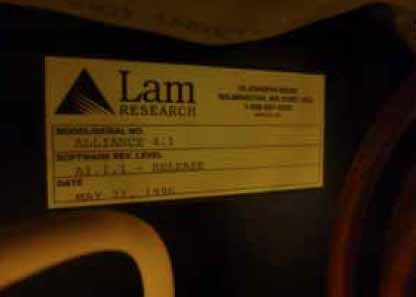

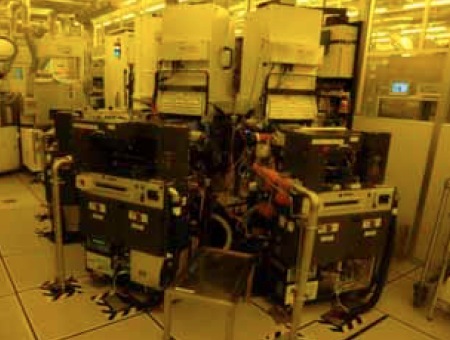

Used LAM RESEARCH Alliance A4 9400SE #9072558 for sale

URL successfully copied!

Tap to zoom

ID: 9072558

Wafer Size: 8"

Vintage: 1998

Poly etcher, 8"

Cassette: plastic, 8"

Wafer shape: SNNF

SMIF interface: no

System Information:

Platform: Alliance 4.1

Process chamber qty: 3

Software version: A2.2-018

SECS/GEM: yes

Chambers:

Position 1 (PM1): TCP9400SE / Poly etch

Position 2 (PM2): TCP9400SE / Poly etch

Position 3 (PM3): TCP9400SE / Poly etch

Position 4 (PM4): none

Etch chambers:

Turbo pump EDWARDS STP-A1303CV80

Turbo N2 fixed or MFC Type Fixed

Helium UPC UPC-8130

Endpoint detector No

Pendulum valve model VAT 65046-PH52-ADE

Chamber Manometer MKS E29B-23813

Turbo Manometer MKS 625A-23347

Foreline Manometer MKS 625A-11TD

Helium Manometer yes

Top RF generator model AE / 3155059-026

Bottom RF generator model AE / 3155059-028 (RFG1250 HALO)

TCP Match yes

Bias Match yes

TOP RF Sense Box yes

Bias RF Sense Box yes

Auto Tune Board yes

DIP Board yes

VCI Connected No

Gas Configuration:

Chamber volume used for gas cal: 36200ml

Gas Box:

Type: -

Gas box qty: 3, stacking

Manual valve: yes on each line

Pressure gauge: yes on each line

Regulator: yes on each line

Filter: yes on each line

Gas Panel Pallet:

Gas line qty with N2 purge line 7 lines per chamber

Gas line qty without N2 purge line 0

MFC type UFC-1661 / UFC-1660 / FC-2950MEP5

Gas line (gas name, MFC size):

PM1 SF6 200 / UFC-1660

Line 1 SO2 100 / UFC-1660

Line 2 Ar 200 / UFC-1660

Line 3 O2 100 / UFC-1660

Line 4 He 200 / FC-2950MEP5

Line 5 CF4 200 / FC-2950MEP5

Line 6 NF3 304 / UFC-1661

Line 7 -

Line 8

PM2

Line 1 SF6 200 / UFC-1660

Line 2 SO2 100 / UFC-1660

Line 3 Ar 200 / UFC-1660

Line 4 O2 100 / UFC-1660

Line 5 He 202 / FC-2950MEP5

Line 6 CF4 200 / UFC-1661

Line 7 NF3 405 / UFC-1661

Line 8 -

PM3

Line 1 SF6 200 / UFC-1660

Line 2 SO2 100 / UFC-1660

Line 3 Ar 203 / UFC-1660

Line 4 O2 102 / UFC-1660

Line 5 He 200 / UFC-1661

Line 6 CF4 200 / FC-2950MEP5

Line 7 NF3 315 / UFC-1661

Line 8 -

Mainframe:

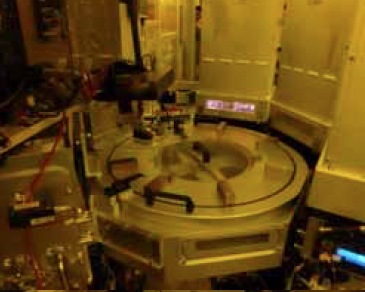

Load lock: Dual VCE loader / manual door open

Robot type: BROOKS Model 001-7600-10 with dual aluminum blade

EMO button: front, side

Signal tower: front; G / Y / R

System monitor display: (1), front

Remotes: (2) RPM

EMO button: yes

Line frequency and voltage: 208VAC, 3 phase

Remote UPS interface: yes

UPS: no

Heat Exchanger type:

For cathode: NOAH PRECISION Model 3300: -20ºC to +90ºC

QTY: 3 (not included)

Pumps type:

Transfer Module EBARA A70W, not included in scope of supply

PM1 EBARA A30W, not included in scope of supply

PM2 EBARA A30W, not included in scope of supply

PM3 EBARA A30W, not included in scope of supply

Gas Scrubber: (1) EBARA GTE-3-0WVT, not included in scope of supply

Currently in cleanroom

1998 vintage.

LAM RESEARCH Alliance A4 9400SE is a highly advanced etch and ash equipment that offers enhanced etching and ash performance for many tools and processes. This advanced etcher / asher has both repeatable and consistent results to meet the most demanding demands of customers. The system includes an auto-loader/unloader and a 3-axis robotic arm for loading/unloading wafers, making it ideal for productivity-enhancing automation. The automated unit provides precision control over wafer movement with fast cycle times and precise methodology. The process control software is also configurable to ensure optimized accuracy during processing. As an etcher/ash machine, the A4 9400SE can be used to treat a variety of materials from metals to glass. The tool also features a robust power supply and low-voltage input to ensure consistent and exacting results for both etch and ashing processes. With a high-throughput capacity of up to 120 wafers per hour, the asset is capable of achieving volume and tight process control. The model is also designed with a variety of tool interfaces, so that customers can easily configure the equipment to fit their specific requirements. LAM RESEARCH ALLIANCE A4 9400 SE also offers real-time data monitoring and analysis for validation and issue resolution, enabling users to monitor the complete process on a real-time basis. Through comprehensive protection and analysis of the wafers in the system, users can adjust process parameters to correct and optimize solutions for maximum performance. Besides being an efficient and automated etch and ash unit, Alliance A4 9400SE also offers advanced process control capabilities and maintenance features. The machine includes protection against contaminants and rapid measurement of wafers as well as detailed diagnostics and precision control over the process. In addition, the tool can measure wafer geometry and thickness, allowing for precision and accuracy in the etching and ashing processes. Overall, ALLIANCE A4 9400 SE is a reliable, efficient and precise automated etcher/ asher asset that combines precise control, enhanced performance and automation with real-time monitoring and analysis to enable efficient production and process optimization. Its advanced features make it the ideal model for high-quality, rapid and repeatable etch and ash jobs.

There are no reviews yet