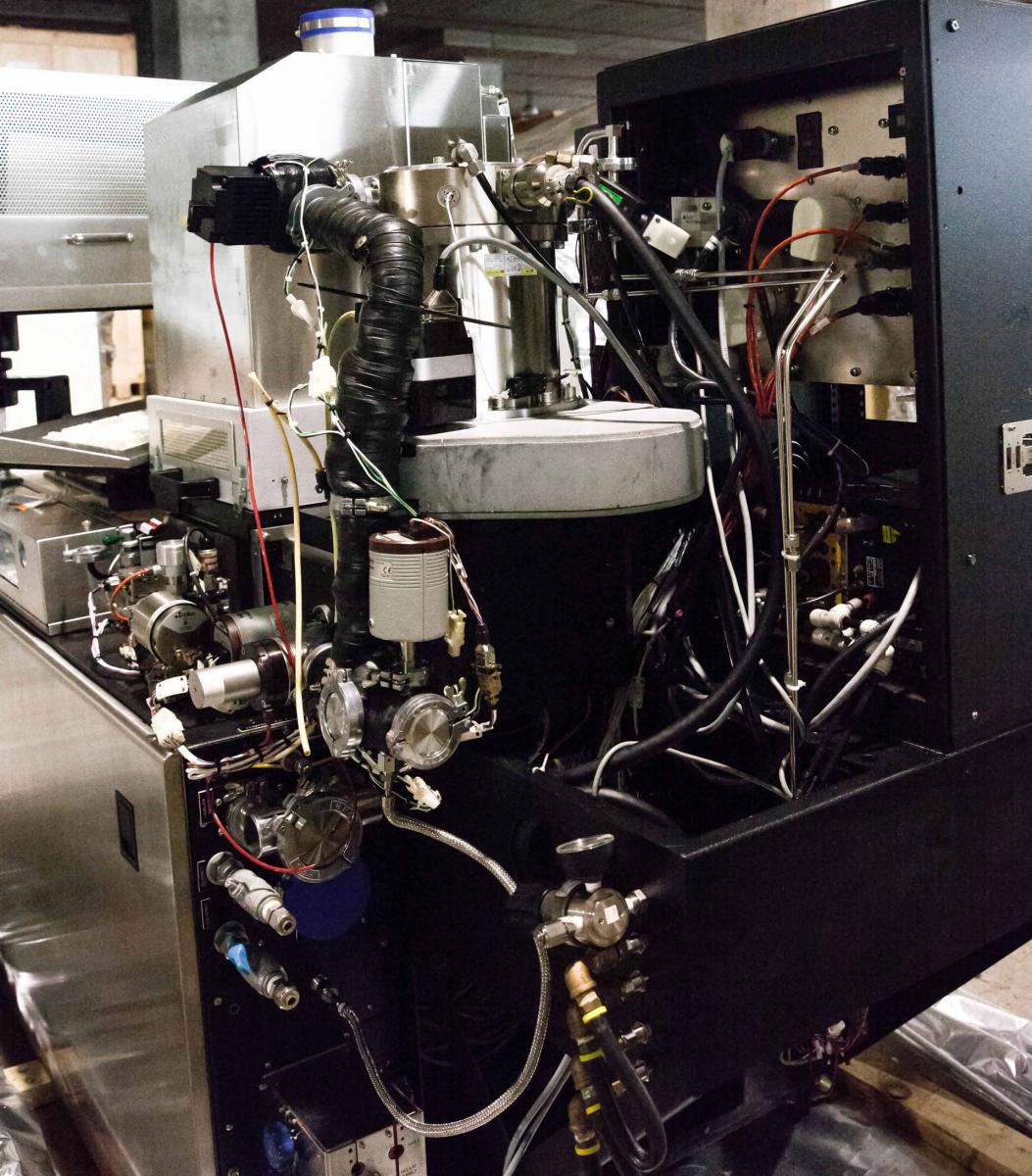

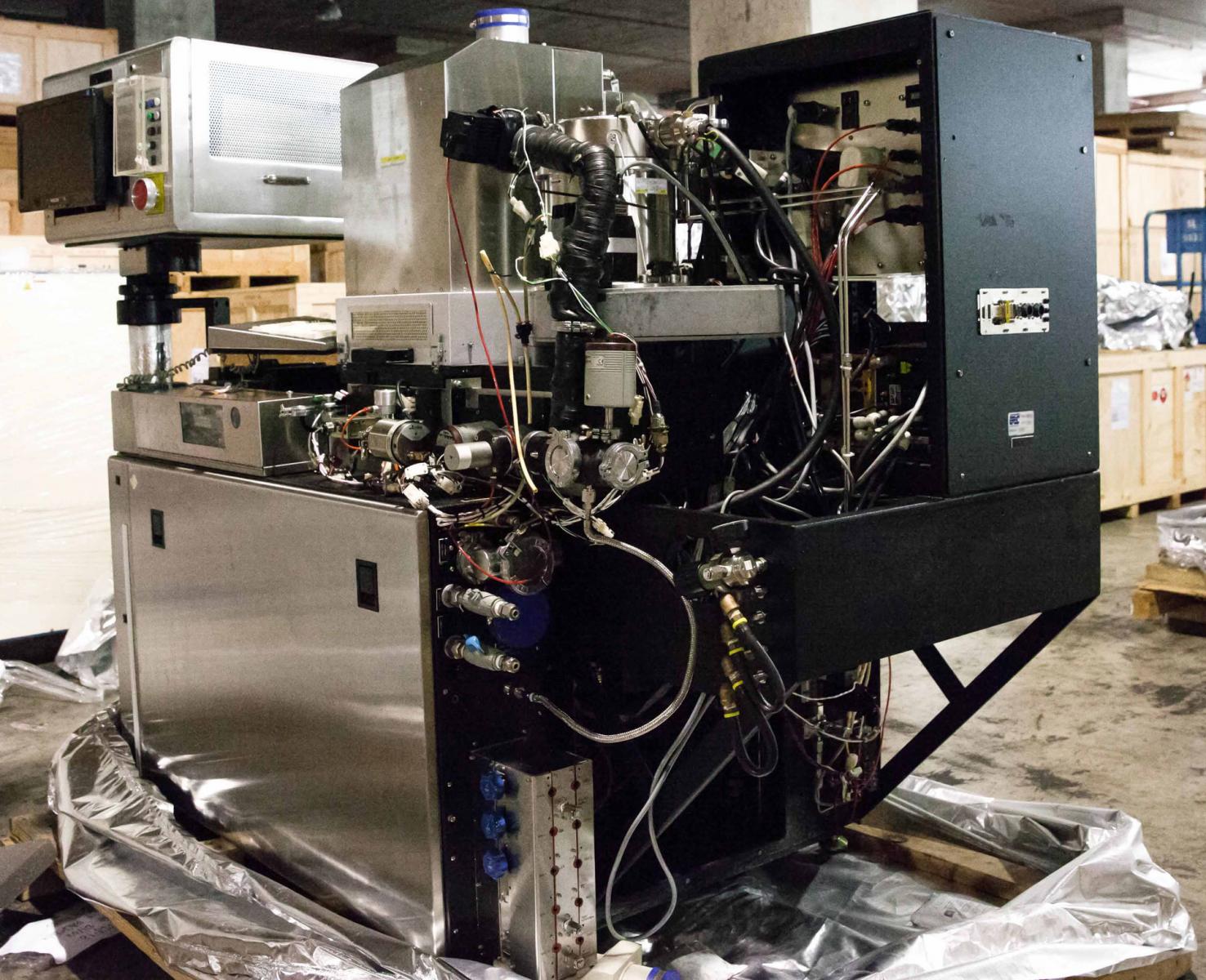

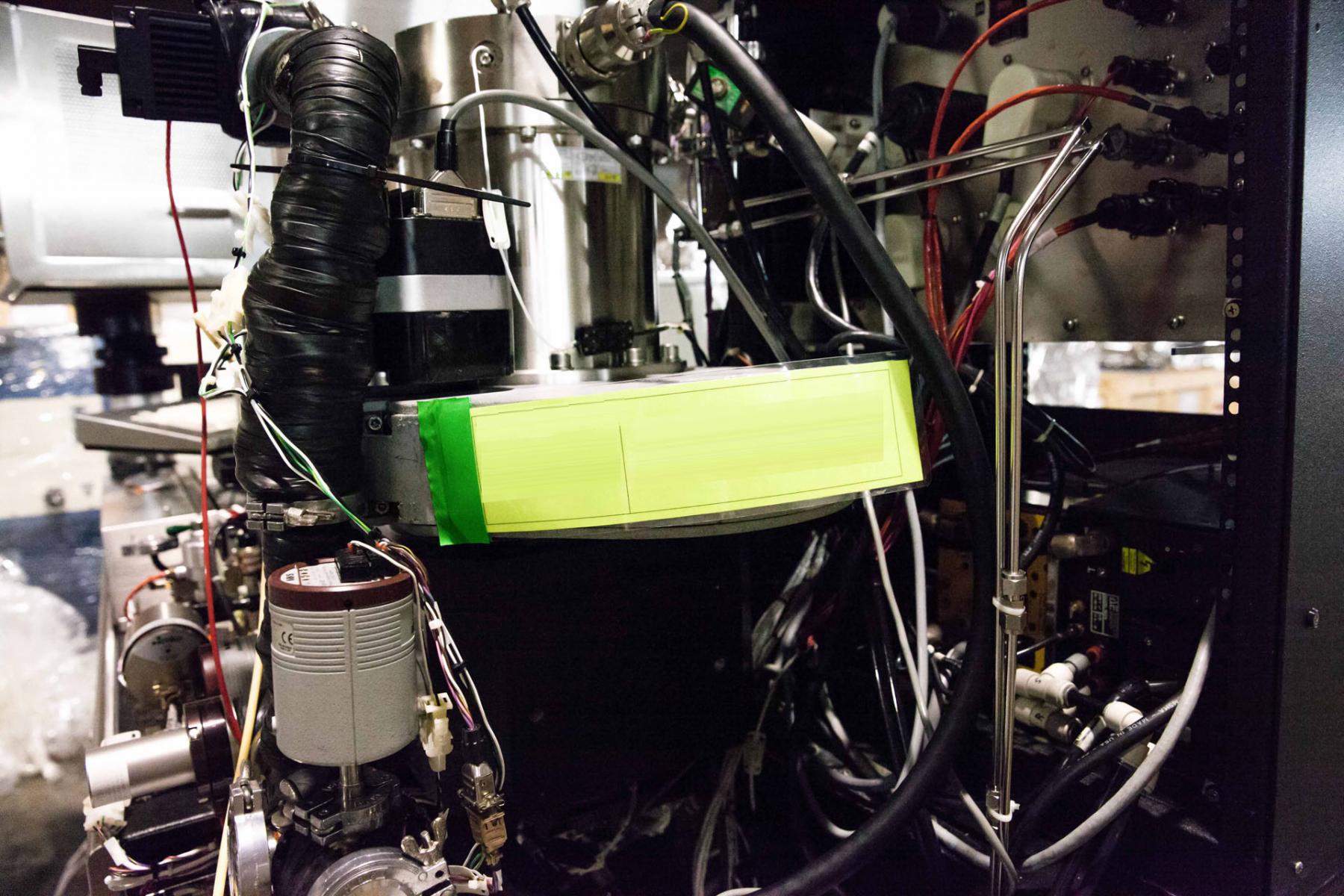

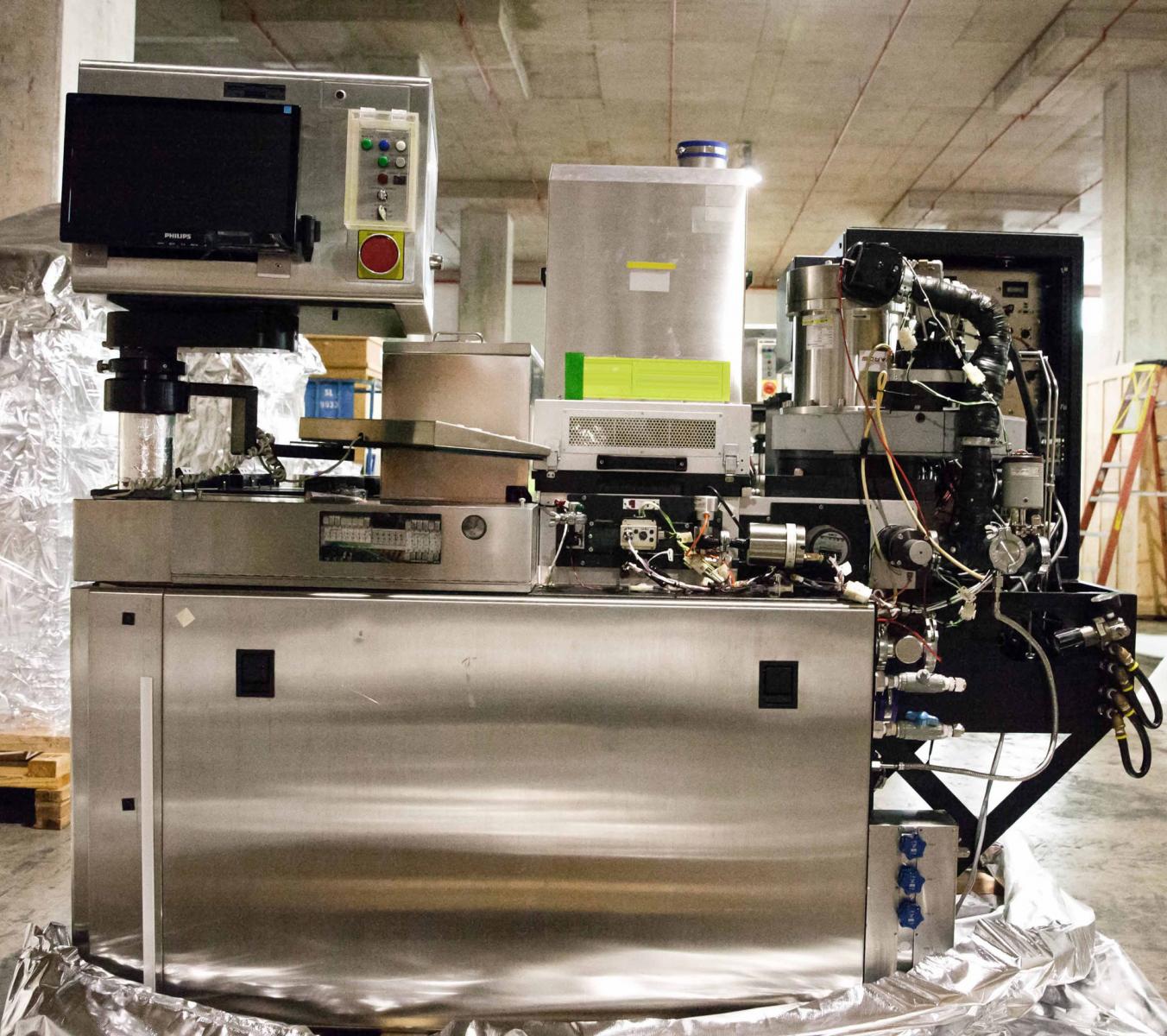

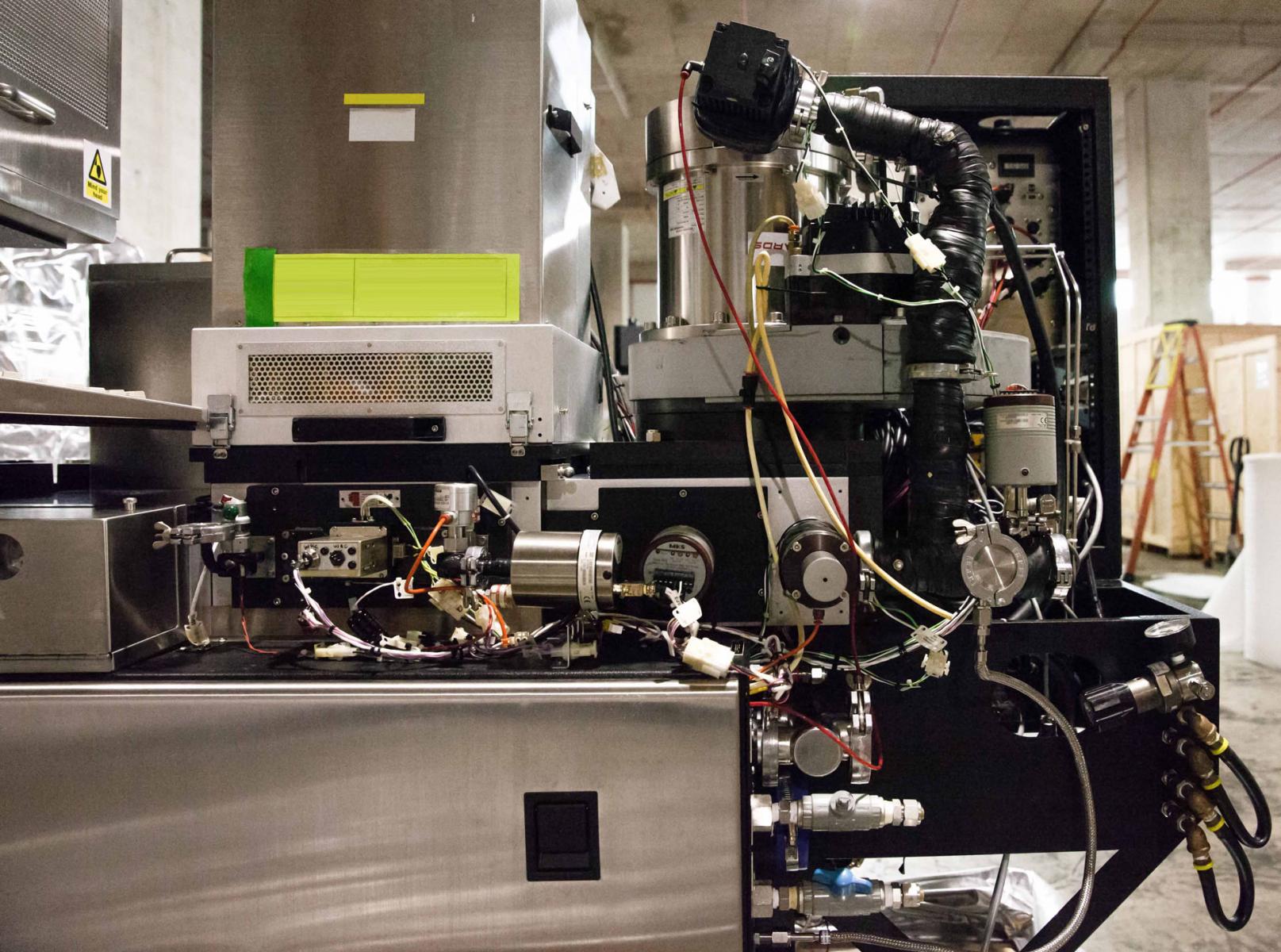

Used LAM RESEARCH TCP 9408 SE #9178706 for sale

URL successfully copied!

Tap to zoom

ID: 9178706

Wafer Size: 8"

Vintage: 2004

Poly etcher, 8"

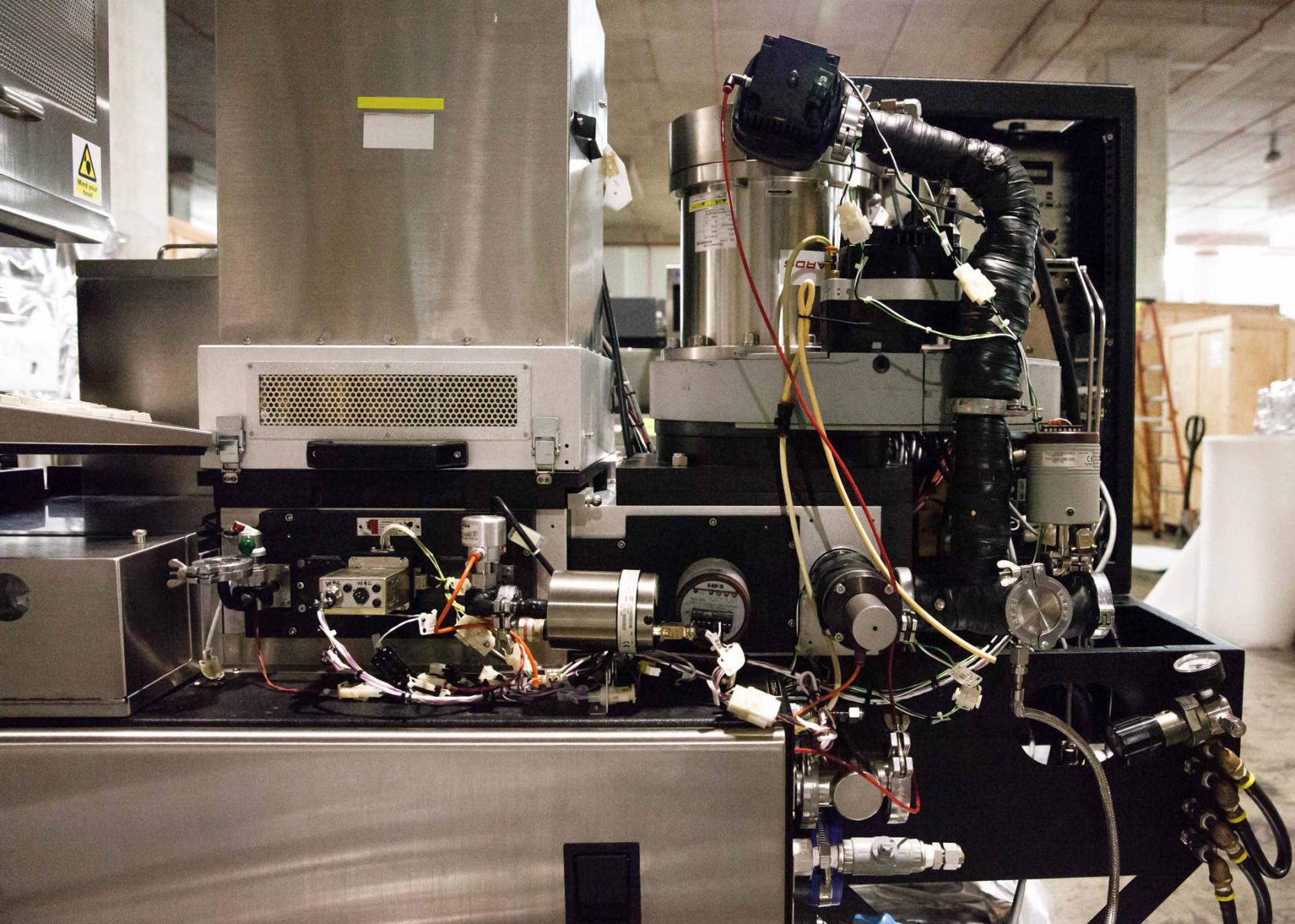

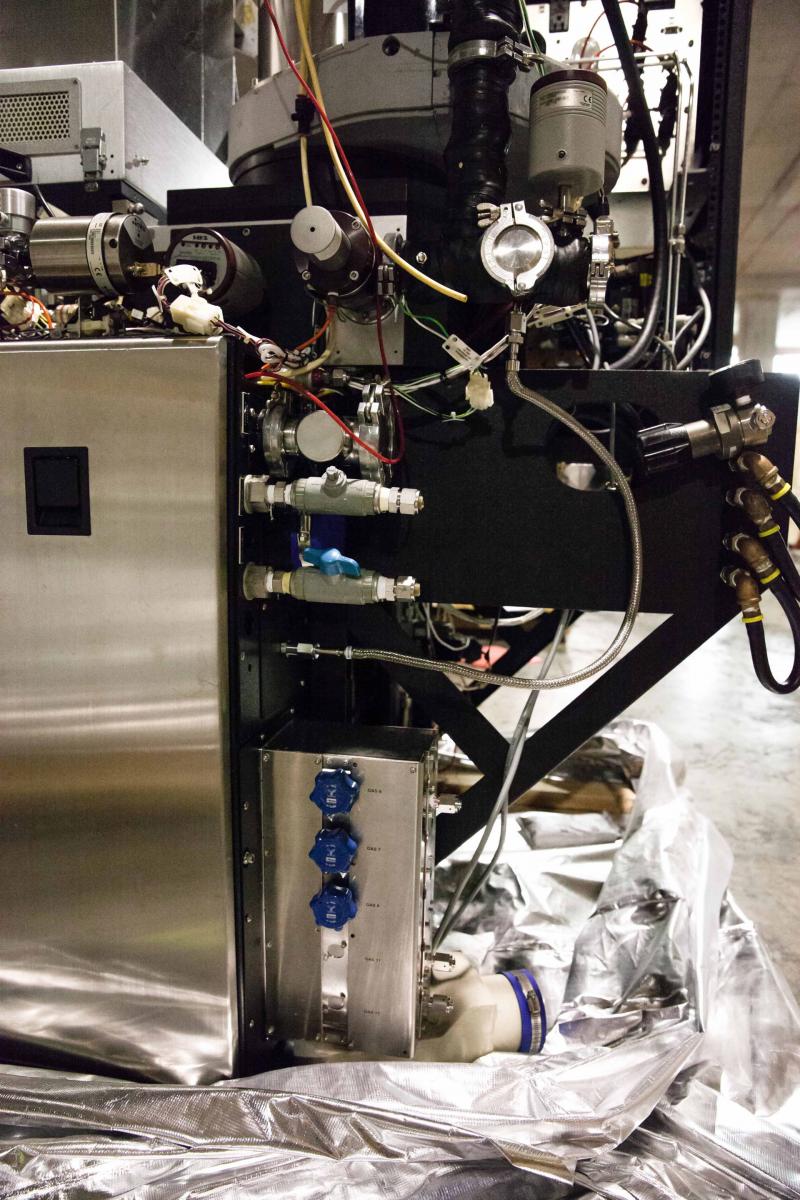

Process chambers: SCCM

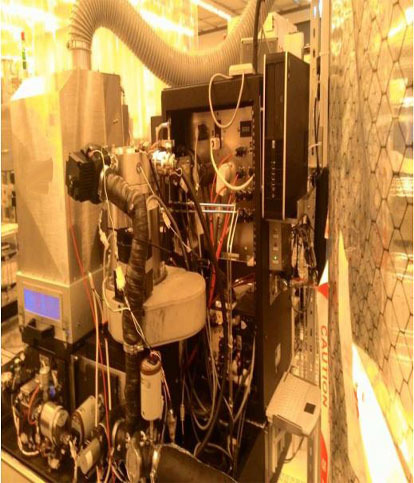

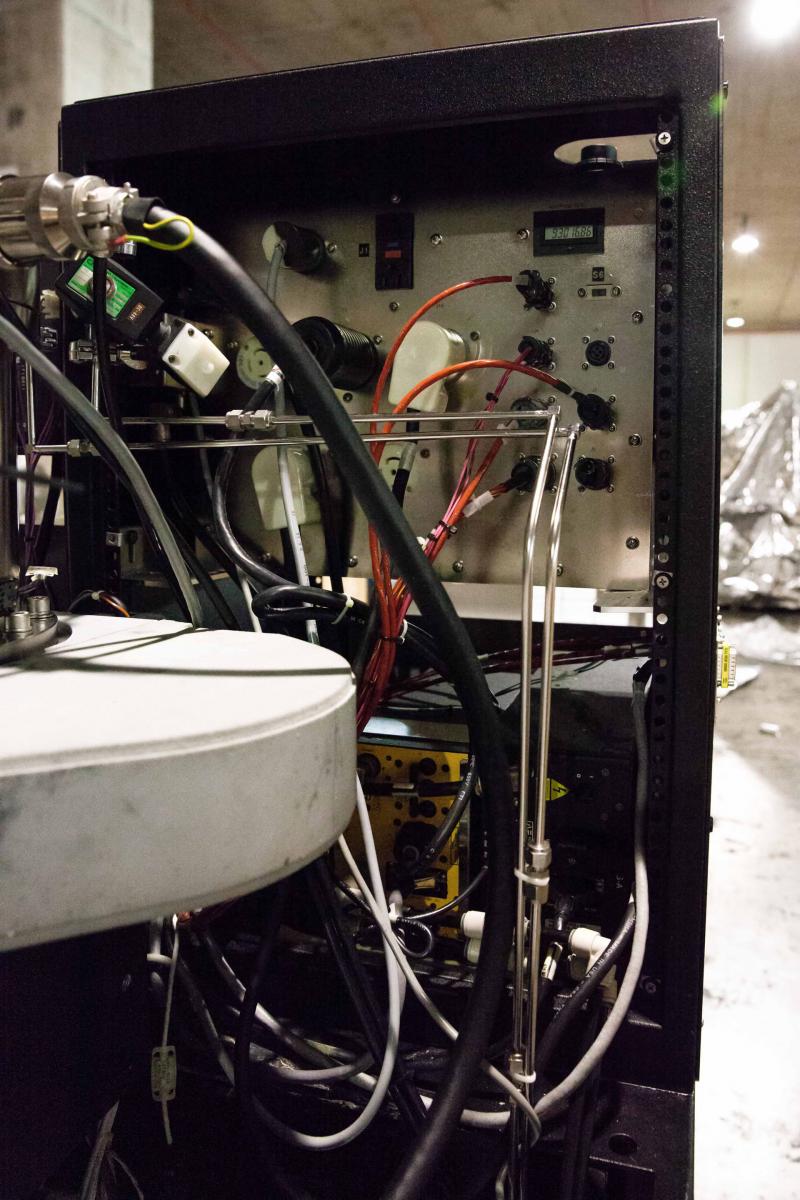

(2) RF Racks

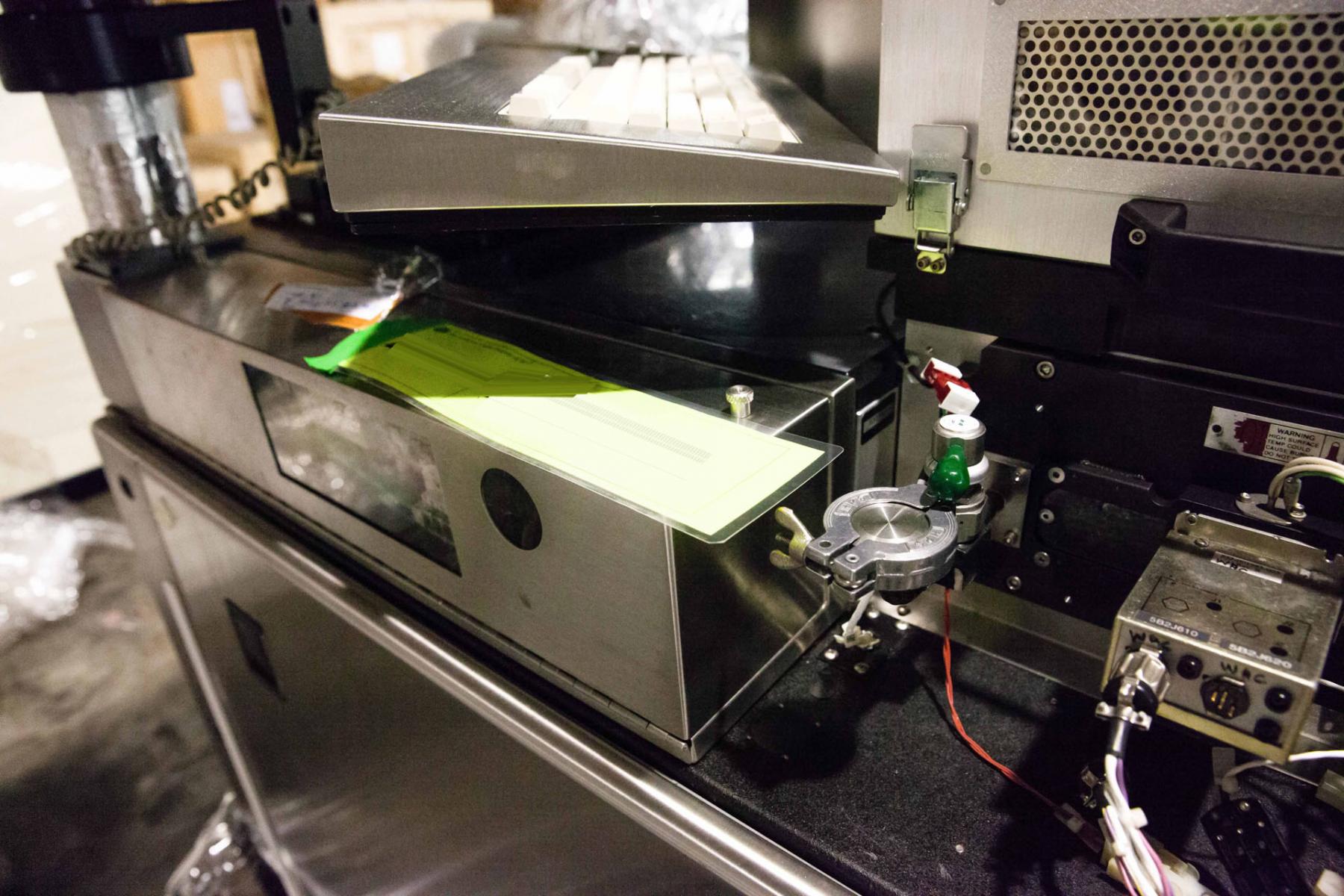

SMIF System: (2) Assyst

AC Power box

P/N: 853-0322294-002

Bias RF match: 853-025083-001

ESC Power supply: 810-017086-010

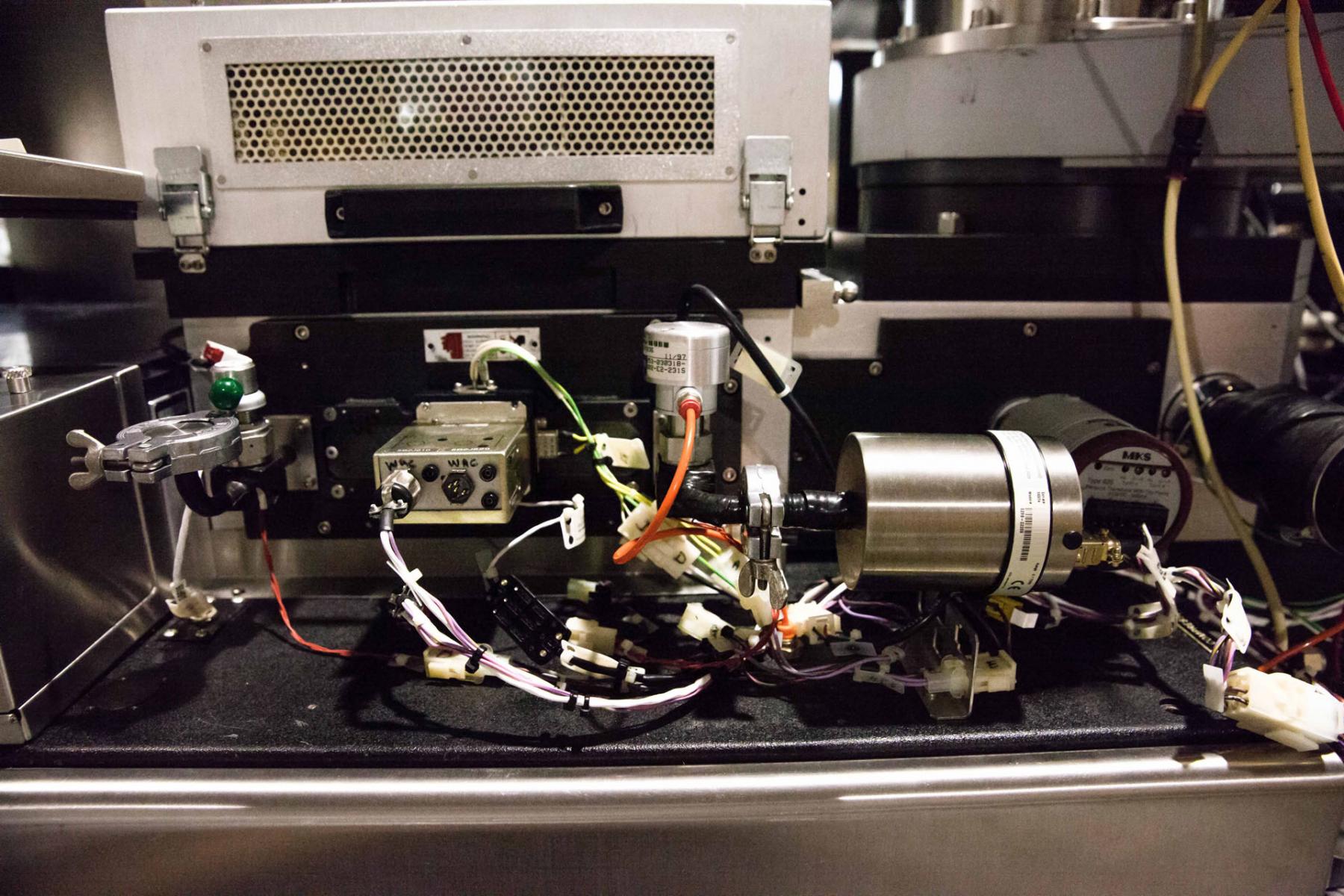

Chamber manometer. MKS make (All): 629B-22205

Turbo manometer MKS make (All): 625A11TDE

Ref Manometer MKS make (All): 625A11TDE

Turbo pump: STPA1303C

TCP RF Gen. AE Make(AII): 660-024637-006 RFDS

BIAS RF Gen.AE Make( All): 660-024637-013 HALO

Wafer drag back: Enable

Wafer offset alignment alignment: 280

Gas ring capacitance: 1175 +/-15 pf

Software version: 1.6.012A

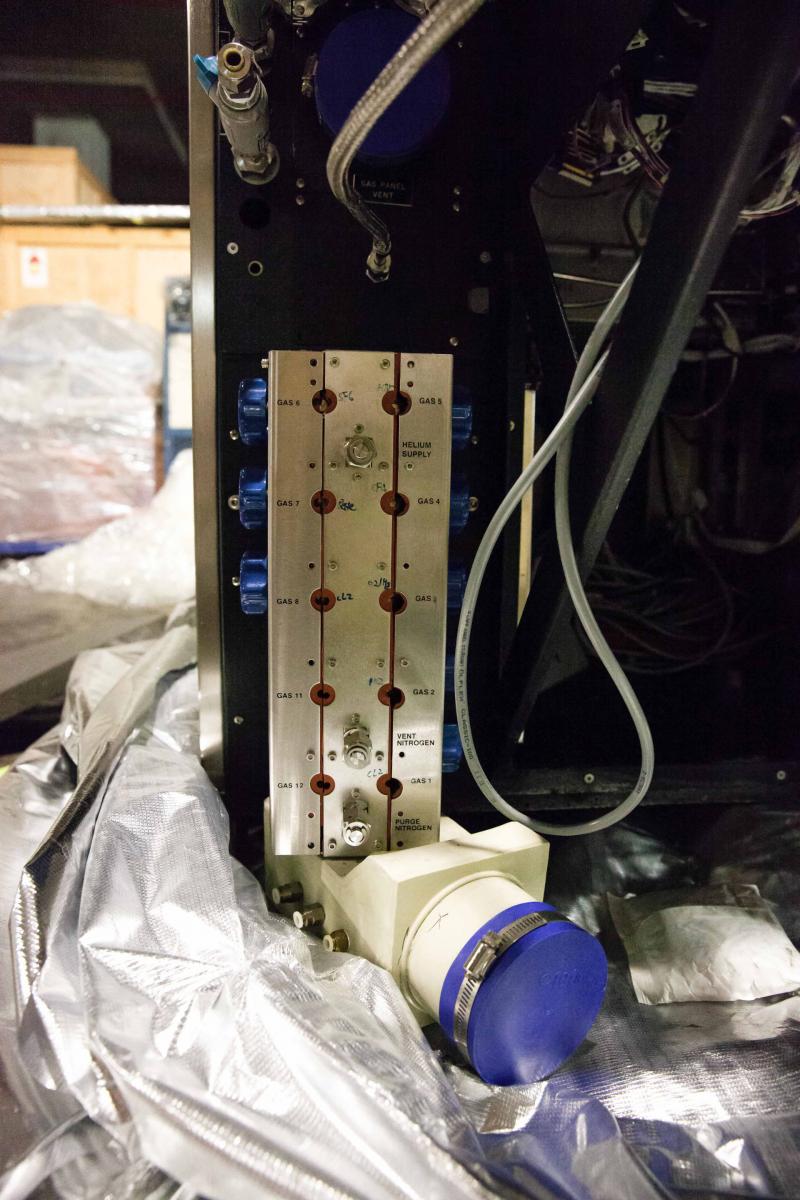

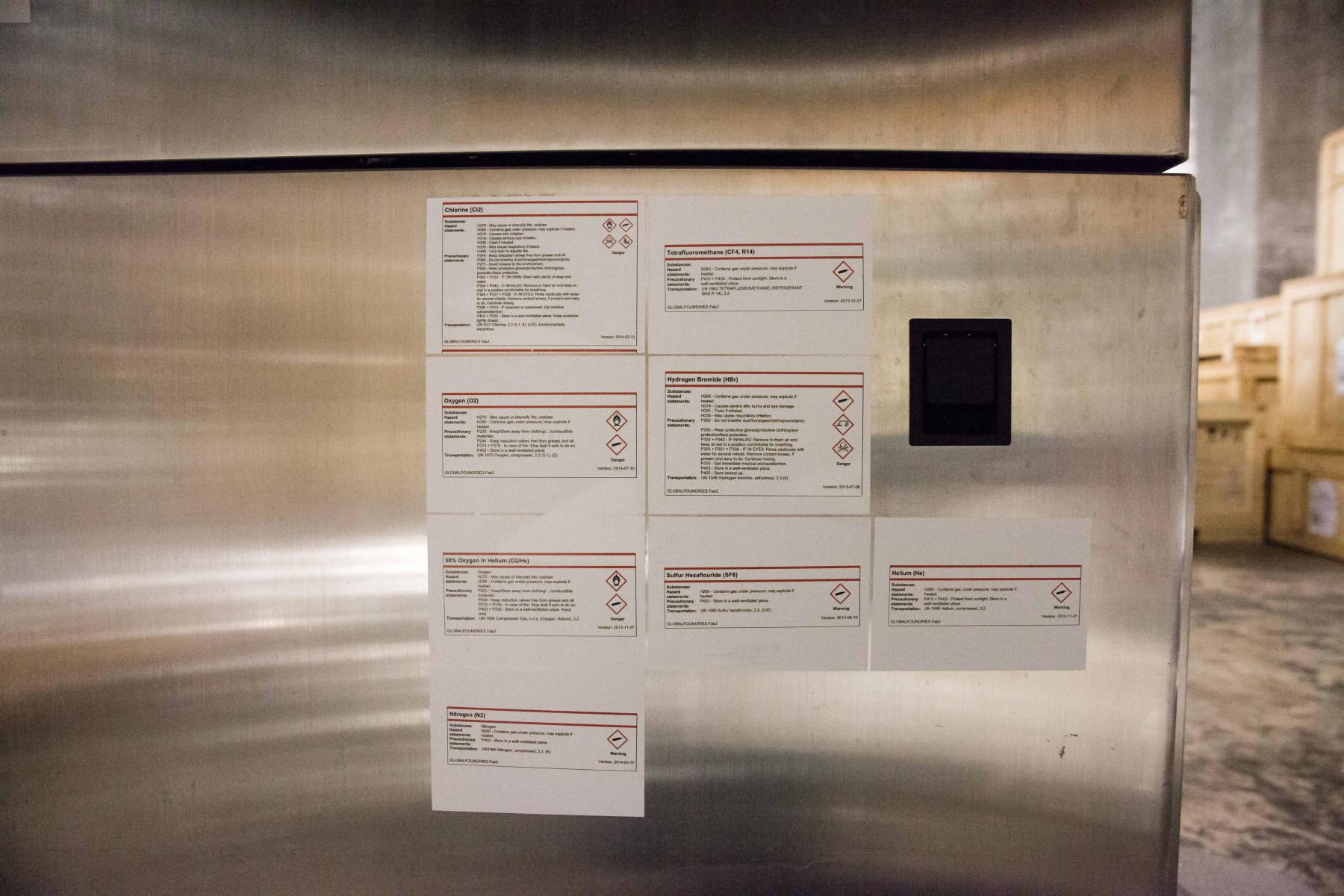

MFC Config.CL2-200 seem: 200

MFC Config.02-100 seem: 100

MFC Config.HE/O2-20 seem: 20

MFC Config.CF4-100 seem : 100

MFC Config.HBR-500 sccm: 500

MFC Config.SF6-100 seem: 100

MFC Config.HE-500 seem: 500

MFC Config.CL2-30 seem: 30

TCP Coil position: 8 O * CLK

Chiller used: BOC 40/80

Vat vale / Pendulum valve: VAT -64 Valve

PC Pump: A30W

Load lock pump: A30W

Turbo pump capacity: 1300L

2004 vintage.

LAM RESEARCH TCP 9408 SE is an advanced etcher/asher equipment that provides the highest throughput and yield for advanced MEMS, MEMS-enabled, and wafer-level packaging (WLP) processes. The system utilizes advanced laser-based scanning and ablation techniques to pattern thin dielectric and polyimide layers on a range of substrates including glass, quartz, sapphire, CVD/PECVD, and other specialty materials. The unit provides superior etching accuracy and repeatability, allowing for more precise feature definitions, repeatability and higher yield. TCP 9408 SE machine has the capability to ablate the most advanced dielectric layers and polyimide layers with the highest precision and repeatability. The tool is equipped with a high-powered laser that is calibrated and focused on the substrate, enabling the asset to achieve high resolution patterning capabilities. The reliable and fast ablation process of the laser ensures that the most intricate patterns can be achieved. The model is equipped with an integrated wafer handling equipment, allowing for high throughput. This wafer handling system includes a wafer alignment station, wafer cooling unit, and a wafer exchange station. The alignment station includes highly accurate motion control and vision-based determination of the exact position of the substrate for accurate laser ablation. The wafer exchange station can quickly change substrates with minimal process interruption. LAM RESEARCH TCP 9408 SE machine also features automated process control and monitoring, ensuring that process parameters are adjusted in real time for accurate and repeatable etching and ablation. This automated process control is enabled by a high-precision laser vision tool that allows for three-dimensional mapping of the substrate prior to ablation. The ablation parameters can then be easily adjusted to accord with the process specifications without manual operation. The asset is designed to meet the most stringent industry standards, with low cost of ownership and superior reliability. To ensure consistent and high yield results, the model is designed to be user-friendly and is backed by LAM RESEARCH industry leading support. This advanced etcher/asher equipment is perfect for complex MEMS and WLP applications, and offers the highest throughput and yield available.

There are no reviews yet