Used LAM RESEARCH Alliance 9600 PTX #9233428 for sale

URL successfully copied!

Tap to zoom

ID: 9233428

Wafer Size: 8"

Vintage: 1997

Etcher, 8"

Transfer chamber:

VCE Type: LIP Seal

Aligner: 001-4130-03

Transfer robot: BROOKS Magantran 7

ARM Type: Dual thin blade

Rocker valve P/N: 715-012208-001

LL & TM Pressure gauge: HPS Series 907 / MSK

Cooling station

Turbo pump model: STP-H200C

Etch chamber: PM2 / PM3

Turbo pump: STP-1301L / STP-H1303CV3

Chamber: TCP 9600 PTX

Pressure gauge: MSK E29B-23813 (0.1 Torr) / 625A11TDE (10 Torr)

Throttle gate valve: VAT 65046-PH52-AFI1 / 0052

Source RF generator: RFDS 660-024637-006

Bias RF generator: RFG 1250 HLAO

Configuration of MW chamber: PM1 / PM4

Chamber: Alliance stripper

Throttle gate valve: VAT/64040-PE52-1009/0429

MW Generator: ASTEX FI10021

MFC:

PM1: O2 5000sccm / N2 1000sccm

PM4: O2 5000sccm / N2 1000sccm

Gas panel / Etch chamber: PM1 / PM4

Gas panel: 8 Channels

(6) Gas channels

MFC Model: TYLAN 2950 Series

Gas: PM1 / PM4

Ar 100 sccm

CHF3 100 sccm

O2 200 sccm

N2 50 sccm

CL2 200 sccm

BCL3 200 sccm

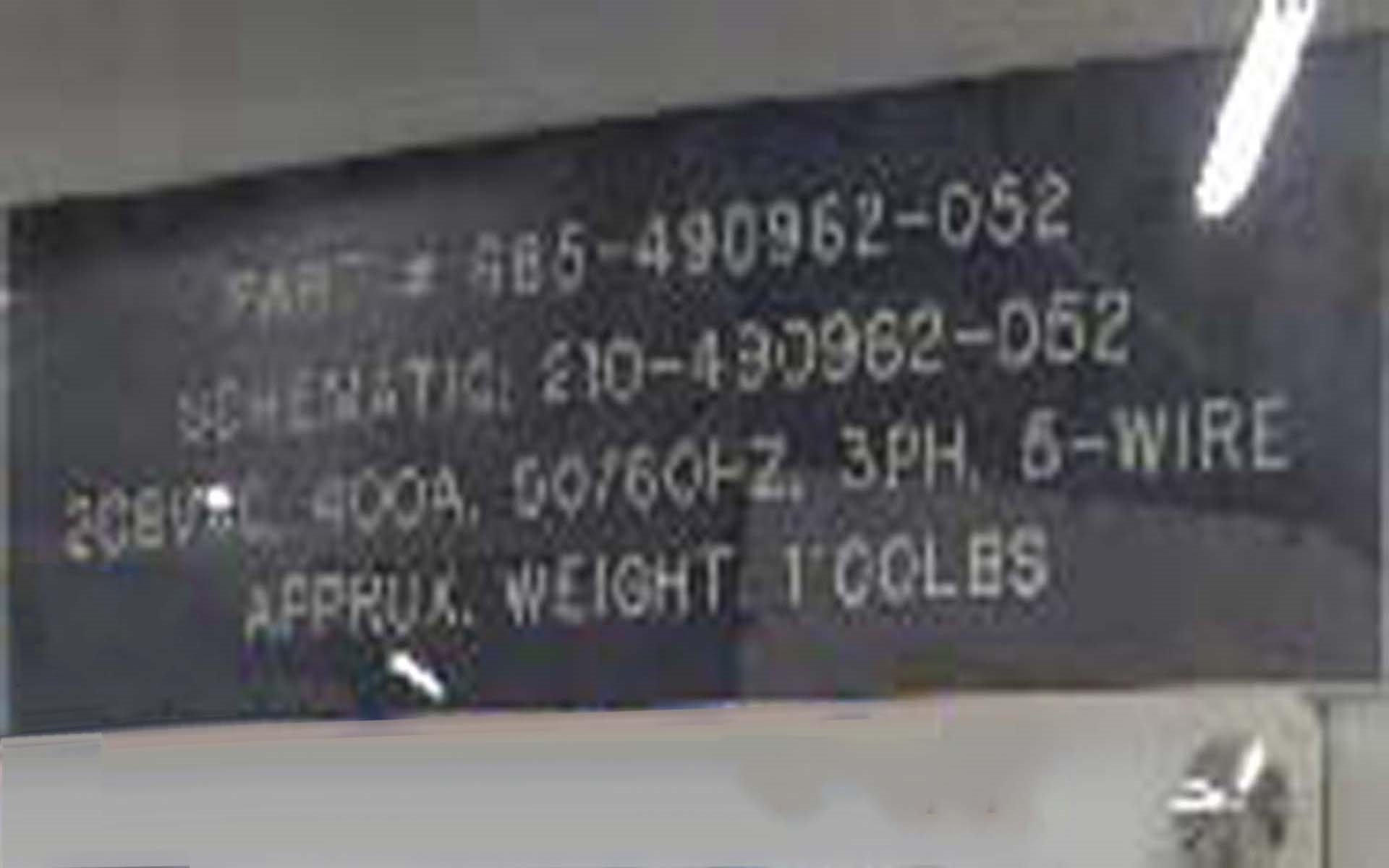

AC Rack:

Power supply: 208 VAC, 400 A, 50/60Hz, 3 Phase, 4 Wire

1998 vintage.

LAM RESEARCH Alliance 9600 PTX is an advanced etcher/asher equipment designed to integrate cutting-edge processing technology for the most exact and precise etching and ashing results. This system provides enhanced performance, improved throughput, increased uptime and lower operating costs for users. Alliance 9600 PTX is capable of processing substrates from 75mm to 152mm. This unit is designed to deliver extremely fast cycle times for etching/ashing needs in the semiconductor industry. The Alliance 9600 is equipped with high-end features for superior material processing. With the PEDC technology, ultra-short pulses are used to achieve extremely precise and accurate etching/ashing to facilitate production of devices with smaller and higher densities. The machine is also designed to accommodate both wet-chemical and dry etch/ash processes. The Cross-Flow filter features an integrated filament for fast recovery of post process byproducts. The heated drum design provides excellent uniformity, minimizing variation in surface topography with its improved multi-zone temperature control. The integrated collector stores the post-process wafers for waste collection. LAM RESEARCH Alliance 9600 PTX also offers advanced control abilities. The upgraded InfinityFlex™ Control is a comprehensive software package that provides numerous powerful features such as real time process and recipe tracking, predictive maintenance, recipe optimization and remote diagnostics. The tool also offers a single-button operation and auto-calibration for simple and intuitive user interface. The process accuracy is also optimized with in-situ metrology asset to ensure that precise, consistent, and repeatable results are generated. Alliance 9600 PTX is a reliable and powerful etcher/asher systems, providing advanced capabilities for a wide range of etching/ashing processes in the semiconductor industry. With comprehensive control abilities and improved throughput, LAM RESEARCH Alliance 9600 PTX model helps reduce tool complexity and costs, while decreasing downtime and maximizing process efficiency.

There are no reviews yet