Used LAM RESEARCH Rainbow 4420 #293595155 for sale

URL successfully copied!

Tap to zoom

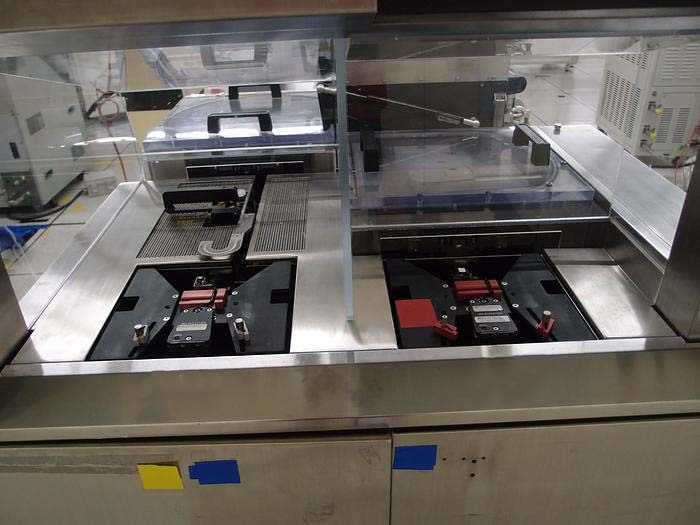

LAM RESEARCH Rainbow 4420 is an advanced etcher/asher equipment developed for wafer processing applications. This system provides superior process capability, enabling superior surface finish and accuracy of etch profile. With the help of its on-board computer, Rainbow 4420 is able to process up to 600 wafers per hour with precision and repeatable uniformity. LAM RESEARCH Rainbow 4420 is designed with an all-steel frame, providing superior protection against radial vibration, plus a range of motion that allows all plant parameters to be precisely calibrated and adjusted. This ensures precision and repeatability, even when processing high-density wafers. Its dual-beam laser cell design allows concurrent etching of two wafers at once, increasing throughput efficiency and reducing cost. Rainbow 4420 also incorporates advanced motion control with 4-axis motion capability and high-speed bearings, providing the user with superior accuracy and repeatability of the etch profile. It has an efficient exhaust evacuation unit to ensure safe operation and eliminate the possibility of wafer contamination. An integrated maintenance monitoring machine is provided to automatically detect and alert the user of any problems so that proper corrective action can be taken in a timely manner. LAM RESEARCH Rainbow 4420 is also equipped with an industry-leading end-point control tool for consistent and repeatable endpoint accuracy. This asset allows for the rapid determination of suitable etch limits for not only seeded or masked wafers, but for a variety of metals, such as aluminum, copper, and titanium. An RAIS (resonance acoustic imaging model) is also integrated into the equipment to field inspect each wafer die after processing and verify process uniformity. Rainbow 4420's advanced laser marking system enables wafer tracking and allows significant reduction in cost and lab time since there is no need for additional external identification steps. Finally, the unit is connected via Ethernet to the remote machine control location, providing the user with a range of monitor and control abilities. These features allow for extended process monitoring, specific parameter adjustment, as well as remote diagnostics and data collection for comprehensive troubleshooting.

There are no reviews yet