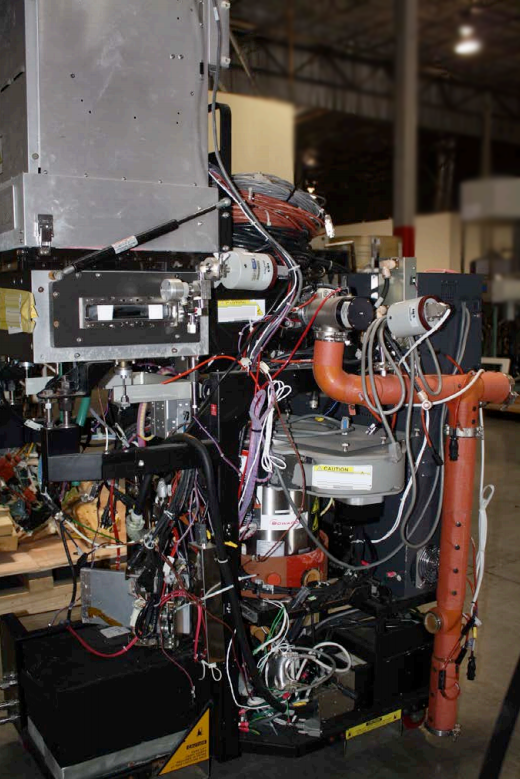

Used LAM RESEARCH Alliance A6 9600 PTX #9098070 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9098070

Wafer Size: 8"

Process Module, 8"

Pressure Control: VAT 65

Upper Match Enclosure Fan

Turbo Pump: BOCE 1300L

Endpoint Filters: 405/703nm

Monochromator

Wafer Configuration: SEMI

Missing parts:

Lower match can

RF match

Lifter assy

ISI upper match controller

Upper heaters

Harness and overtemp harness

Card cage.

LAM RESEARCH Alliance A6 9600 PTX is a dry-etching plasma technology (DPT) equipment for semiconductor device fabrication. This is a dual-chamber, multi-process system that enables multiple etch or asher operations to be performed in a single sequence. The unit features a plasma source and RF power-control components, along with a vacuum-controlled chamber, airlock operation, and motion capabilitites. The chamber is also designed with an RF plasma generator and a cold plate for optimal thermal processing. The main components of the machine include two independent process chambers, an etch chamber and an asher chamber. The etch chamber is equipped with a microwave source, unique RF/DC powered plasma source, and fully automated RF source controllers for precise etch adjustments. It also features a reliable substrate delivery tool, as well as interlocked safety systems to help protect samples from unintended contamination. LAM RESEARCH ALLIANCE A6-9600PTX asset can be used to perform etch and asher operations such as deep reactive ion etch (DRIE), plasma-enhanced chemical vapor deposition (PECVD), and etch-damage reduction by adiabatic etching. It also offers annealing capability with programmable temperature up to 600°C, making it suitable for advanced annealing of wafers. It offers a maximum process pressure of 40 mTorr with a base pressure of 5×10-7 Torr, with an effective etch rate up to 130 nm/min. The model has a maximum RF power of 1,500 W with a frequency range of 10 MHz-2.45 GHz. In addition, the equipment offers a highly accurate process control with 6 plasma parameters that can be adjusted. This etcher/asher is highly efficient, providing repeatable process sequences for producing high-quality results on flexible substrates. Furthermore, the system's intuitive GUI and safety interlocks offer increased operator safety, helping to prevent unwanted damage to the sample and process chamber. ALLIANCE A6 9600PTX is therefore an excellent choice for efficient etch/asher operations for semiconductor device fabrication.

There are no reviews yet