Used MATRIX 105 #188833 for sale

URL successfully copied!

Tap to zoom

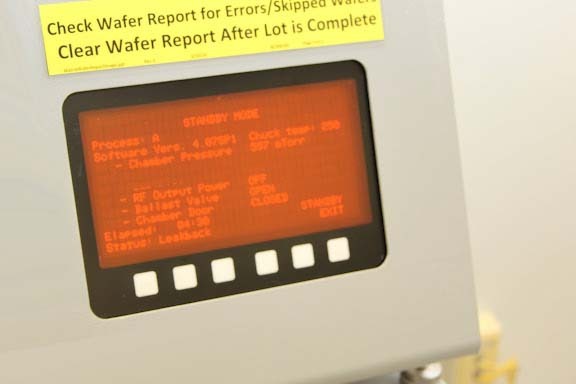

MATRIX 105 is a high-precision etcher and asher that is designed for use in the manufacturing sectors. It is ideal for advanced prototyping, small batch production, and production of high complexity parts. 105 offers automated loading and unloading capabilities, as well as superior ion energy and beam uniformity for uniform depth over a larger area. MATRIX 105 utilizes an RF inductive plasma source with a programmable grid voltage that can be tuned precisely to the customer requirements. Its adjustable process parameters provide greater process stability and improved precision in the etching and ashing process. The multi-language user interface enables easy operation of the machine, and it includes an intuitive user-friendly graphical user interface. This machine is suited for various kinds of etching and ashing applications, including DRAM gate etching, wafer polishing, and etched hole processes. 105 is equipped with a rotary indexer and a linear synchronous motor that provide excellent motion control and accuracy. The workpiece is securely held in place by a two-piece clamp, eliminating the need to use bulky micromanipulators, further improving repeatabilty and decreasing etch chamber loading time. It is also equipped with an array of protection systems that ensure safety and maintain long-term operational reliability. MATRIX 105 can be used with a variety of etch gases such as chlorine, oxygen, and oxygen with a range of parameters such as ion energy, ion bombardment surface temperature, etch rate uniformity, repeatability, etc. Process parameters can be tuned to the requirements to achieve fine control with the highest quality results. It is compatible with multiple substrates such as glasses, ceramics, polymers, and metals. Overall, 105 is an excellent choice for advanced etching/ashing applications. The adjustable process parameters and automated loading and unloading features make this etcher and asher an ideal choice for precise and high-quality results. It enables manufacturers to reduce overhead and increase efficiency, enabling smarter business decisions and faster production cycles.

There are no reviews yet