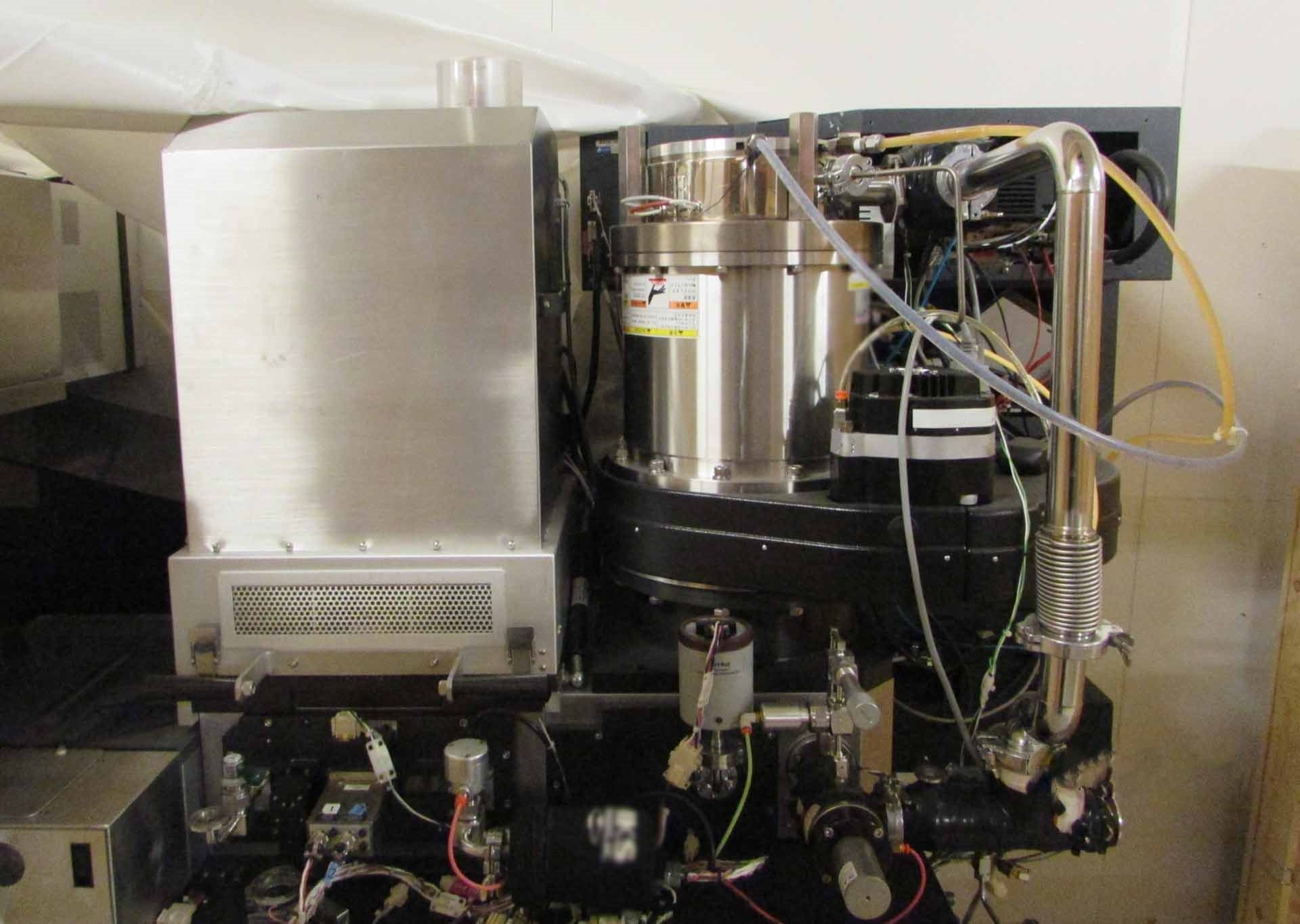

Used LAM RESEARCH TCP 9400 #9233832 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

LAM RESEARCH TCP 9400 is an advanced etcher/asher designed to provide robust, high-speed, high-precision wafer etch processes. The machine is capable of performing both wet and dry etch steps, and offers excellent control over all etching parameters. The etch chamber contains multiple chambers of reactants or carriers, along with a heating module capable of sustaining temperatures up to 650°C for dry etching and up to 600°C for wet etching. In addition, it also has a RF generator for controlling the RF power in both wet and dry etching applications. The machine also features an advanced semiconductor processing robot capable of accurately and rapidly handling wafers in high-precision etch or ash process. The robot is capable of handling 4" up to 8" wafers. The machine also contains an instrumentation package that includes a multi-prop sensor chamber that provides additional control over multiple etch parameters such as flow, pressure, temperature, and RF. TCP 9400 also features a pressure-based, high-velocity gas delivery system. This system uses a combination of high-pressure and low-pressure gases to deliver uniform etching or ash across the entire wafer. A helium-based gas delivery system is also available that allows for additional control over etch aspect ratios and etch selectivity. The machine also contains an advanced control electronics package that is capable of supporting both manual and automation of etching/ashes processes. The extensive application library provides users with a wide variety of options for both manually and automatically controlling the process. The display touchscreen also provides an intuitive user interface which makes programming and monitoring the process easy and straightforward. Overall, LAM RESEARCH TCP 9400 is an advanced, flexible, high-precision etcher/asher capable of meeting the demanding requirements of modern semiconductor processing. Its robust design and high-performance features make it a valuable asset for any semiconductor fabrication facility.

There are no reviews yet