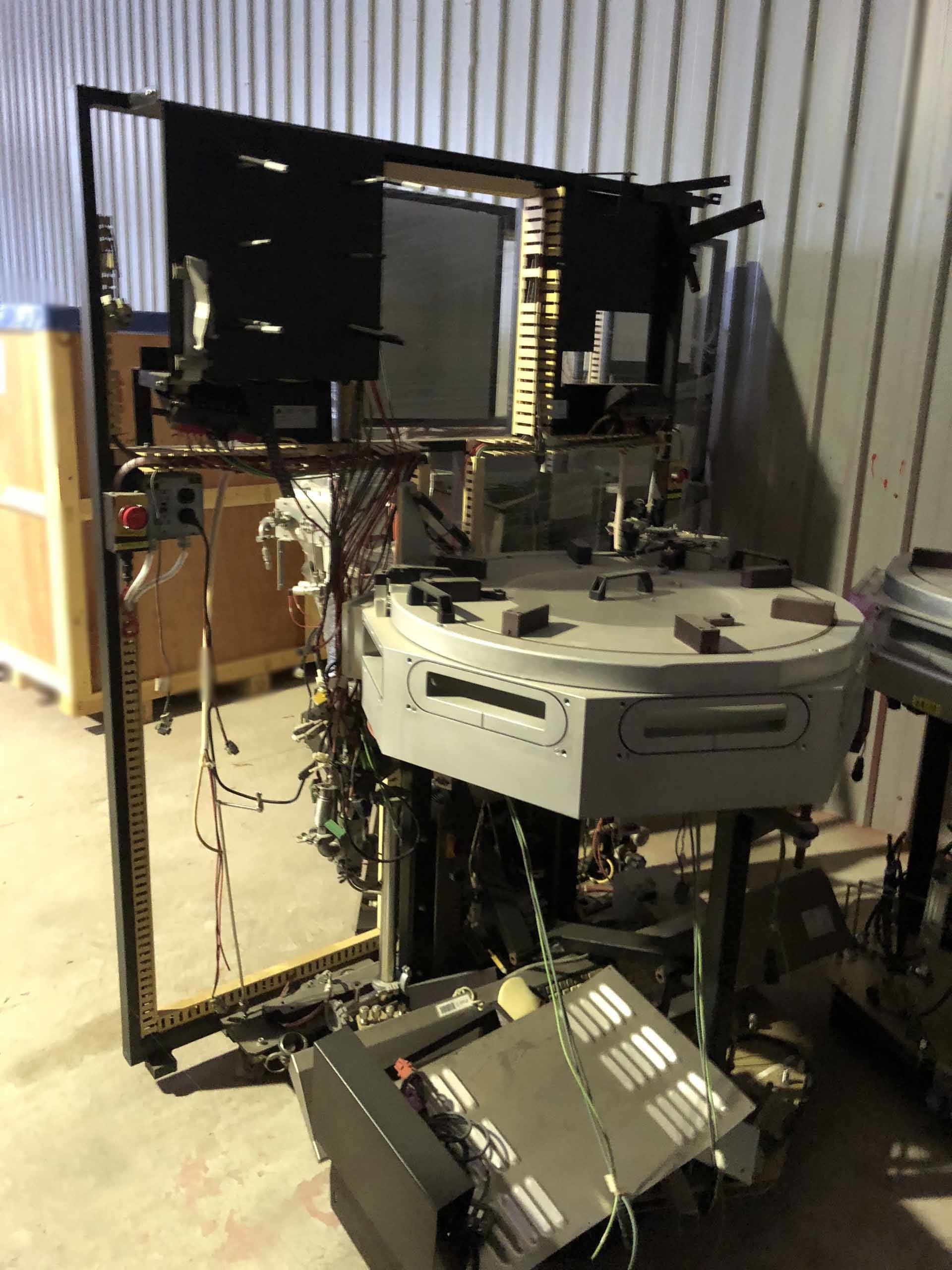

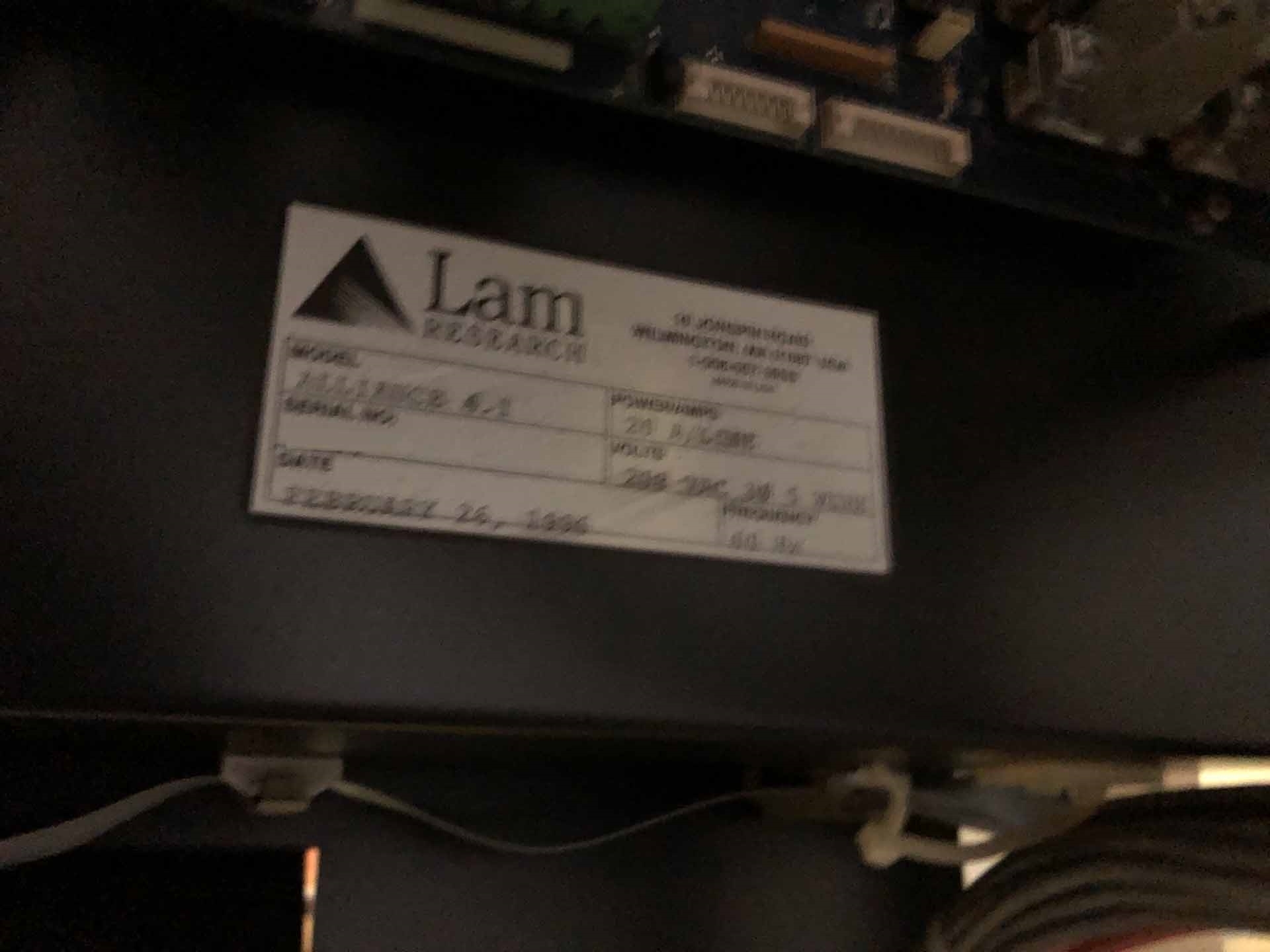

Used LAM RESEARCH TM4.1 #9198145 for sale

URL successfully copied!

Tap to zoom

LAM RESEARCH TM 4.1 is a state-of-the-art etcher / asher that has been designed to provide a high-quality and repeatable process for a variety of applications across a large range of gases, pressures, and temperatures. The TM 4.1 etcher / asher combines a robust and high-precision design with dynamic in-situ process control to maximize yield and throughput in a variety of processes. The TM 4.1 etcher / asher is built with robust and reliable mechanical components to ensure a long operating life with minimal maintenance. Its robust design also helps to ensure repeatable uniformity across wafer runs. The TM 4.1 includes a Quartz chamber with electrical feedthroughs, stainless steel flanges, a 200mm selector valve, and a process gas assembly which can be customized to accommodate a large range of process gases. The specialized controller system of the TM 4.1 provides dynamic in-situ process control and adaptive response to ensure repeatable performance for all process recipes. Additionally, the TM 4.1 includes a secondary process chamber for sample baking, as well as a wafer alignment and load port for ease of loading and unloading wafers, masks, and other items. The TM 4.1 also provides advanced safety features such as automatic emergency shutoff valves, an inert gas storage system, and the ability to integrate with active chamber purging systems. The TM 4.1 is designed for use in a variety of applications, including but not limited to etching and ashing, resist strip, thin film deposition, thicker film deposition, and wafer deburring. In summary, LAM RESEARCH TM 4.1 etcher / asher is a robust and high-precision system that provides an advanced laser-etched process recipe and dynamic in-situ process control for custom processes. Its robust mechanical and electrical design, versatile process gases, and advanced safety features ensure consistent performance and repeatability. By combining the capabilities of the TM 4.1 etcher / asher with an effective and efficient wafer processing service, manufacturers can get the most out of their wafer processing applications.

There are no reviews yet