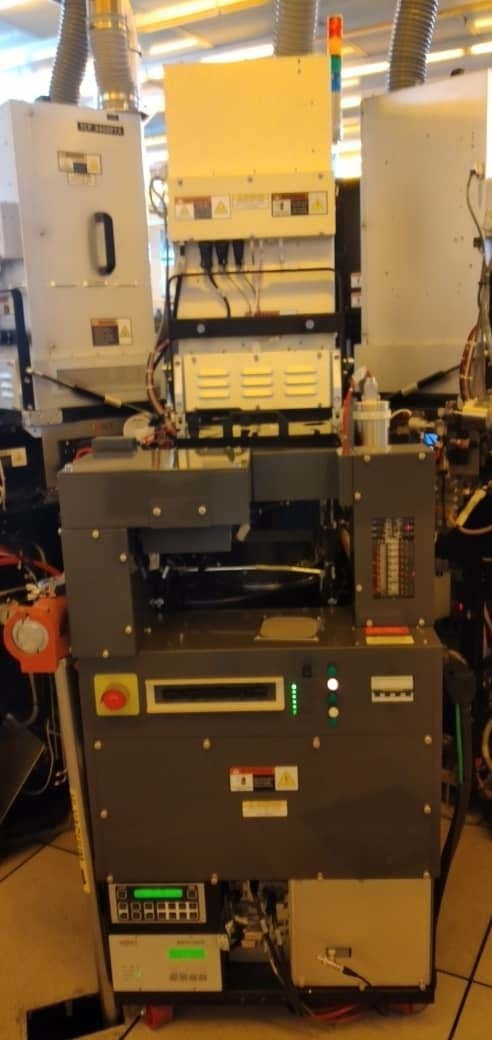

Used LAM RESEARCH Alliance TCP 9400 PTX #293627727 for sale

URL successfully copied!

Tap to zoom

ID: 293627727

Wafer Size: 8"

Etcher, 8"

Chamber

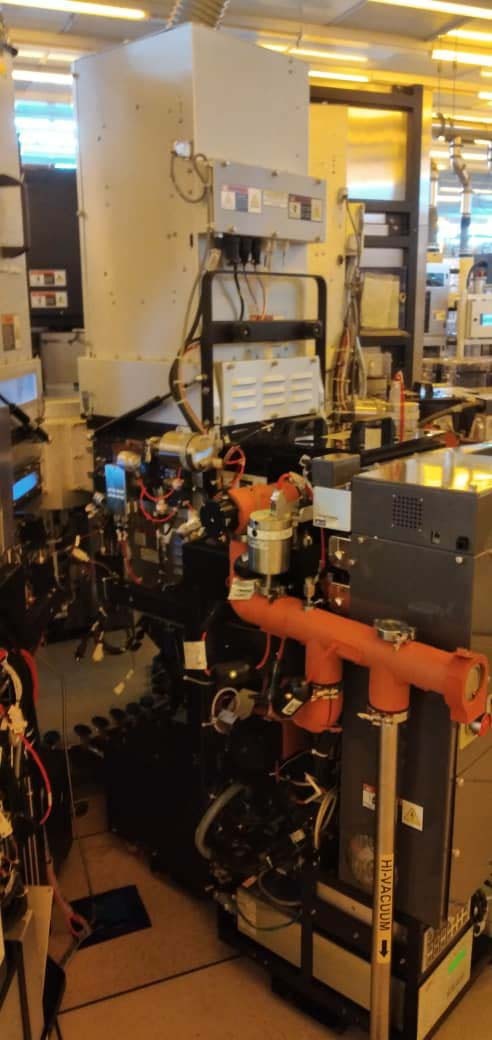

ALCATEL / ADIXEN / PFEIFFER ATH 1300M Turbo molecular pump

ACT 1300M PM Pump controller

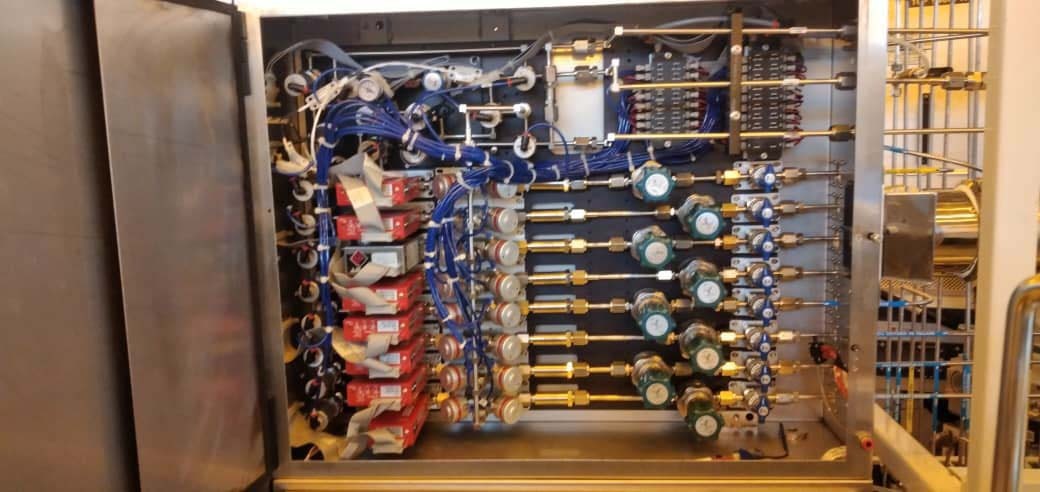

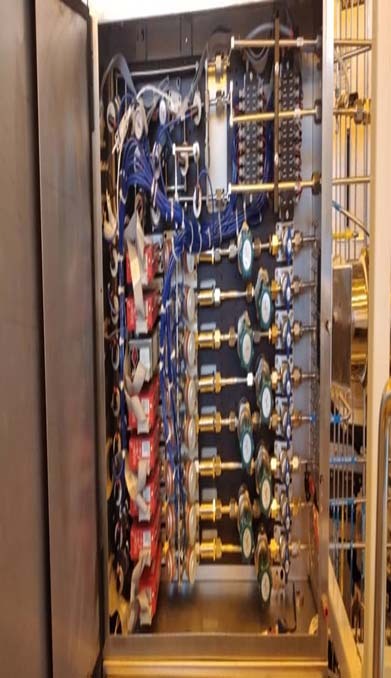

Enhanced gas box

Spooled inlet gas panel

HORIBA / STEC Mass Flow Controller (MFC) Type: Digital

Gas filter: ≥0.003 um

Gas box stacking: 4 PM Stacking

Pump ballast with AOV 85

Chamber manometer: MKS 0.1 Torr

Turbo manometer: MKS 10 Torr

Fore line manometer: MKS 10 Torr

Pressure control valve: Pendulum VAT65

Helium pressure control unit: UPC-1300

ESC 718-094523-281 Bipolar anodize (Notch), 750 V, 24 VDC

Chamber configuration: Elevated top hat

Direct pressure monitoring

He Cooling size (Center): 50 SCCM

(8) Gas lines:

Line / Gas / Size

1 / O2 / 50 SCCM

2 / C2F6 / 100 SCCM

3 / Cl2 / 100 SCCM

4 / HBr / 350 SCCM

5 / He / 500 SCCM

6 / 20% O2/He / 20 SCCM

7 / CF4 / 200 SCCM

8 / SF6 / 200 SCCM

Upper chamber temperature: 60°C

Wall chamber temperature: 60°C

Lower chamber temperature: 65°C

ADVANCED ENERGY RFDS-1250 RF Generator, 1250 W (P/N: 660-024637-026)

RF Generator cooling type: Water

Coil (P/N: 853-330601-001)

Match (P/N: 853-032294-002)

Auto tune PCB (P/N: 810-015987-101)

Upper match enclosure with fan

ADVANCED ENERGY RFG-1250 Halo RF Generator, 1250 W (P/N: 660-024637-028)

RF Generator cooling type: Water

P/N: 853-015130-103 Match

P/N: 810-017003-005 DIP PCB.

LAM RESEARCH Alliance TCP 9400 PTX is a desirable asher/etcher machine for factory production. This compact, easy to use machine is primarily used for processing of wafer substrates. The PTX model is ideal for material growth and removal applications requiring high degrees of accuracy and precision. Its automation capabilities maximize throughput, reduce cost per application, and simplify operation. The PTX uses a plasma enhanced etch technology, with optimized chamber design and advanced etching parameters providing superior quality results. This highly advanced etcher has an excellent deposition profile, uniform overlaps and sharp feature definition, resulting in defect-free wafers and a greater yield. The TCP 9400 PTX features a Tilt Rotation stage allowing precise processing alignment with precise pattern recognition. This allows processing of substrates of any size and thickness while maintaining precise uniformity. The machine also has an exceptional service life with an average total up time of 97%. The equipment is based on a 90nm single-wafer process which is perfect for both low-power and high-density applications. It offers a wide range of system options for customizing results to a customer's specific needs. Other features include a 25W high-power radio frequency source delivering uniform power over the entire wafer, automatic notch selection, and a secure remote data management unit for process control and monitoring. The PTX is designed for long-term reliability, accurate patterning and repeatability, and a high-performance machine to accommodate demanding production requirements. The machine also provides a high level of operator comfort and flexible operation with a color touch screen and updated software making the operation and maintenance of the equipment simpler and more efficient. This machine is well suited to any production environment and provides optimum uptime, process control and reproducibility.

There are no reviews yet