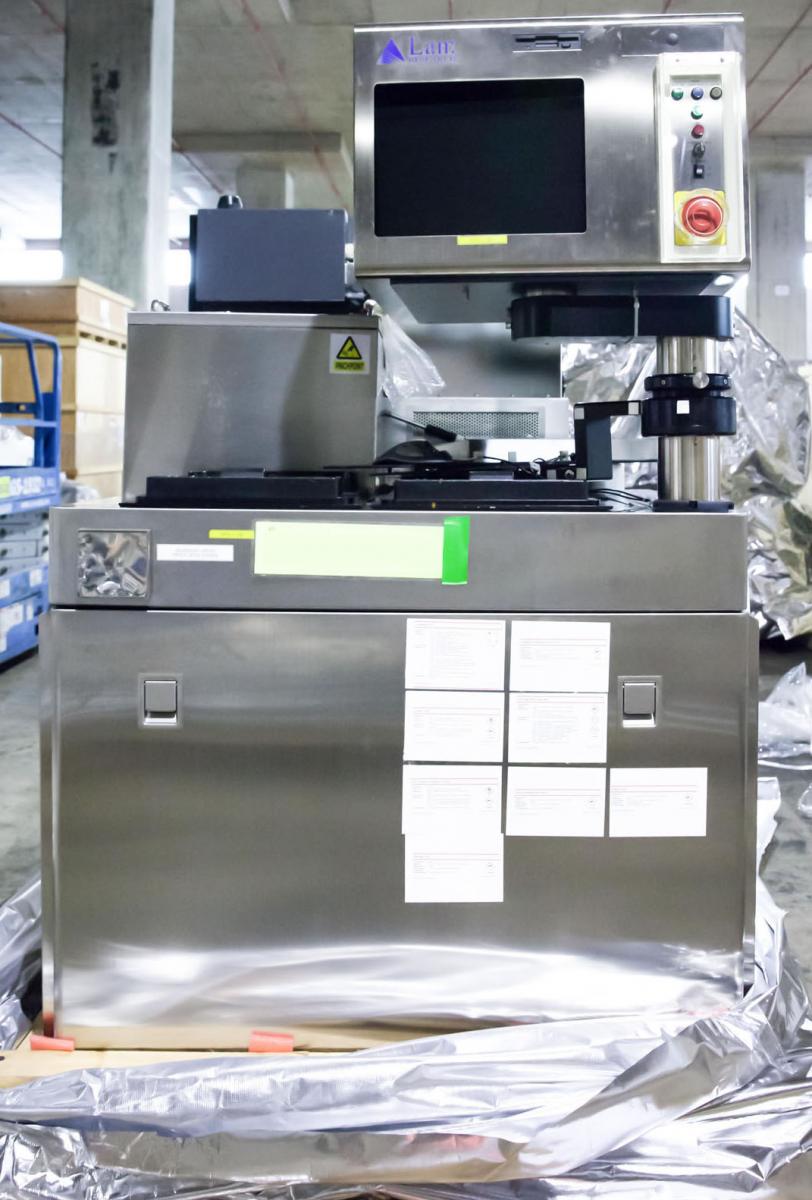

Used LAM RESEARCH TCP 9408 SE #9178710 for sale

URL successfully copied!

Tap to zoom

ID: 9178710

Wafer Size: 8"

Vintage: 2004

Poly etcher, 8"

Software version: 1.6.012A

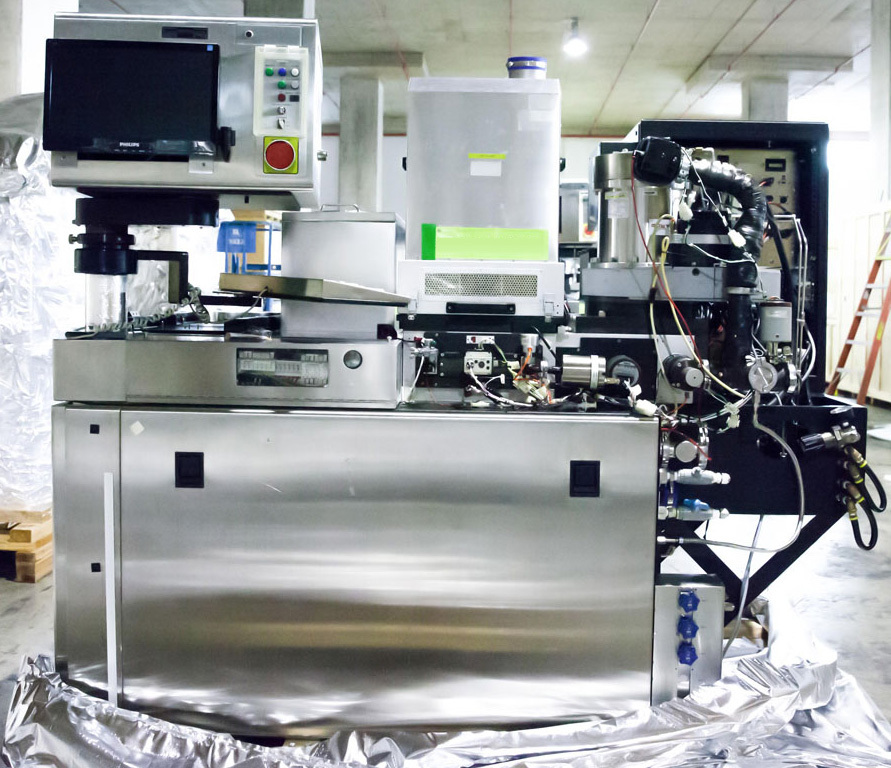

SMIF System: (2) ASSYST

Process chms: (1) SCCM

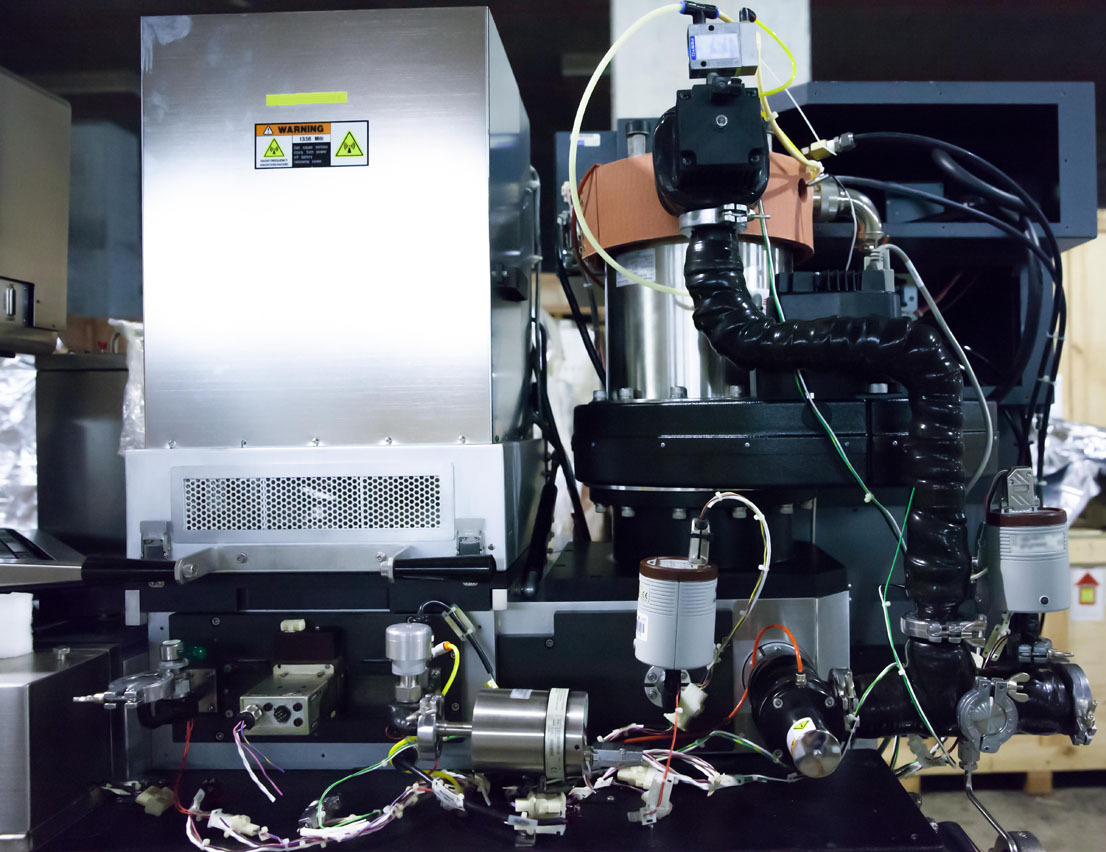

Hardware configuration (Subfab / Auxilliary units):

(1) AC Power box

(2) RF Racks

2004 vintage.

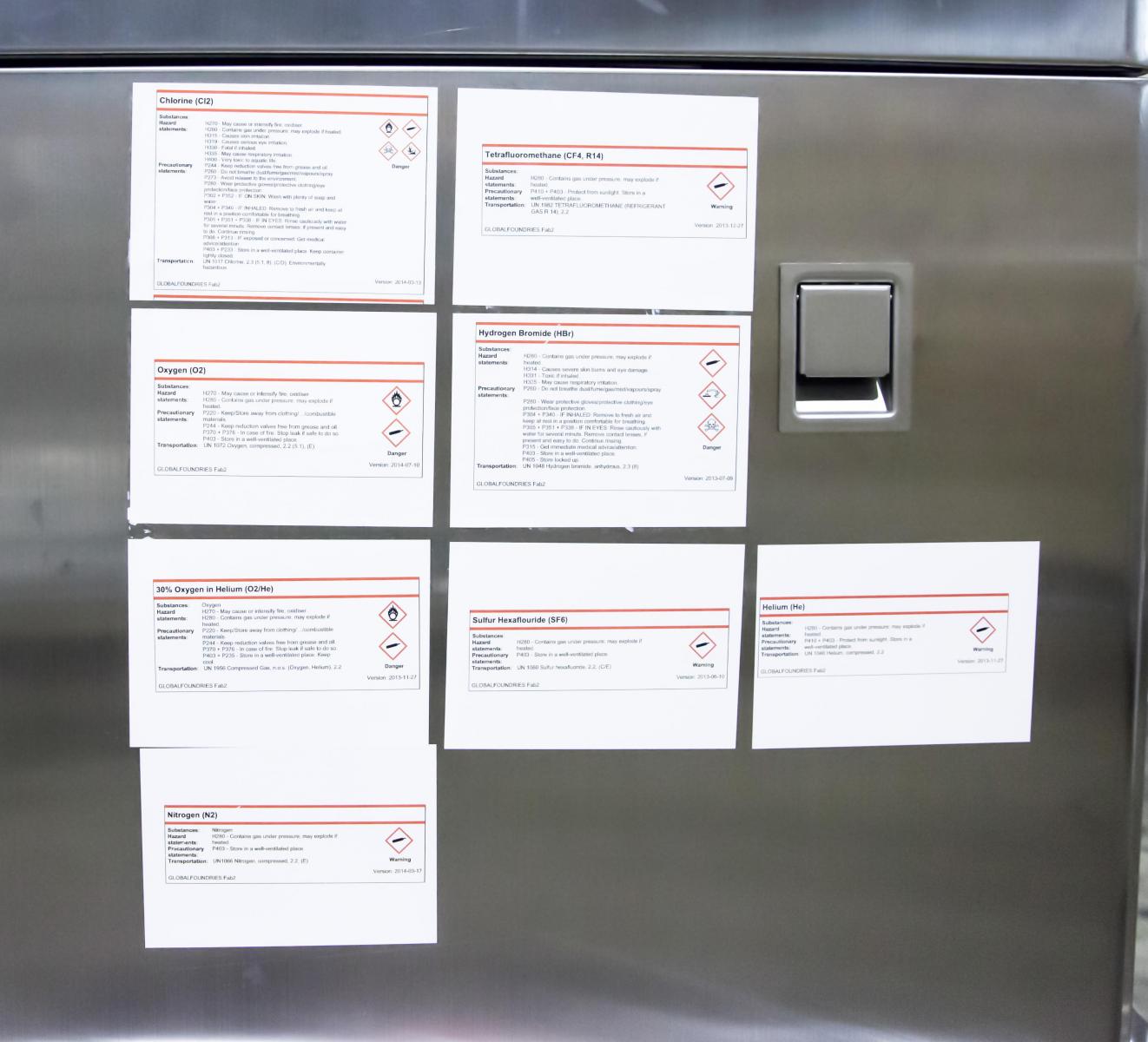

LAM RESEARCH TCP 9408 SE is a precision etcher / asher with an advanced thermal control equipment that offers reliable etching, ashing, and combined etch/ash processes. This system has horizontally-siliconized chamber walls to reduce mechanical shock, flats and rinsing with pure water. It comes with a user-friendly, intuitive graphical user interface (GUI) that greatly simplifies operation. The unit is designed for processing a wide variety of substrates, including metal, silicon, ceramic and glass. TCP 9408 SE has a helium flush gas machine that offers constant pressure and temperature control. This tool is designed for maximum throughput, with a fast process cycle time, up to a maximum of 14 chamber cycles per hour. The etch/ash process time ranges from 5 to 7 minutes, depending on the substrate type and process parameters. In addition, the asset has a maximum of 5 process recipes, enabling the user to save and recall recipes for different applications. LAM RESEARCH TCP 9408 SE features a robust design, with the ability to accommodate larger parts and higher etch/ash loads. The model is capable of processing up to 2 kg of material, with a load size of 4 to 6 cm. It also includes lateral, motorized chamber and cover movements to accommodate different size/shape parts. TCP 9408 SE equipment has a high resolution work chamber, with a 1 micron heated stage. The process chamber is electronically heated, with a temperature range of up to 1050°C. In addition, the system has an optional cooling of the heated stage, with a cooling range of -60°C. The unit offers full monitoring and control of etch/ash parameters; the helium flush pressure, temperature and the cooling rate. It also has an automatic cycle stop and gas management machine, where the user can monitor the process parameters and cycle time. LAM RESEARCH TCP 9408 SE has a variety of safety features, including a safety-lock lid, a double-pinch hermetic O-ring seal, Interlock and overload detection, and a fault isolation tool. The asset is designed for optimal hazardous environment control and user safety, with an array of protective alarms and a provision for additional shielding. In conclusion, TCP 9408 SE is a reliable and robust etcher / asher with an advanced thermal control model. It offers a variety of process parameters and safety features, with a fast process cycle time and high throughput. The equipment is capable of processing a wide variety of substrates, with a high resolution work chamber and a user-friendly GUI.

There are no reviews yet