Used LAM RESEARCH Alliance A6 9400 #9050180 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9050180

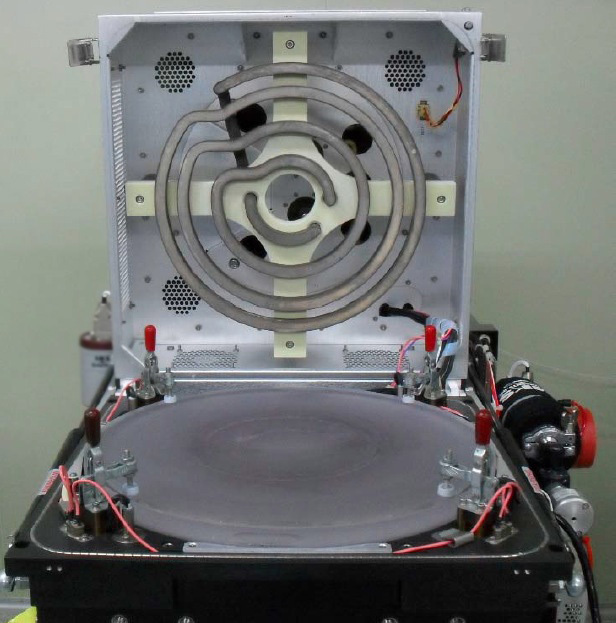

TCP Etcher. 6"

Robot: Brooks Magnatran 7

Process Module 1:

(8) Gas lines

TCP RF Generator (RFG 1250)

BTM RF Generator (RFG 1250 HALO)

ESC & ESC Power supply (P/N: 810-025054-018)

TCP Match (P/N: 853-032294-002)

Endpoint detector: 405 nm, 520 nm (P/N: 853-540066-005)

Turbo pump: STP-H1300

Pressure control valve: Pendulum VAT65

MFC's: 200 Cl2, 200 HBr, 55 O2, 100 O2, 200 SF6, 100 CF4, 200 He, 100 CHF3

Process Module 2:

(8) Gas lines

TCP RF Generator (RFG 1250)

BTM RF Generator (RFG 1250 HALO)

ESC & ESC Power supply (P/N: 810-025054-018)

TCP Match (P/N: 853-032294-002)

Endpoint detector: 405 nm, 520 nm (P/N: 853-540066-005)

Turbo pump: STP-H1300

Pressure control valve: Pendulum VAT65

MFC's: 200 Cl2, 200 HBr, 55 O2, 100 O2, 200 SF6, 100 CF4, 200 He, 100 CHF3

Process Module 3:

(8) Gas lines

TCP RF Generator (RFG 1250)

BTM RF Generator (RFG 1250 HALO)

ESC & ESC Power supply (P/N: 810-025054-018)

TCP Match (P/N: 853-032294-002)

Endpoint detector: 405 nm, 520 nm (P/N: 853-540066-005)

Turbo pump: STP-H1300

Pressure control valve: Pendulum VAT65

MFC's: 200 Cl2, 200 HBr, 55 O2, 200 SF6, 100 CF4, 200 He, 100 CHF3

Gas box:

Modular gas box

Remote power module.

LAM RESEARCH Alliance A6 9400 is a high-performance etcher / asher equipment specifically designed for precise etching and ashing. It is suited for processing temperature-sensitive materials such as silicon, SiO2, II-VI compounds, low-k dielectrics, and III-V compounds. The system is highly configurable and comes with a wide range of rf sources and process gas sources which allow it to process wafers of various dimensions. The unit features a loadlock module, a thermal chamber, an integrated wafer chuck, a multiple-zone heater, and a vacuum pump. The loadlock module includes a load chamber with automatic load and un-load machine, a substrate focusing tool in the load chamber, and an exhaust asset with an integrated gas panel and an exhaust fan. The thermal chamber comprises a separate chamber and a heater module. The heater module is capable of maintaining the temperature of the chamber at a constant desired condition. This is essential for preventing the wafers from degrading during processing temperatures. The integrated substrate chuck eliminates the need for manual loading and unloading of substrates. This automation helps to improve etch uniformity and reproducibility. The model is powered by a purpose-built electronics cabinet and is operated using a touch-sensitive GUI. The GUI provides a range of features such as recipe creation, real-time data display, ion source tuning, and display of chamber pressure. It also enables programmable process control and monitoring from a centralized station. The equipment is also integrated with the Adaptive Process Control (APC) module and the Advanced Process Containment (APC) systems. The APC module enables automatic adjustment of the etch process parameters based on the measurement feedback data, thus ensuring consistent results with utmost precision. The APC system helps to minimize the impact of process drift and process variation. Alliance A6 9400 is a state-of-the-art etcher / asher unit offering unparalleled precision and versatility. It is designed to provide optimal precision and performance under the most demanding etching and ashing conditions. Its advanced automation and control features make it an essential tool for any etching or ashing application.

There are no reviews yet