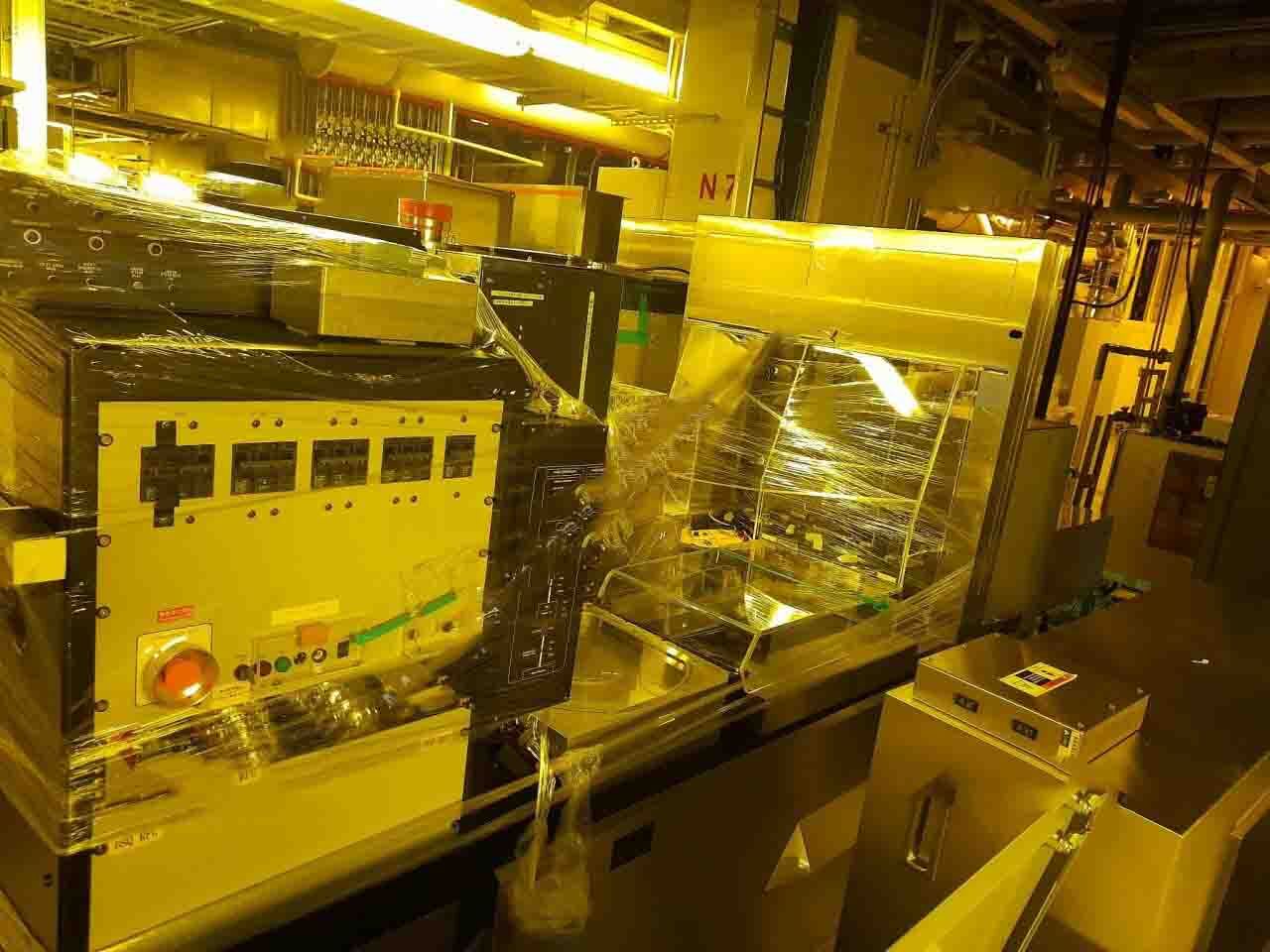

Used LAM RESEARCH TCP 9600 SE #293636060 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 293636060

Wafer Size: 8"

Etcher, 8"

SECS

Gas panel type: Standard

Etcher type: Stand alone

Robot: Auto loader

Backside helium cooling MFC type: 622A-13224

On-board RF Generators

Endpoint detector

Endpoint type: Photodiode

Fixed electrode gap

ESC Wafer clamp

TCP Coil, 8"

Signal lamp tower

Main On-board AC distribution type: Circuit breaker

Remote AC box

WVDS

Gas box:

(8) Gas lines

Gas line / Gas / Flow

1 / Cl2 / 200

2 / BCl3 / 100

3 / SF6 / 100

4 / N2 / 20

5 / N2 / 500

6 / Ar / 200

7 / O2 / 2000

8 / CF4 / 200

Does not include:

EDWARDS iQ80/500 Etch chamber pump

EDWARDS iQ80/500 Strip / Ash chamber pump

TAITAC DEX-30A Chiller

CE Marked.

LAM RESEARCH TCP 9600 SE is an advanced plasma etching equipment engineered for superior etching performance and high productivity. With an overall chamber length of 73 inches, the system is capable of handling single and double-sided wafers with a maximum size of 6 inches. The chamber is vacuum sealed and includes a horizontal etching zone and an isolation zone for controlling substrate loading during the etching process. The unit also features a temperature controlled chamber that maintains the working environment of the wafer at its optimum level. LAM RESEARCH TCP 9600SE is equipped with a fully integrated multi-tool/stations, 350 Volt main power panel, and a range of external manifolds that provide flexible transport routing and process gas delivery (N2, H2, Ar). The machine also utilizes a high-resolution Inductive Coupled Plasma source, which is capable of providing high-energy density plasma with excellent power regulation, enabling better process control and improved etch quality. Additionally, TCP 9600 SE comes with an integrated Software Suite, which provides users with an intuitive control over the tool and allows the user to modify process parameters, such as the duration and plasma power levels of the etching cycle. It also includes a number of automated features like automatic speed and distance control, remote ejector station for vacuum operation, and automatic substrate registration for accurate etching. TCP 9600SE also features a range of safety features such as plasma pressure controls and automatic emergency shutoff, which ensures the safety of personnel and equipment.

There are no reviews yet