Used LAM RESEARCH Alliance 4.1 #9182311 for sale

URL successfully copied!

Tap to zoom

ID: 9182311

Wafer Size: 6"

Vintage: 1996

Etcher, 6"

(3) System monitors

TM LID: Cylinder open/close (manual type)

Wafer present sensors (WPS)

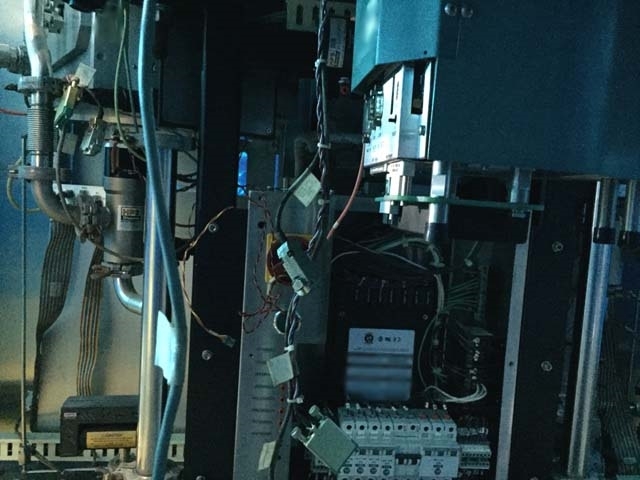

TM & VCE Pump option: Single pump type

Fab clean room configuration: Bulkhead

Robot:

BROOKS / MTR 5 / (2) Blades

Aux position 1: Aligner

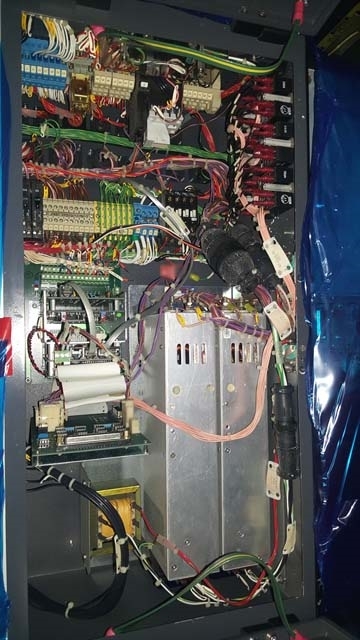

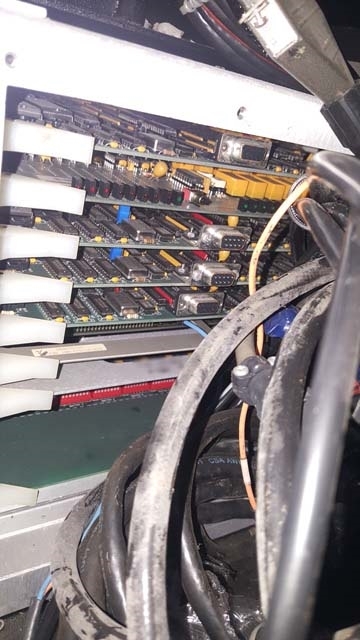

Transport system control:

Transport VME

Multiplexer PCB

Load lock:

Auto door

VCE Elevator: Bellows seal

Mapping sensor includes

Cassette type: (25) Slots

VCE Vacuum isolation valves

TM Vacuum isolation valves

TM Pneumatic valves

Chamber position 1:

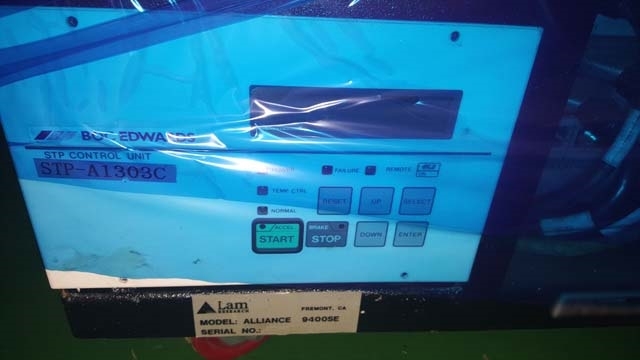

9400SE, 6"

Chamber process: Poly

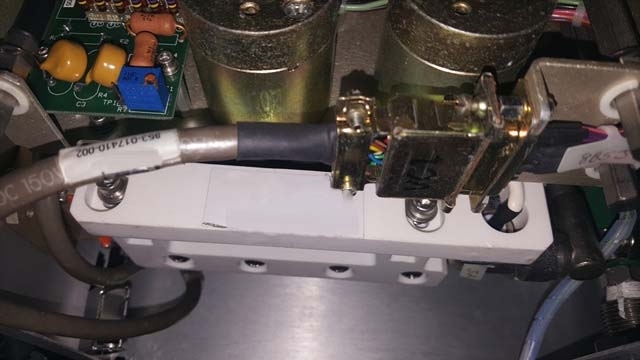

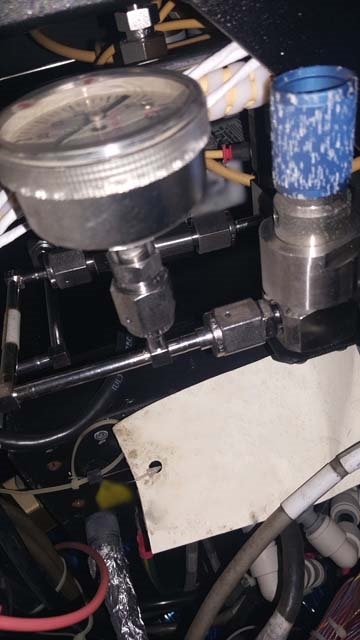

Turbo pump: SEIKO SEIKI STP-A1303

VAT 65 Pendulum valve

RF Generator TCP: ADVANCED ENERGY RFG1250 13.56MHz

RF Generator bottom: ADVANCED ENERGY Halo 1250 13.57MHz

Chamber position 2:

9400SE, 6"

Chamber process: Poly

Turbo pump: SEIKO SEIKI STP-A1303 (Turbo missing)

VAT 65 Pendulum valve (VAT Valve controller missing)

RF Generator TCP: ADVANCED ENERGY RFG1250 13.56MHz

Chamber position 3:

9400SE, 6"

Chamber process: Poly

Turbo pump: SEIKO SEIKI STP-A1303 (Turbo controller missing)

VAT 65 Pendulum valve (VAT Valve controller missing)

RF Generator TCP: ADVANCED ENERGY RFG1250 13.56MHz

Missing part:

Position 2 / 3: RF Generator bottom: ADVANCED ENERGY Halo 1250 13.57MHz

1996 vintage.

LAM RESEARCH Alliance 4.1 is an etching or ashing equipment, designed specifically for the fabrication of electronic and semiconductor components. It is an advanced platform for the deposition of multiple features on single or multiple substrates. Alliance 4.1 features a high-performance, cost-effective, and technically advanced etching chamber. It delivers robust and reliable etch process performance for a wide variety of processes, materials, and applications. The Alliance 4.1's superior etching capability allows for deposition of features with market-leading precision and high accuracy. This is achieved through its advanced upper and lower electrode structures and the use of precise material-management systems. The system utilizes an inverted angle substrate orientation to ensure a precise etching result. In addition, the Alliance 4.1 has an integrated user interface with advanced control capabilities. The unit is designed to allow users to easily interact with the etching chamber, including programming the specific parameters of the etching process. This advanced control machine can be used to ensure that the desired results are achieved while meeting the cost and process objectives. The Alliance 4.1 features an ultra-thin film precision etching chamber with the capacity to produce features smaller than 5 nanometers. It also provides etching processes that are suitable to meet high-precision needs, while maintaining cost efficiency. Additionally, the Alliance 4.1 etching chamber is designed to provide optimal performance and reliability with minimal maintenance needs. The tool's design enables rapid reaction to process changes and ensures repeatable process results. Furthermore, the asset's maintenance requirements are minimal, making it an excellent choice for cost-sensitive applications. In conclusion, LAM RESEARCH Alliance 4.1 is a cost-effective and high-performance etching model, providing the ability to deposit multiple features on single or multiple substrates with market-leading precision and accuracy. Its integrated user interface and advanced control equipment provide the ability to precisely program the etching space and ensure that the required results are achieved. As a result, the Alliance 4.1 is an excellent choice for high-precision, cost-sensitive applications.

There are no reviews yet