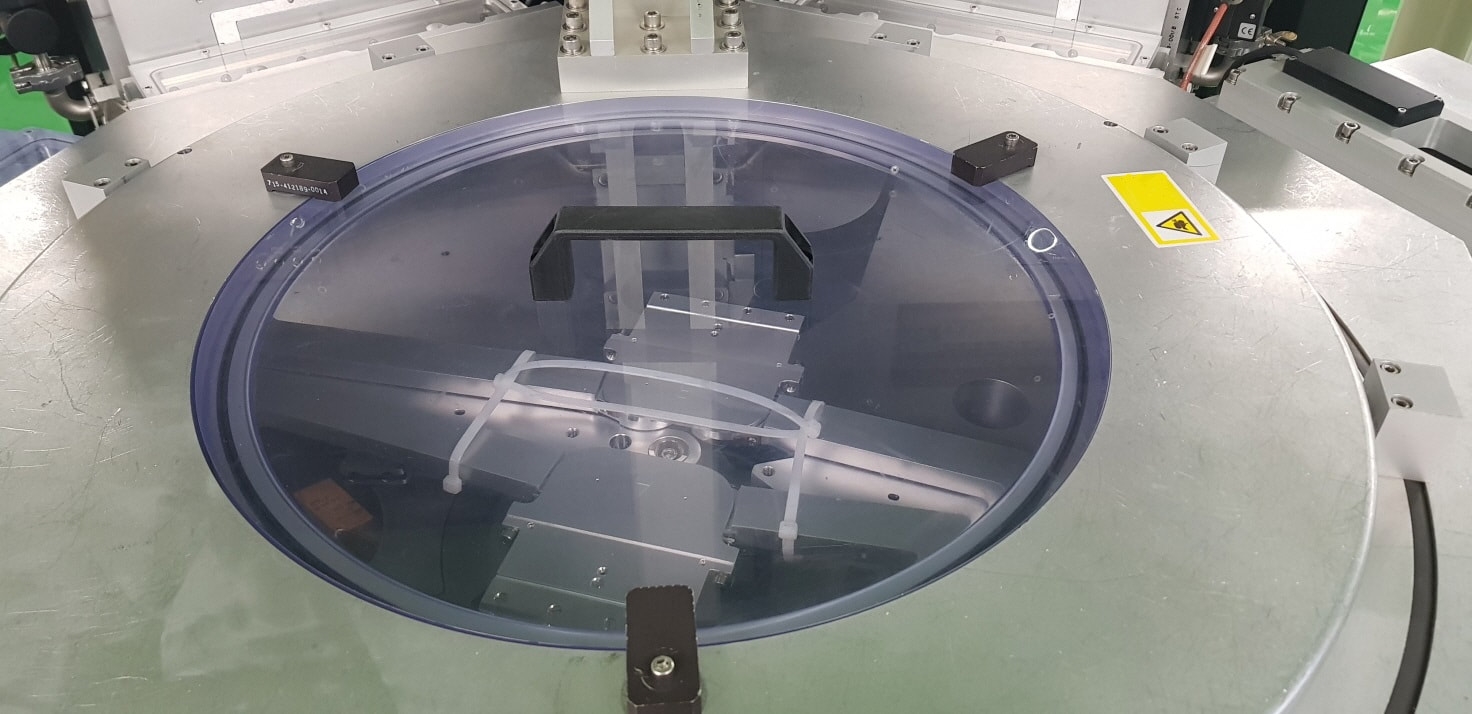

Used LAM RESEARCH Alliance A6 9608 PTX #9266046 for sale

URL successfully copied!

Tap to zoom

ID: 9266046

Wafer Size: 8"

Etcher, 8"

Integrated gas panel

PM1: Microwave

PM2: 9600 PTX

PM3:9600 PTX

PM4: Microwave

PM5: Aligner

PM6: Cool station

Electrostatic chuck

Turbo pump

Turbo gate valve: VAT65

Photodiode endpoint detection system

Gases: N2, O2, BCL3, CHF3, CL2, AR

CD ROM Manuals included

Mainframe

Robot MAG7

Dual blade

VCE6, Rotation, with dynamic seal

Signal lamp tower

Turbo Pump:

PM1: NA

PM2: SEIKO SEIKI H1303CV3

PM3: SEIKO SEIKI H1303CV3

PM4: NA

RF/ Microwave generator:

PM1: MKS CPS

PM2: ADVANCED ENERGY RFG 1250 / ADVANCED ENERGY RFG1250 HALO

PM3: ADVANCED ENERGY RFG 1250 / ADVANCED ENERGY RFG1250 HALO

PM4: MKS CPS.

LAM RESEARCH Alliance A6 9608 PTX is an advanced physical vapor deposition (PVD) and etching technology created to enable device manufacturers to create complex non-volatile memory chips with a higher yield and more performance. With a large vertical range, Alliance A6 9608 PTX provides a range of dedicated modules to meet device fabrication needs, allowing integrated circuits to be designed faster and with greater precision. LAM RESEARCH Alliance A6 9608 PTX features a full range of vacuum process capabilities, from physical vapor deposition (PVD) to chemical etching, which are essential for making non-volatile memory chips. This allows for precise control over process conditions such as chamber pressure and temperature, as well as deposition speed and uniformity. These capabilities allow device mechanisms to be precisely etched and accurately controlled between layers, eliminating the need for costly and time-consuming manual adjustments. Additionally, this system is equipped with temperature programming, a safeguard to prevent damage to the chamber and process parts. This allows for easy and accurate tuning of the process conditions, providing a higher yield and reducing the risk of contamination. In addition, with its high degree of controllability, Alliance A6 9608 PTX can be used to fabricate difficult structures with three-dimensional contours. This can be used to build complex architectures, such as nano-scale memory chips, with a much higher yield and performance than was previously possible. LAM RESEARCH Alliance A6 9608 PTX also features high efficiency robotic sample handling and slit/source zones. This feature is provided to ensure that the appropriate amount of sample is handled with high accuracy and at a faster rate. The robotic handlers are linked to a central control system that gives the operator control over the various process steps in order to ensure smooth operation and efficiency. In conclusion, Alliance A6 9608 PTX is a top-of-the-line etcher and asher for those needing to fabricate complex non-volatile memory chips. Its integrated vacuum process capabilities, temperature safety programming, and sophisticated robotic sample handling allow it to deliver precision and controllability in a shorter time frame and with higher yield and performance than older systems.

There are no reviews yet