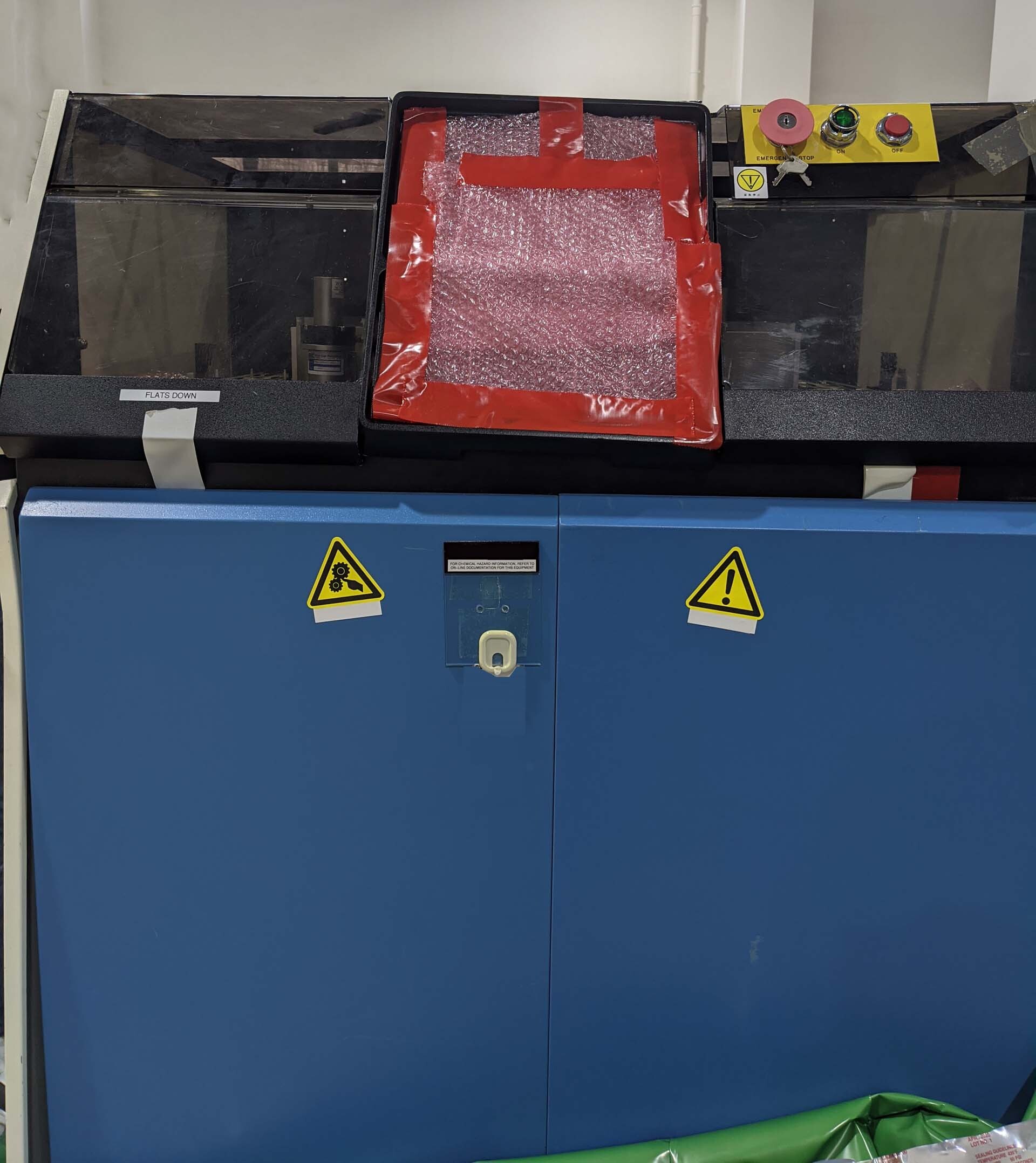

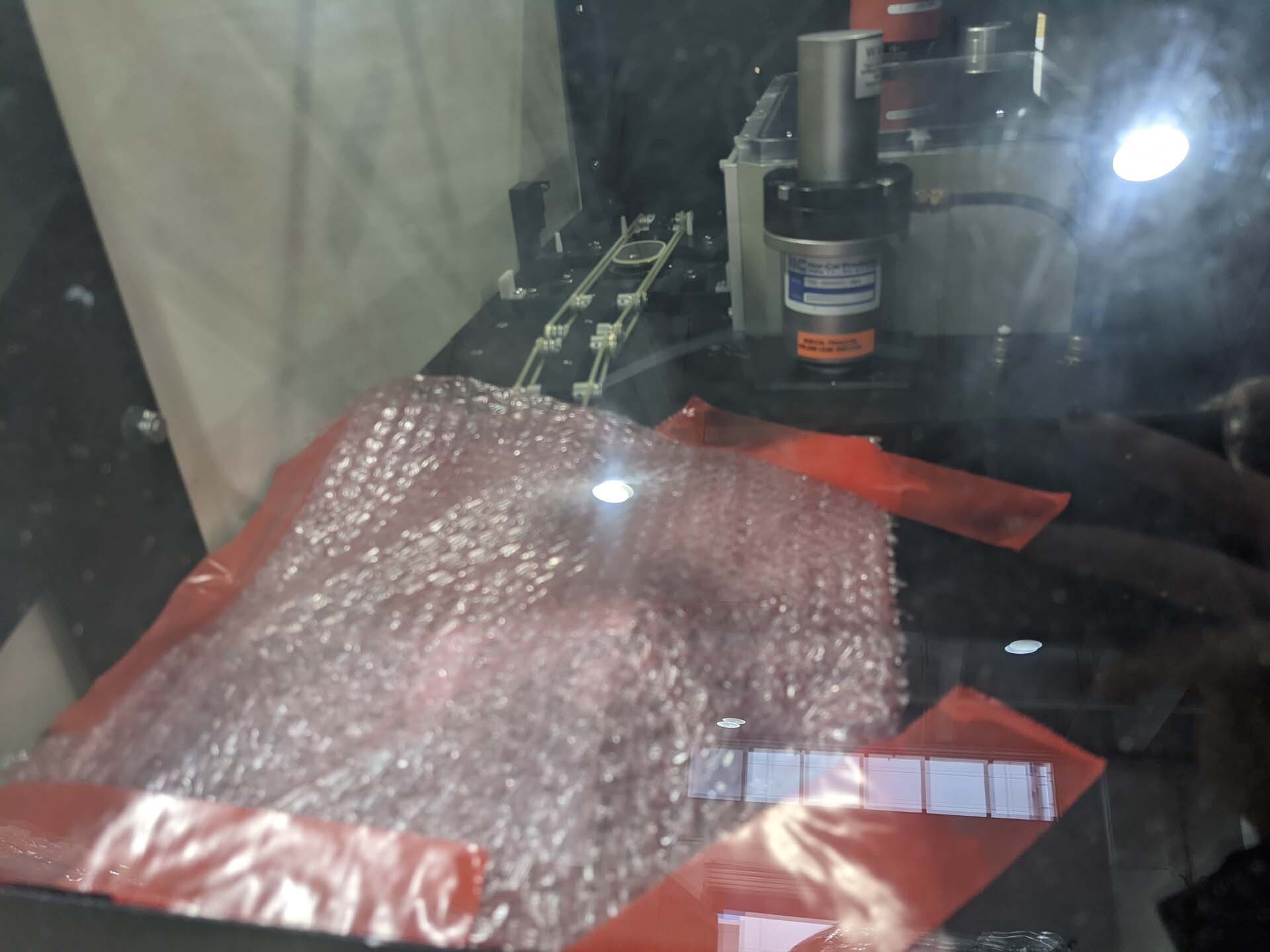

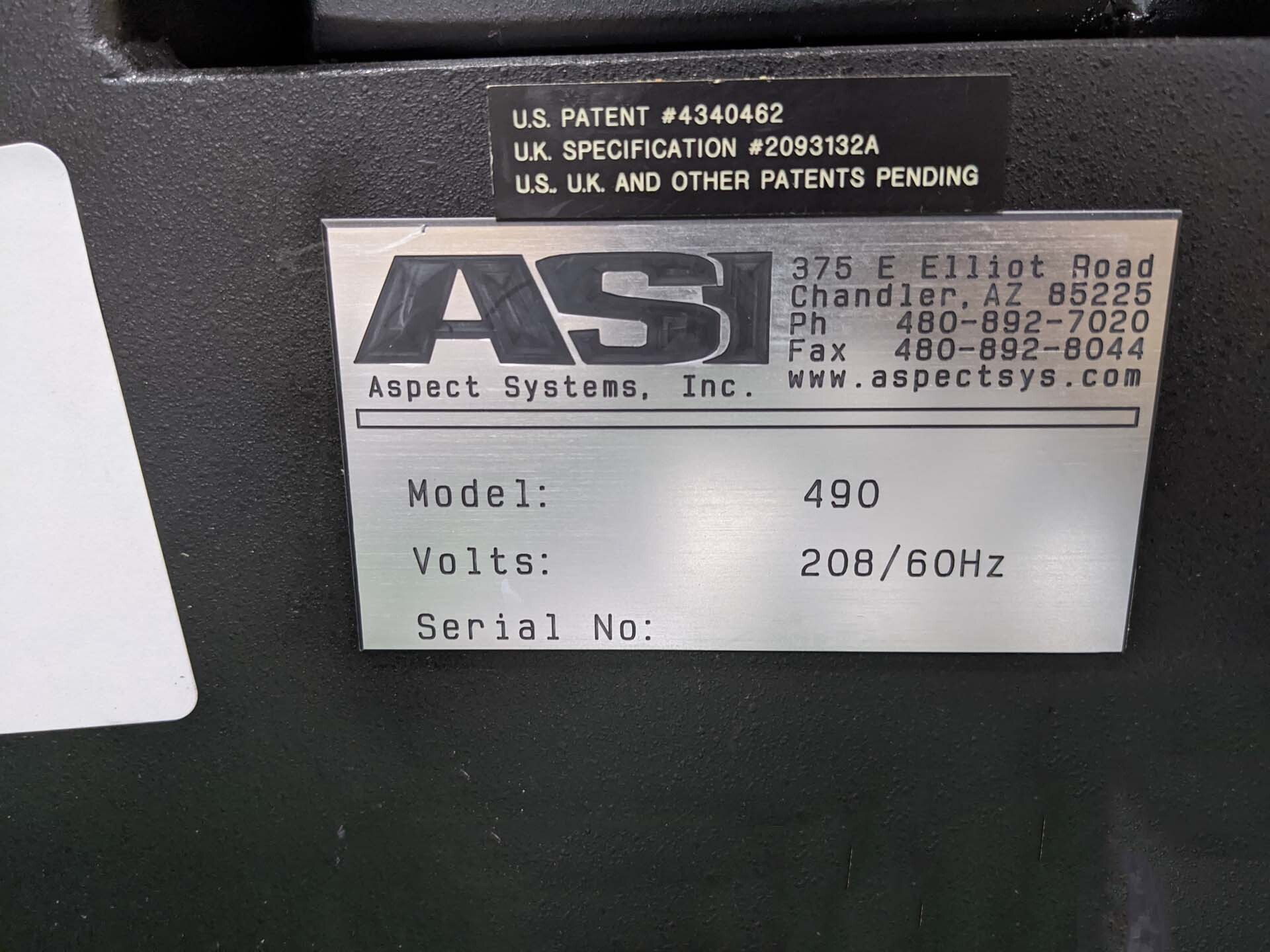

Used LAM RESEARCH Autoetch 490 #293647716 for sale

URL successfully copied!

Tap to zoom

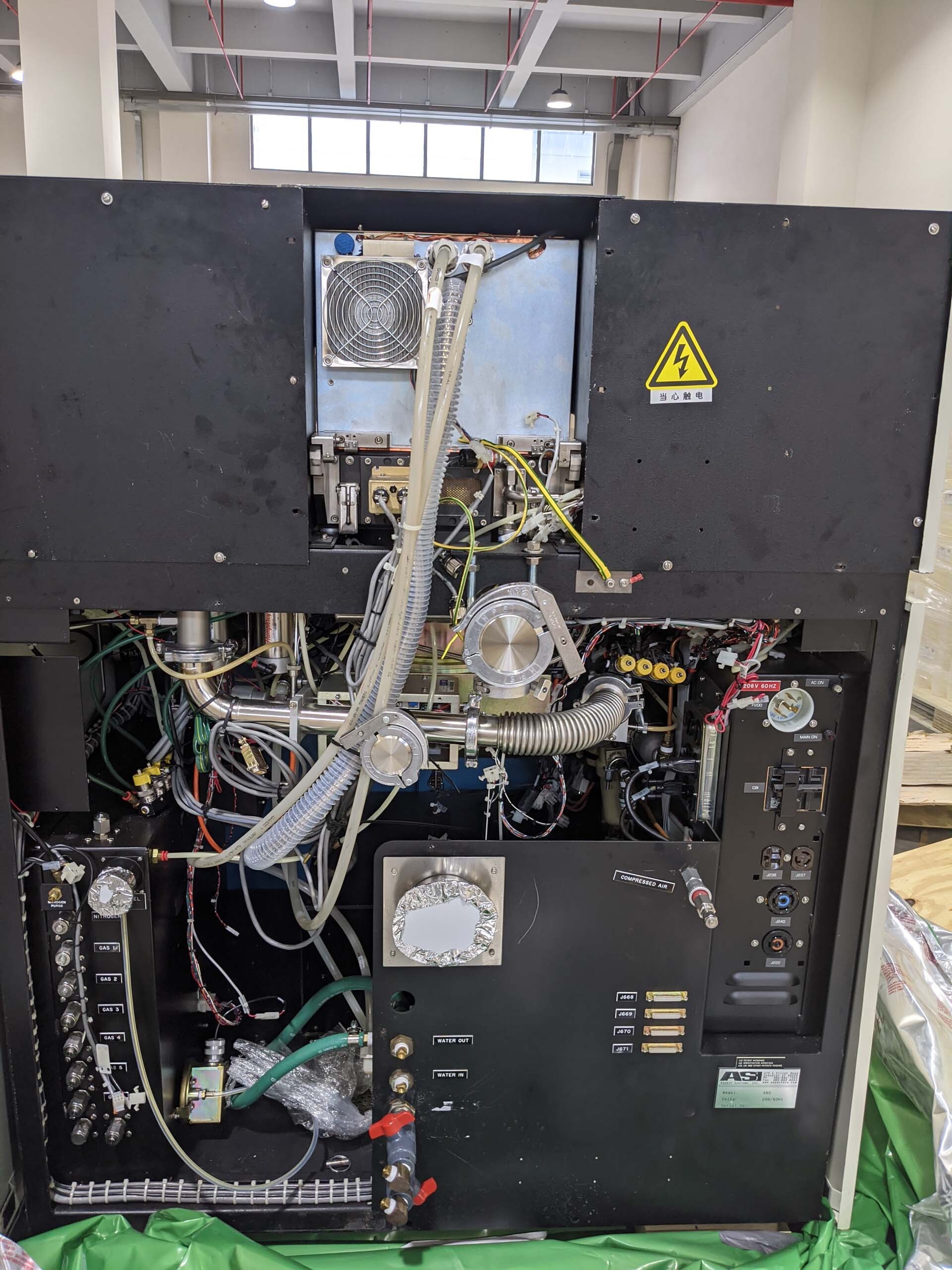

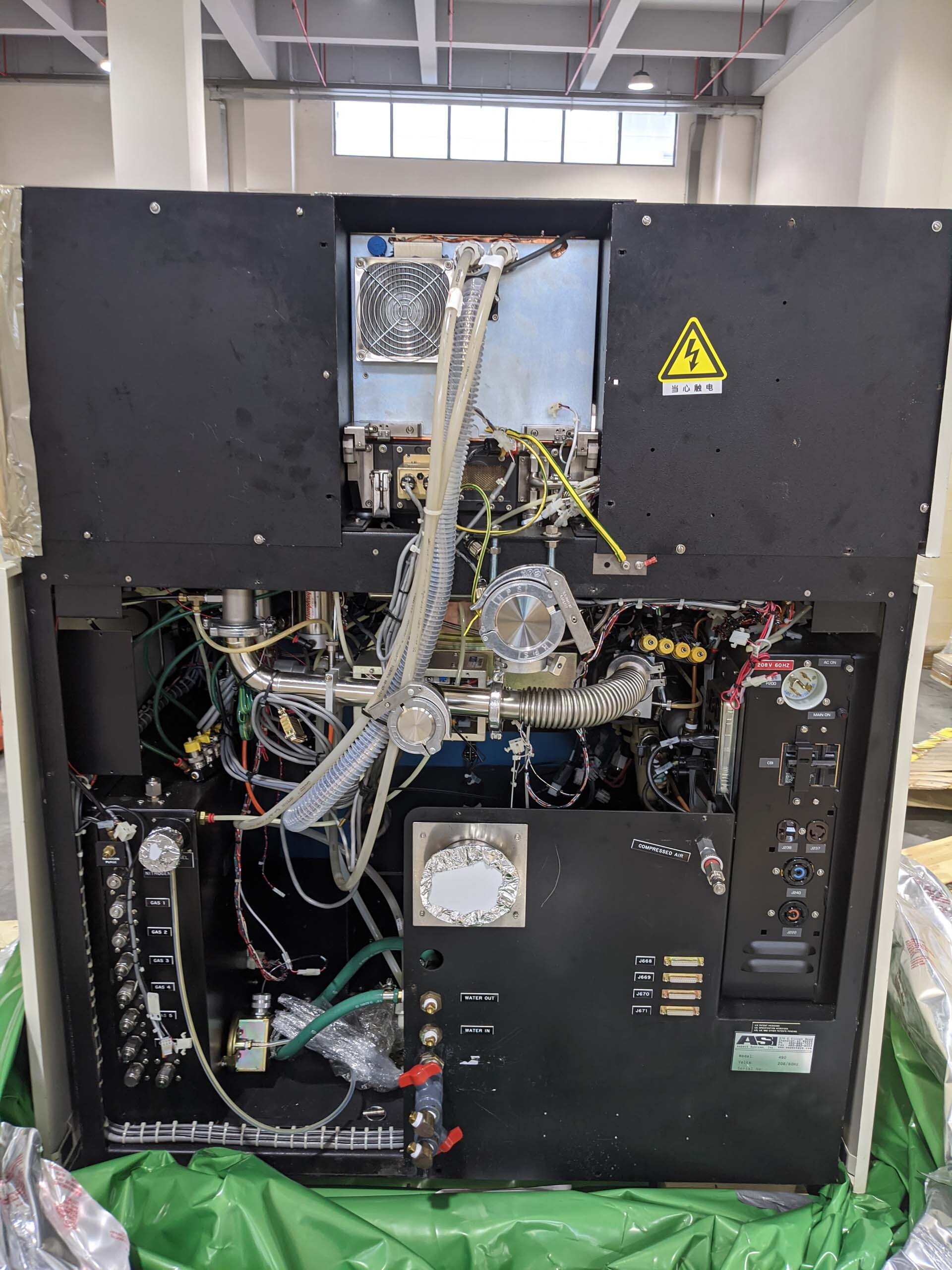

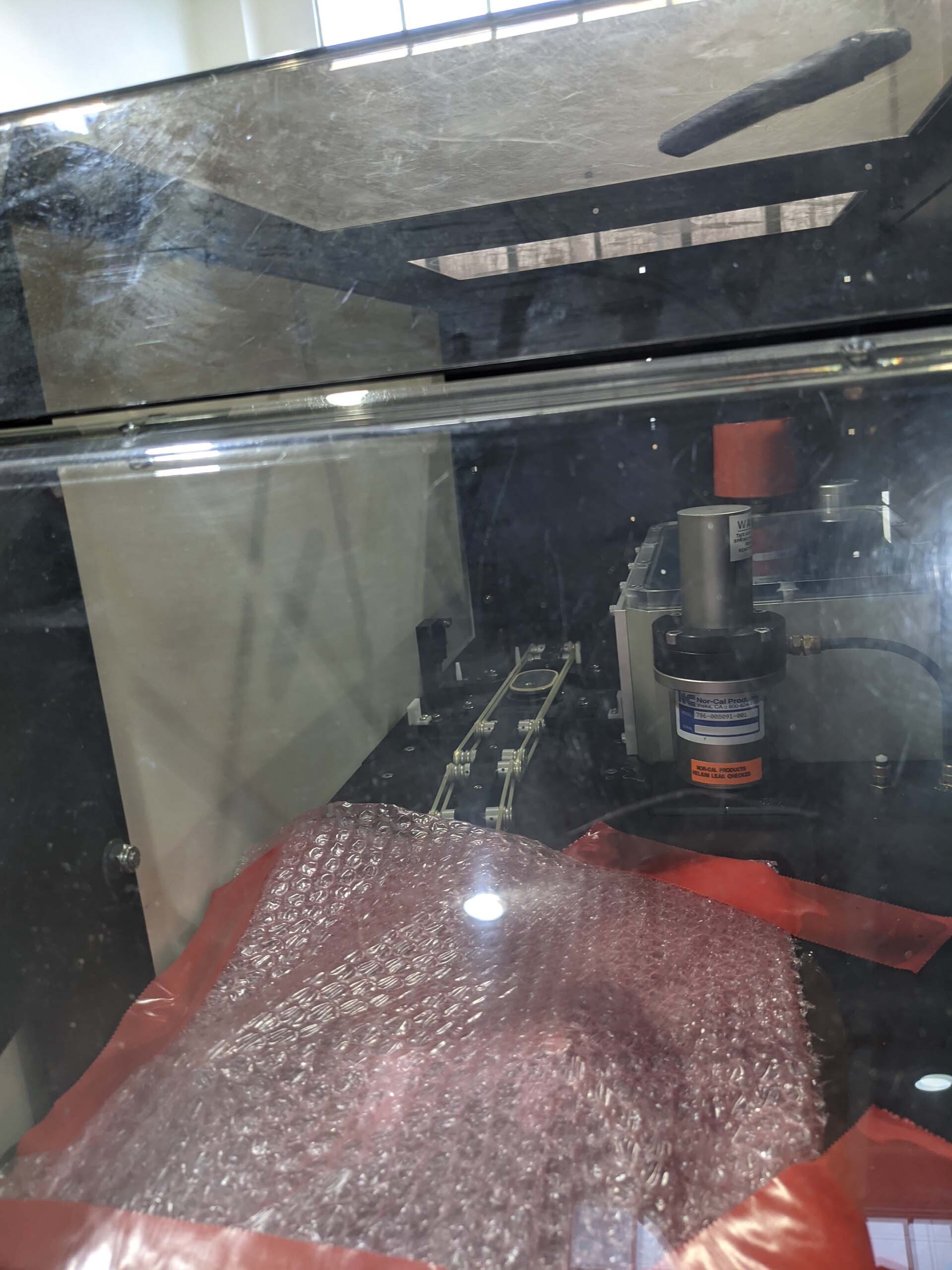

LAM RESEARCH Autoetch 490 is an advanced etcher/asher that has been developed to meet the requirements of advanced etching and ashing processes. This equipment is designed to feature an integrated high-performance etcher and asher in a single user-friendly platform. This system is ideal for precision etching and ashing applications and is constructed for maximum output and agility for high-volume production. It offers high-performance, event control capabilities to meet the demands of a wide variety of process and product requirements. Autoetch 490 has been designed with a highly reliable, low-maintenance, high-performance etcher and asher to ensure quality and throughput. The controller provides sophisticated real time process control unit to monitor and adjust etch and ashing processes. The engineering also includes a high precision tilting capability to provide excellent quality ashing and etching results. LAM RESEARCH Autoetch 490 also offers advanced options to increase process capability and performance. These include multi-gas, which allows for the processing of multiple gases simultaneously to enhance the process capability, and advanced turbo-pump technology for increased throughput and productivity. Autoetch 490 also offers multi-tool hardware platform support for production environments. The advanced processing support from the company's proprietary hardware and software machine provides a robust, statistical process control data analysis. This advanced analysis provides performance feedback and actionable data to help optimize the process and reduce tedious human intervention LAM RESEARCH Autoetch 490 is a powerful and reliable advanced autoetch and asher tool. It is capable of high-volume production and ensures the highest quality and throughput with its real-time process control asset and advanced turbo-pump technology. The multi-tool platform support allows for easy integration and deployment of multiple tools and gases in production environments, while the proprietary software model provides detailed feedback to help optimize process control. It is capable of meeting a wide variety of industry requirements and offers the reliable high-performance and event control capabilities necessary for precision etching and ashing.

There are no reviews yet