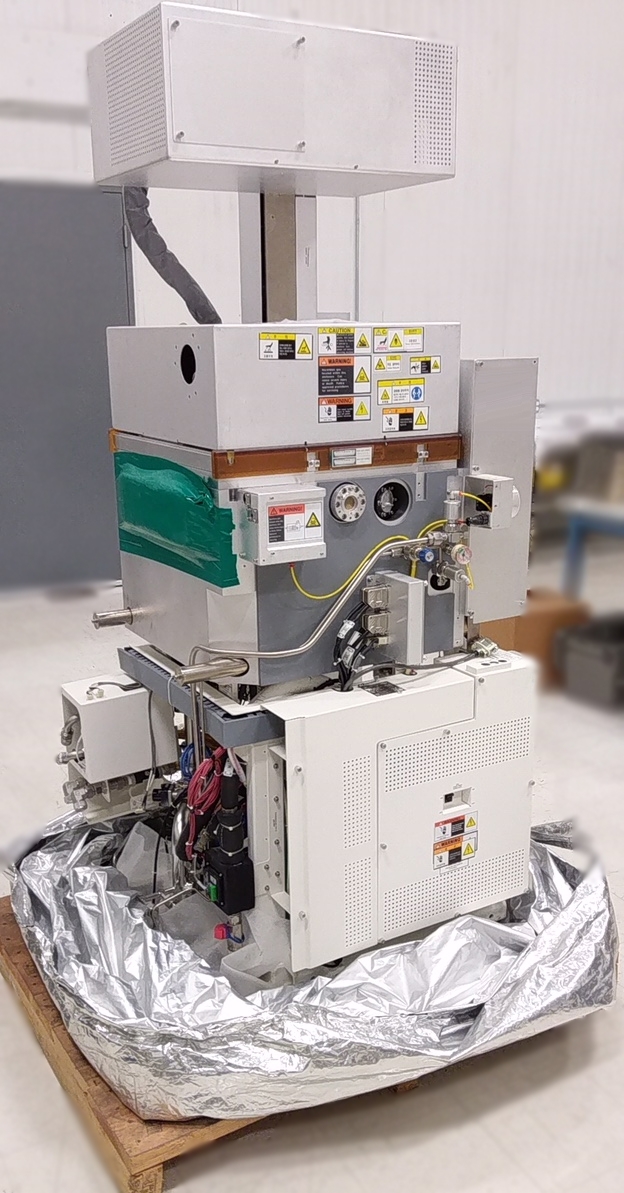

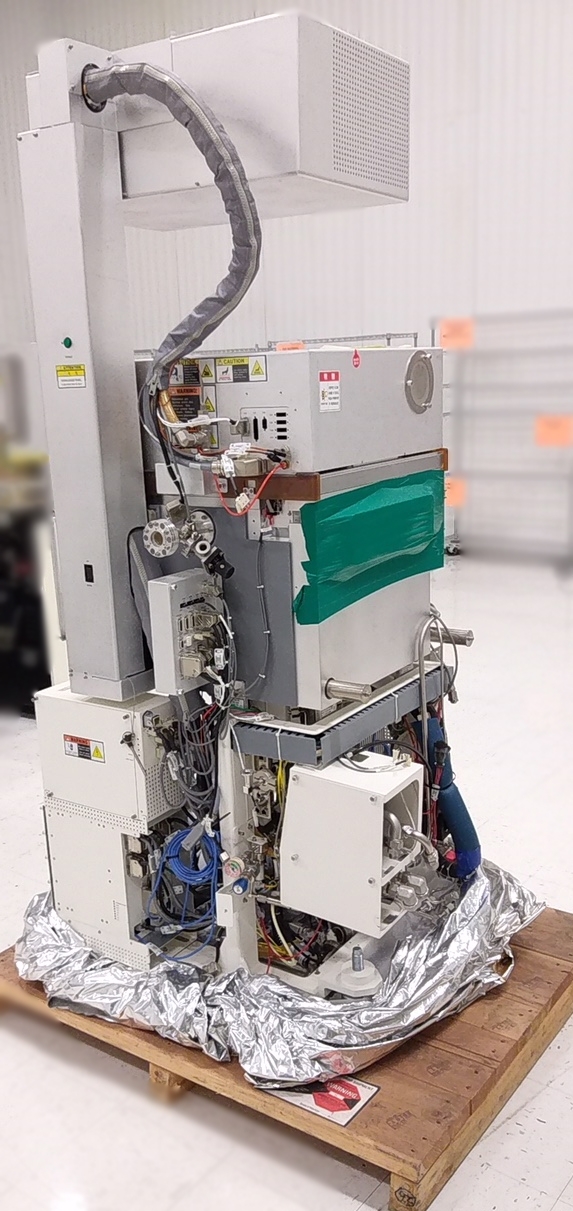

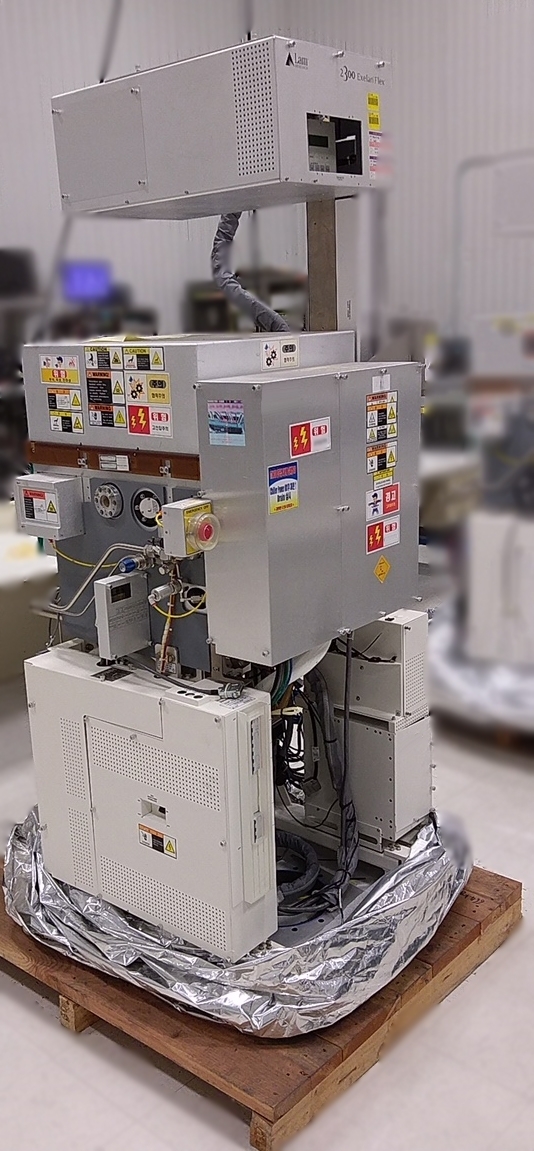

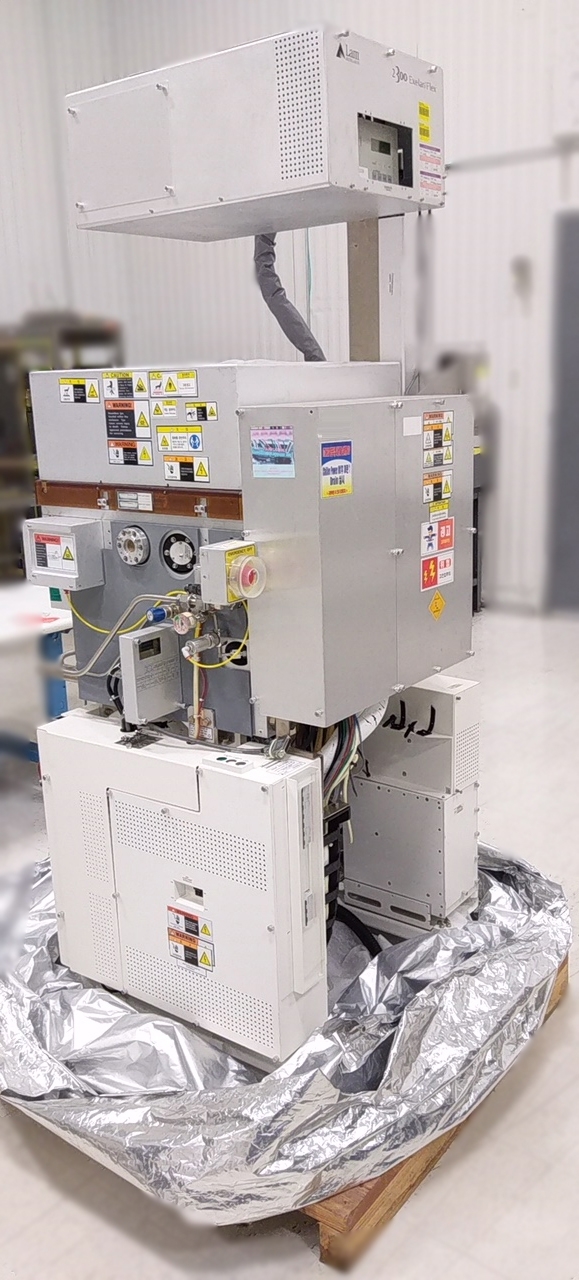

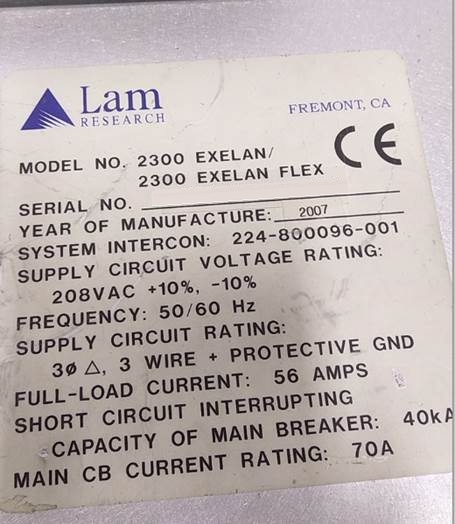

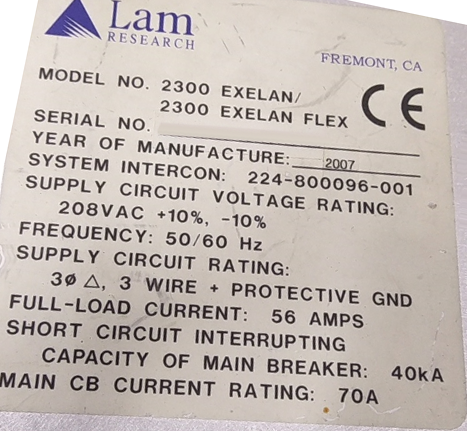

Used LAM RESEARCH Exelan Flex 45 #9157701 for sale

URL successfully copied!

Tap to zoom

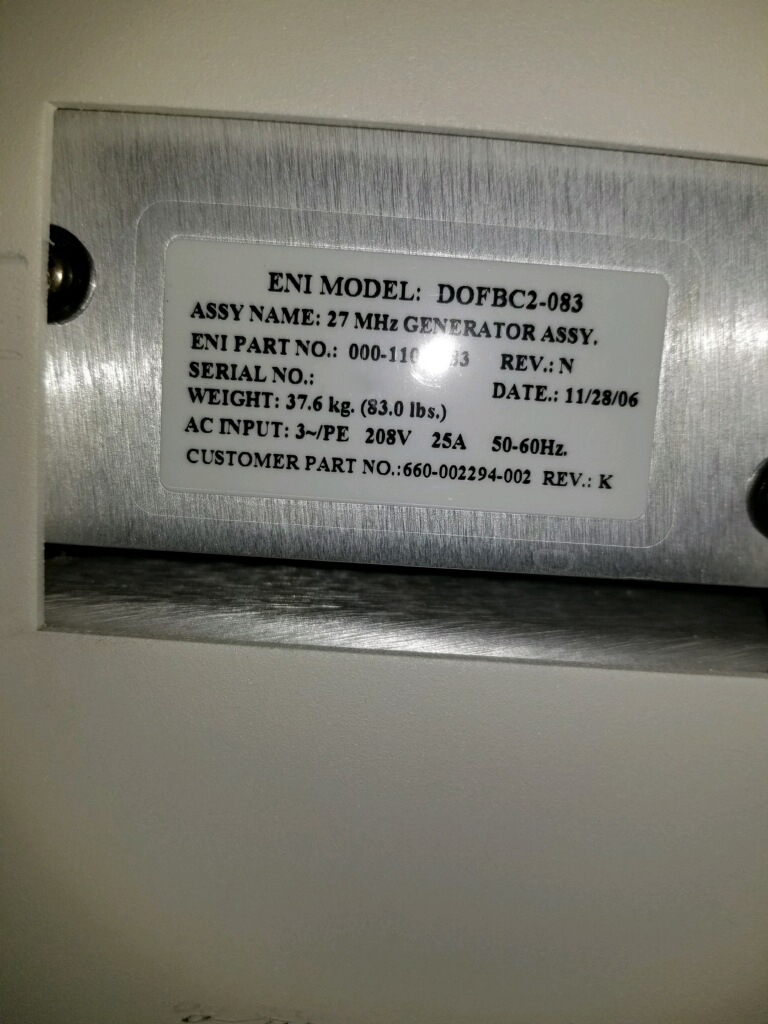

LAM RESEARCH Exelan Flex 45 is an etcher and asher designed to perform application-specific etching and ashing processes. It is based on the reliable, versatile Exelan Flex Platform, which has been proven to deliver superior process performance and yield for a range of applications, including photolithography, semiconductor, and MEMS fabrication. It utilizes advanced processes and technologies such as wafer handling, uniformity, high precision, defect-tolerant etching, and HF- and SF-based ashing, giving you the flexibility to produce higher yields at lower cost. It also offers an array of automated features for easy operation and monitoring, such as temperature control, process monitoring, substrate monitoring, manual control, and diagnostics, providing you with greater data and control. The Flex 45 features a process chamber made of 304L stainless steel with a maximum chamber size of 450 x 450 x 500mm, allowing it to accommodate larger substrates and process wafers up to 300 mm. It includes a Carbon Dioxide (CO2) based process gas delivery equipment, which uses a combination of microwave and hot plasma to create high-density ion beams for improved selectivity and two gas mixers for the delivery of precursor and etchant gases. A built-in ECR etcher is also featured, which is capable of achieving high etching selectivity with an exceptionally low leakage current. In addition, it offers plasma treatment before or after an etch process, and is capable of handling multiple wafers at a time. The Flex 45 is a cost-effective, 24/7 wafer processing platform, providing uniformity, uniform film uniformity, and features heated load locks and nozzle stations, enabling you to quickly change wafer types and gas mixes with minimal downtime. The process software is designed to meet your specific application requirements, with an intuitive graphical user interface (GUI) that allows for easy parameter setting and system control. The unit features a modular design, allowing it to be configured for other applications such as Oxide, Nitride, and Silicon-on-insulator (SOI) processing, as well as deposition and back end processes. It also offers optional equipment such as plasma- or light-enhanced processes and an integrated optical inspection machine. Exelan Flex 45 is perfect for semiconductor and MEMS applications that require precision etching and ashing processes. Its advanced features and user-friendly software make it easy to use, while providing the flexibility and performance to meet the demands of the most challenging semiconductor and MEMS applications. It is the ideal etcher / asher for achieving maximum yields at a cost-effective price.

There are no reviews yet