Used LAM RESEARCH Exelan HPT #195406 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 195406

Wafer Size: 8"

Vintage: 2001

Oxide etcher, 8"

(3) Chambers

Configuration:

Transfer Module: A6

VCE: L-VCE : Brooks 004-9200-24

R-VCE : Brooks 004-9300-24

Robot: BROOKS, Magnatran7, Model 002-4037-02

PM-1: EXELAN HPT

PM-2: EXELAN HPT

PM-3: EXELAN HPT

Aligner: present

Aligner Controller: Model 001-4130-03

User Interface: CRT Monitor, PC, Keyboard, Signal Tower

Gas Box: Standard 8-Channel (With GIB)

TMP-PM1: ALCATEL ATH1600M

TMP-PM2: ALCATEL ATH1600M

TMP-PM3: ALCATEL ATH1600M

RPM: 685-495112

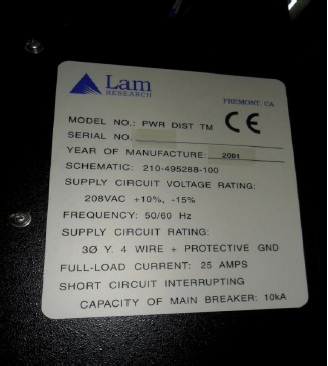

Main-Power

UPS-Power

Signal Tower: 3-Color (red, green, yellow)

EMO: Push Button

Arm type: twin arm

Lid lifter: present

Wafer Detection System

EMO Hub

Cable receways

Facilities Distribution

PM Gate Valves: 853-442064-002

TM Vacuum Valve: 796-095595-001

VCE Vacuum Valve: 796-094747-002

Module Configuration(M/D,P/N,S/N)

Process module type: Exelan HTP

One Box: ENI Parts NO : OB1-R03, LRC Parts NO.: 660-099877R101

CM gauge-1 (process chamber): MILLIPORE, 2Torr

CM gauge-2 (manifold chamber): MKS, 10Torr

Turbo pump: ALCATEL, ATH1600M

Turbo pump controller: ALCATEL, ACT 1300M/1600M

Throttle valve: Pendulum Valve, 65046-PH52-ALQ1

CM gauge-1 (process chamber): MKS, 629A-14608, 0.1Torr

CM gauge-2 (manifold chamber): MKS, 625A11TDE, 10Torr

CM gauge-3 (foreline): MKS, 625A11TDE, 10Torr

Turbo bypass valve: -

Turbo exhaust valve: Present

Slot valve: Present, 853-442064-002

Endpoint detector: 4-CH(A-390nm, B-480nm, C-440nm, D-400nm)

Cooling He MFC: MKS Type649

Turbo Pressure Switch - 1: Present

Turbo Pressure Switch - 2: Present

Chamber Vacuum Switch: Present

Chamber ATM Switch: Present

Gas No Gas Name Range Model

1 AR 1L UNIT, UFC-8161

2 N2 200CC UNIT, UFC-8161

3 O2 50sccm UNIT, UFC-8161

4 CF4 100sccm UNIT, UFC-8161

5 CHF3 50CC UNIT, UFC-8161

6 O2 20CC UNIT, UFC-8161

7 CH2F2 50sccm UNIT, UFC-8161

8 C4F8 20CC UNIT, UFC-8161

Chamber Parts - Bad

ESC - Bad (Crack & Chipping)

2001 vintage.

LAM RESEARCH Exelan HPT is an etcher / asher systems that is designed to meet and exceed the performance requirements for high-precision etching and ash processing of most advanced semiconductor devices. It is used in applications such as MEMS devices, integrated circuits, and other novel devices. The equipment uses high precision, automated process control features that enable high throughput, outstanding processing uniformity, and excellent process repeatability. Exelan HPT consists of a multi-tank processing module, an elevated load lock, an interface chamber, a wafer handling station, and a vacuum pump. The beauty of this system is that it is offered with an optional integrated automated in-situ cleaning unit to ensure optimal results. The multi-tank module provides up to three processing tanks and a reclaim tank for efficient processing of different types of materials. The dual tank module is available in either single substrate or dual substrate configurations and offers a versatile range of processing modes such as wet/dry etching, wet/dry oxide etching, wet/dry protective coatings, and electroless plating/sputtering. The elevated load lock allows for an improved wafer handling station to provide for improved handling and unloading of the wafers. The interface chamber prevents cross contamination between the substrate and the gases and liquids used in any of the processing steps. The wafer handling station provides for automated wafer transfer between processing tanks, probes, and other peripheral instruments. The versatile LAM RESEARCH Exelan HPT machine also offers a multi-language menu tool for maximum workflow flexibility. This feature allows the operator to program and control the asset according to the specific processing needs of the application. The model also features a number of control features including process monitoring, user-defined recipe control functions, and a range of support functions. The excellent performance of Exelan HPT makes it the equipment of choice for high precision etching and ash processing. The system's flexibility allows for efficient and repeatable etching of a wide range of materials and substrates, enabling high throughput and excellent continuity of processing. This unit is an excellent choice for high-end etching applications in semiconductor device manufacturing.

There are no reviews yet