Used LAM RESEARCH TCP 9400 #9131590 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9131590

Wafer Size: 4"-8"

Poly/Nitride etcher, 8"

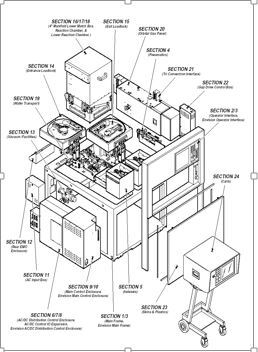

System configuration

Wafer transfer

Cassette to cassette

Chamber

1 Process Ch, 2 loadlock ch

Fixed gap electrode( 11.6cm)

1.25KW and 13.56㎒ RF power supply (Process Chamber Upper/Lower)

(RF generator Model : RFG 1250)

Automatic match system

3-Turn TCP coil

Electrode temperature unit interface

Photodiode optical endpoint detector

Electrostatic chuck (Process Chamber)

Bottom redial gas injection

Back HE cooling

1 Turbo pump(Seiko Seiki 2203)

Viton /Fsilicon O-Ring

Orbitally welded gas box

(3) Color Tower Lamps

System controller

Envision –E1.5.1 / LCD moniter

Pressure control

Automatic pressure control(VAT65)

Temperature control system

Single chiller(M&W) temp control range:-20℃~+80℃).

LAM RESEARCH TCP 9400 is an etcher and asher equipment designed for high-throughput process control and etching with maximum process flexibility. It is equipped with a variable power supply, digital x-y-z motion control, and the Universal Process Chamber (UPC) Module. This system utilizes a SmartScan Technology which allows for precise etching without drifting, allowing for quick and accurate etch depths and finishes. TCP 9400 is suitable for etching aluminum, aluminum alloys, electrical wiring, and stainless steel, as well as other conductive materials. It also features a Constant Scanning Technique (CST) for enhanced process repeatability and accuracy. This device has the ability to precisely etch a variety of materials with superior process control. LAM RESEARCH TCP 9400 has a full range of settings available for controlling the etching parameters. These settings allow for fine-tuning the etching process for maximum yield efficiency. Additionally, the settings can be easily changed as needed to match the etch job requirements. The unit also comes equipped with a powerful heating machine, which allows for both manual and automatic control. This allows the user to accurately heat the process chamber and substrate in order to obtain optimal etch results. Additionally, the etching tool utilizes fan cooling technology for improved etch performance. This etch asset has a enclosed process chamber for improved etch results and safety. The 9400c is also equipped with enhanced process control monitoring capabilities as well as a software package that allows for improved control over the etching process. The software also allows for easy graphical user-interface data input and process control. Overall, LAM RESEARCH TCP 9400c is a highly versatile and flexible etcher and asher model. It offers a full range of settings for process control, easy graphical user-interface data input, and the Constant Scanning Technique (CST) for maximum repeatability and accuracy. This equipment is ideal for a variety of etching applications and is suitable for etching aluminum, aluminum alloys, electrical wiring, and stainless steel.

There are no reviews yet