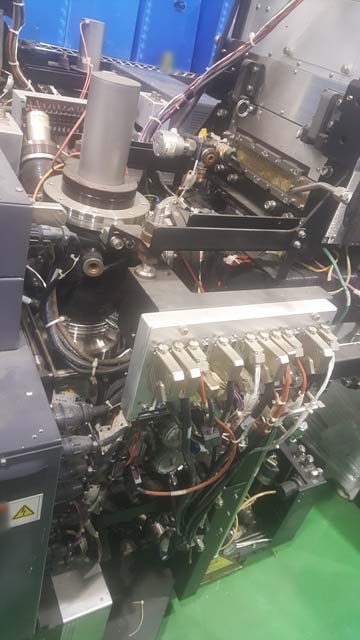

Chamber position 3:

4420XL, 6"

Chamber process: Poly

Endpoint type: Photo diode

Turbo pump: SEIKOSEIKI STP-H200C

RF Generator TCP: ADVANCED ENERGY RFG1250 13.56 MHz

1996 vintage.

LAM RESEARCH Alliance 4.1 is a state-of-the-art etcher / asher equipment that is designed to meet the most rigorous semiconductor fabrication requirements. This system utilizes advanced technology to provide the highest-level of precision, speed and flexibility in the etching and ashing processes while still maintaining superior throughput. The core of LAM RESEARCH Alliance 4.1 is its advanced high capacity deposition unit, which enables high layer deposition rates while enabling unmatched uniform etching. This machine makes use of a multi-stage tool architecture to attain superior etching results. It also utilizes a combination of hot and cold gas tuning systems in order to maintain optimal etch rates at both low and high temperatures. The asset also incorporates a unique gas flow monitor to detect gas leaks or irregularities. LAM RESEARCH Alliance 4.1 ensures exceptional process control by using the advanced Process Development Toolset (PDT). This toolset gives users the ability to develop and tune their processes to meet specific needs and parameters. It is used to evaluate and tune chamber parameters such as pressure, flow rate, temperature, gas mixtures, etc, in order to achieve perfect, uniform etching processes. This tool also offers a real-time feedback model, allowing for rapid trouble shooting in the event of any process related issues. LAM RESEARCH Alliance 4.1 also offers superior safety features that are unmatched in the marketplace. An advanced wafer safety equipment ensures that the wafers are not exposed to damaging levels of energy throughout the etching process. Additionally, multiple downstream filters are included to protect against the possibility of downstream contamination. Finally, a robust and reliable control system ensures that the process is not interrupted due to any unforeseen unit failure. The overall design and functionality of LAM RESEARCH Alliance 4.1 make it one of the most competitive etcher/asher systems on the market. Its level of precision, speed, and flexibility make it capable of tackling any etching and ashing task. Thus, LAM RESEARCH Alliance 4.1 is the best choice for any semiconductor fabrication needs.

There are no reviews yet