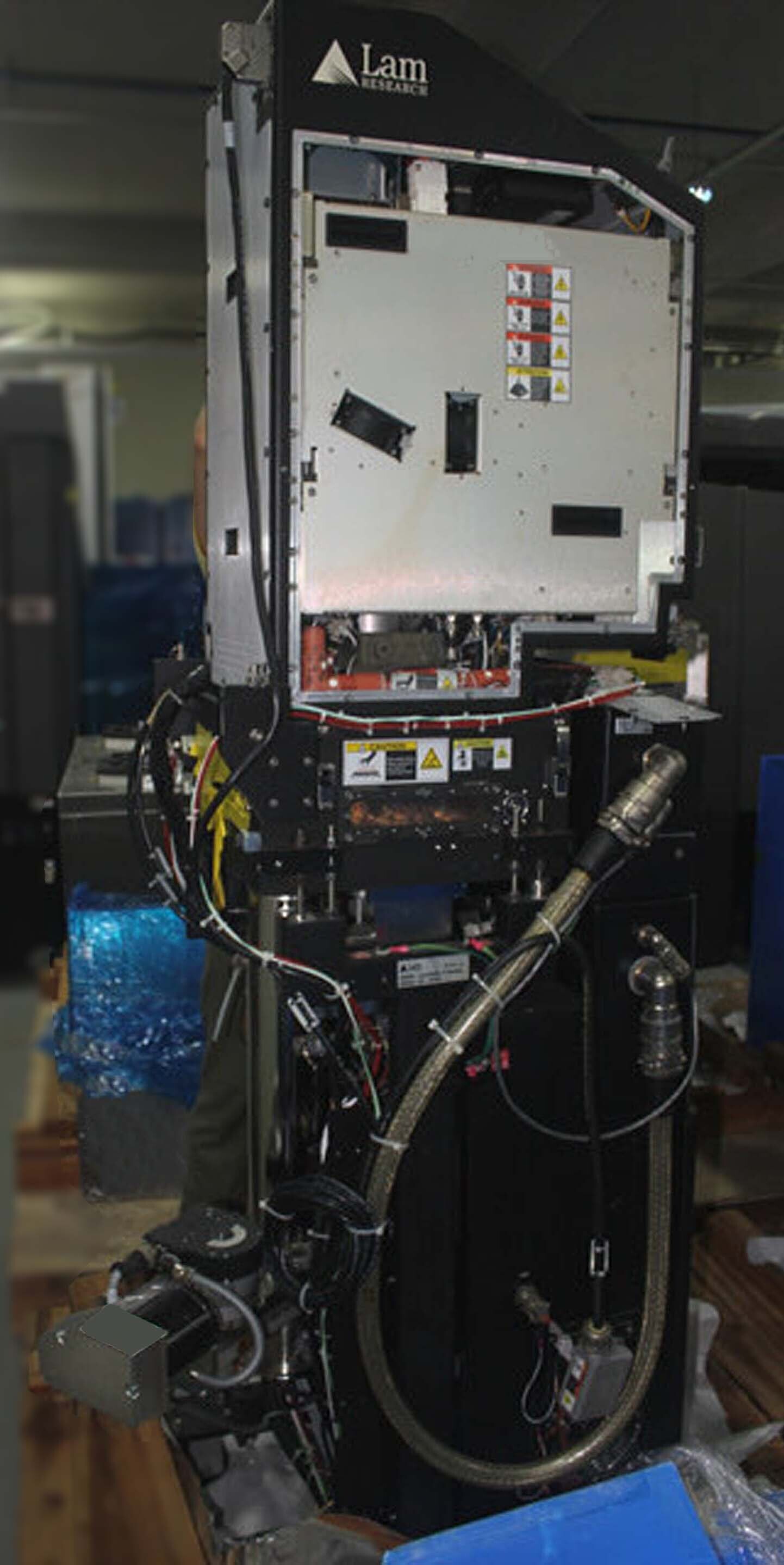

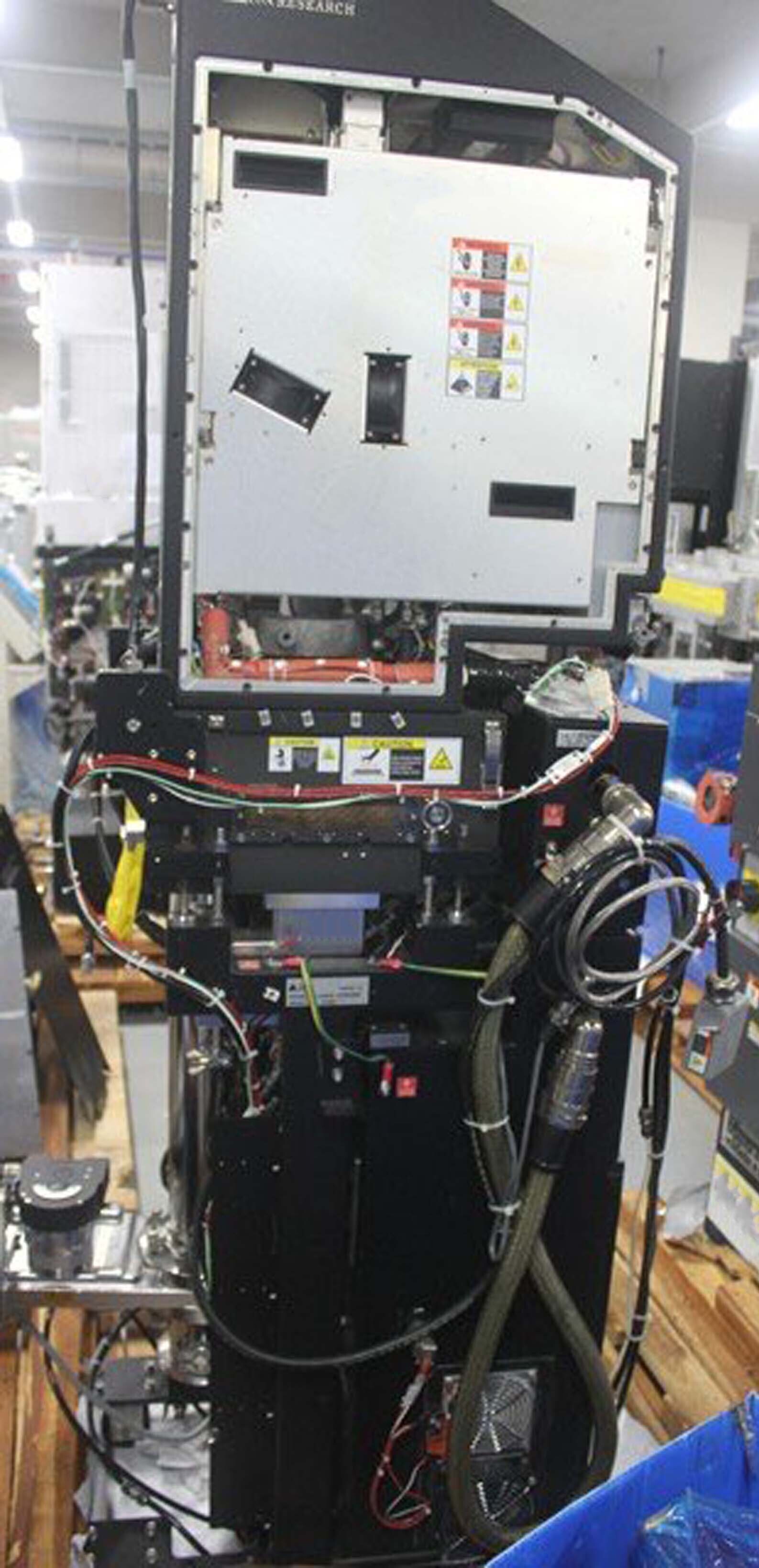

Used LAM RESEARCH Alliance A6 9600 #9354470 for sale

URL successfully copied!

Tap to zoom

ID: 9354470

Wafer Size: 8"

Etcher, 8"

Install type: Through the wall

Integrated gas panel

No SMIF

PM 1: Microwave

PM 2: 9600 PTX

PM 3: 9600PTX

PM 4: Microwave

PM 5: Aligner

PM 6: Cool station

Electrostatic chuck

On process turbo pump channels

VAT65 Turbo gate valve

Endpoint detection system

Photodiode endpoint

End point 1 P/N: 853-540066-011

CD Rom manuals

Alliance mainframe:

MAG7 Robot

Dual blade

Rotational VCE6 with dynamic seal

Signal lamp tower

Gate valve: Heated (PM2, PM3)

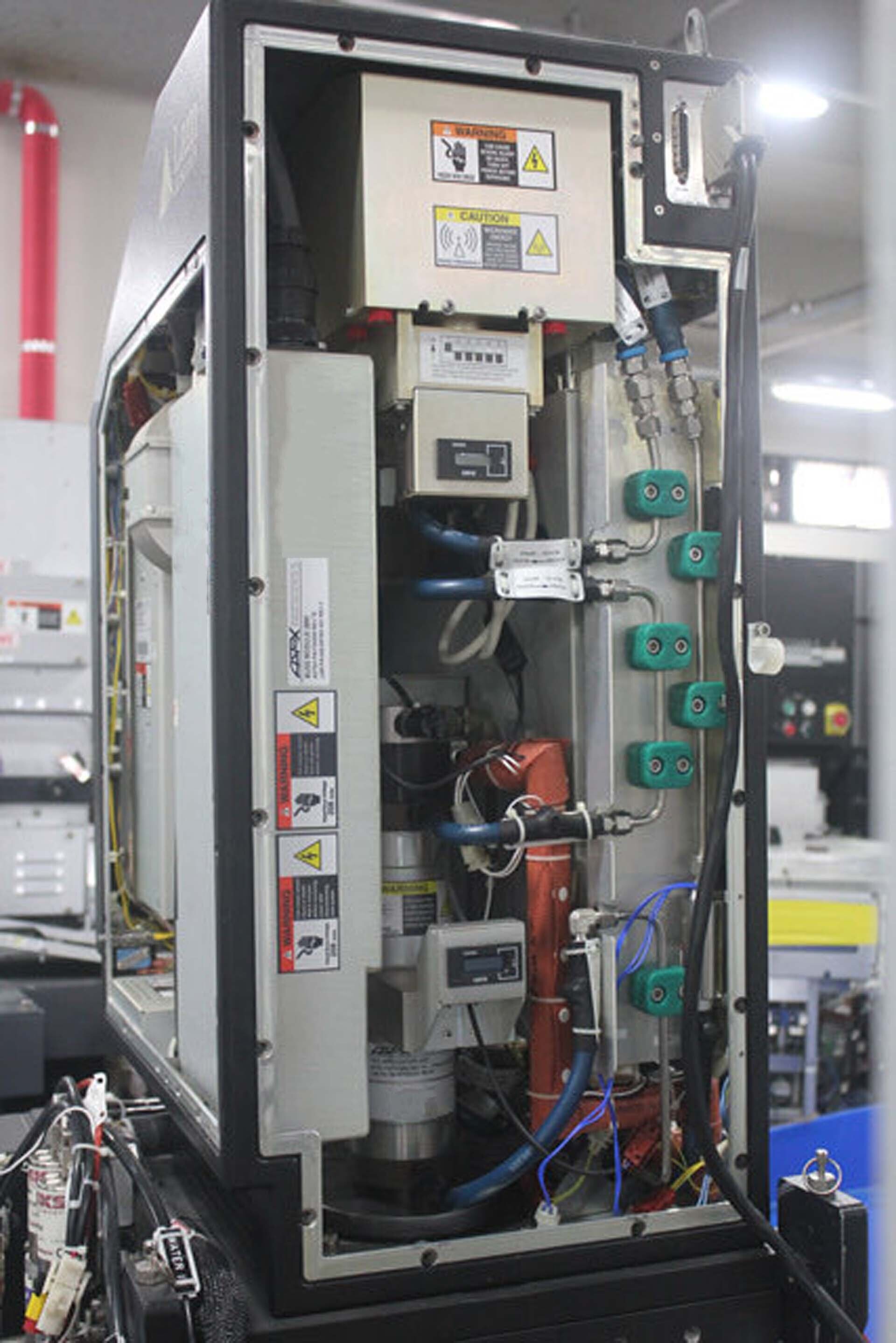

Turbo pump (PM2 and PM3):

SEIKO SEIKI H1303CV3 Turbo pump

RF / Microwave generator:

MKS CPS PM 1 Top

ADVANCED ENERGY RFG 1250 PM 2 Top

ADVANCED ENERGY RFG1250 HALO PM 2 Bottom

ADVANCED ENERGY RFG 1250 PM 3 Top

ADVANCED ENERGY RFG 1250 HALOPM 3 Bottom

MKS CPS PM 4 Top

Chiller:

One/Two cooling channels

Quantity: Up to 4

Gas box configuration:

PM1:

Gas line / Make / Model / Flow (SCCM) / Gas

1 / TYLAN / FC-2950MEP5 / 1000 / N2

3 / TYLAN / FC-2950MEP5 / 5000 / O2

PM2:

Gas line / Make / Model / Flow (SCCM) / Gas

1 / STEC / - / - / BCL3

2 / STEC / - / - / CL2

3 / TYLAN / FC-2950MEP5 / 200 / N2

4 / TYLAN / FC-2950MEP5 / 200 / O2

5 / TYLAN / FC-2950MEP5 / 100 / CHF3

6 / TYLAN / FC-2950MEP5 / 50 / AR

PM3:

Gas line / Make / Model / Flow (SCCM) / Gas

1 / TYLAN / FC-2900MEP5 / 200 / BCL3

2 / TYLAN / FC-2900MEP5 / 200 / CL2

3 / TYLAN / FC-2900MEP5 / 200 / N2

4 / TYLAN / FC-2900M / 200 / O2

5 / TYLAN / FC-2950MEP5 / 100 / CHF3

6 / TYLAN / FC-2950MEP5 / 50 / AR

PM4:

Gas line / Make / Model / Flow (SCCM) / Gas

1 / TYLAN / FC-2950MEP5 / 1000 / N2

3 / TYLAN / FC-2950MEP5 / 5000 / O2

No standard manuals.

LAM RESEARCH Alliance A6 9600 is a fully automated rapid thermal processing equipment based on advanced technologies, designed to provide its users with maximum precision and efficiency. The system operates within a temperature range of 25°C to 900°C and offers excellent temperature uniformity of +/- 5°C, meaning that the environment inside the processing chamber remains consistent while heating up and cooling down. The temperature stability ensures optimal etching or ashing performance at any temperature and substrate combination. The unit is equipped with an intuitive embedded control machine that offers a flexible recipe control, allowing for the integration of atmospheric, heating rate, cooling, end point correction and many other process parameters. This control tool is also capable of dynamic adjustments of these process parameters if required. The asset is capable of processing up to 6 substrates at one time with a process chamber size of 100mm diameter and a substrate size of 8" or 12", giving it higher throughput capacity. The Chamber is designed to perform etching and oxidation processes and it is also equipped with a quartz window viewer so that users can clearly view the progress of their work without having to open the chamber cover. Alliance A6 9600 rapid thermal processing model is an ideal solution for users looking to achieve precise temperature stability and achieve maximum efficiency and performance when processing their substrates.

There are no reviews yet