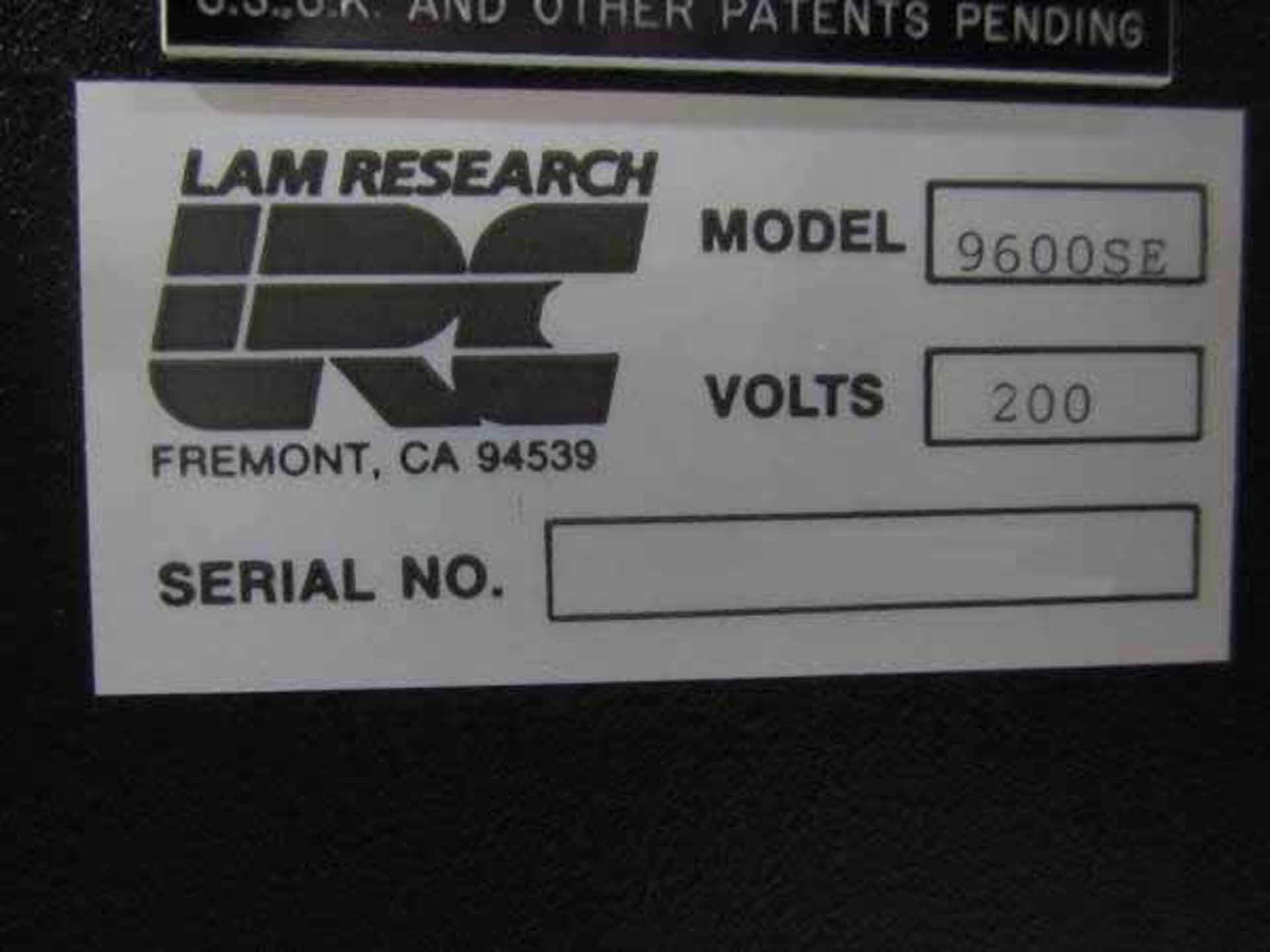

Used LAM RESEARCH TCP 9600 SE #9226415 for sale

URL successfully copied!

Tap to zoom

ID: 9226415

Wafer Size: 8"

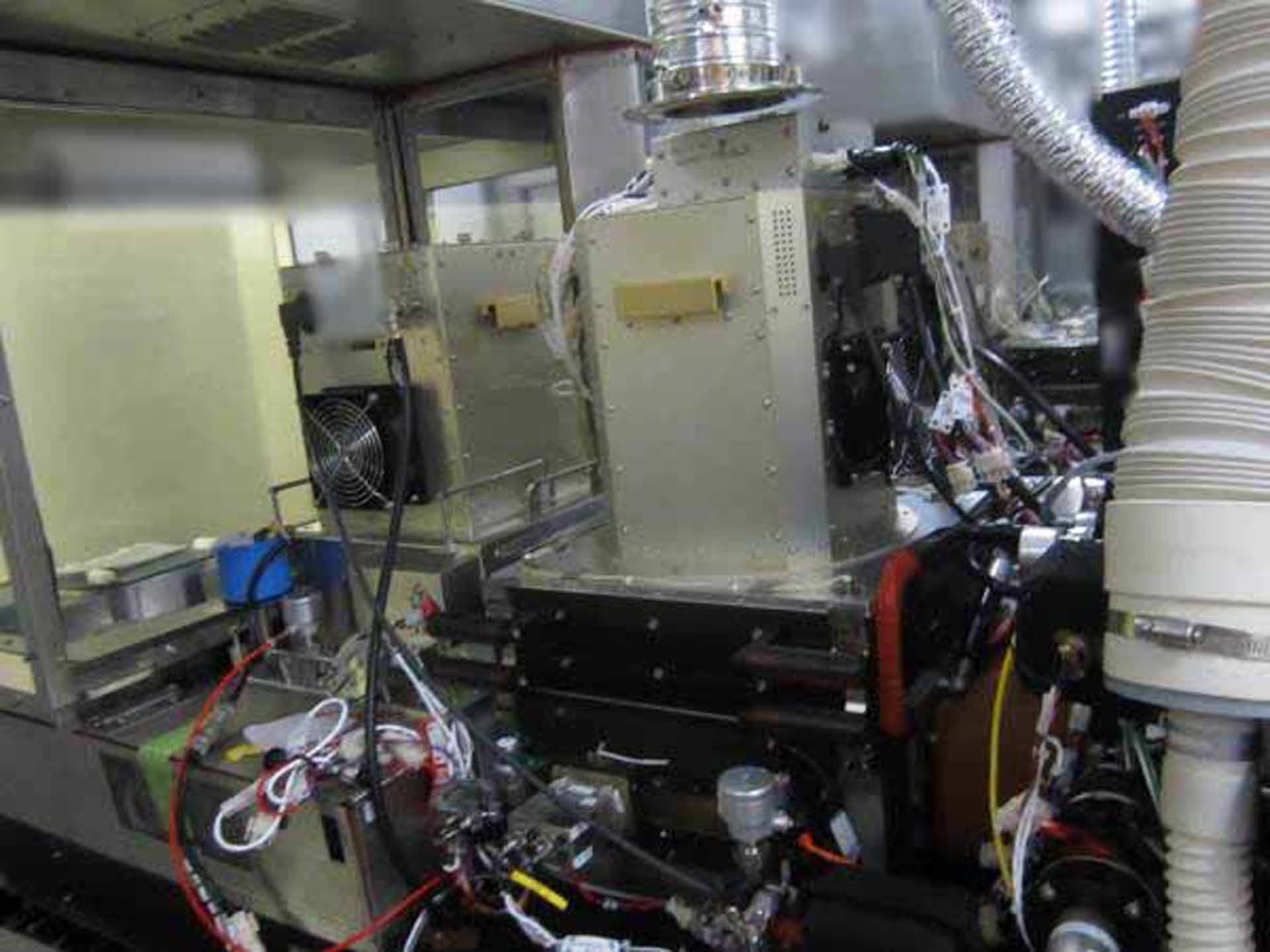

Metal etcher, 8"

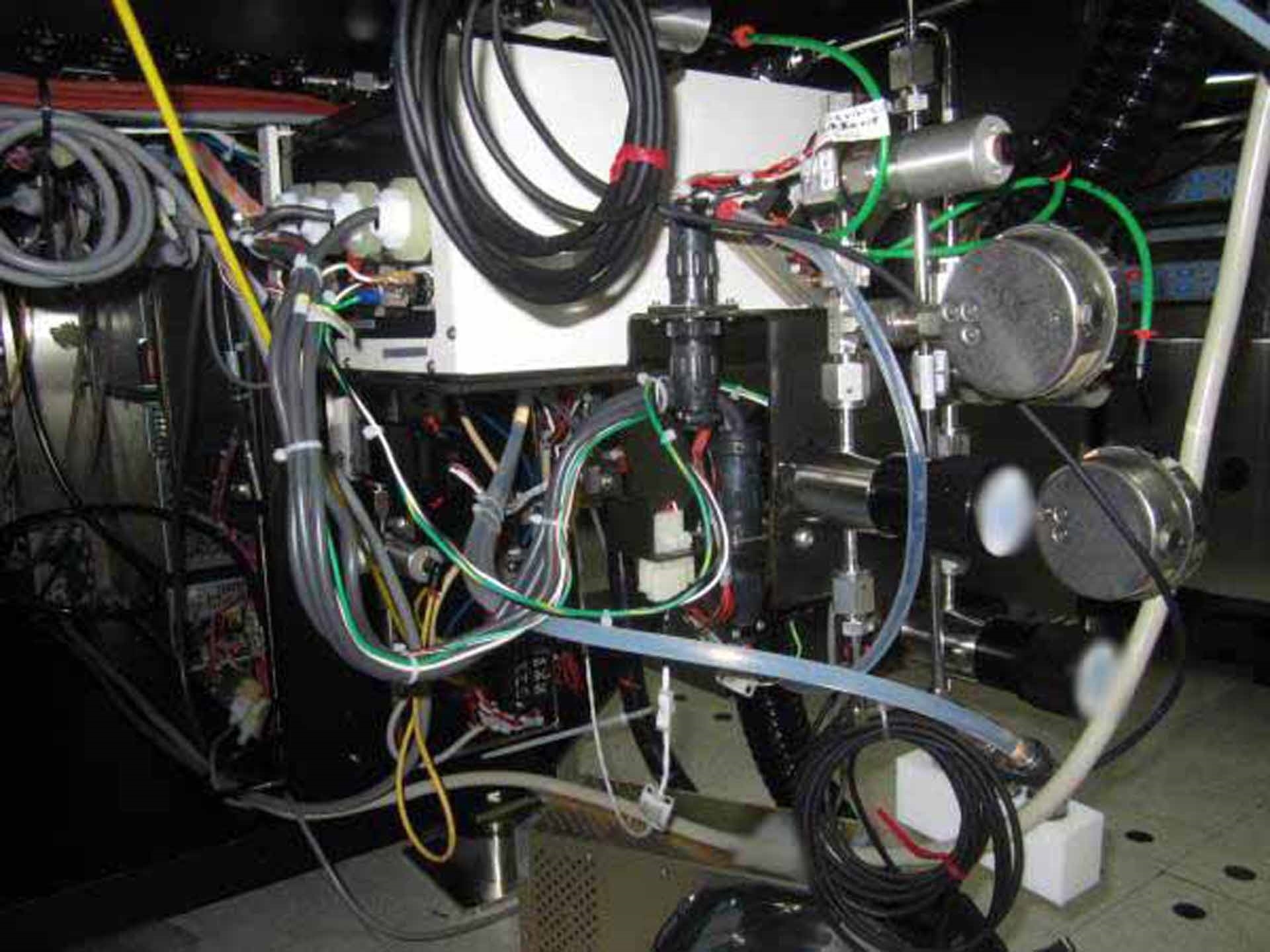

Gas box MFC

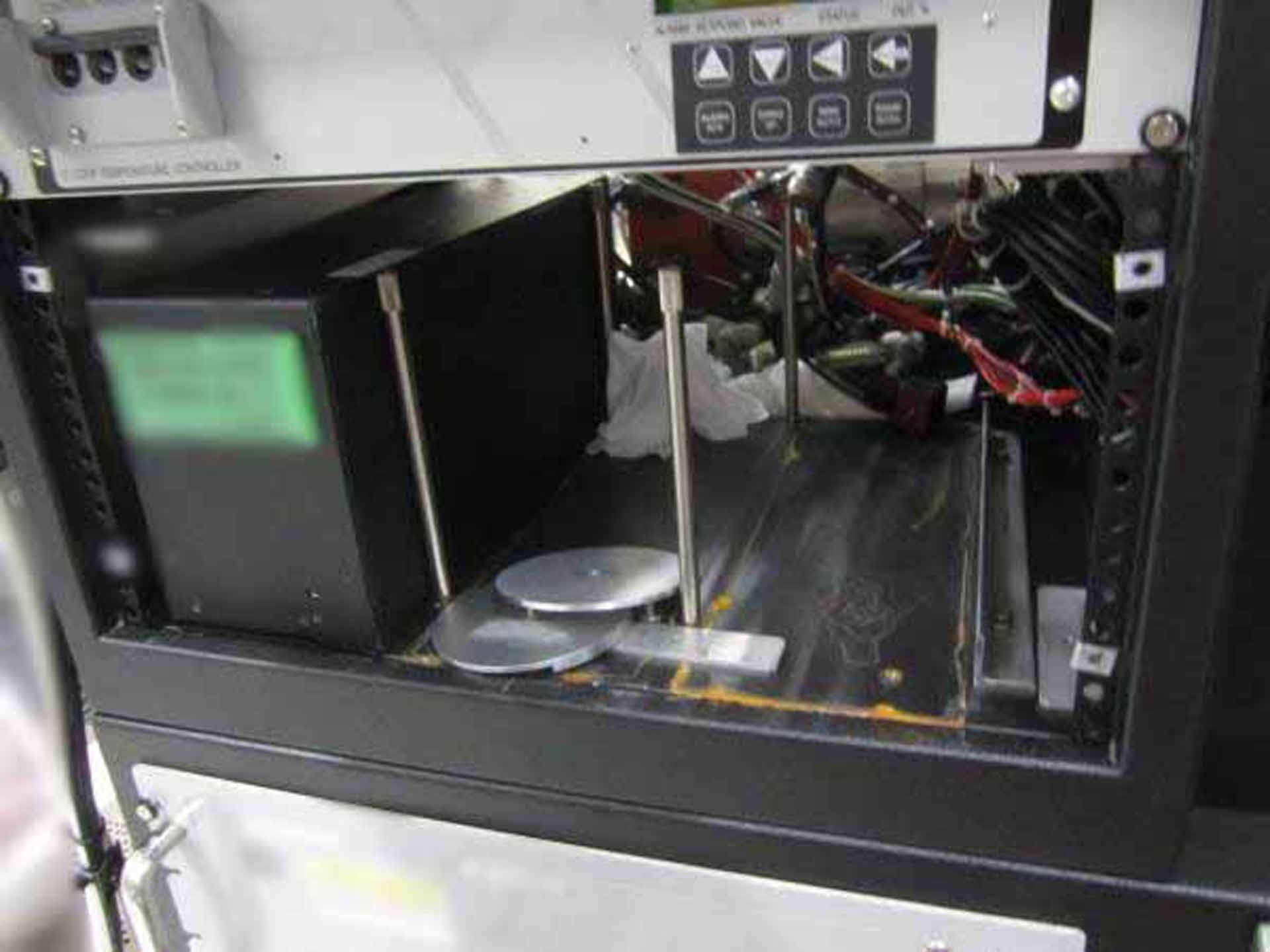

Temperature controller

Process kit: EPD Sensor

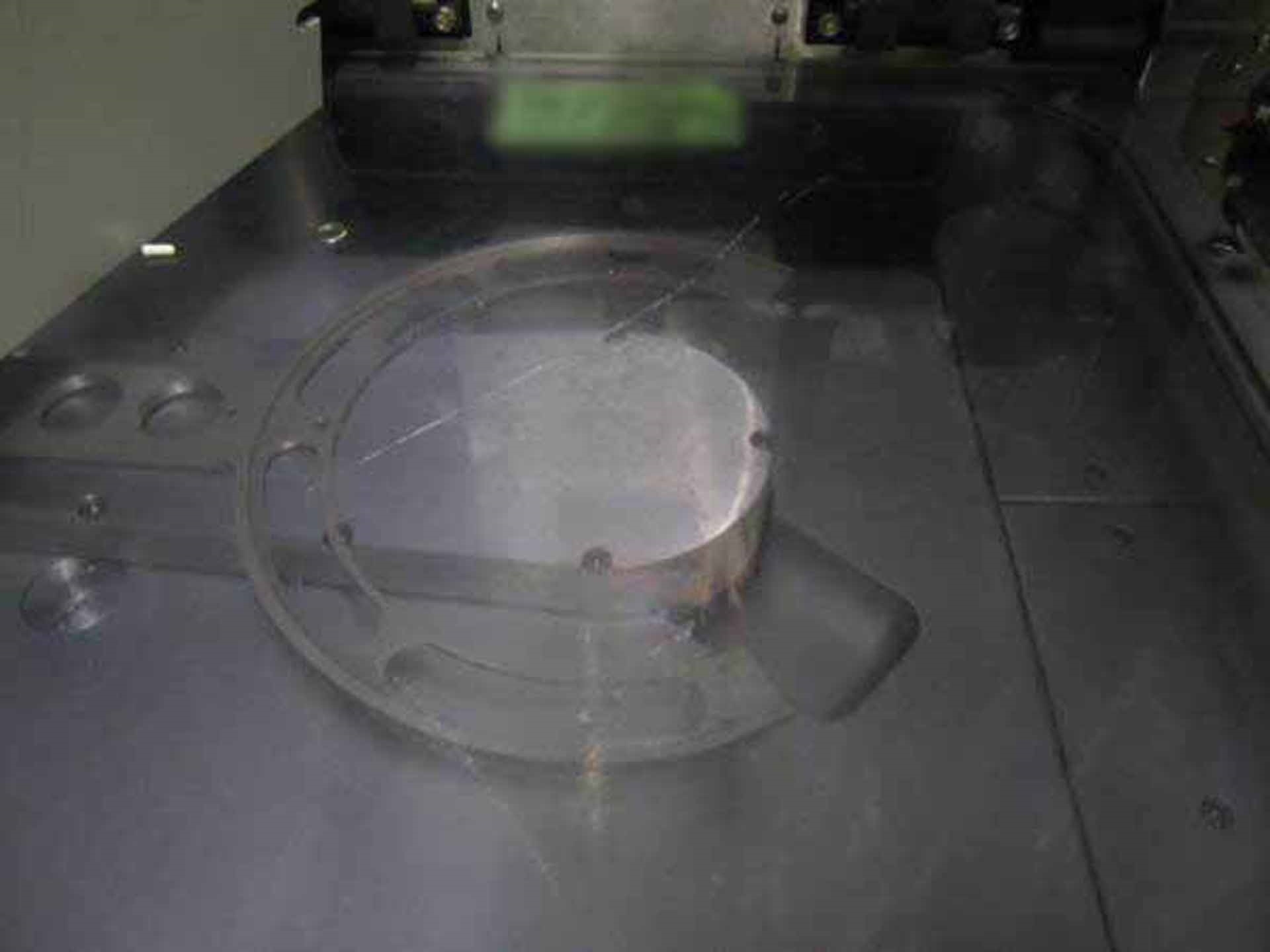

Chuck type: Mechanical

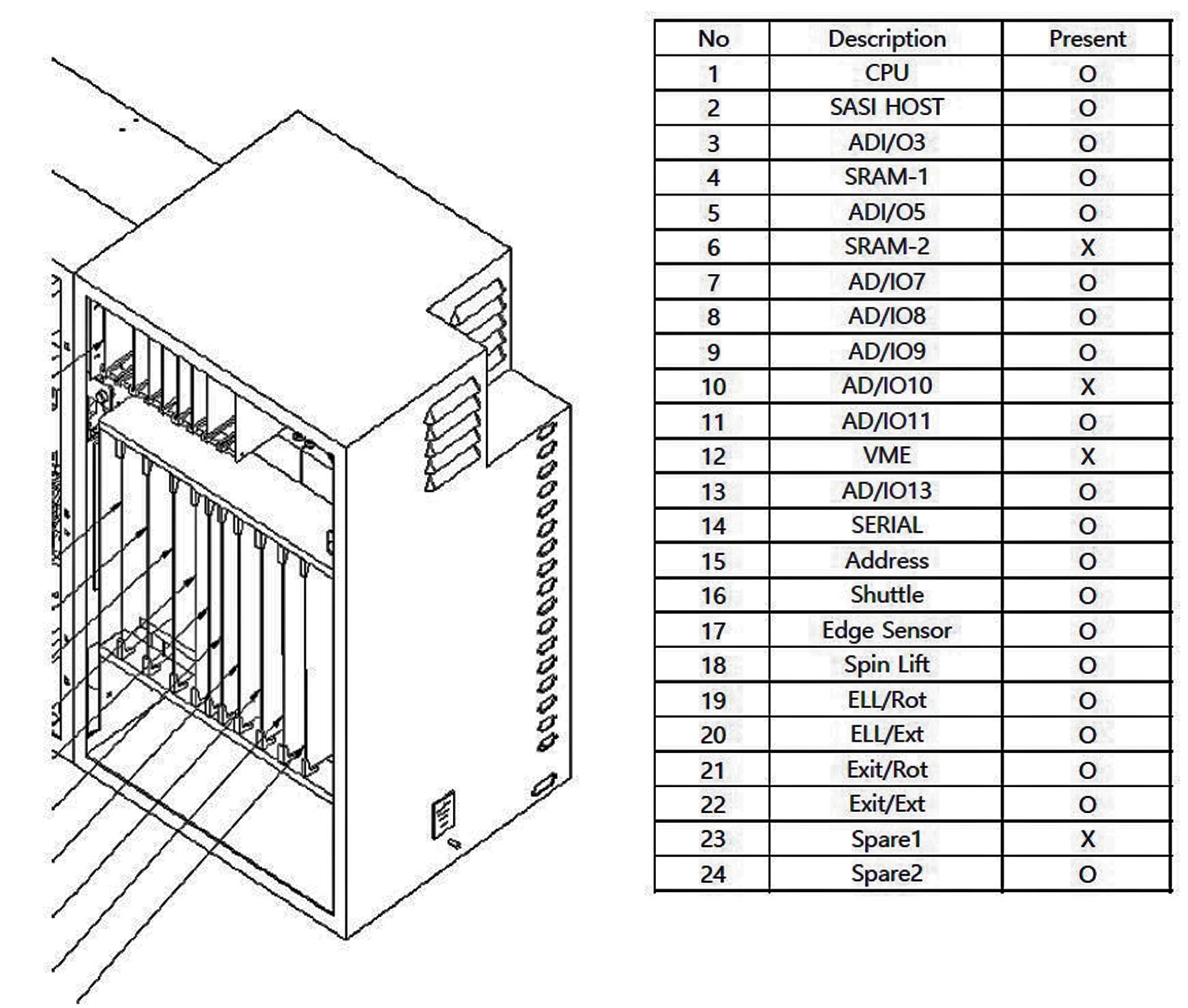

(12) Board checkers

MKS: 13.32 PA

P/C ESC

VAT Valve

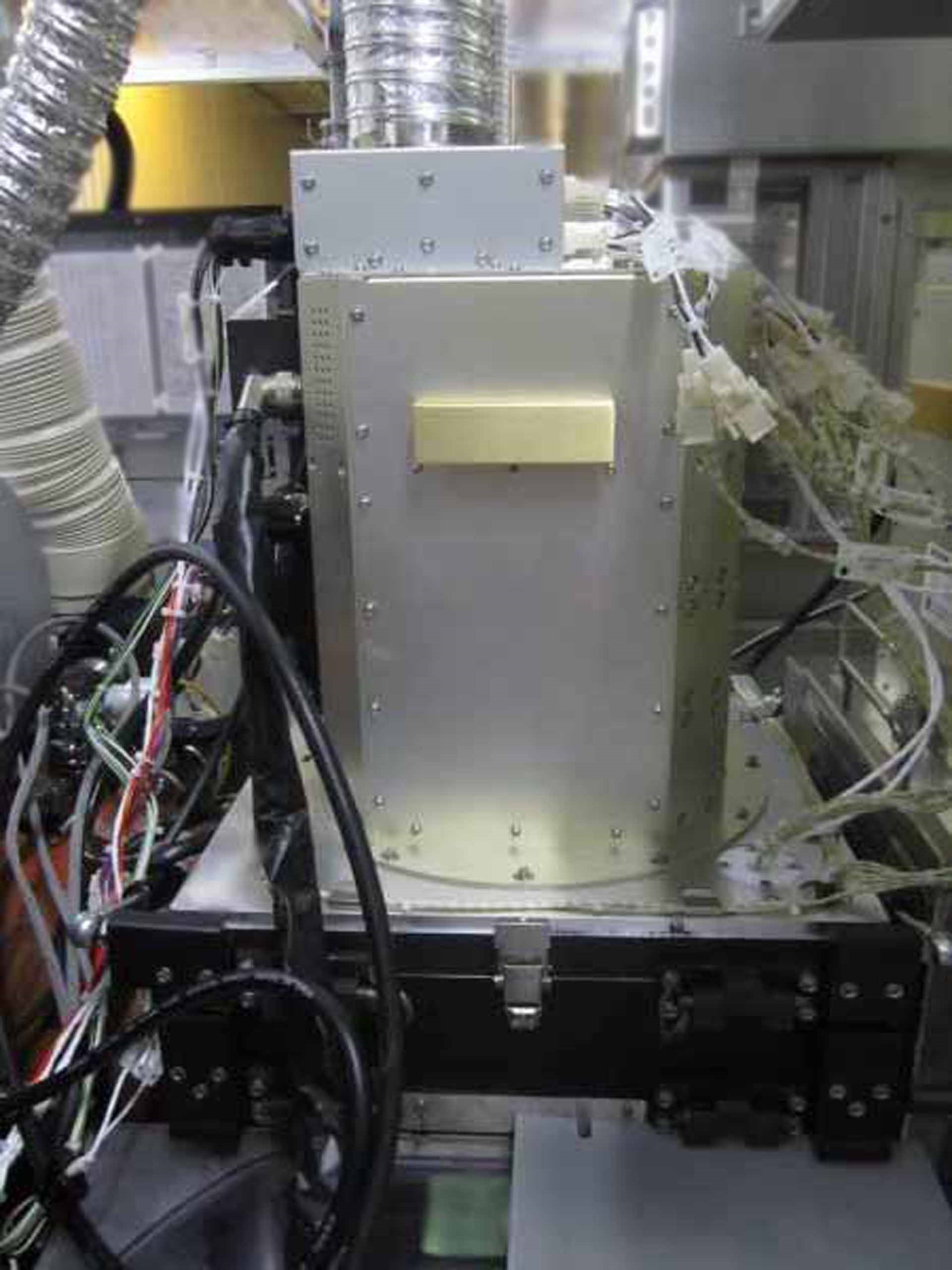

SBC Board type: BOSS

Video board type: Floppy disk

VME Type: Hard disk controller slot

WPS Sensor

Slit valve: Mini controller

Robot type: Cassette handler

STO Elevator type: I/O Wafer sensor

EPD Exhaust line

RF Match: L/L Purge, L/L slow vent

RF Generator type: P/C Metal etcher

(8) Motor drivers

CPU

TAITEC CH-800B H/E Chiller

Dry pump

Gauge type: TC XLL Wafer sensor

Monitor

Gas panel

TCP

Top & bottom generator: ADVANCED ENERGY RFG 1250 Bias

Chamber A:

O2: 200 SCCM

CF4: 100 SCCM

O2: 2000 SCCM

H2O: 500 SCCM

CHF3: 20 SCCM

N2: 50 SCCM

CL2: 200 SCCM

BCL3: 200 SCCM

Turbo pump:

EDWARD SCU H1000C

EDWARD STP-1000

Standalone

Autoloader type

STP H1000 with TMP

Bottom match

Wafer shape: Flte

No SMIF interface

MF Facilities

APM Chamber

ELL Arm

Load port

GEM & SESC Interface

Cassette stage

XLL Arm

RF Generator

Chamber type: 9600

Chamber process: Metal

Manometer: 0.1 mT Millipore

Standard cooling water

Top & bottom RF match

Gate valve & Throttle valve: Pendulum valve

STP H-1000L Turbo controller

Standard 4-pin cylinder

EPD Controller: 703/261.8

Chamber gases:

Gases / MFC Size / Gas name / MFC Maker / MFC Model number

Gas 1 / 300 / N2 / AERA / FC-780C

Gas 2 / 200 / N2 / AERA / FC-780C

Gas 3 / 50 / N2 / AERA / FC-780C

Gas 6 / 3000 / N2 / AERA / FC-780C

Gas 7 / 200 / N2 / AERA / FC-780C

Gas 8 / 200 / N2 / AERA / FC-780C

Missing parts:

VDS

Side covers

DSQ Chamber

APM Chuck motor

DI Nozzle

WVDS

Includes:

AC Rack

Cable

Signal cable box

Power: 208V

1996 vintage.

LAM RESEARCH TCP 9600 SE etcher/asher is an advanced wafer etching and ashing equipment, used in the semiconductor fabrication process. It offers a variety of etching and ashing processes, ranging from UV etching to alkaline etching, enabling users to fabricate a wide range of semiconductor devices. The system is designed to be highly user-friendly, featuring intuitive user interfaces and quick controls for process setup. LAM RESEARCH TCP 9600SE utilizes a three-dimensional electrostatic chuck (ESC) to achieve uniform distribution of etching gas and uniform etch uniformity across the wafer surface. This results in highly precise etching and ashing, ensuring that products are produced with the highest possible quality and yield. The high-resolution pins used in the electrostatic chuck helps to ensure the uniform distribution of etch gas and the controlled temperature of the substrate, necessary for precise etching and ashing. TCP 9600 SE comes with a built-in controller, which simplifies the process setup and allows users to quickly select appropriate parameters such as etch rate, substrate, etch pressure, and etch gas composition. Moreover, the unit is equipped with a high-speed motors, enabling users to achieve superior etch uniformity while reducing process time. In addition, the machine features an auto-cleaning function, which automatically cleans the wafer during the process, eliminating particulate and other contaminants from the product. In addition to its efficient etching and ashing capabilities, TCP 9600SE offers a range of additional features, such as a modular design, allowing users to customize their process setup to their own requirements. Moreover, its enhanced thermal management features help to ensure that substrate temperatures are carefully monitored and remain within safe limits throughout the process. Overall, LAM RESEARCH TCP 9600 SE is an advanced etching and ashing tool, offering an intuitive user interface, highly precise etching, and enhanced thermal management. The asset's modular design and enhanced automation allows users to easily customize the process to their own requirements, while its fast speed and auto-cleaning functions help ensure that the highest possible product quality is achieved.

There are no reviews yet