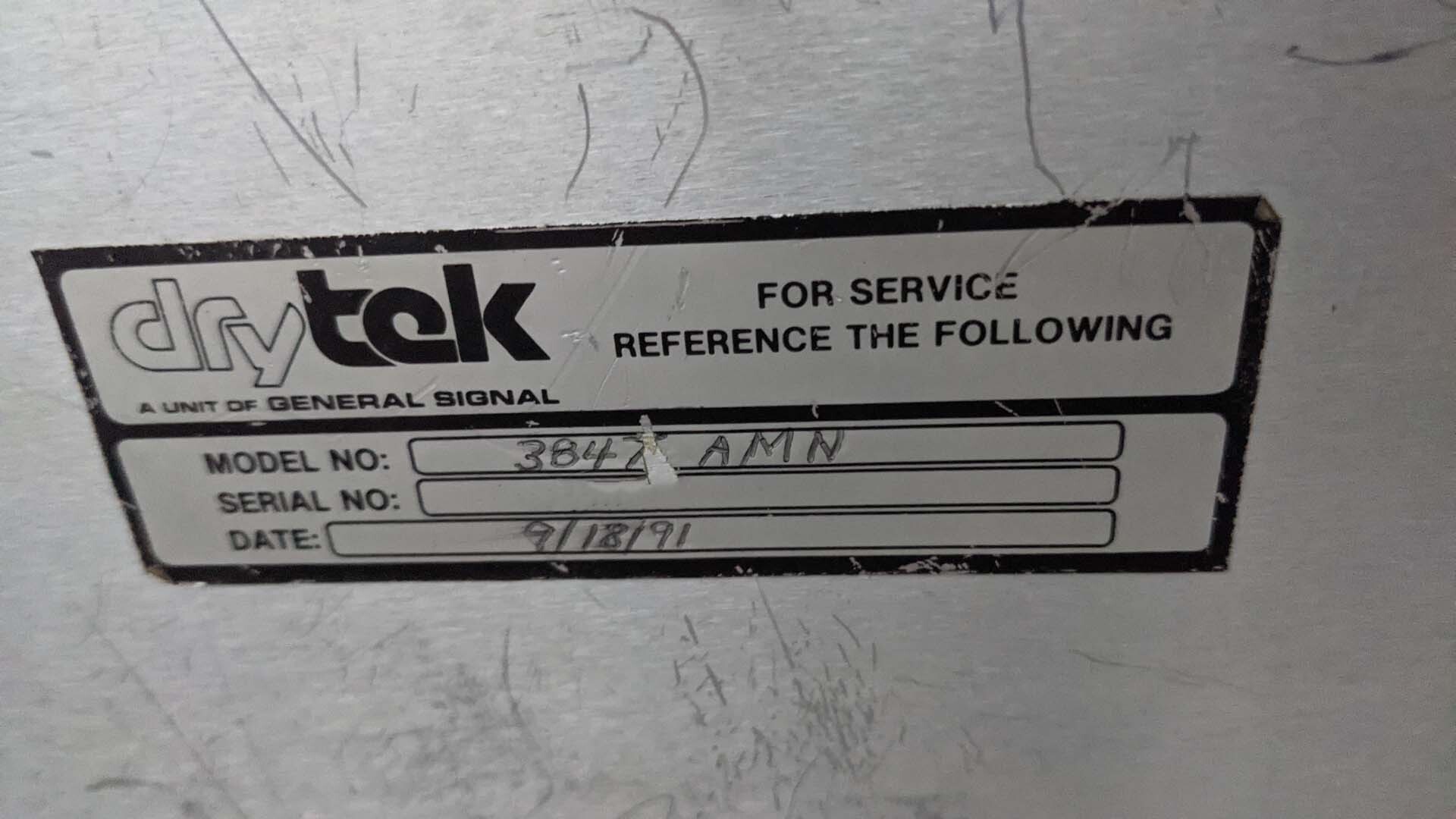

Used LAM RESEARCH / DRYTEK 384T AMN #9386131 for sale

URL successfully copied!

Tap to zoom

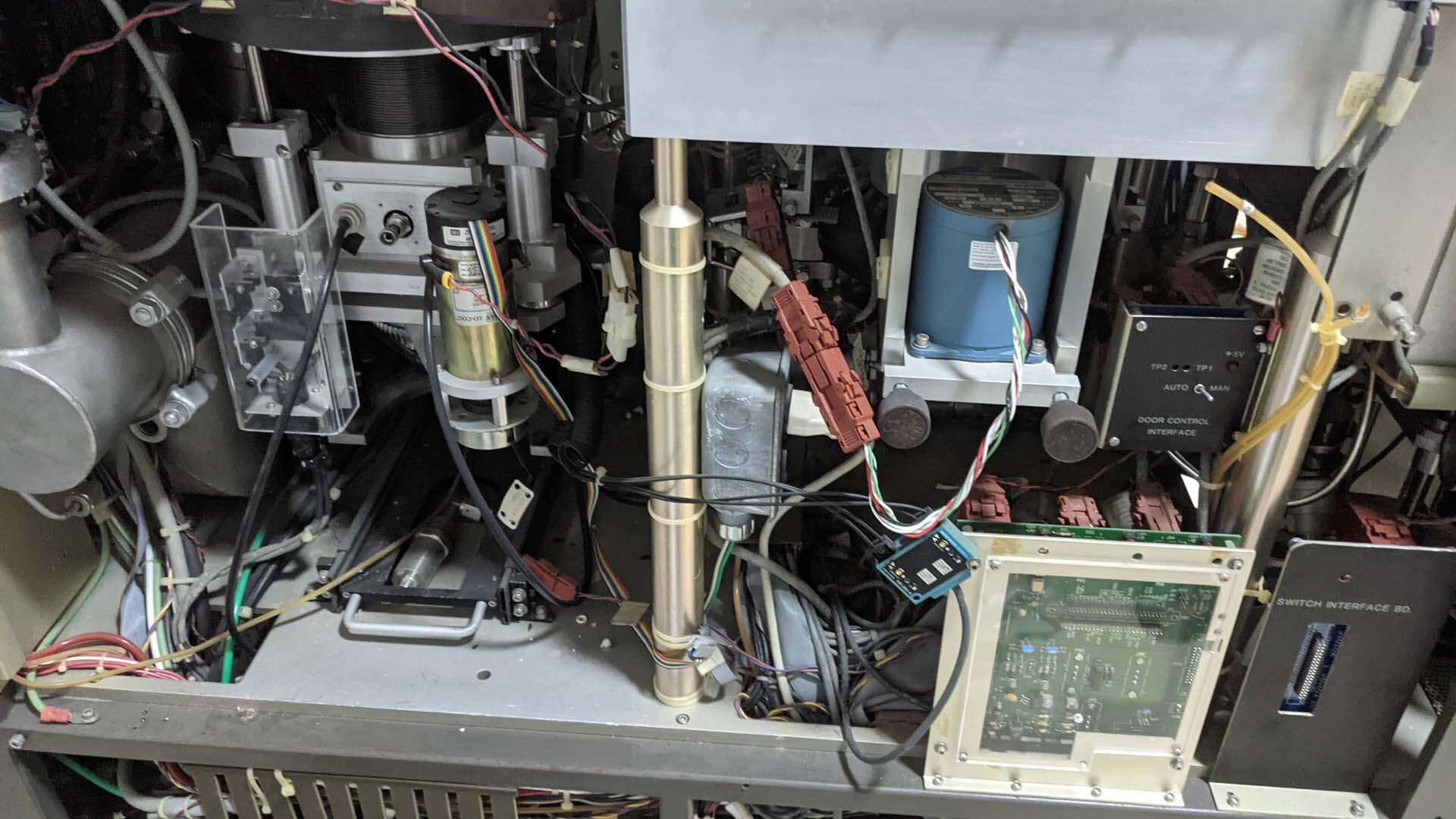

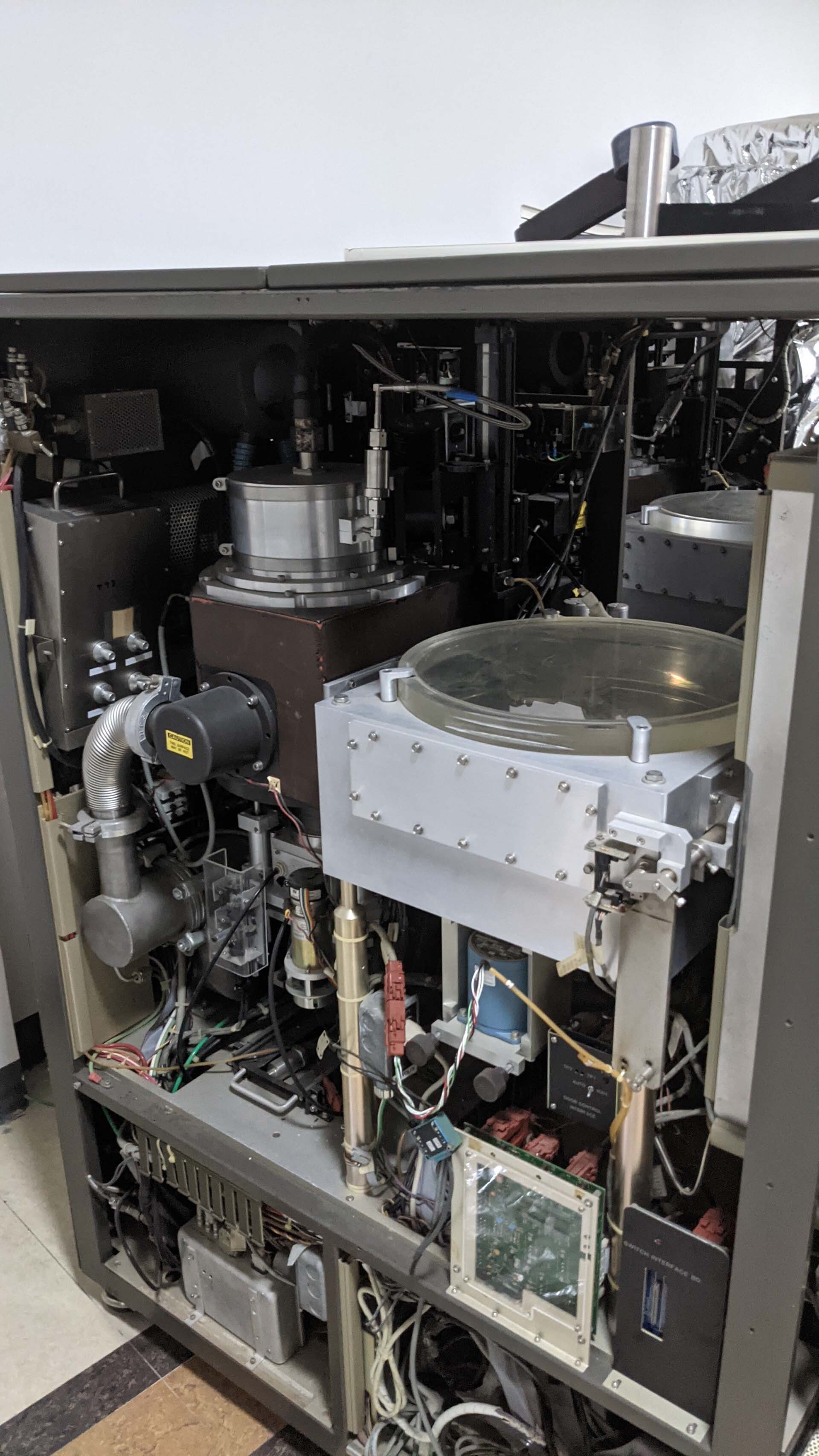

LAM RESEARCH / DRYTEK 384T AMN dry etcher/asher is a tool specifically designed for applications requiring precise etching and ashing multiple layers simultaneously. This equipment is capable of generating high rates of etching and ashing, with high uniformity, repeatability, and layer reliability. It provides etching and ashing features in a compact and reliable design. DRYTEK 384T AMN utilizes a three-stage plasma source design for etching and ashing. This design consists of an RF generator, a high-density plasma source, and a vacuum equipment. The generator is capable of providing up to 8,000 watts of power, enabling high etching and ashing rates. The high-density plasma source provides a uniform, repeatable etch which provides granularity control over the etching process. The vacuum system is capable of a base pressure of below 1 mTorr, creating a clean, dry etch/ash environment. LAM RESEARCH 384T AMN also utilizes a chamber design that is capable of thermal cycling of the etching process. This allows for improved performance and reliability of the etch. Additionally, the chamber incorporates a magnet right arrangement for increased high-density Plasma generation and superior process uniformity. The chamber is also equipped with a quartz wafer boat, which is essential for rapid thermal cycling, and a gas distribution manifold that is capable of precisely controlling the gas flow rate for precise, repeatable etching and ashing. 384T AMN unit is equipped with a wide array of process tools such as an end point detection machine, a diagnostic gas injection tool, an interlock asset, and a plasma source monitoring model. These tools help provide improved process control and enable the etcher/asher to deliver results that are uniform and repeatable. In conclusion, LAM RESEARCH / DRYTEK 384T AMN dry etcher/asher is an efficient and reliable tool for etching and ashing multiple layers simultaneously. It utilizes a three-stage plasma source design, a chamber design capable of thermal cycling, and a wide array of process tools to provide precise etching and ashing. All of these features make it an ideal tool for a wide variety of applications.

There are no reviews yet