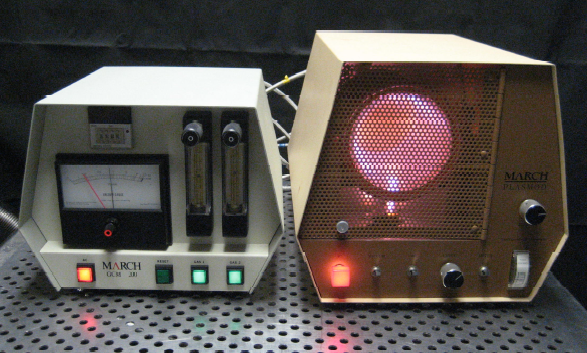

Used MARCH Plasmod #9058869 for sale

URL successfully copied!

Tap to zoom

ID: 9058869

Etcher

100 W Generator

Vacuum Tube RF source

Manual tune

Quartz outer chamber

Pyrex inner chamber

Option available: GCM 200 with (2) gas control.

MARCH Plasmod is a state-of-the-art etching technology used to fabricate nanoscale patterns on the surface of various materials. It works by using a combination of physico-chemical processes such as deep reactive-ion etching (DRIE) and atomic layer deposition (ALD) to create a chemically distinct pattern on the surface. Plasmod equipment is a cluster tool that consists of several modules to enable a modular approach to patterning nanometer scale features. The core module, for example, contains the plasma source and the etch/clean chambers, as well as a set of electrodes. In addition to this, each module may contain a different set of gases, flux and flushing connection systems, a pressure controller, power supplies, and an interlock. The first step in using MARCH Plasmod system is to prepare a suitable substrate for the etch process. This is accomplished by creating a pattern in the substrate that has a high surface area. This is done by using a combination of lithography, RF sputtering, and chemical etching techniques. Once this is done, the substrate is then placed in the core module of Plasmod unit. Once in the core module, the substrate is exposed to a high power and low-frequency RF plasma. This generates a strong etching chemistry that reacts with the material that is being etched, leading to the desired pattern on the surface. During this process, the substrate needs to be monitored for cleanliness, etching rate, and temperature, and it can be adjusted as needed by adjusting the power level and gas flows. Once etching is complete, MARCH Plasmod machine can be used for an atomic layer deposition (ALD) process. ALD is a deposition technique that is used to create uniform thin films on the surface of the substrate. This is done by alternately exposing the substrate to two different precursors and then polymerizing them to form a mono-atomic layer of material. Once the deposition process is complete, the substrate is then cleaned and ready to be removed from Plasmod tool. Depending on the type of application, the feature size can range from a few nanometers to several micrometers. MARCH asset can also be used for materials such as metals, ceramics, and polymers. In summary, MARCH Plasmod is an advanced etching model capable of creating nanometer scale features on a wide range of substrates.

There are no reviews yet