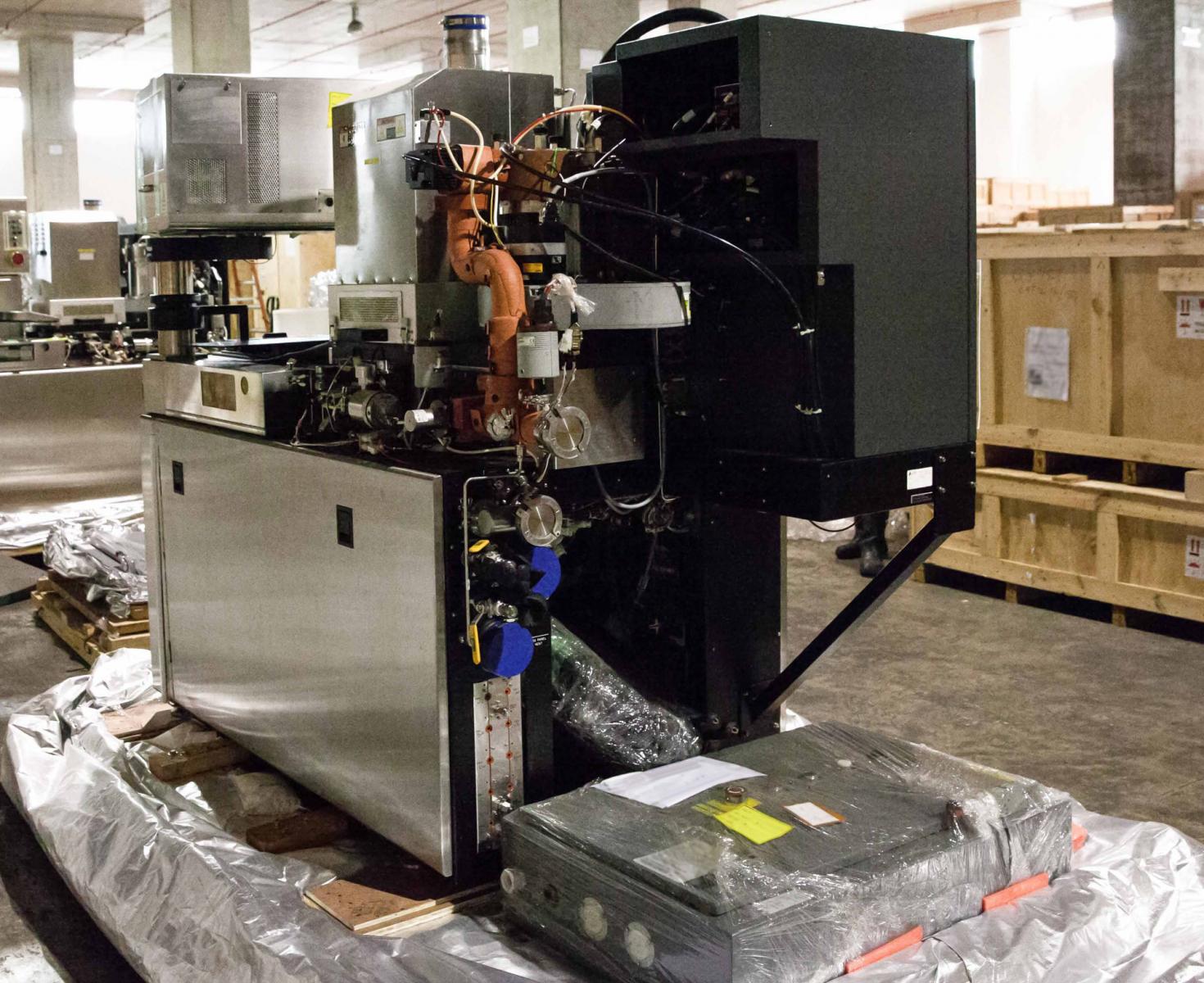

Used LAM RESEARCH TCP 9408 SE #9178705 for sale

URL successfully copied!

Tap to zoom

ID: 9178705

Wafer Size: 8"

Vintage: 2004

Poly etcher, 8"

Software version: 1.6.012A

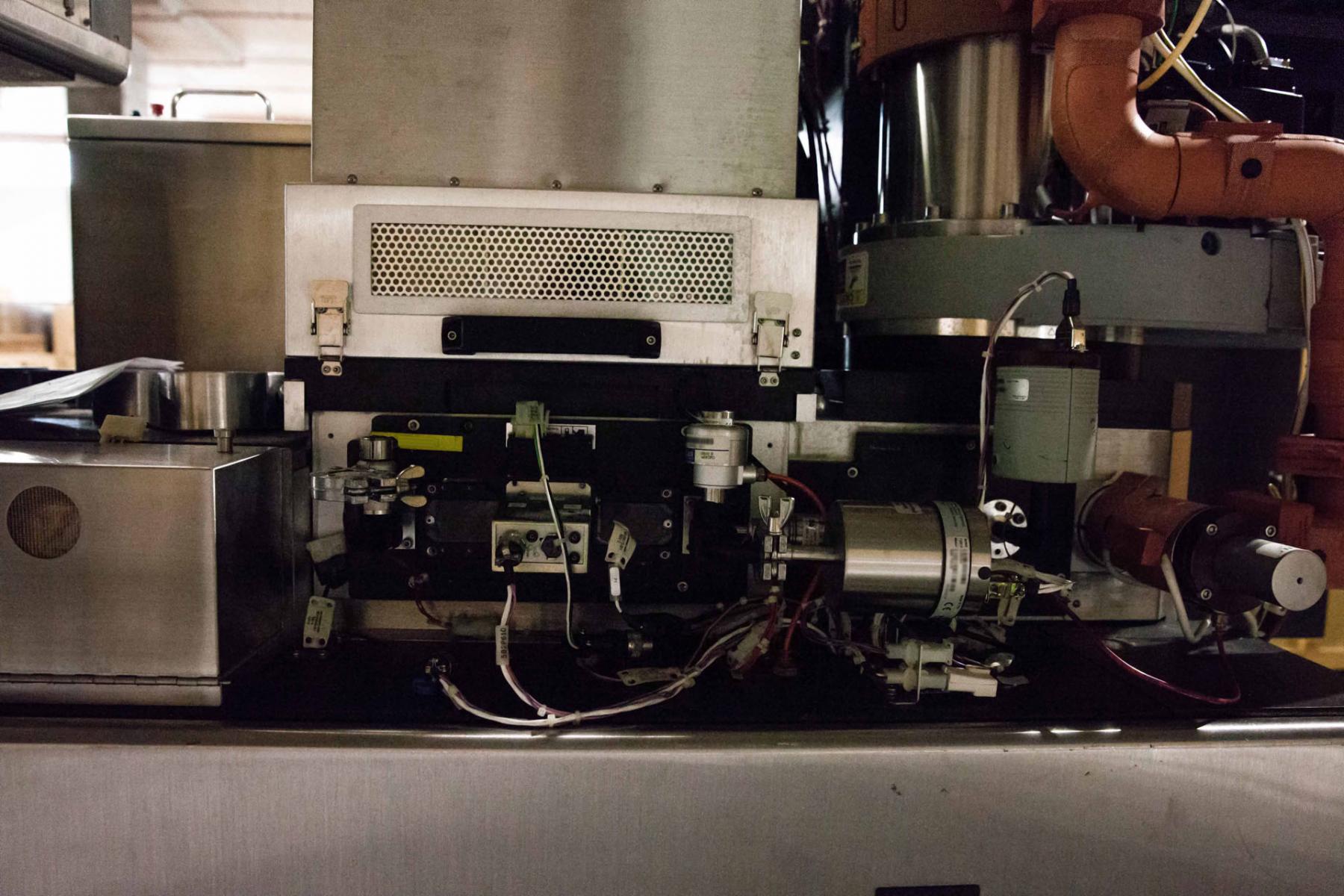

SMIF System: (2) ASSYST

Process chemicals: SCCM

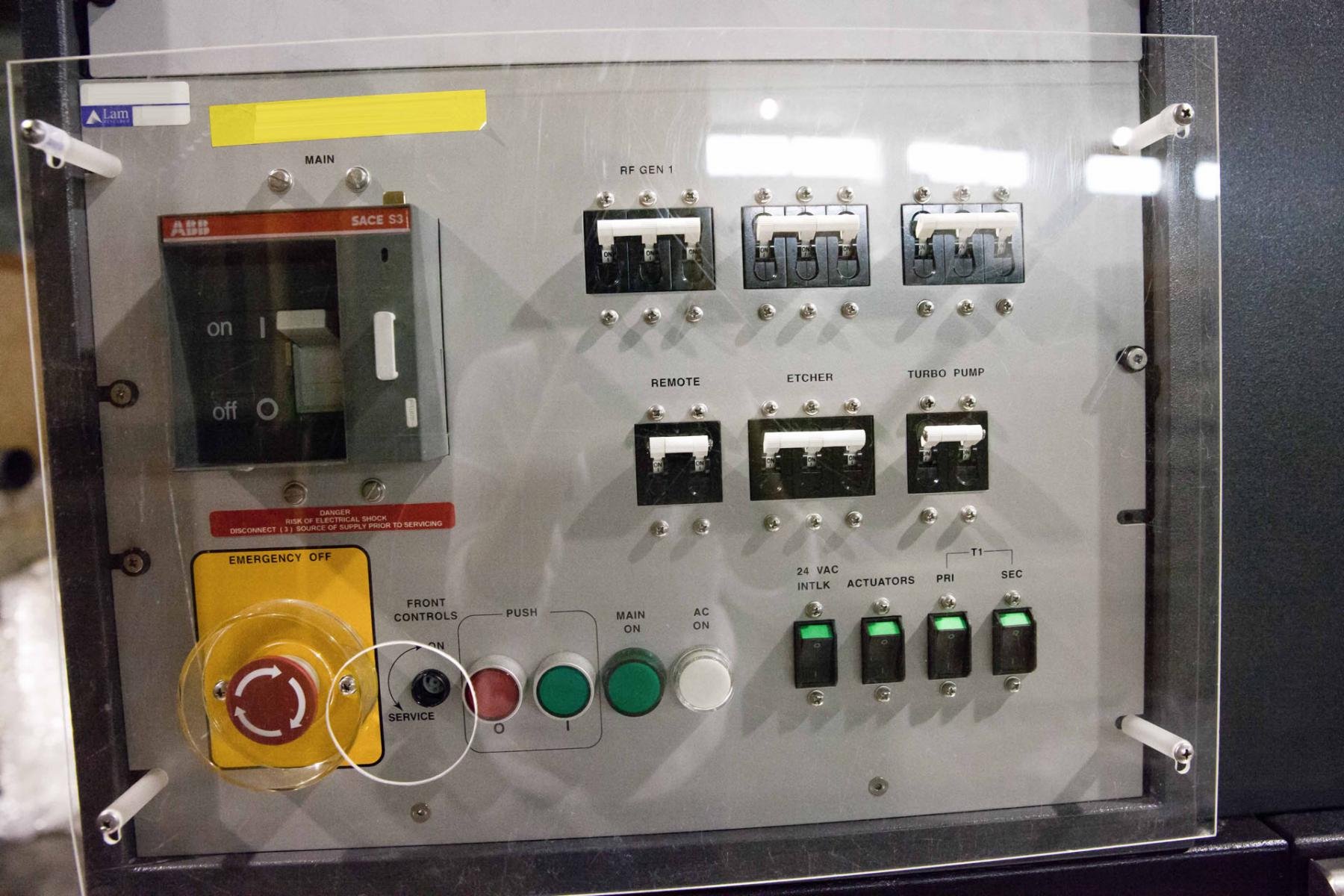

(1) AC Power box

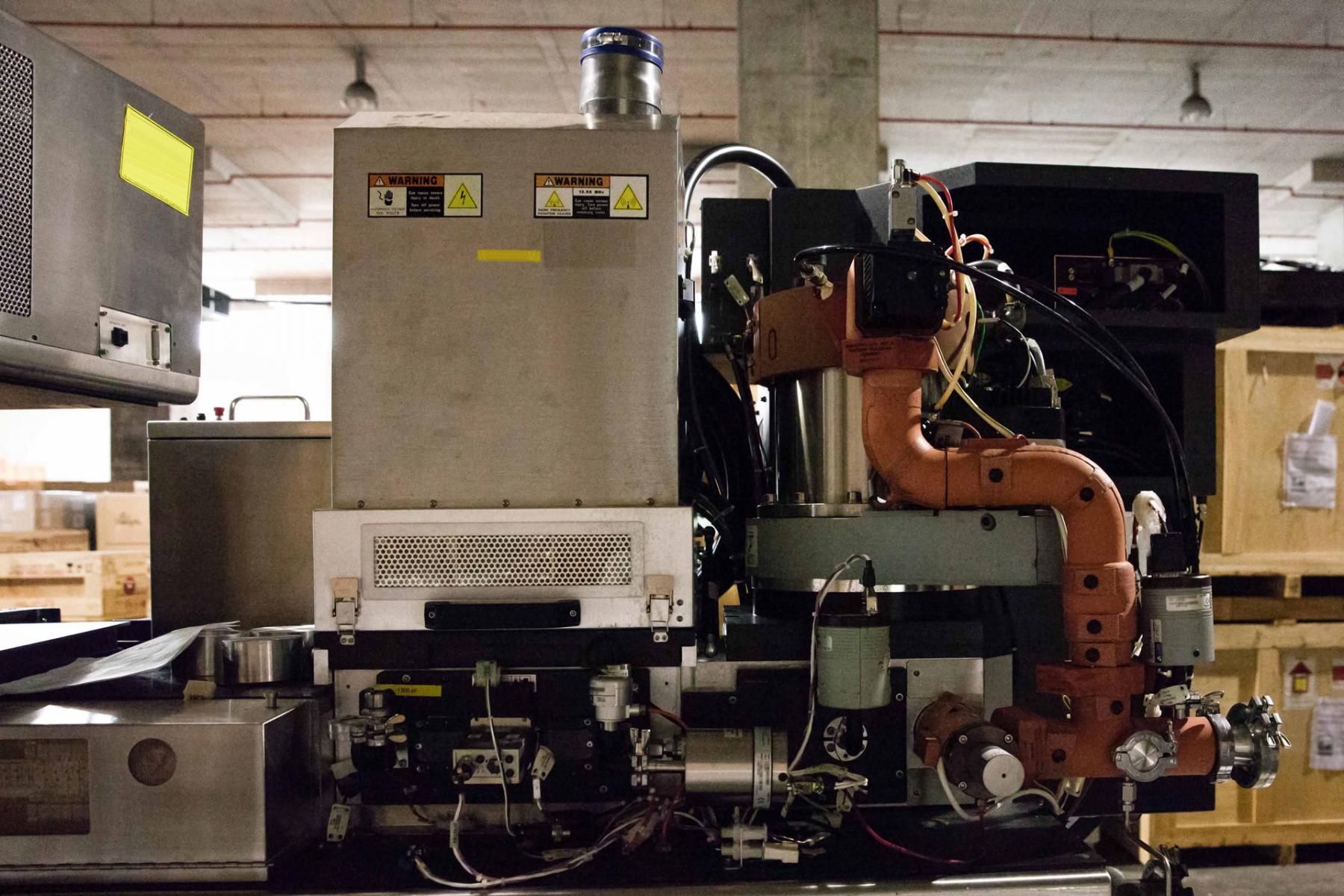

(2) RF Racks

TCP RF Match part no: 853-032294-002

Bias RF match: 853-330951-001

ESC Power supply: 810-017086-018

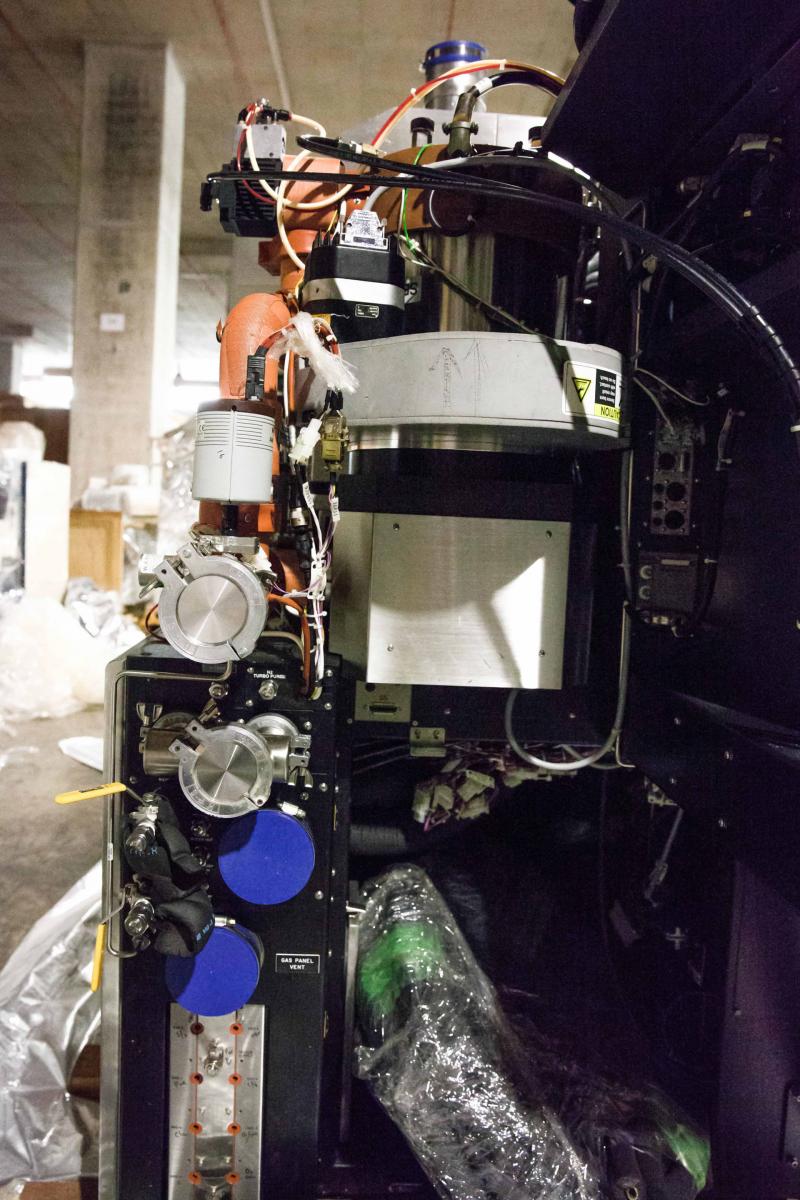

Chamber manometer MKS make (All): E29B-23813

Turbo manometer MKS make (All): 625A-14375

Ref manometer MKS make (All): 625A-14059

Turbo pump: STPH1301L1B

TCP RF Gen.AE make(All): 660-024637-006 RFDS

Bias RF Gen.AE make( All): 3155027-003 B

Wafer drag back: Enable

Wafer offset alignment alignment: 310

Gas ring capacitance: 1300+/- 15 pf

Software version: 1.6.1

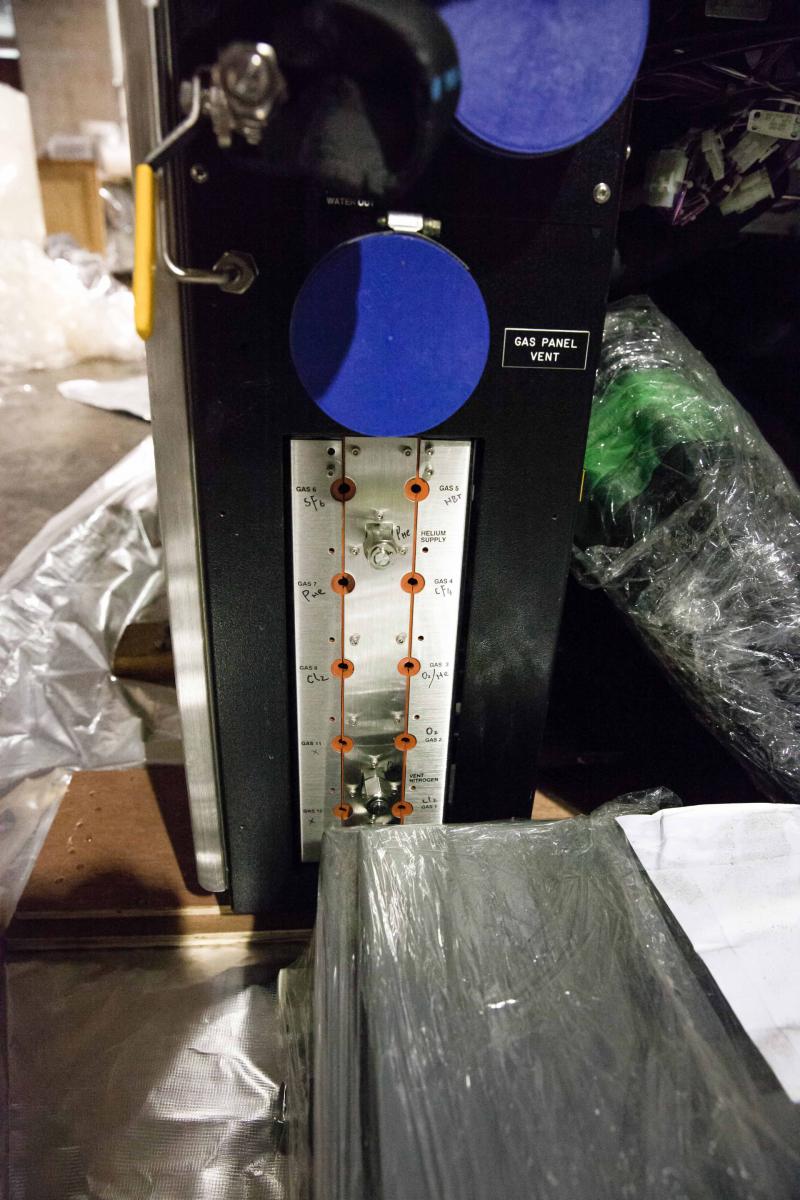

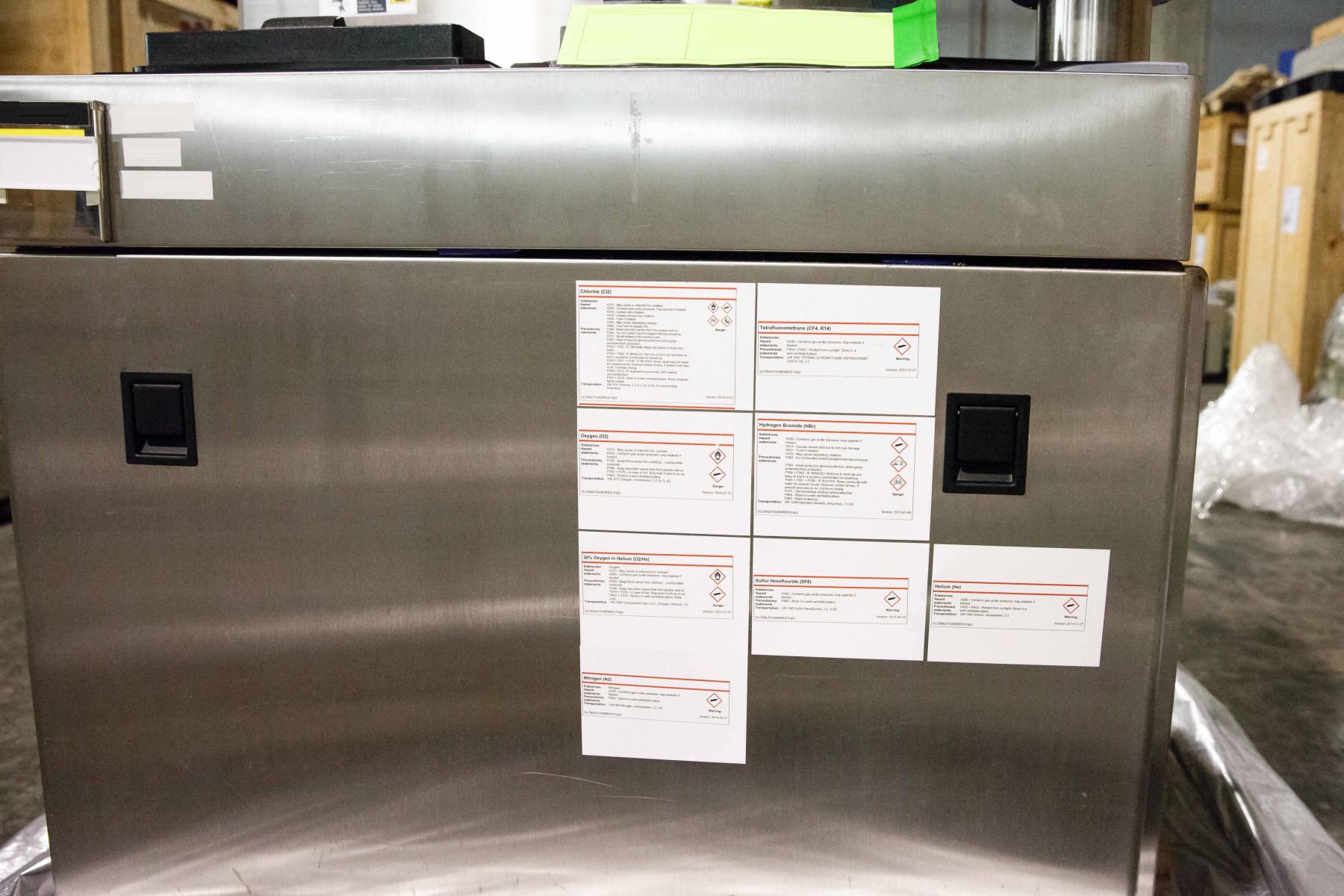

MFC Config.CL2-200 sccm: 200

MFC Config.O2-100 sccm: 100

MFC Config.HE/O2-20 sccm: 20

MFC Config.CF4-100 sccm: 100

MFC Config.HBR-500sccm: 500

MFC Config.SF6-100 sccm: 100

MFC Config.HE-500 sccm: 500

MFC Config.CL2-30 sccm: 30

TCP Coil position: 8 O'CLK

Turbo pump capacity: 1300L

Vat valve / Pendulum valve: Pendulum

2004 vintage.

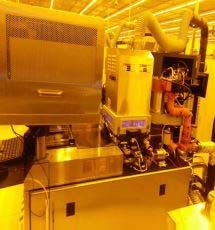

LAM RESEARCH TCP 9408 SE is a powerful standalone etcher and asher equipment. It is a high-performance silicon wafer etcher and asher system specifically designed to meet the most demanding requirements of the semiconductor industry while providing users with the capability to process a wide range of materials. The unit is formed by a precision-engineered, highly automated platform that is equipped with a high-speed, high-quality rotary etch head, providing superb plasma uniformity and reducing etch time. The machine features include a temperature controlled turbo-pump, enabling etching and ashing with maximum repeatability and uniformity, as well as high-end process control, providing users with the capability to precisely control etch rate, overetch, film thickness, and endpoint. TCP 9408 SE is also equipped with a pair of advanced on-board QCM/PCM/FIB detectors and an off-board mass spectrometer, which deliver precise endpoint detection, ensuring precise etch and ashing. Additionally, the tool is fully programmable, allowing users to create various recipes and store them, as well as to quickly recall them and perform etching and ashing with minimal down-time. The user interface is intuitive and user-friendly, enabling operators to conveniently control and monitor the entire process. Furthermore, a range of diagnostics and process monitoring tools available within the user interface, allowing selection and review of the best overall process run. LAM RESEARCH TCP 9408 SE delivers precise and robust etch and ashing, allowing users to achieve the highest levels of process uniformity without sacrificing process throughput. This asset is perfectly suited for etching and ashing processes such as silicon etching, stress relief and dopant sputtering, and offers superior performance for all types of materials, including III-V and high-k dielectrics. Overall, TCP 9408 SE is an excellent etcher and asher model, which further enhances the process repeatability, productivity, and quality of semiconductor manufacturing.

There are no reviews yet