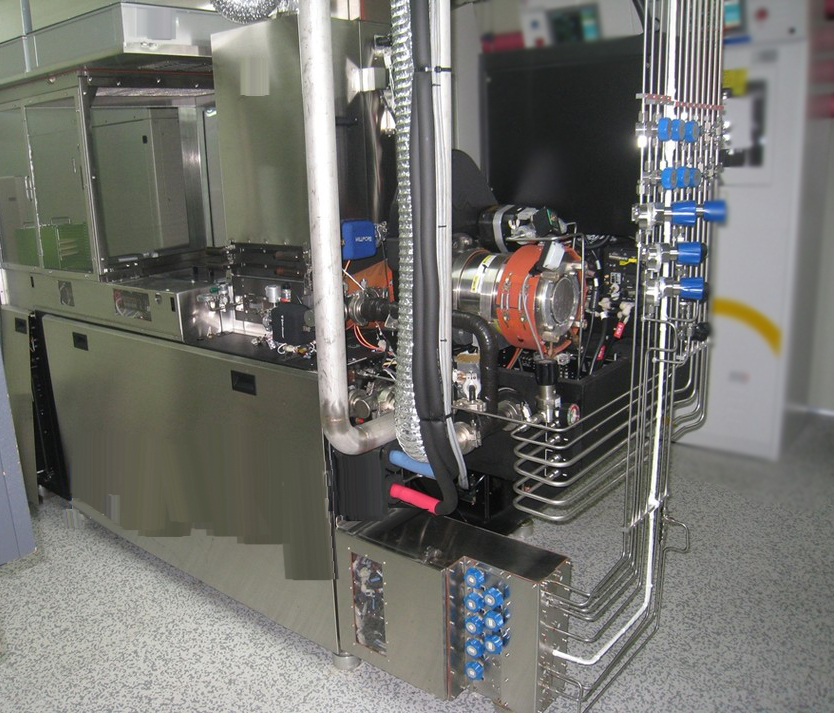

Used LAM RESEARCH TCP 9600 #9098467 for sale

URL successfully copied!

Tap to zoom

ID: 9098467

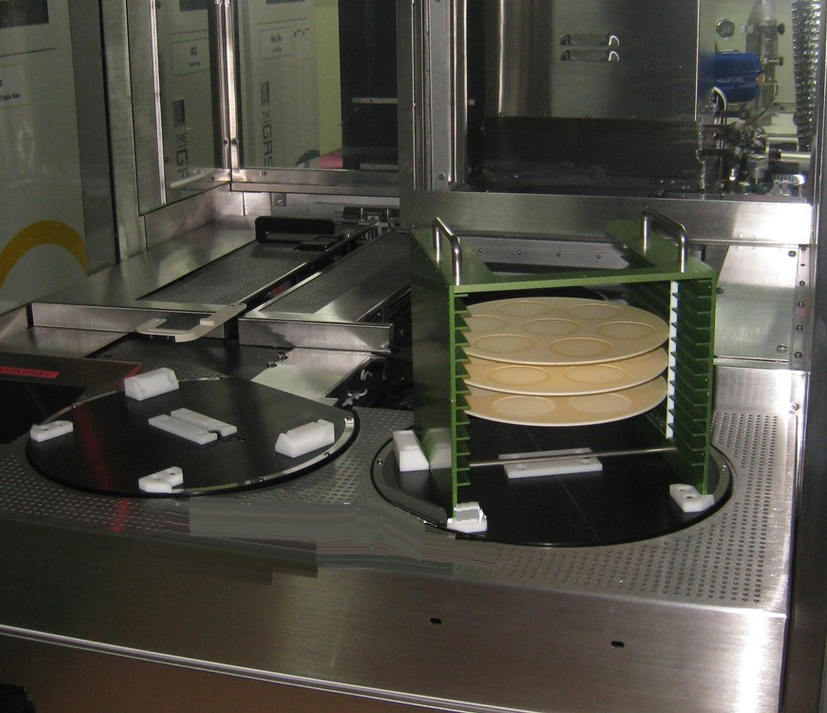

Wafer Size: 6-8"

Vintage: 2010

Etcher, 6-8"

Wafer type: flat (single type chamber)

Loading capacity on 1 process run: (7) sheets X 2” wafer available (GaN process)

Creates plasma on the order of 10e11 - 10e12 ions/cm3

Operating in pressure regime of 1-20 mtorr

Etch rates of 3,000 to 10,000 A/min

2010 vintage.

LAM RESEARCH TCP 9600 is a high-tech dry etcher / asher equipment designed for semiconductor processing applications such as etching, sputtering and thin film deposition. The system uses two ion sources for etching and depositing thin films, one for sputtering, and a heated chuck for sample preparation. The etcher / asher has a vacuum chamber with a base pressure of 5.0 x 10-7 torr, and provides a uniform low pressure throughout the unit. It is a large machine, with eight-foot chamber depth, accommodating multiple wafer configurations up to six-inch wafers in diameter. The tool is designed with an embedded High Performance Process Control (HPPC) asset. This model automates the control of the chamber components and the control of several additional process parameters. It allows users to perform advanced process development, programming, and control of the chamber process and plasma conditions. LAM RESEARCH TCP9600's advanced energy particle control (EPC) provides independent power control to both etching and sputtering sources. This provides optimization of each source independently, while also providing improved process uniformity and high density plasma. The equipment is also designed with a precision alignment system (PAS) for the etching and sputtering sources. This allows for accurate alignment of the sources for the highest throughput possible. With the PAS, the chamber can maintain maximum throughput in constant and shallow etching applications. In addition, TCP-9600 includes a real-time monitoring and reporting unit for the entire chamber, which provides real-time feedback and utilization analysis to allow for process optimization. The machine also has an engineer's package, which includes a full range of process recipes, templates and models. TCP 9600 has been designed to offer extreme process flexibility and uniformity. Its advanced energy particle control and precision alignment systems provide high-quality etch and sputter processes, while its real-time monitoring and reporting systems provide the user with constant feedback. The tool provides a reliable solution for semiconductor processing applications and is ideal for users who require maximum process flexibility and uniformity.

There are no reviews yet