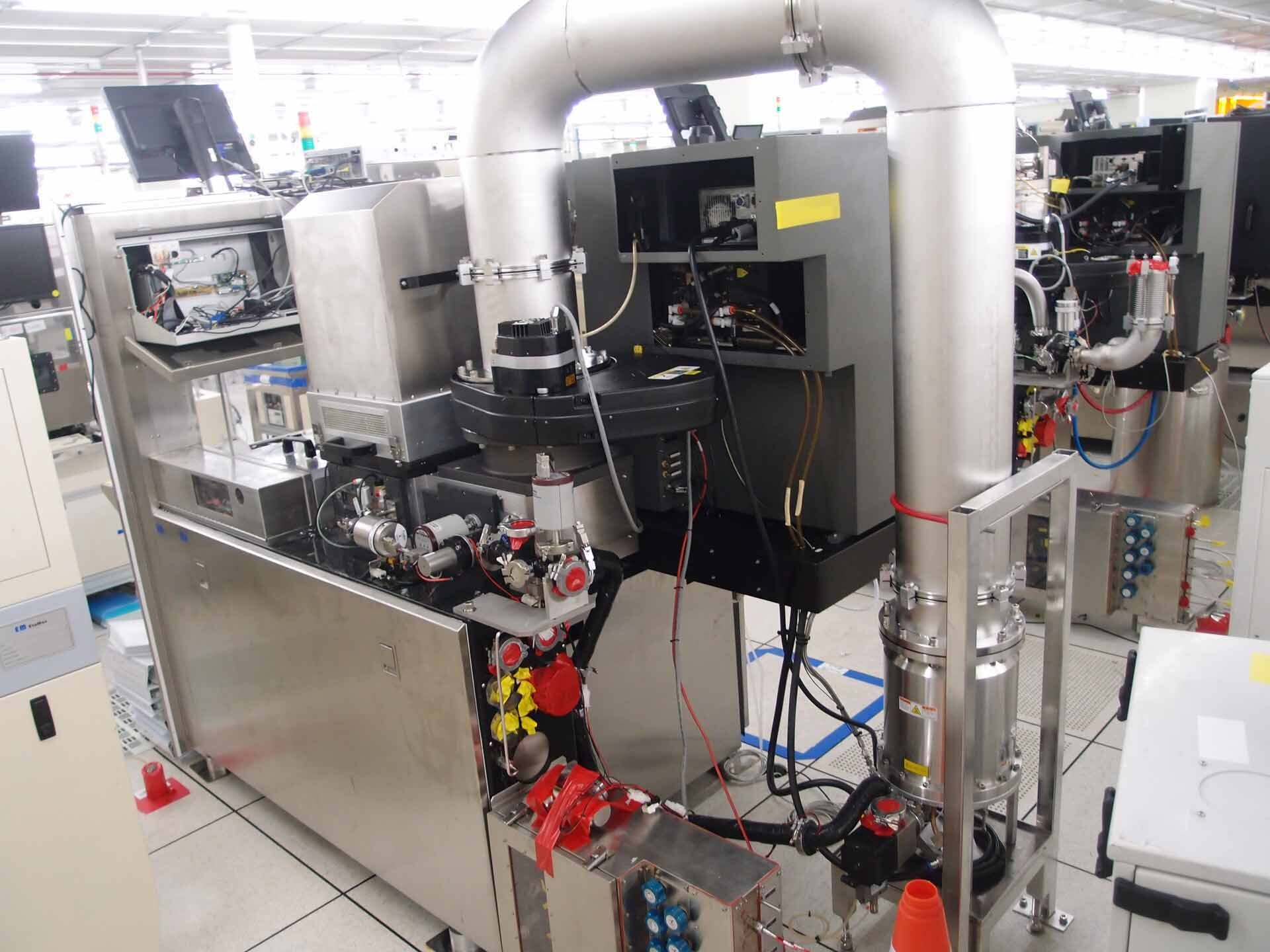

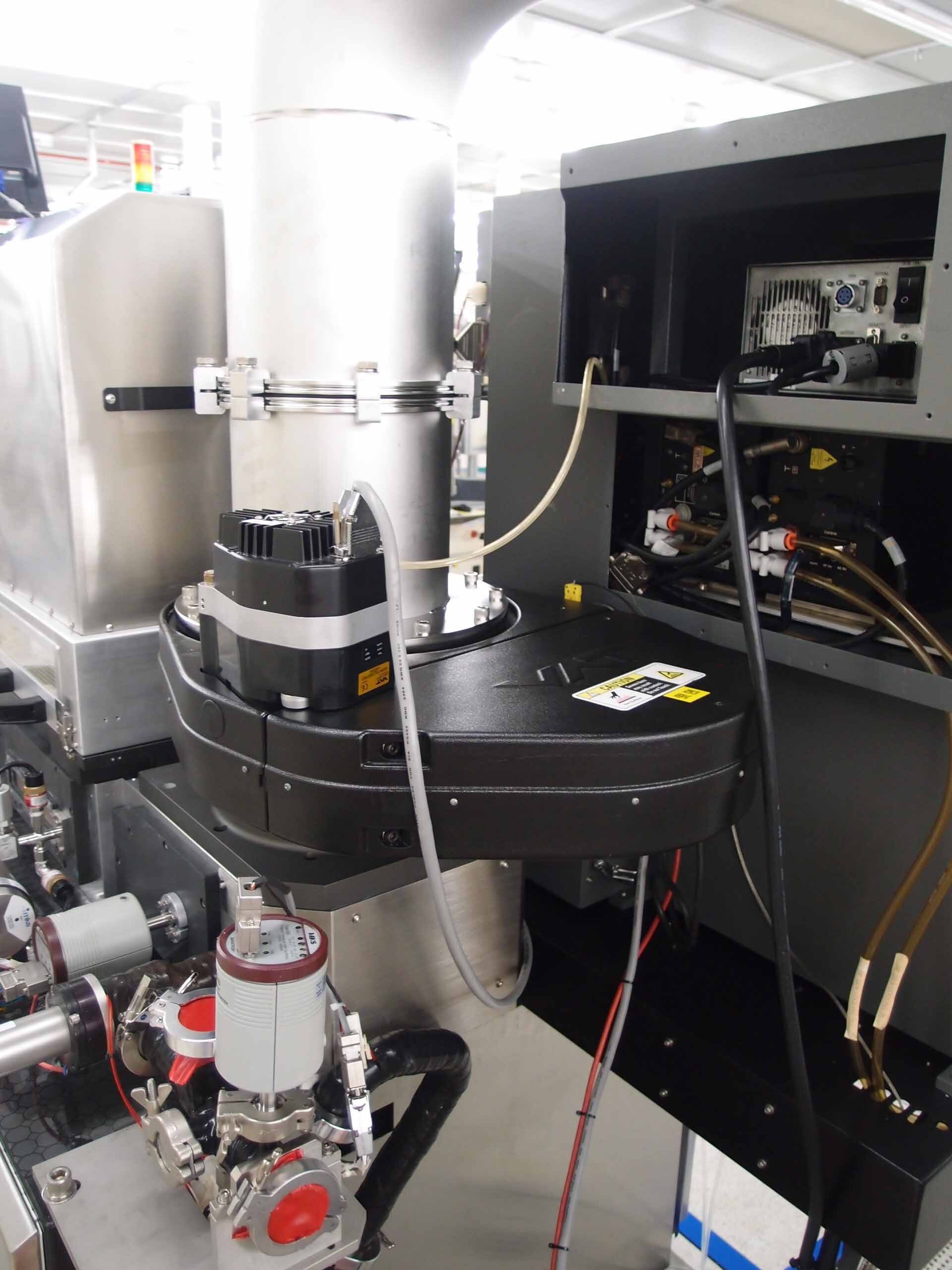

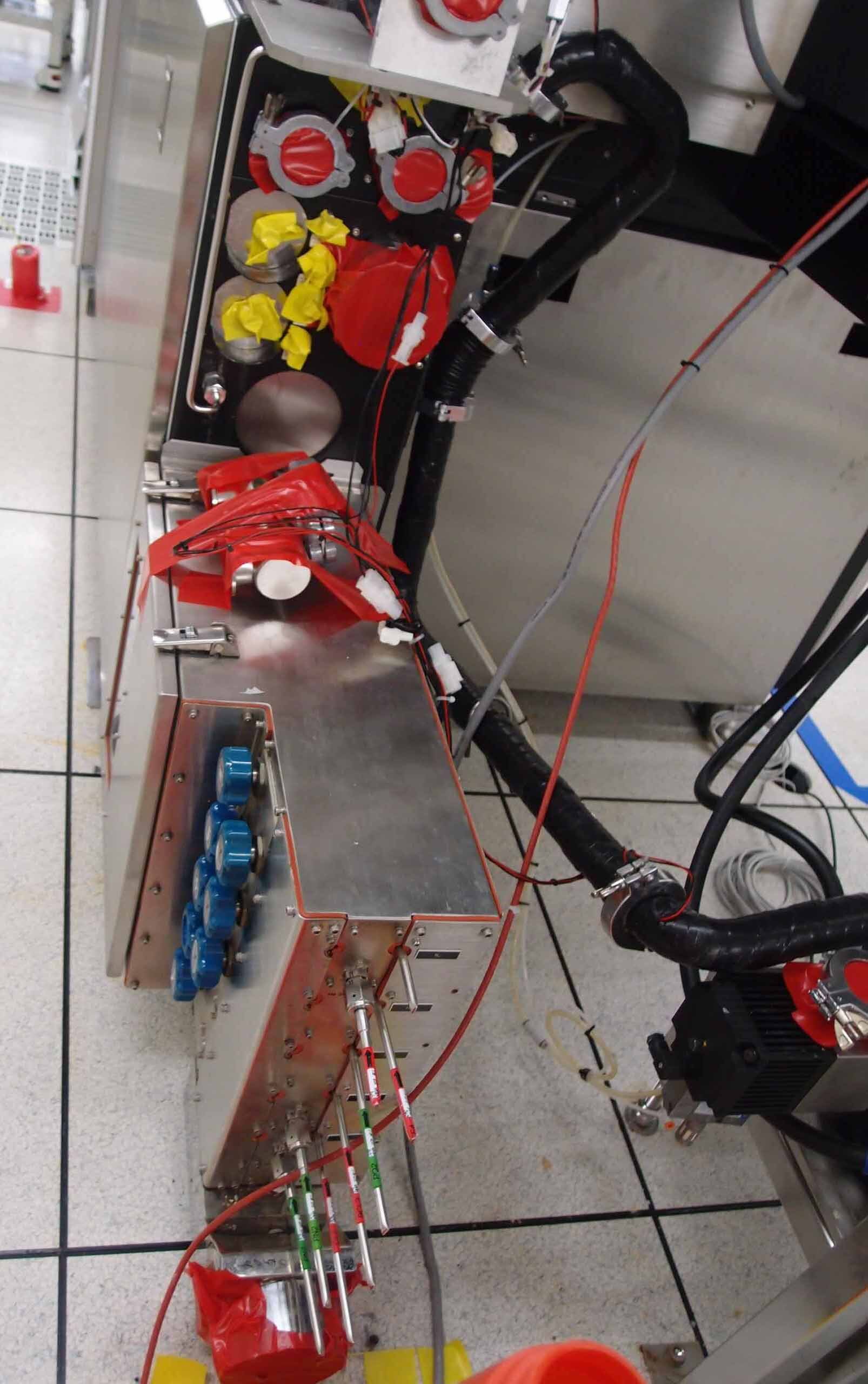

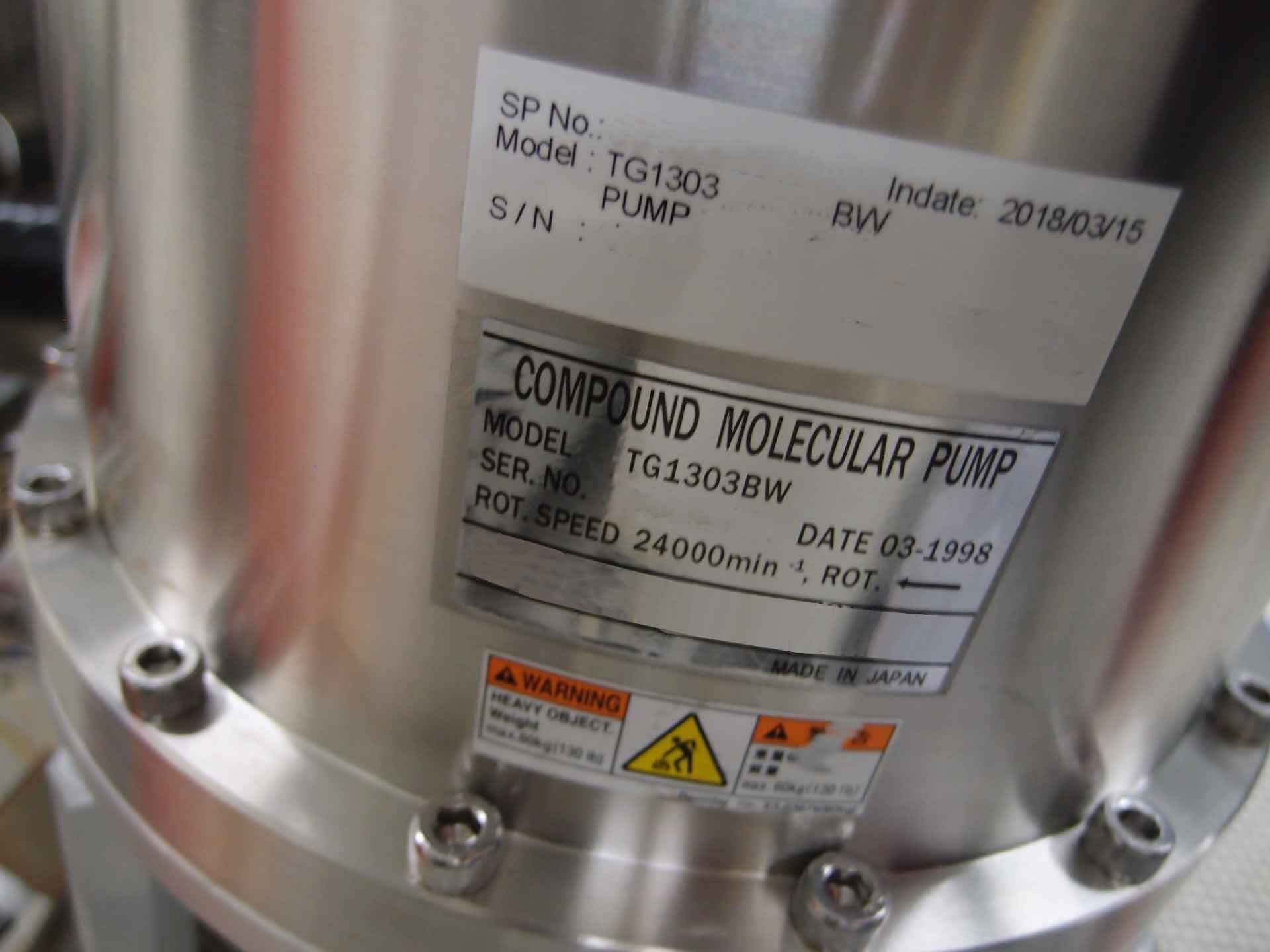

Used LAM RESEARCH TCP 9400 SE II #9402509 for sale

URL successfully copied!

Tap to zoom

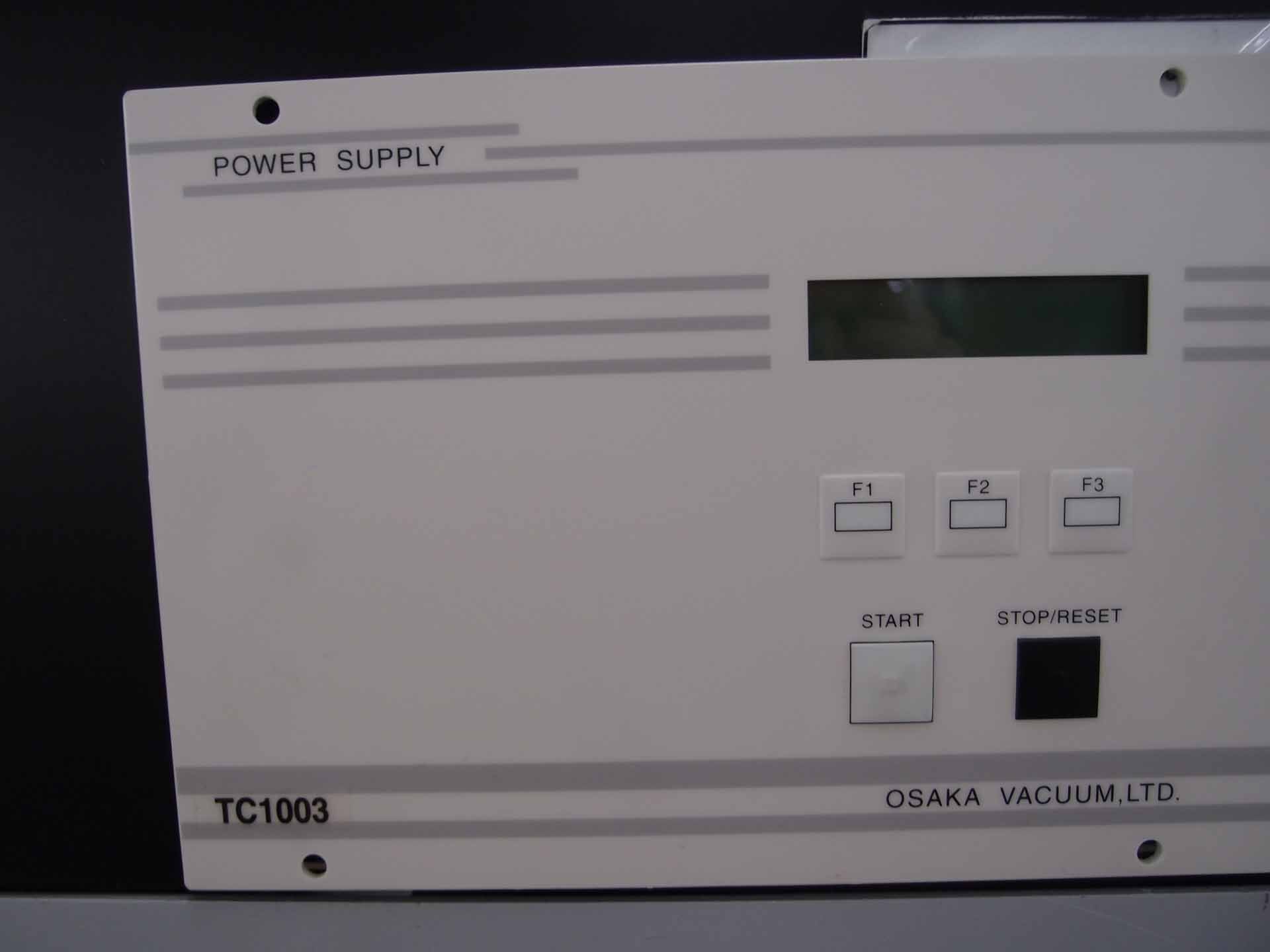

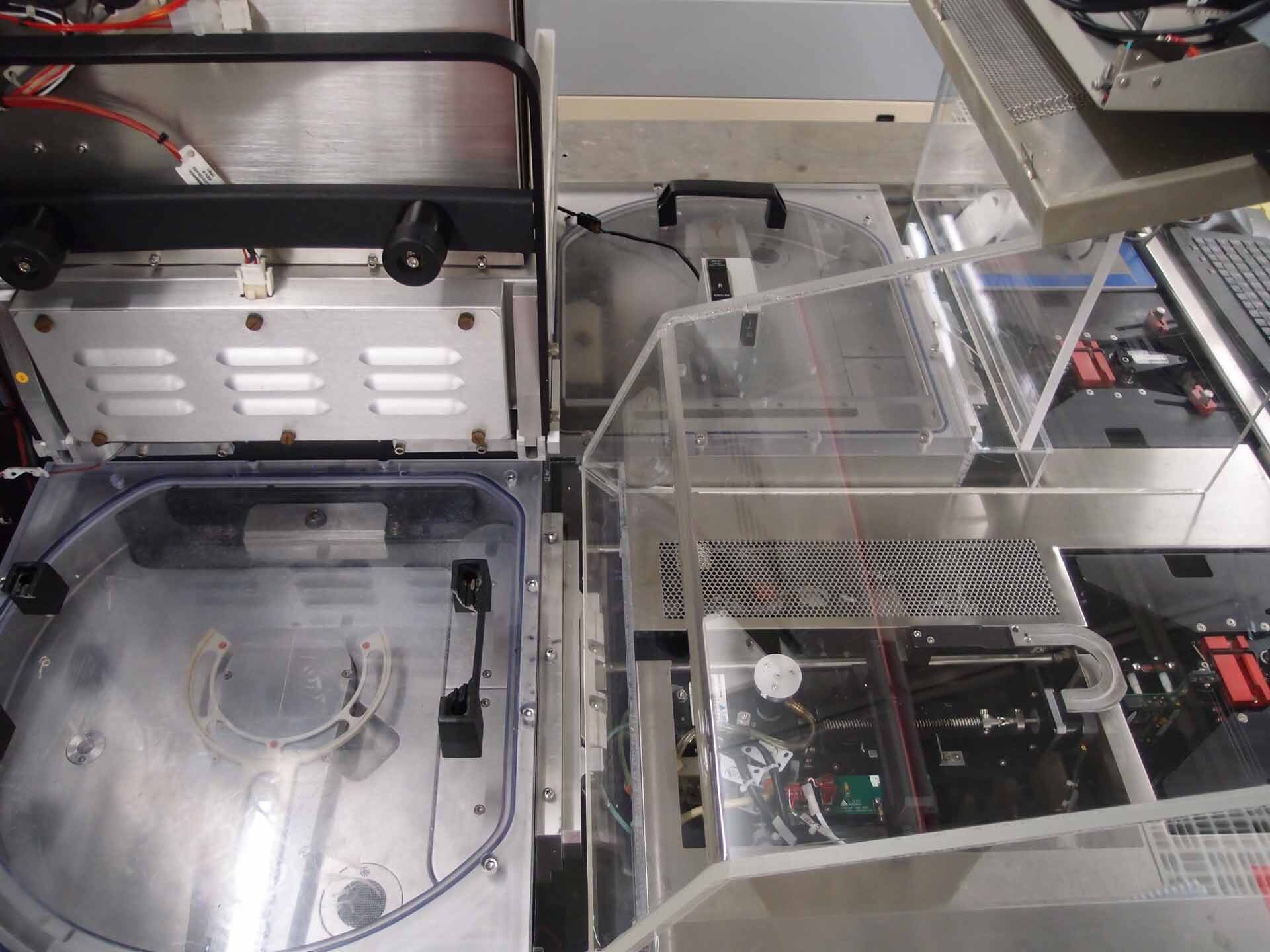

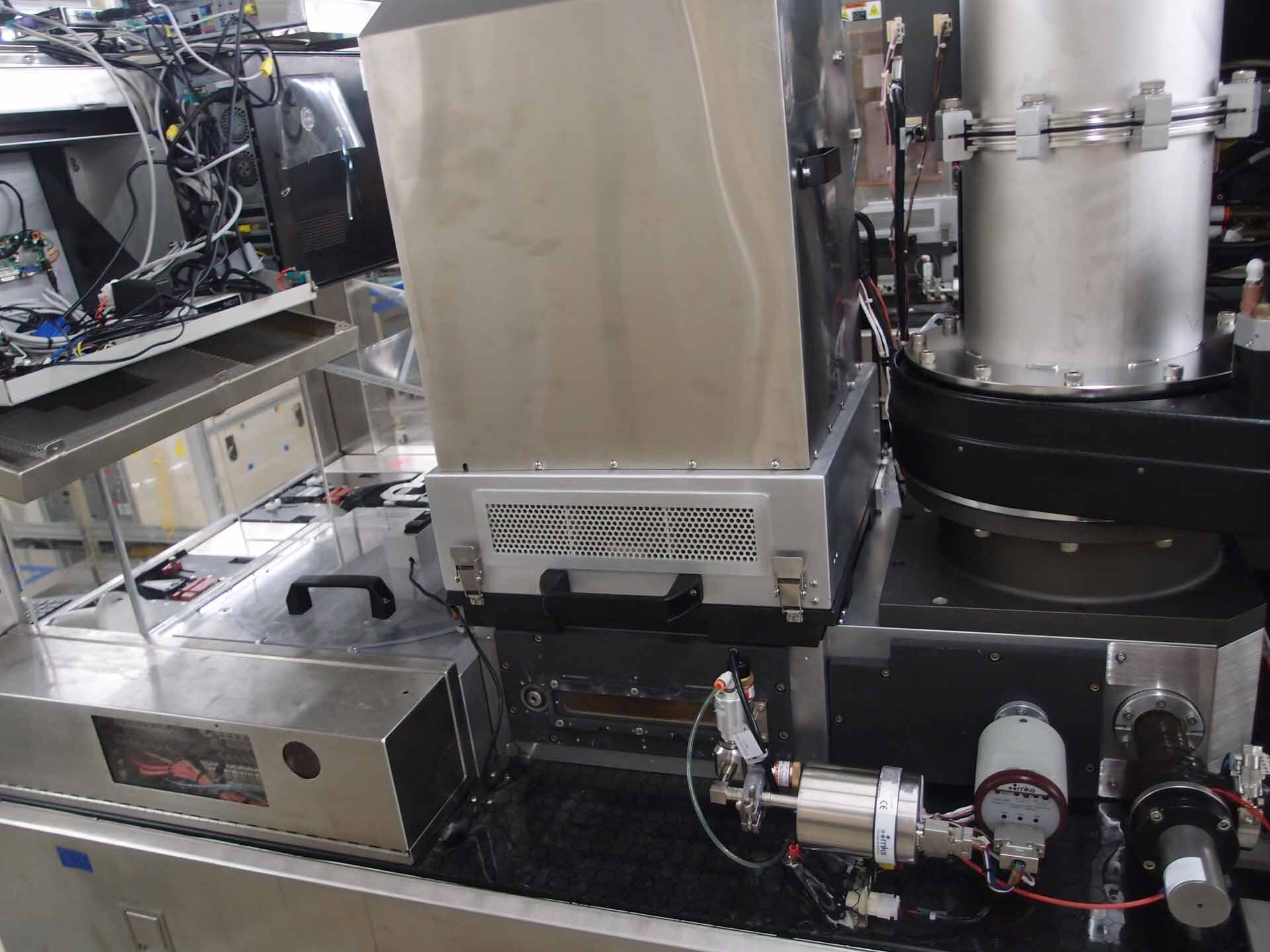

LAM RESEARCH TCP 9400 SE II etching equipment (also known as an asher) is a high-performance, high-precision etching system used in the fabrication of semiconductor devices. Featuring patented technologies, TCP 9400 SE II utilizes advanced materials and processes to produce products with superior uniformity, yield, speed, and reliability. The unit features a cluster tool design to maximize throughput, reduce cost of ownership, and enable integration of multiple process modules into a single platform. These modules consist of a pre-etch stripping unit, a thermal processing chamber for thermal oxidation, a Photo Organic Vapor Deposition (POVD) chamber for high-quality organic film deposition, a plasma etch station with catalyst deposition, and a high-end robocamera machine to inspect substrates prior to etching. The tool's integrated architecture and user-friendly operation enable users to quickly ramp to production. The tool is specifically designed to produce high-quality etching results with minimal defects and optimum uniformity. Its patented SmartEtchTM software solutions enable accurate etching of all types of materials, including thick and thin film materials, with maximum yield and reproducibility. LAM RESEARCH TCP 9400 SE II's thermal processing chamber is particularly suitable for etching small chips, delicate optical coatings, and metals or transparent dielectrics. By using the Photo Organic Vapor Deposition (POVD) chamber, high-quality organic film deposition is achieved, allowing for maximum uniformity even over large areas. The tool's innovative plasma etch station enables optimized etching and catalyst deposition for both fully processed wafers and for process flow experiments. Furthermore, custom chambers can be integrated. TCP 9400 SE II also features a high-end robocamera asset that provides superior inspectability for identifying and correcting substrate defects before etching. Overall, LAM RESEARCH TCP 9400 SE II etching model is ideal for users looking for an advanced etching equipment that provides maximum yield, uniformity, and speed. With its advanced materials, process technology and integrated architecture, this tool is able to deliver superior results while minimizing downtime and increasing profitability.

There are no reviews yet