Used LAM RESEARCH Rainbow 4420 #9226088 for sale

URL successfully copied!

Tap to zoom

ID: 9226088

Wafer Size: 6"

Poly etcher, 6"

Wafer type: Major flat

Clamp

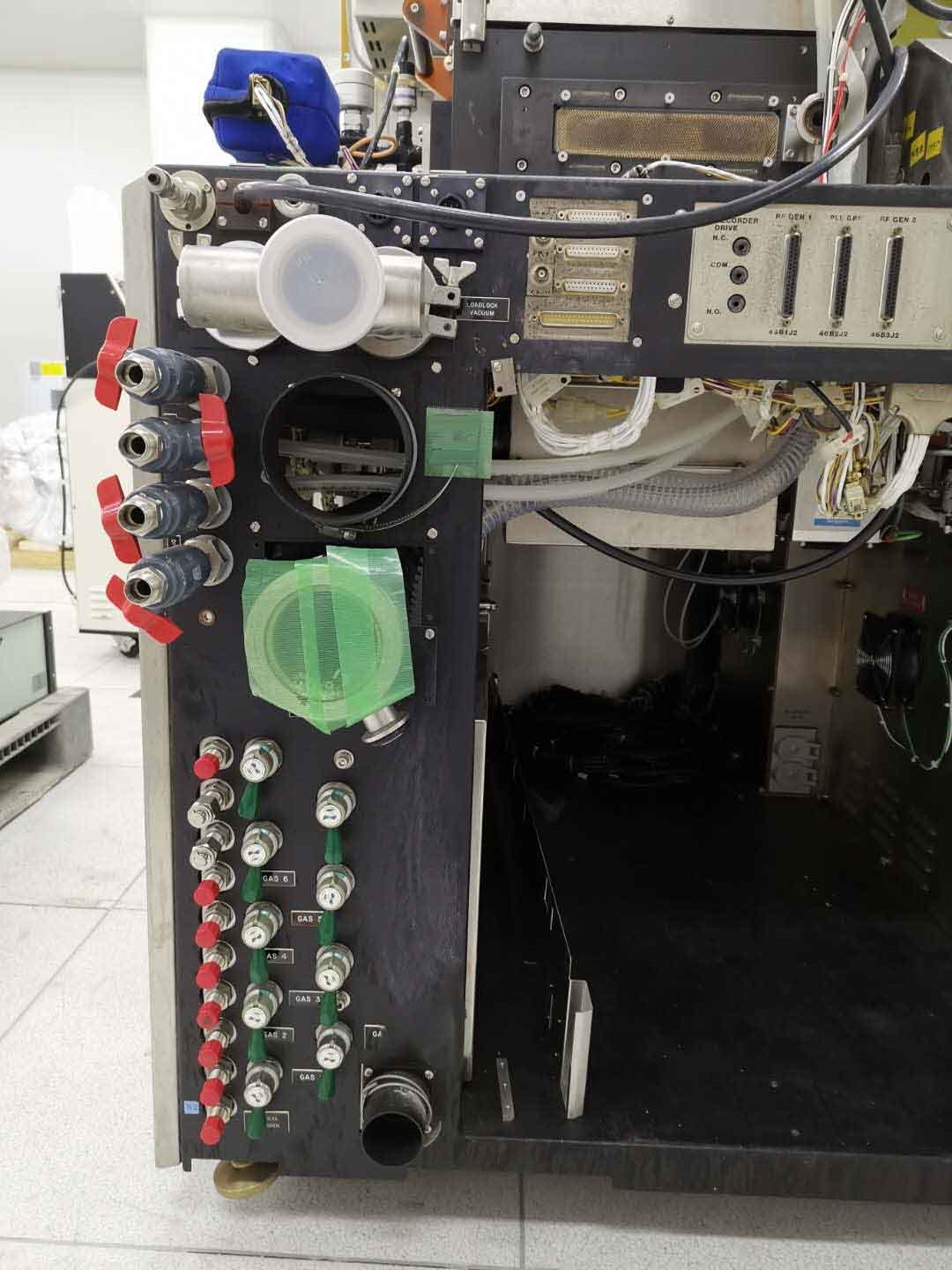

Hardware:

Cassette indexer: Hine indexer 38A

Process kits

Baratron: MILLIPORE 0-10 Torr

RF Rack: ENI OEM-650A

RF Matcher

Helium cool system

(6) MFC Gases:

HE / 500 SCCM / FC-770AC

CL2 / 200 SCCM / FC-780C

HBR / 200 SCCM / FC-780C

CF4 / 200 SCCM / FC-770AC

SF6 / 200 SCCM / FC-770AC

CHF3 / 50 SCCM / FC-770AC

Signal tower.

LAM RESEARCH Rainbow 4420 is an a state-of-the-art etcher/asher equipment used in semiconductor fabrication. It is optimized for high-precision etching and ashing processes, ranging from shallow to deep etch. The system is well suited for Plasma Etching, Reactive Ion Etching/DEB, Metal/Seed Etching, and Ashing of Photoresist processes. It offers a repeatable process function, with uniformity and tight end points, that's superior to manual processes. The unit utilizes a high-precision vertical source, allowing the user to create an etch/ash profile with virtually no overetching or undercutting of critical feature sizes. The multiple-waveform generator of Rainbow 4420 allows for generation of multiple wave forms for each level/lot. This allows process control and repeatability over multiple strip runs. LAM RESEARCH Rainbow 4420 can output DC, RF, and pulse waveforms. It is also equipped with a quartz single width module, providing sametime delivered of quartz to all planar substrates, thereby ensuring uniformity across the wafer. It is also equipped with a 1kW High Energy Peak Pulse, and other features that enable precise control of etch depth, profile, and uniformity across all levels. The machine includes an RF power monitoring tool that controls and optimizes the process and equipment power while maintaining the most precise etching parameters. The asset is also equipped with an ElitePA RF Eyebrow detector, allowing for automated process recipe validation. The model is equipped with a 'Wait for Etch' feature that eliminates no-etch problem caused by DC energy (bias, or plasma) and overetching. A separate 'Job File Manager' and a 'Log File Manager' keep the etching parameters for each lot, ensuring that all important information is captured with every etching job. The equipment allows for the use of standard, reusable hardware and process-qualified consumables to maximize accuracy and reduce cost. Rainbow 4420 is compatible with ISO 9001 certified IC manufacturing processes, and follows the requirements of semiconductor industry standards. When used in combination with the advanced process control and user management systems, LAM RESEARCH Rainbow 4420 offers superior product yield, excellent process repeatability, and viability. The system allows users to easily optimize process parameters according to their specific requirements, offering the flexibility and productivity needed for high-volume production.

There are no reviews yet