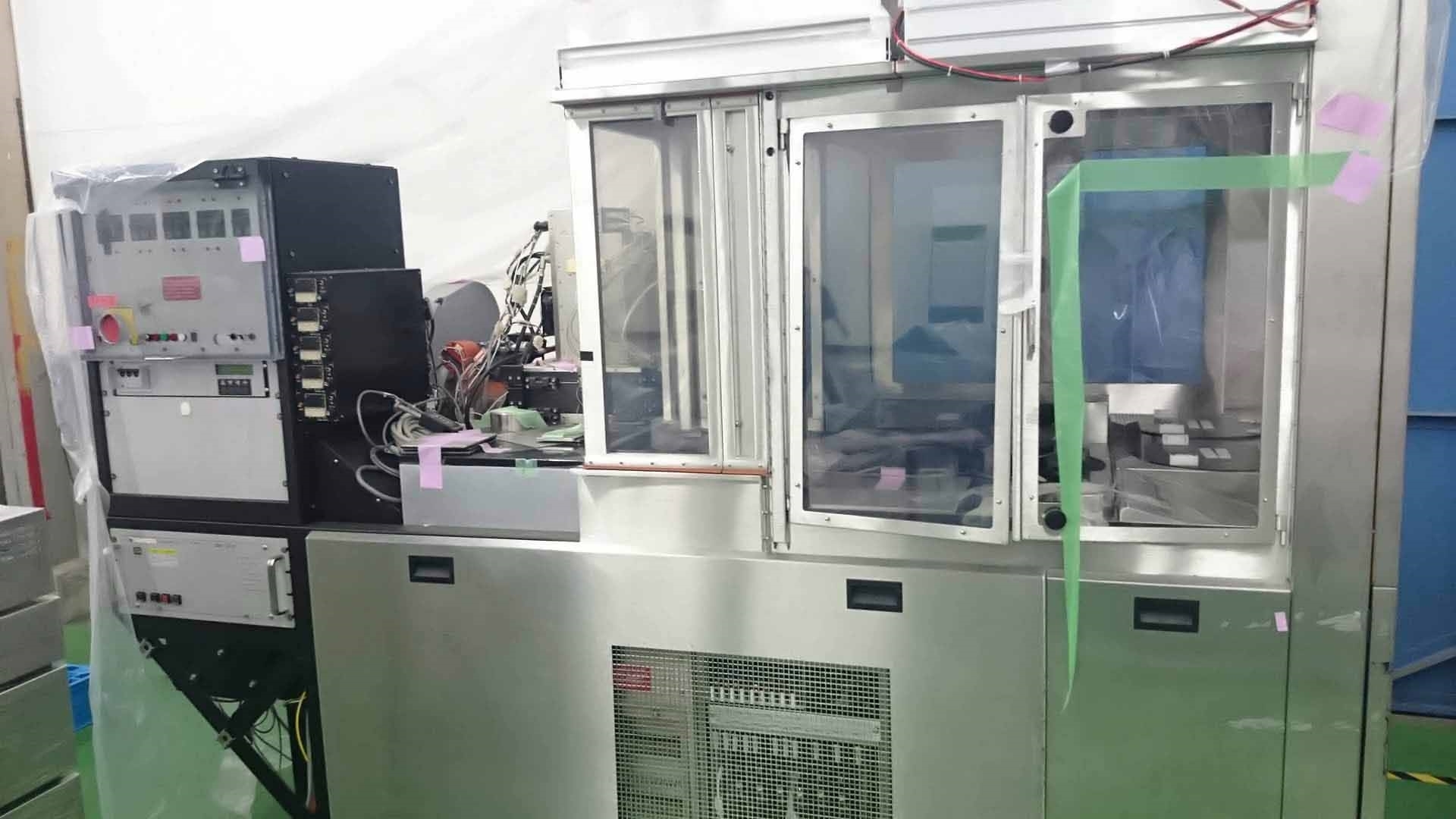

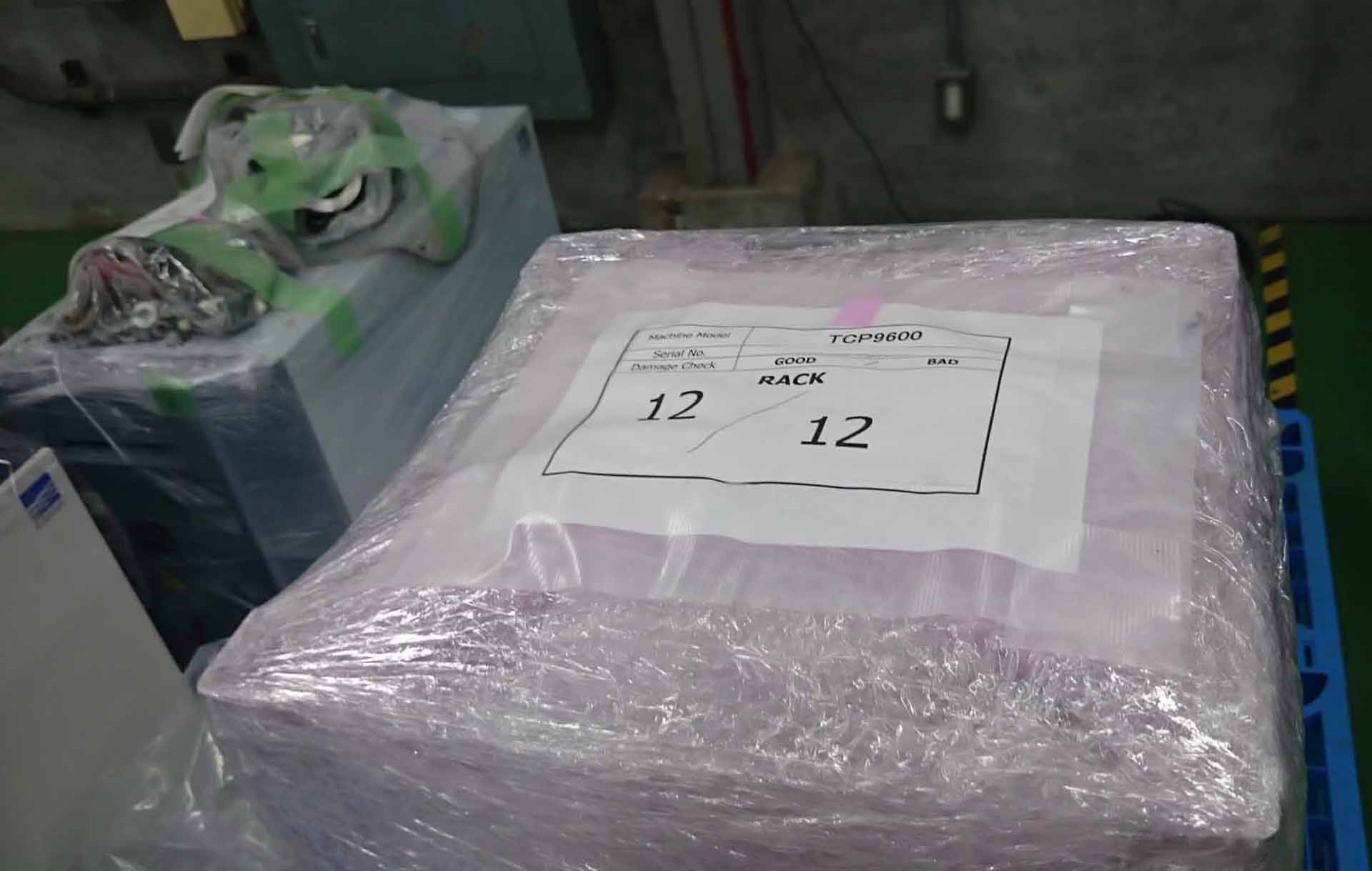

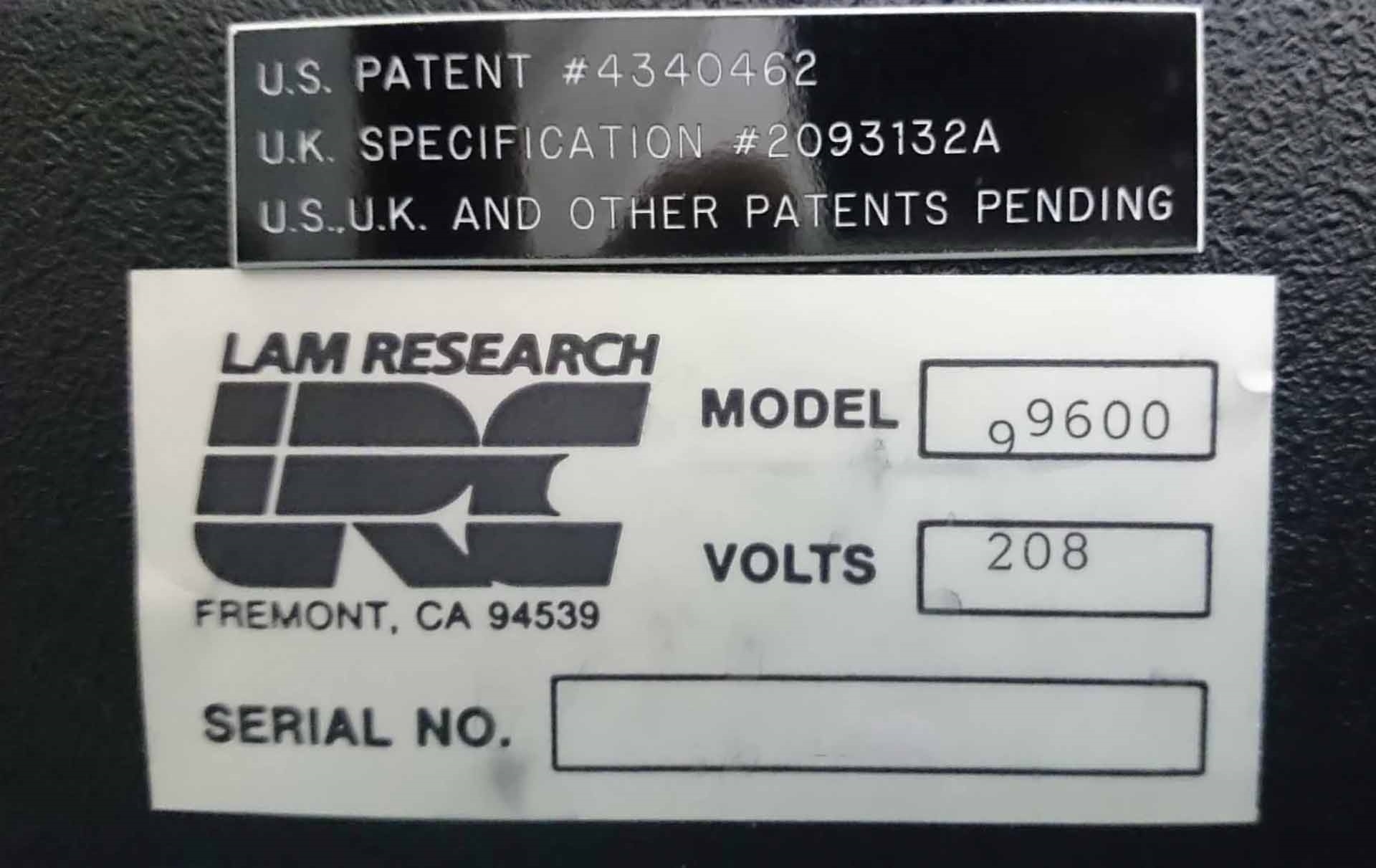

Used LAM RESEARCH TCP 9600 #9225269 for sale

URL successfully copied!

Tap to zoom

ID: 9225269

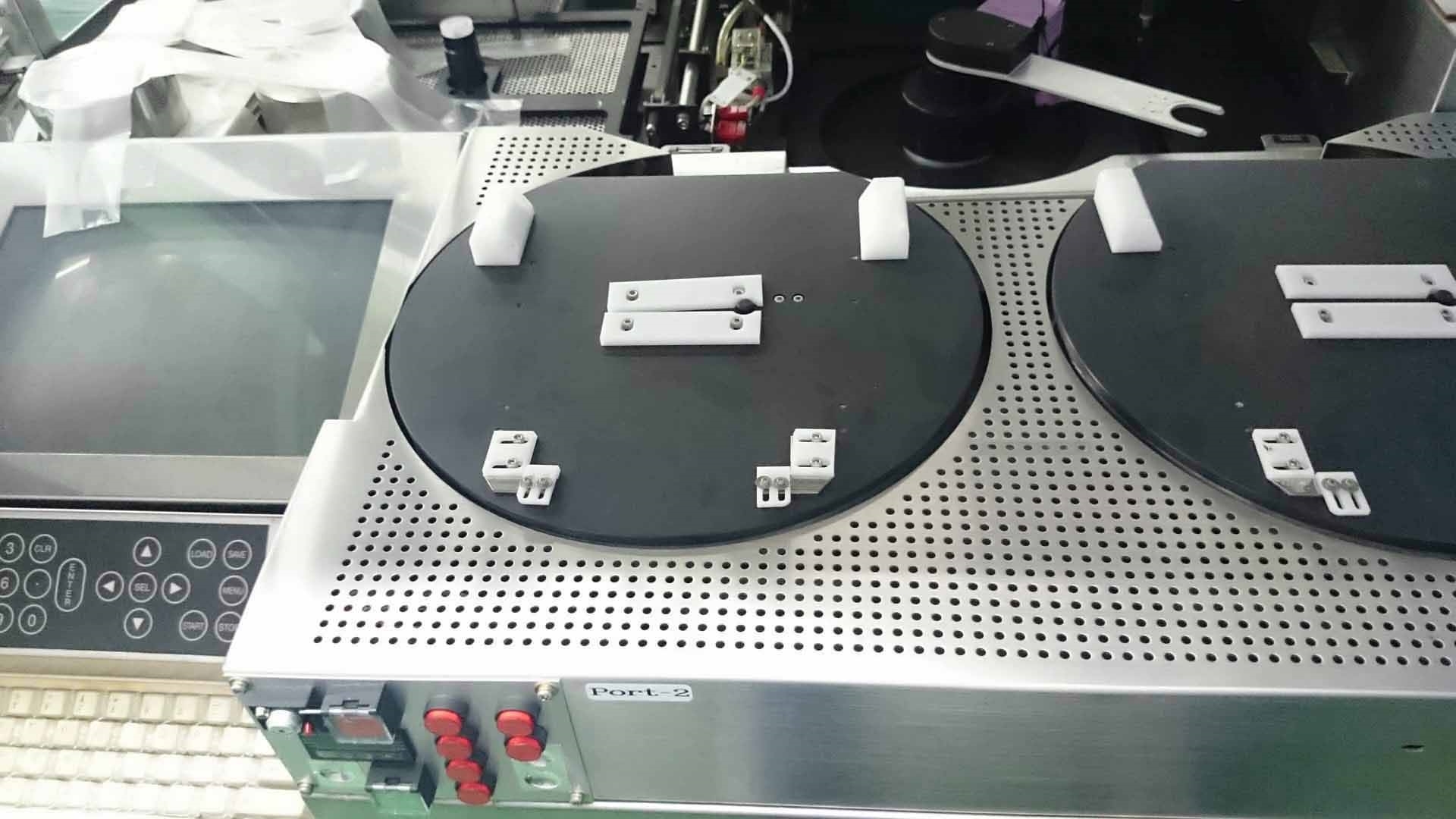

Wafer Size: 8"

Vintage: 1998

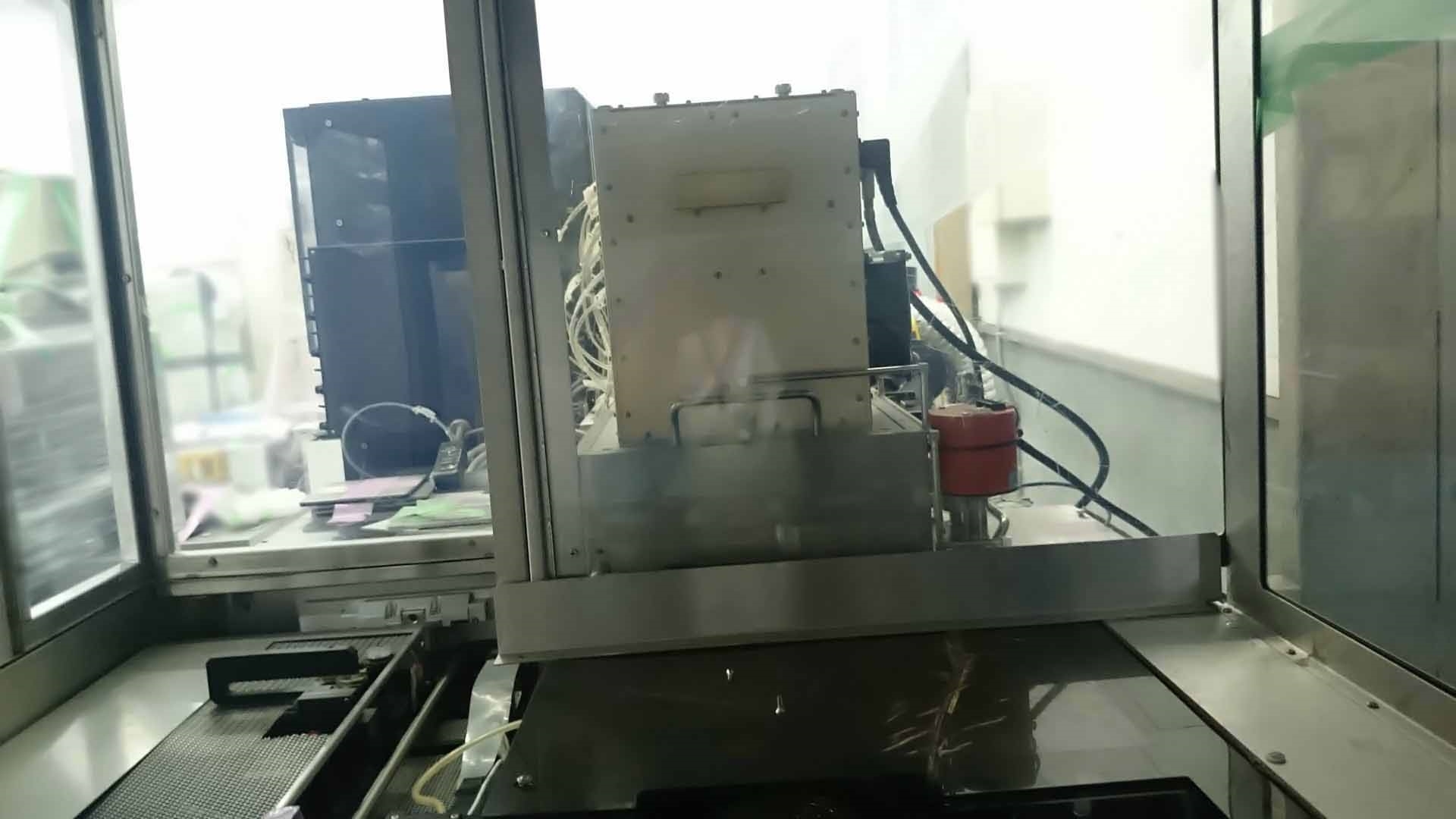

Metal etcher, 8"

Includes:

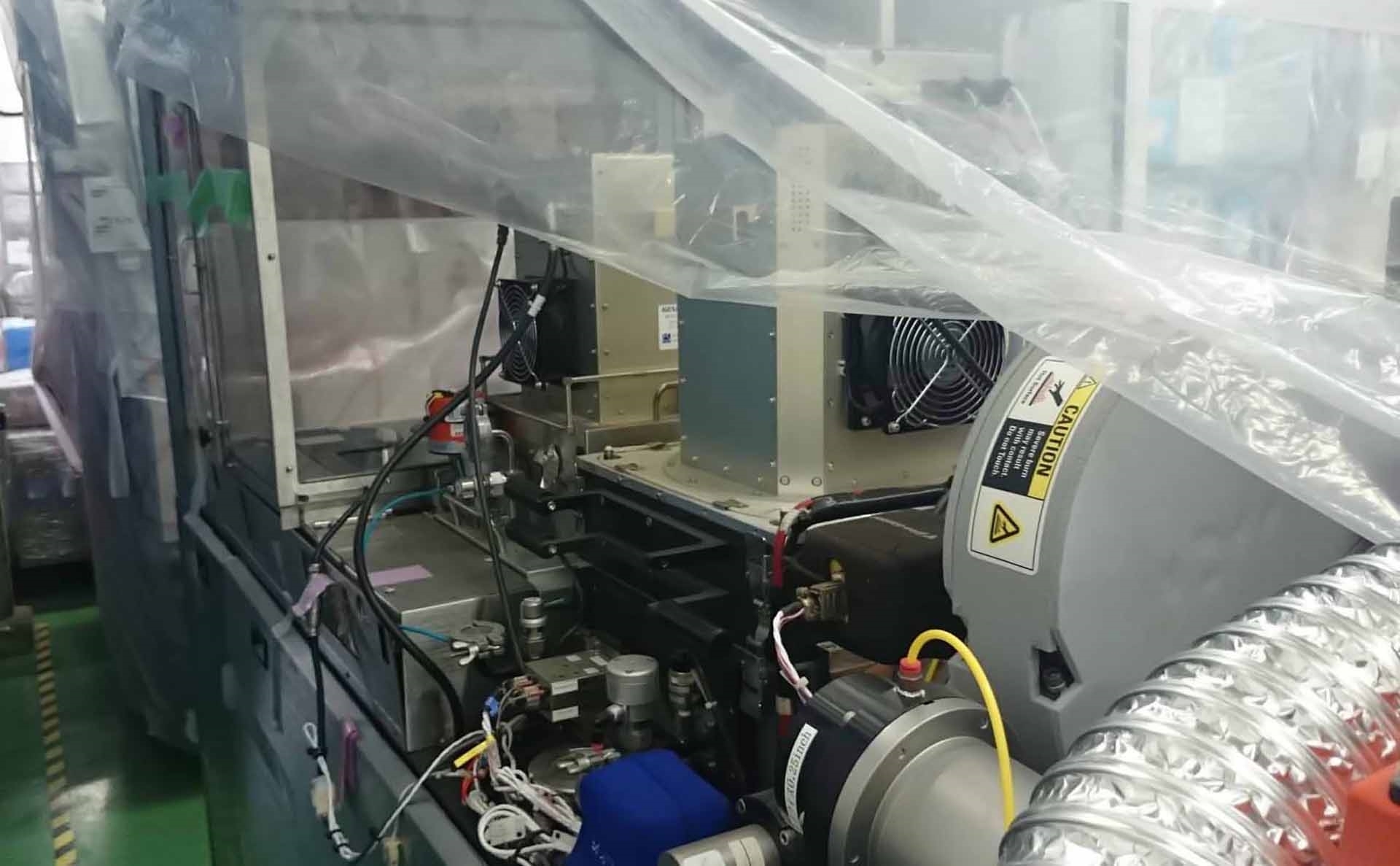

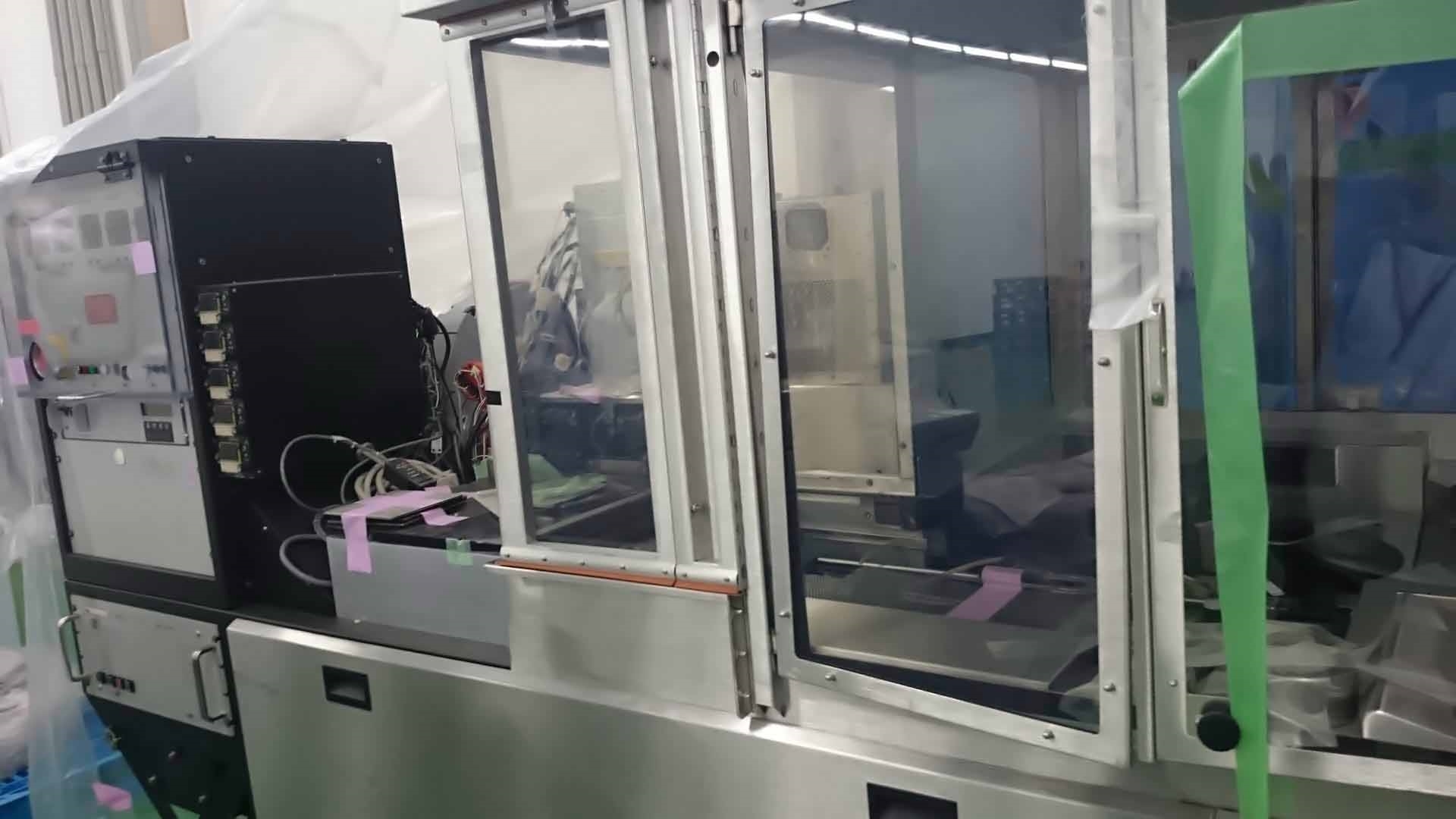

Main body

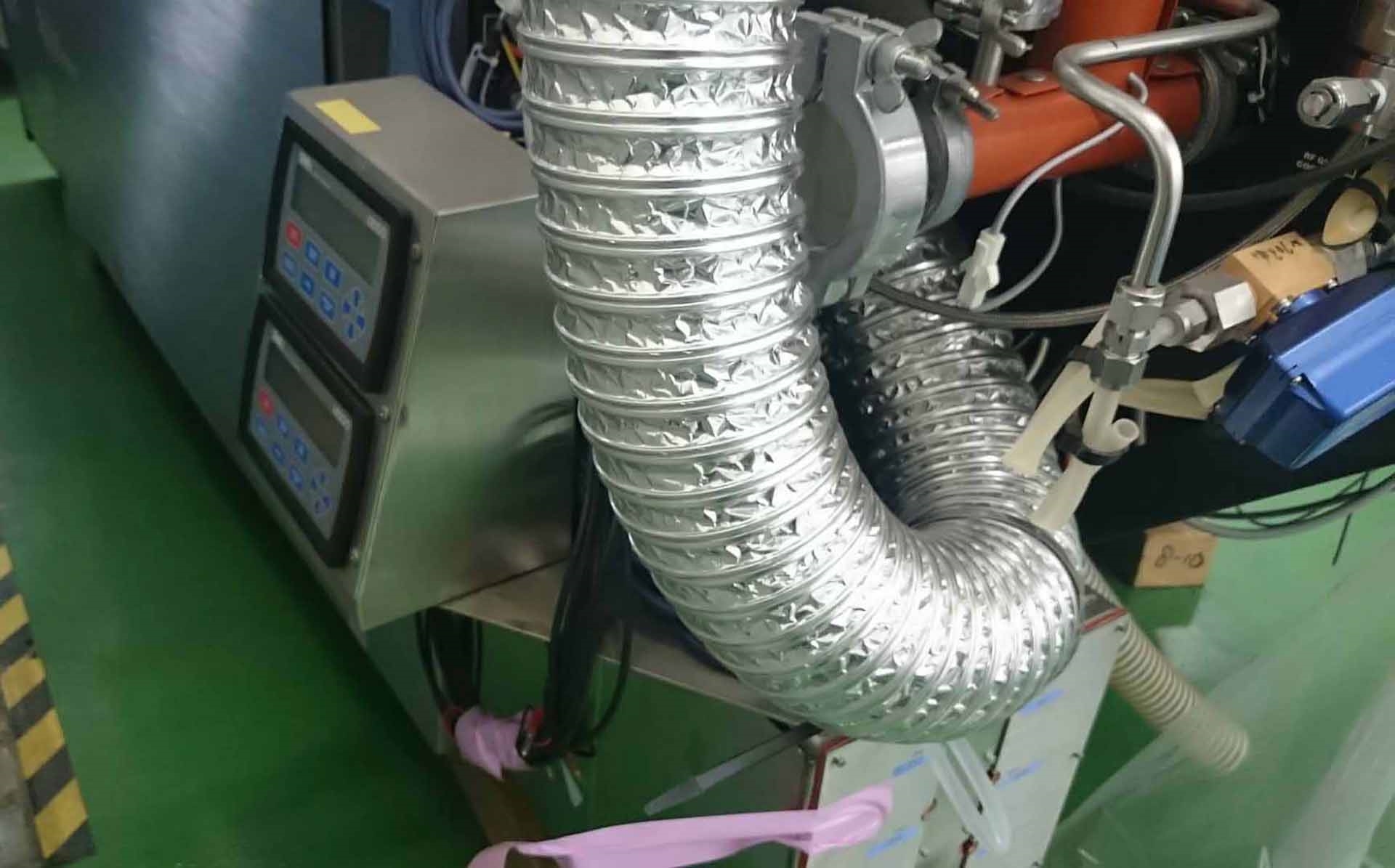

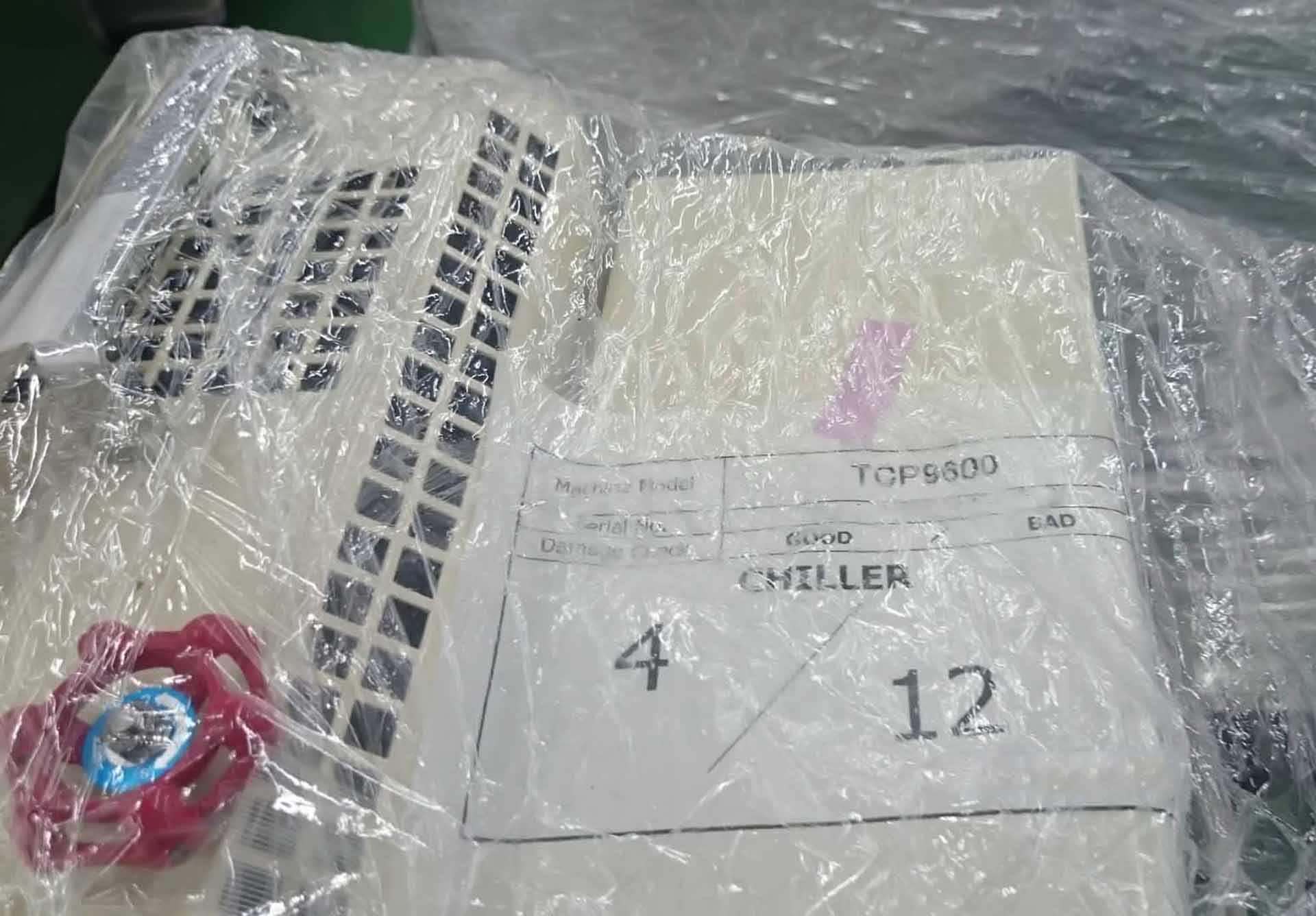

Chiller

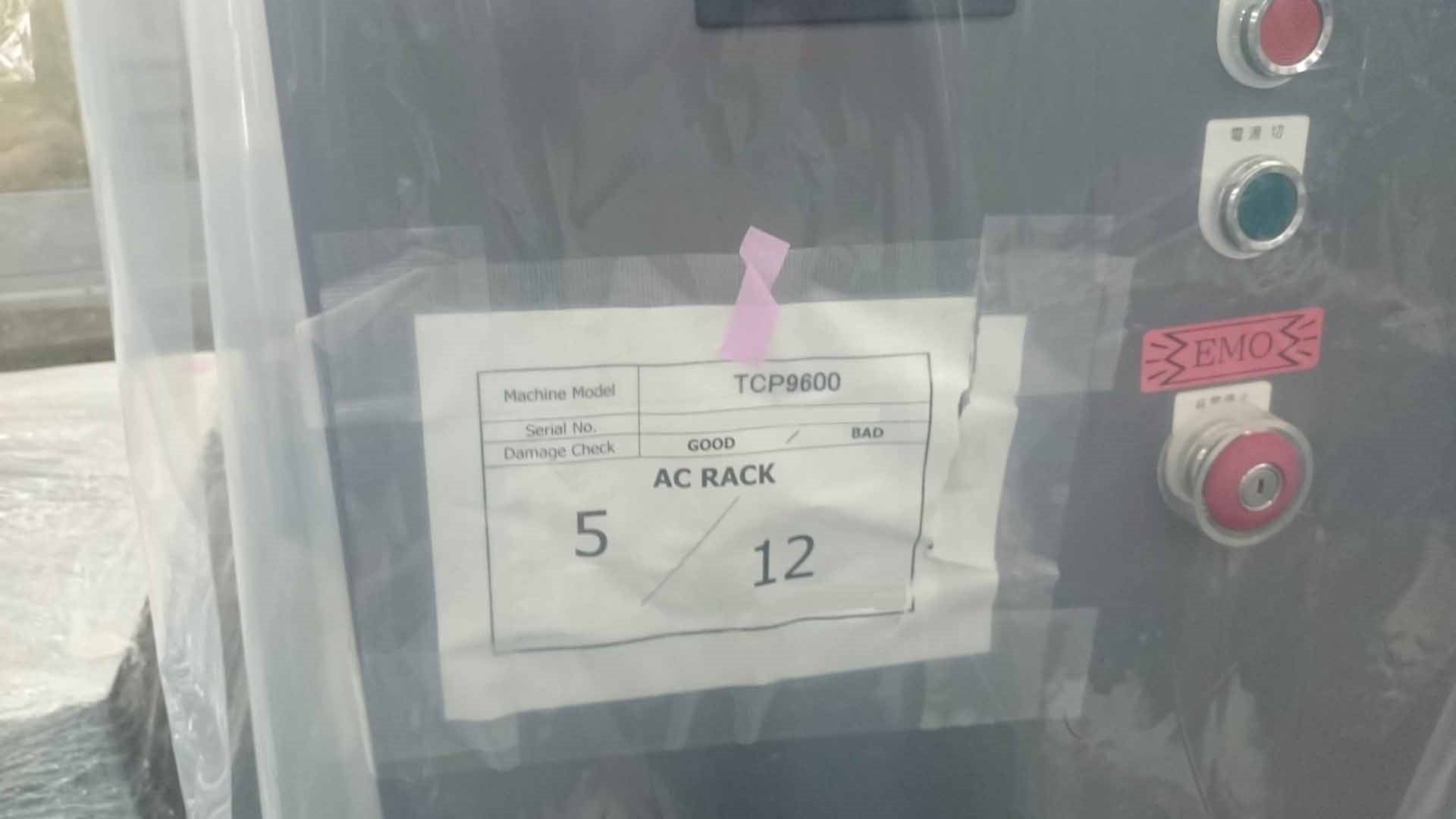

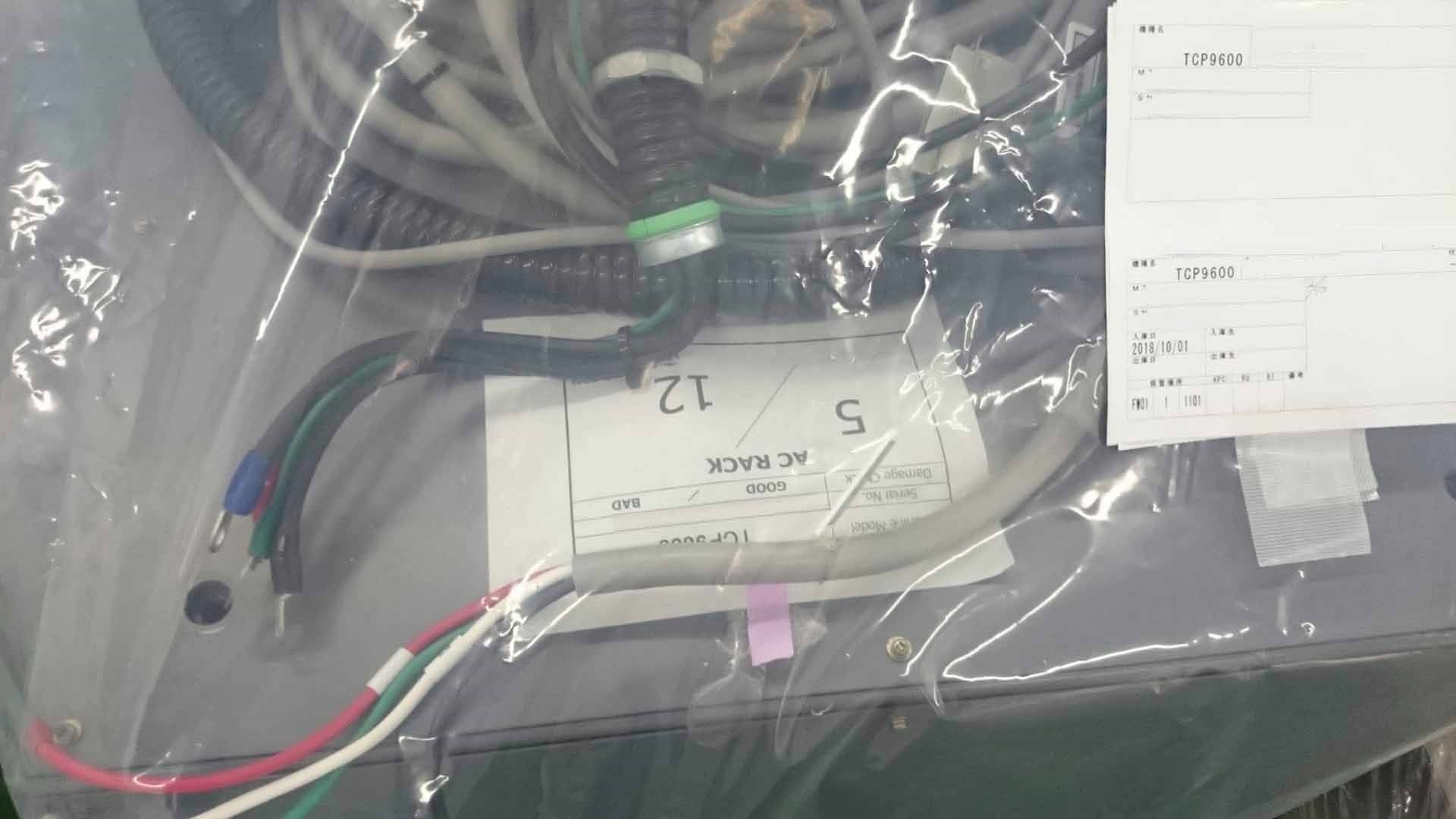

AC Rack

Rack

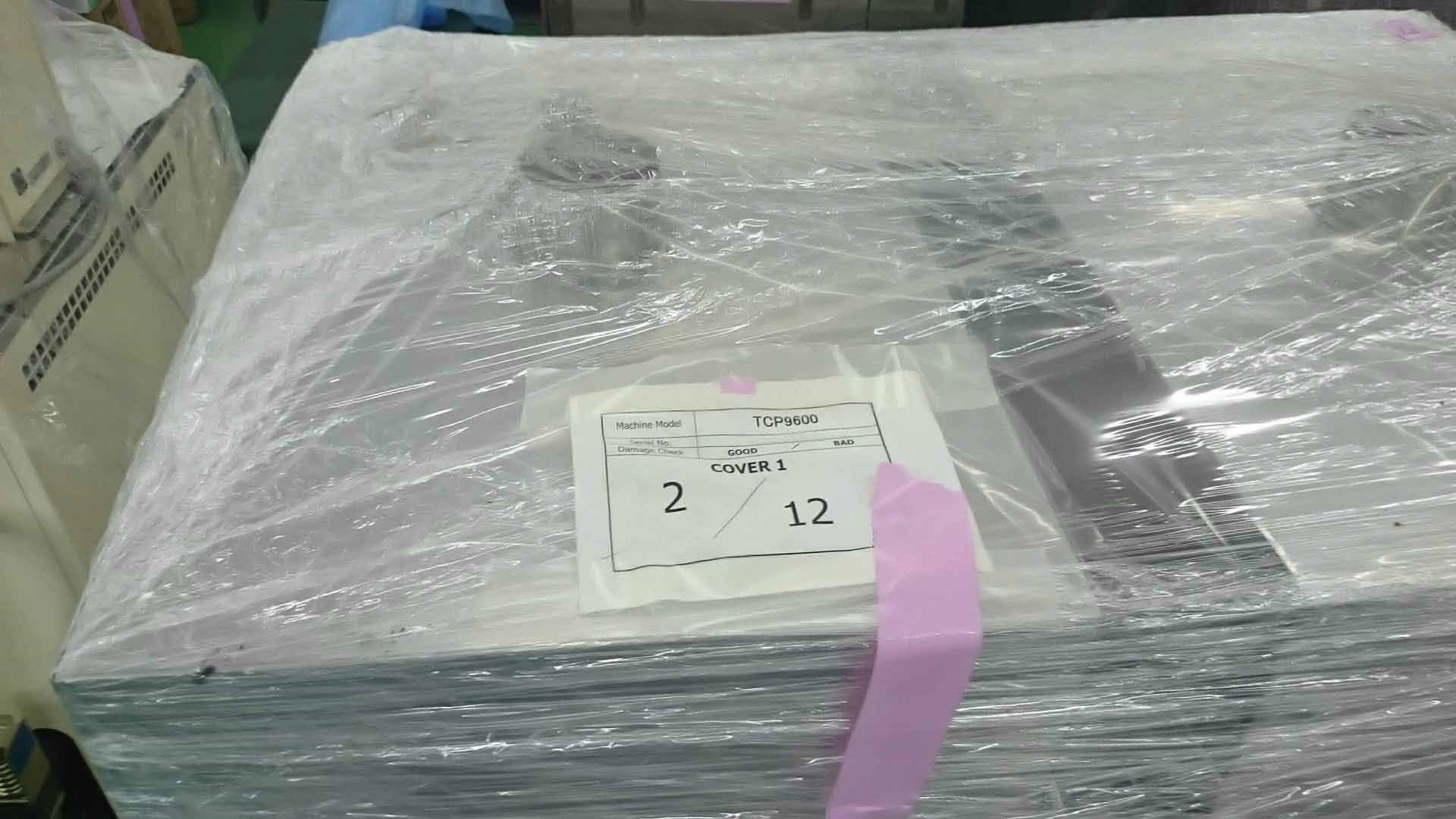

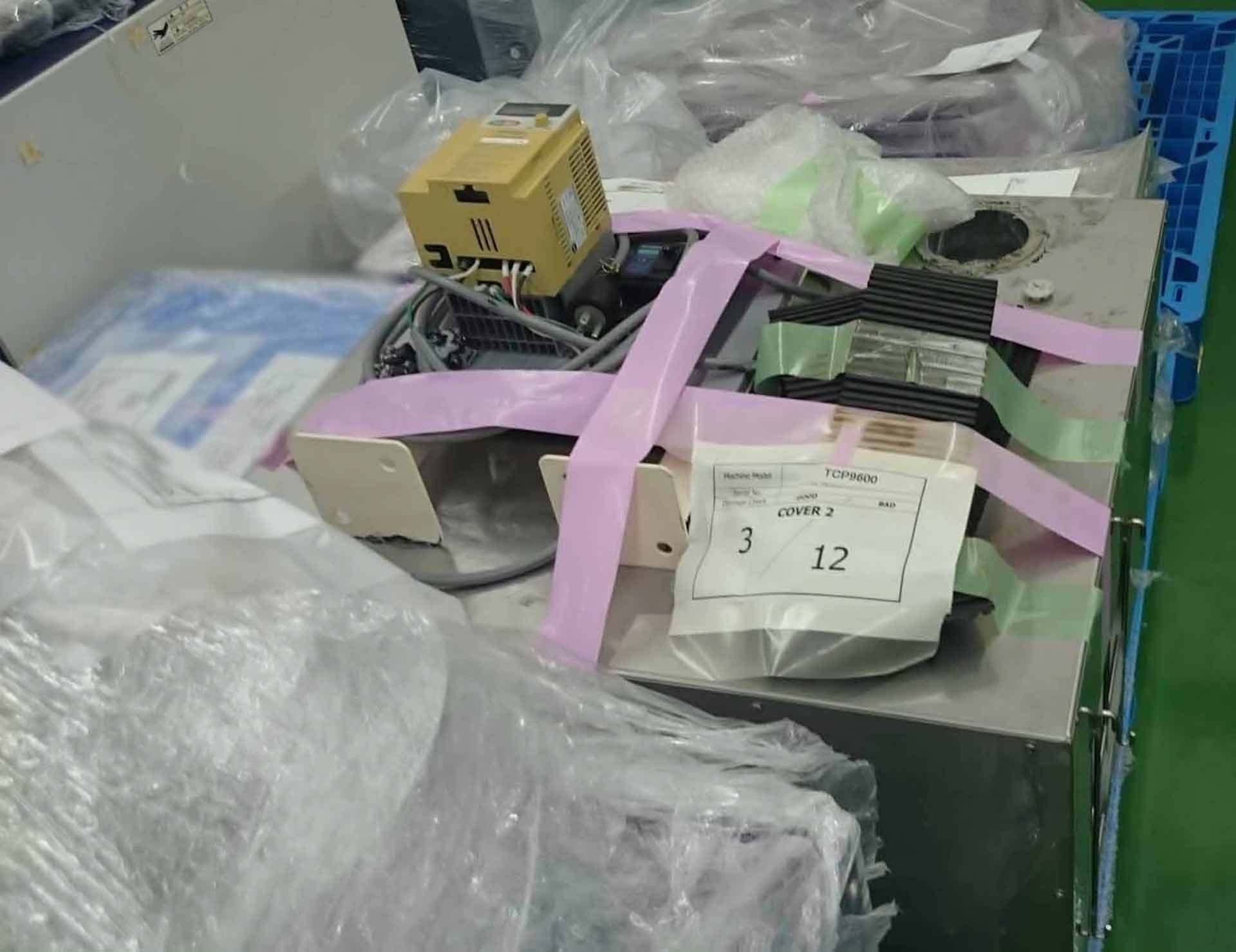

(2) Covers

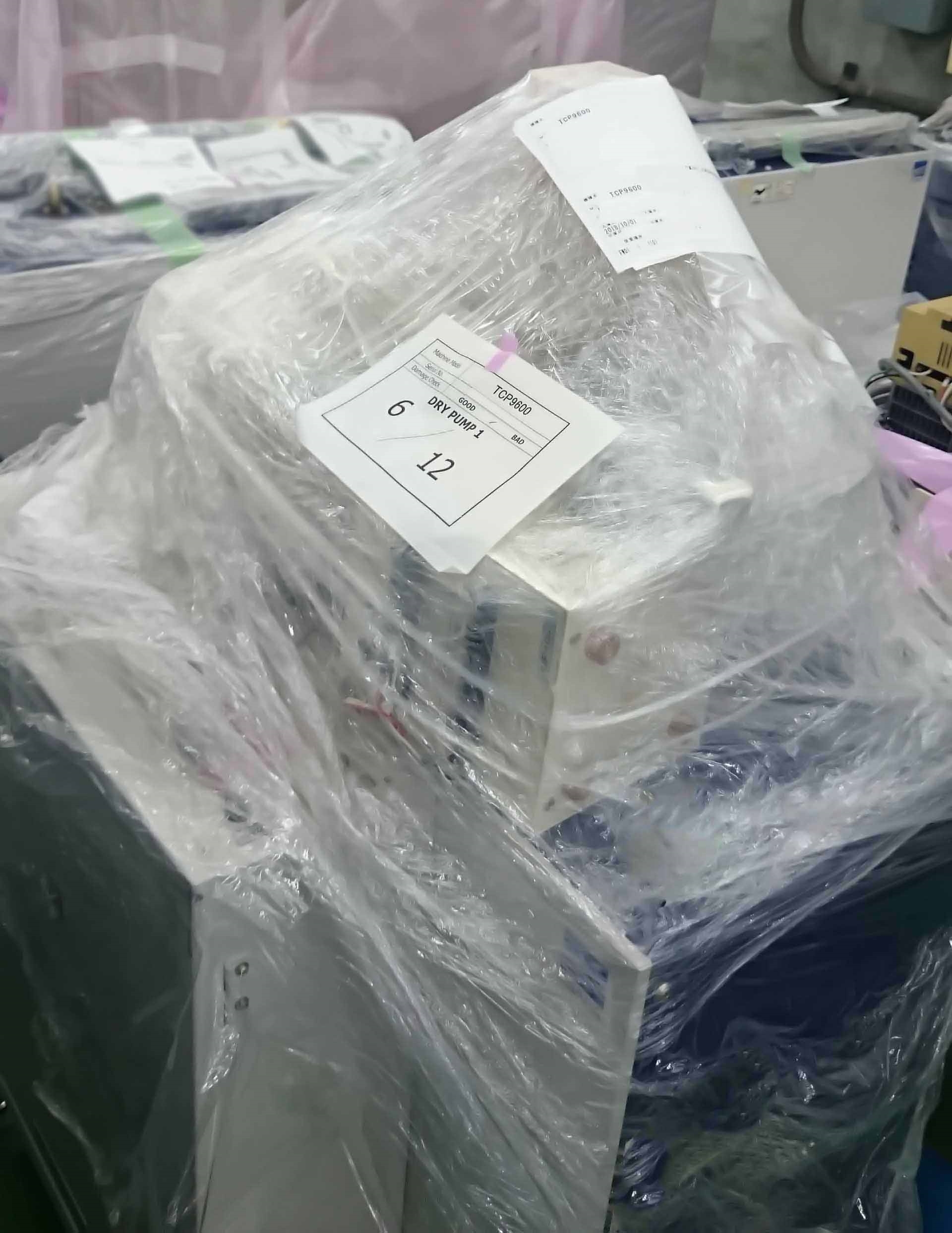

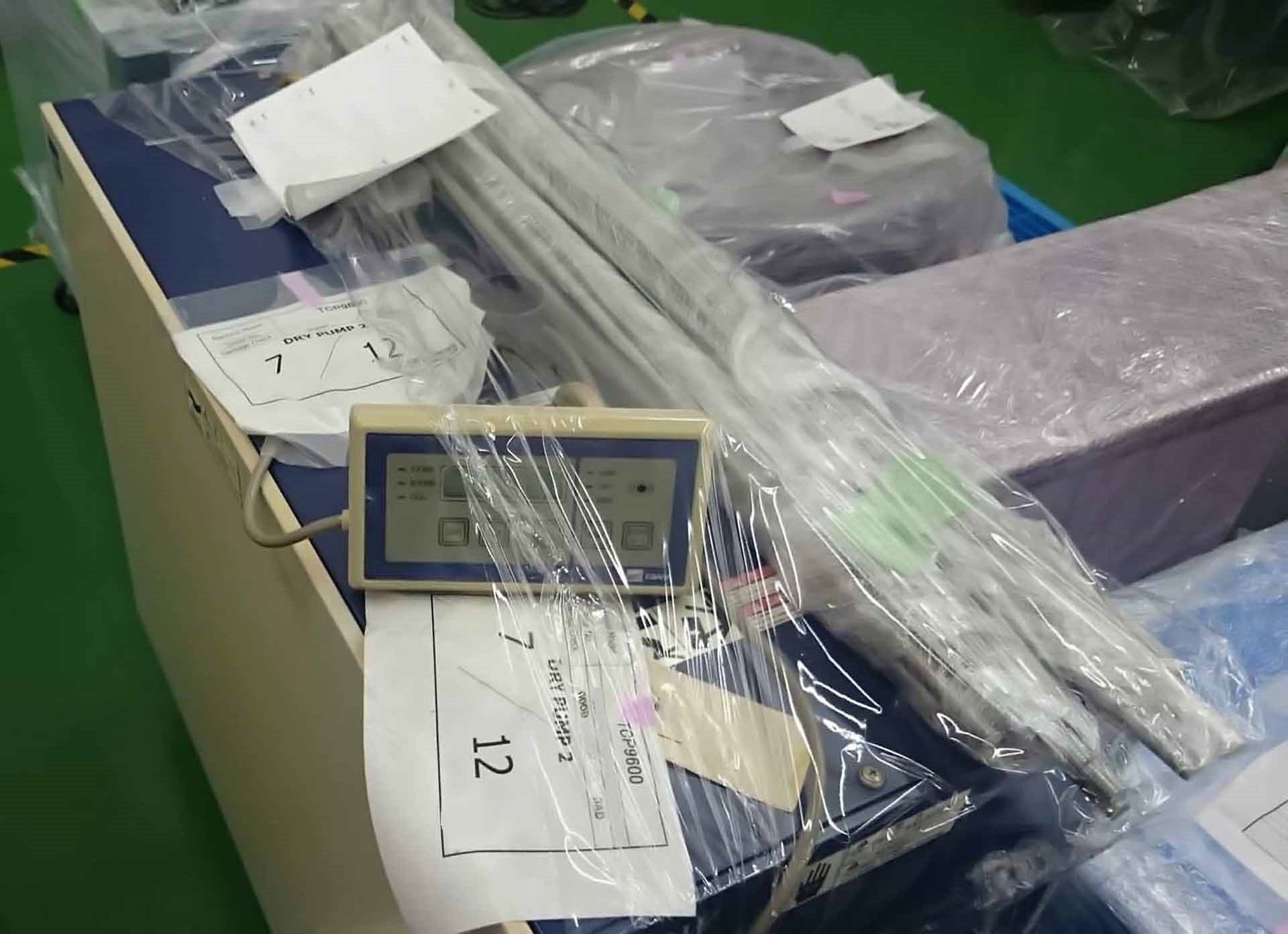

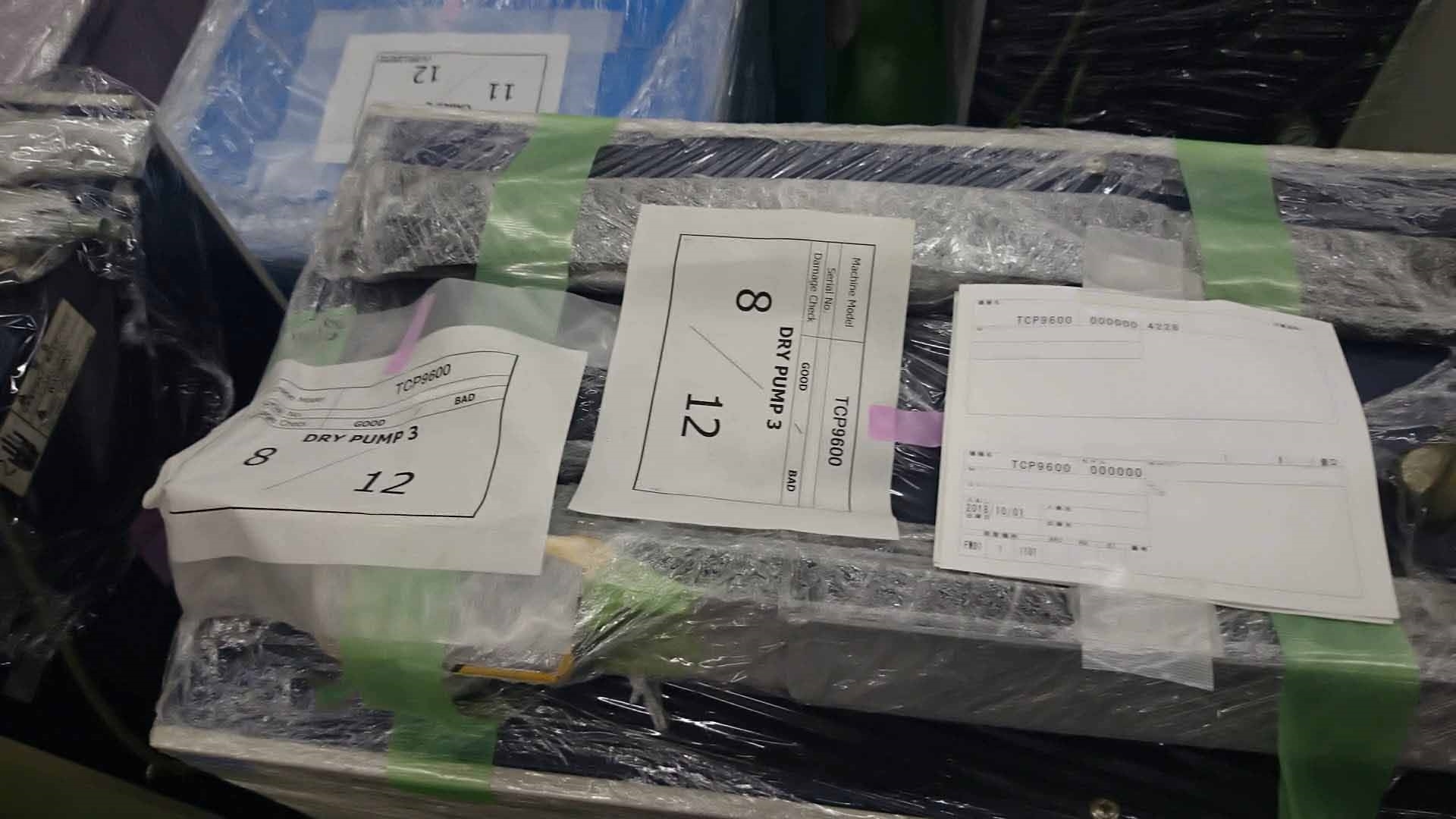

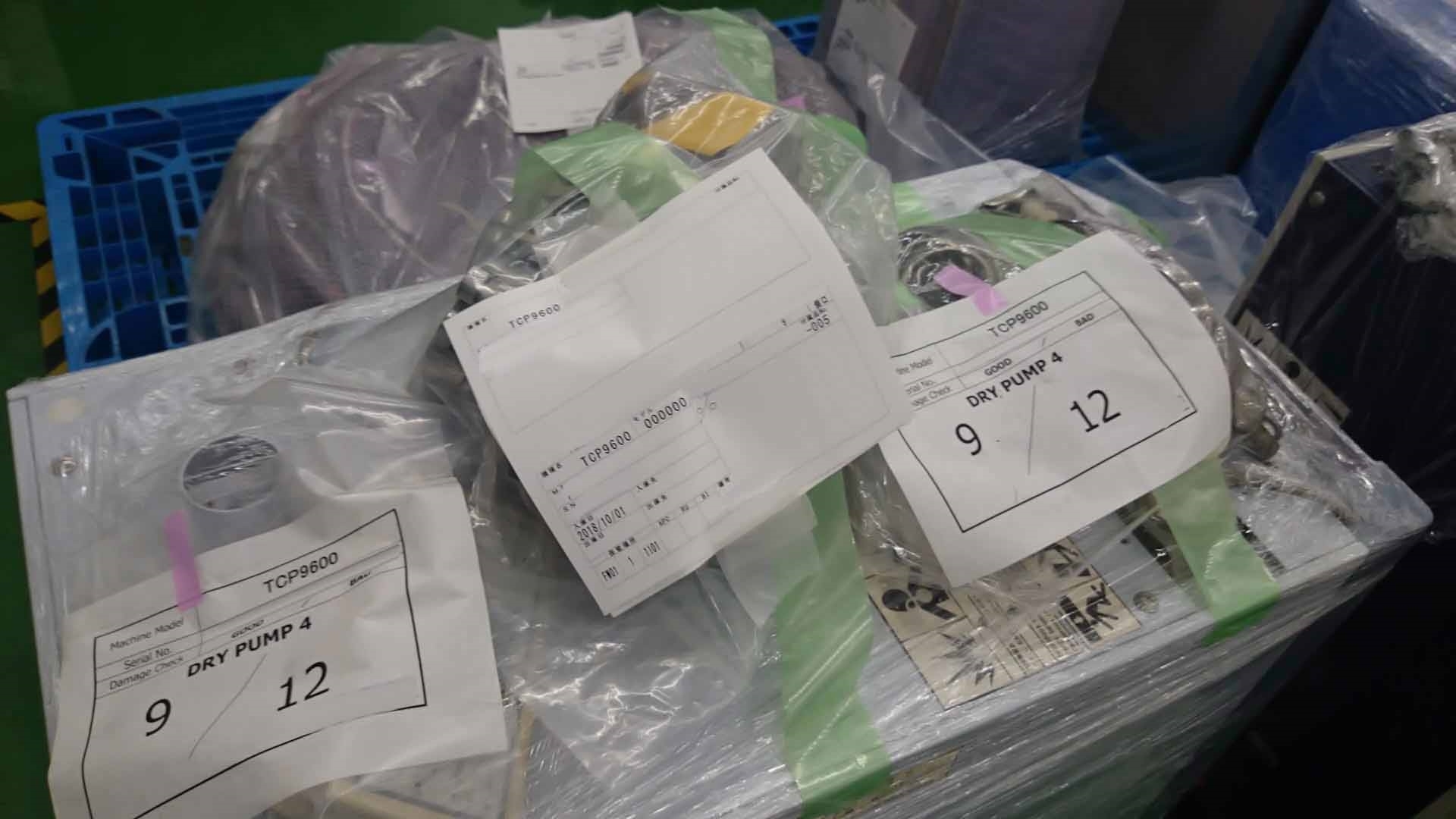

(4) Dry pumps

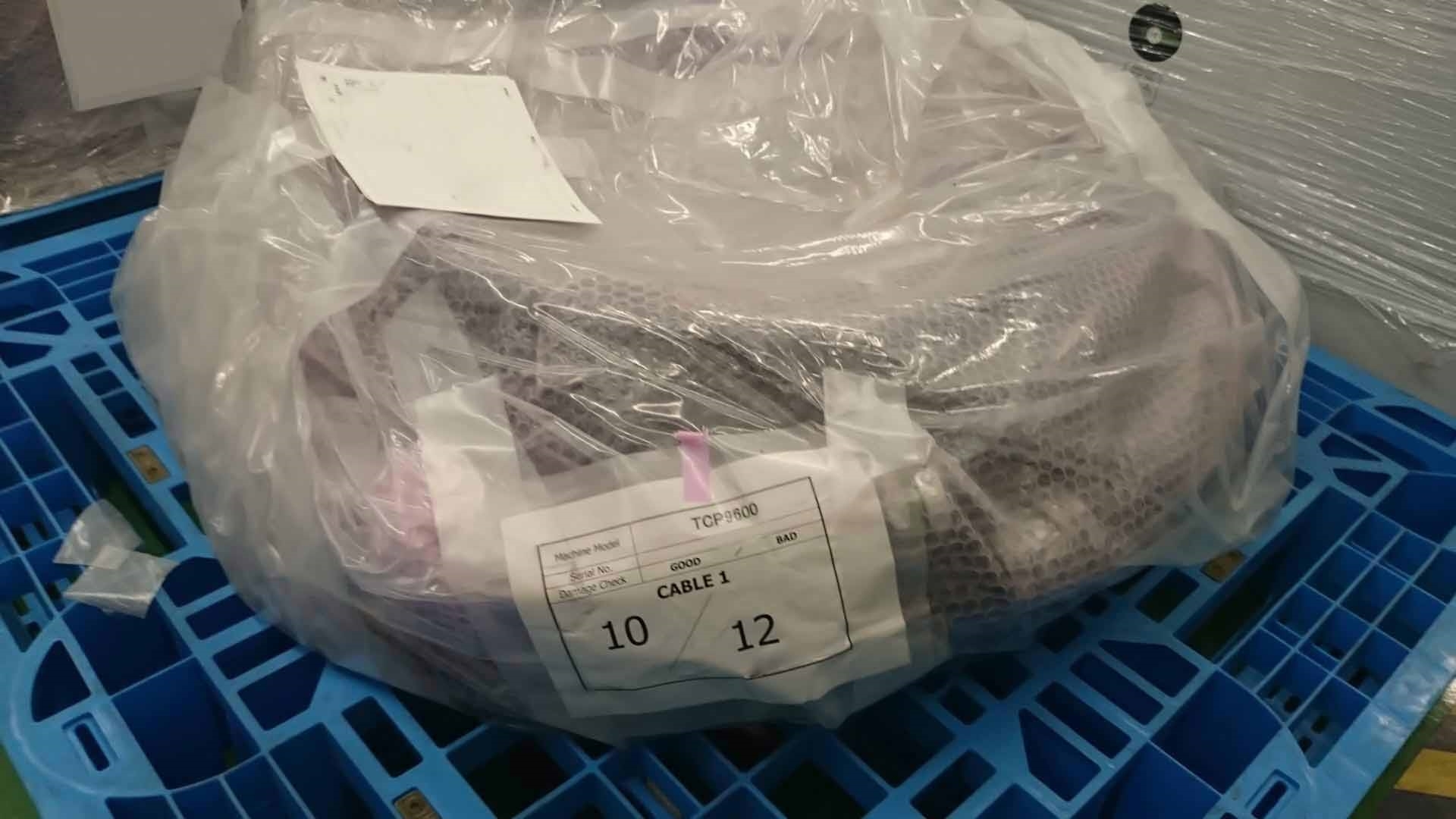

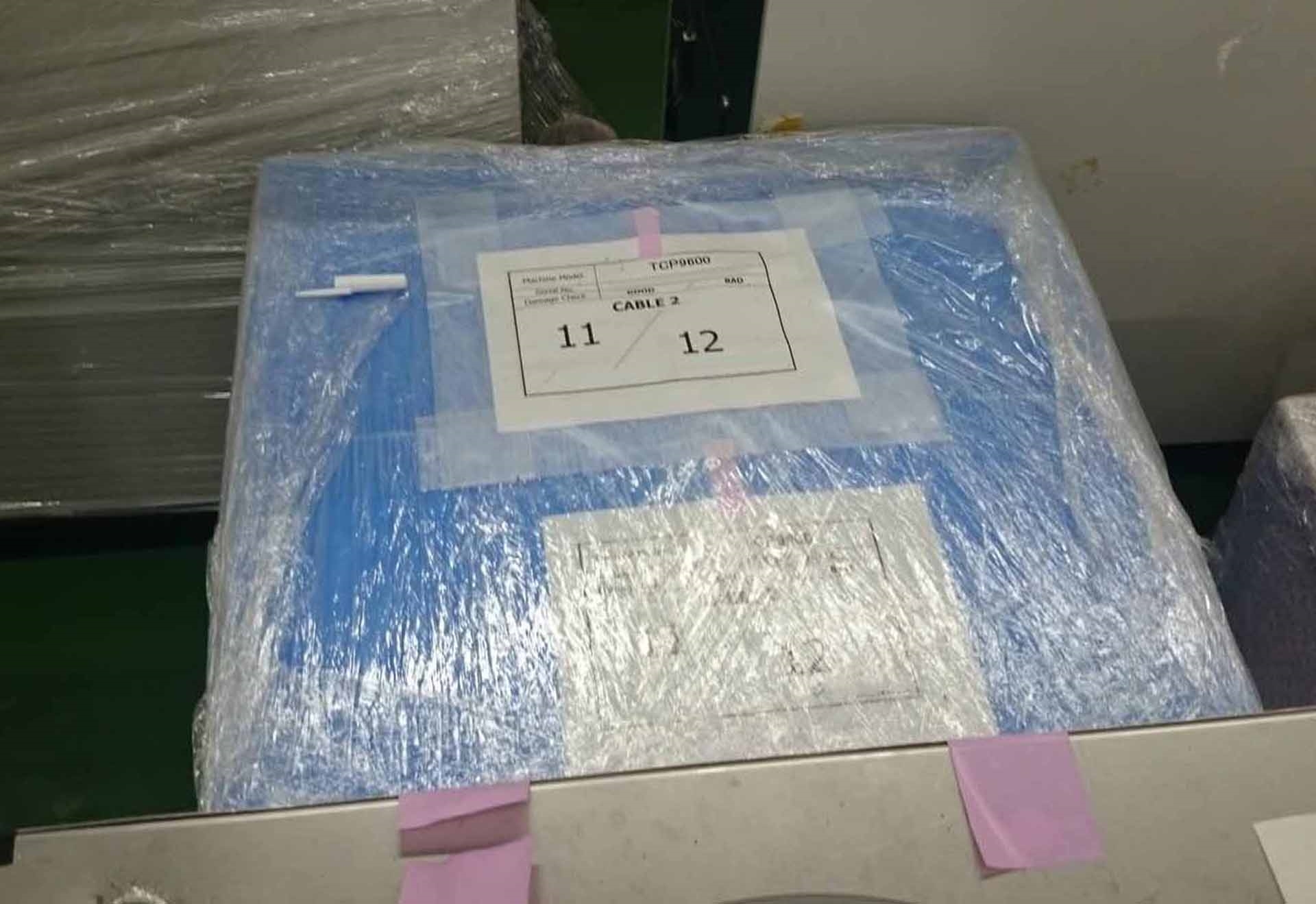

(2) Cables

1995 vintage.

LAM RESEARCH TCP 9600 is a precision Asher that is designed for high-volume manufacturing of advanced devices for the semiconductor industry. The equipment is a modular, tightly integrated platform with a variety of process capabilities. The tight integration of the different modules creates a robust process that minimizes maintenance and operational complexity. LAM RESEARCH TCP9600 utilizes optical alignment technology to ensure precise etching of aluminum, recessed oxide and sensitive feature geometries. The system has both wet and dry etching capabilities, allowing cost-effective processing of a variety of wafers up to 200 mm in diameter. Using two beam sources of both wave and electron excitation, TCP-9600 can precisely maintain the desired etch process marginal rate to within +/- 0.1 microns per hour. TCP9600 can handle up to 60 substrates simultaneously, allowing for flexible and customized processing. It utilizes Intellifex, an advanced unit architecture, to improve productivity by automatically optimizing etch rates and endpoint accuracy. The machine also features Total Process Control, a closed-loop tool that monitors process stability throughout the entire process. This offers the advantages of increased yield, improved throughput and consistent high-quality results. In addition to its high etch rate capability and accuracy, LAM RESEARCH TCP-9600 offers a variety of advanced technologies. It has the ability to perform multi-layer etching and deploys debris-mitigation techniques such as advanced film thickness control and vacuum cleaning asset. The model also includes a range of safety features, such as gas safety equipment and weld monitoring system, that provide further safeguards against hazardous conditions. In its entirety, TCP 9600 offers an efficient, high-precision and precise etching solution for the semiconductor manufacturing industry. The unit's advanced capabilities and safety systems make it ideal for high-volume processing of complex substrates.

There are no reviews yet