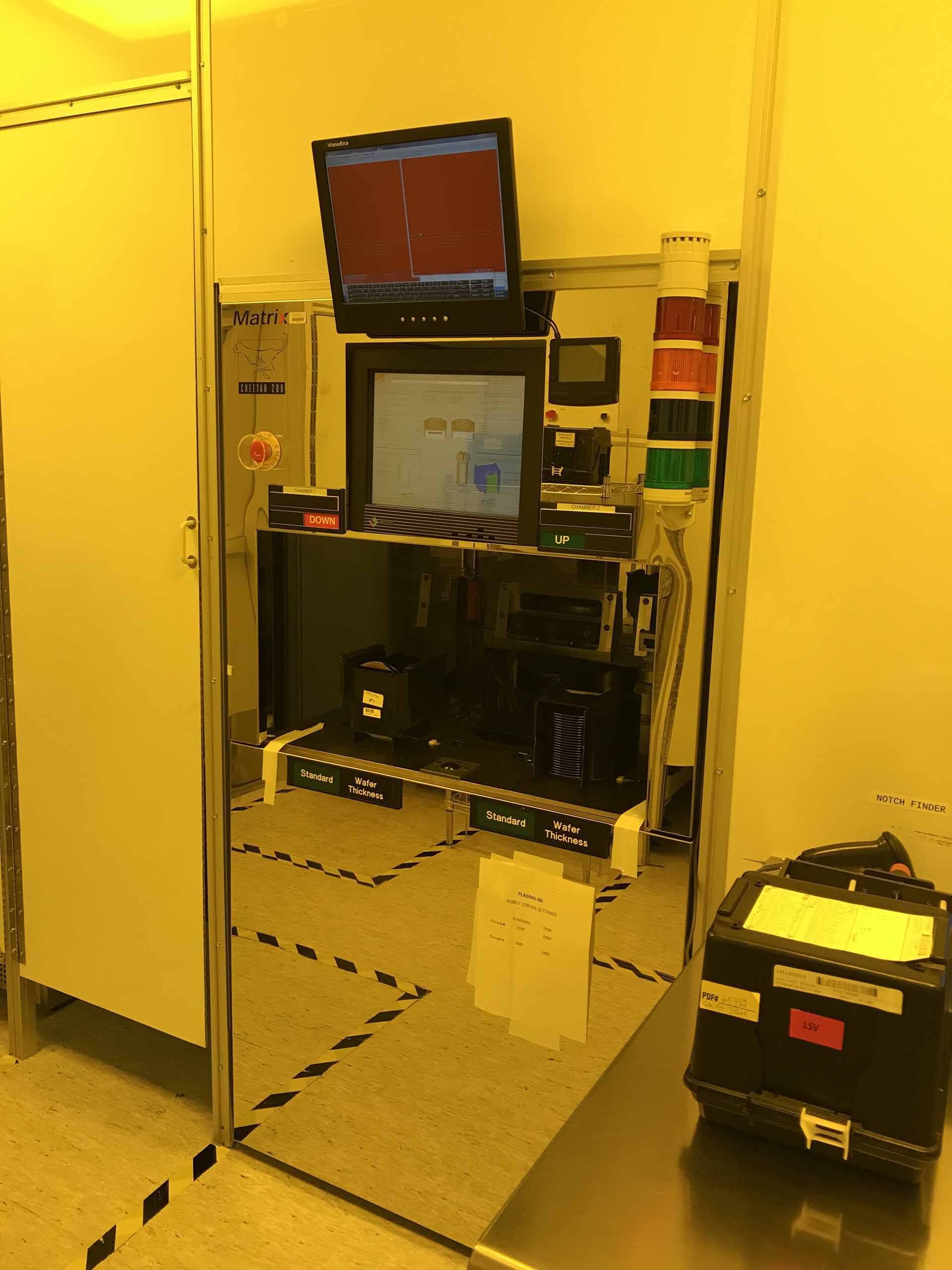

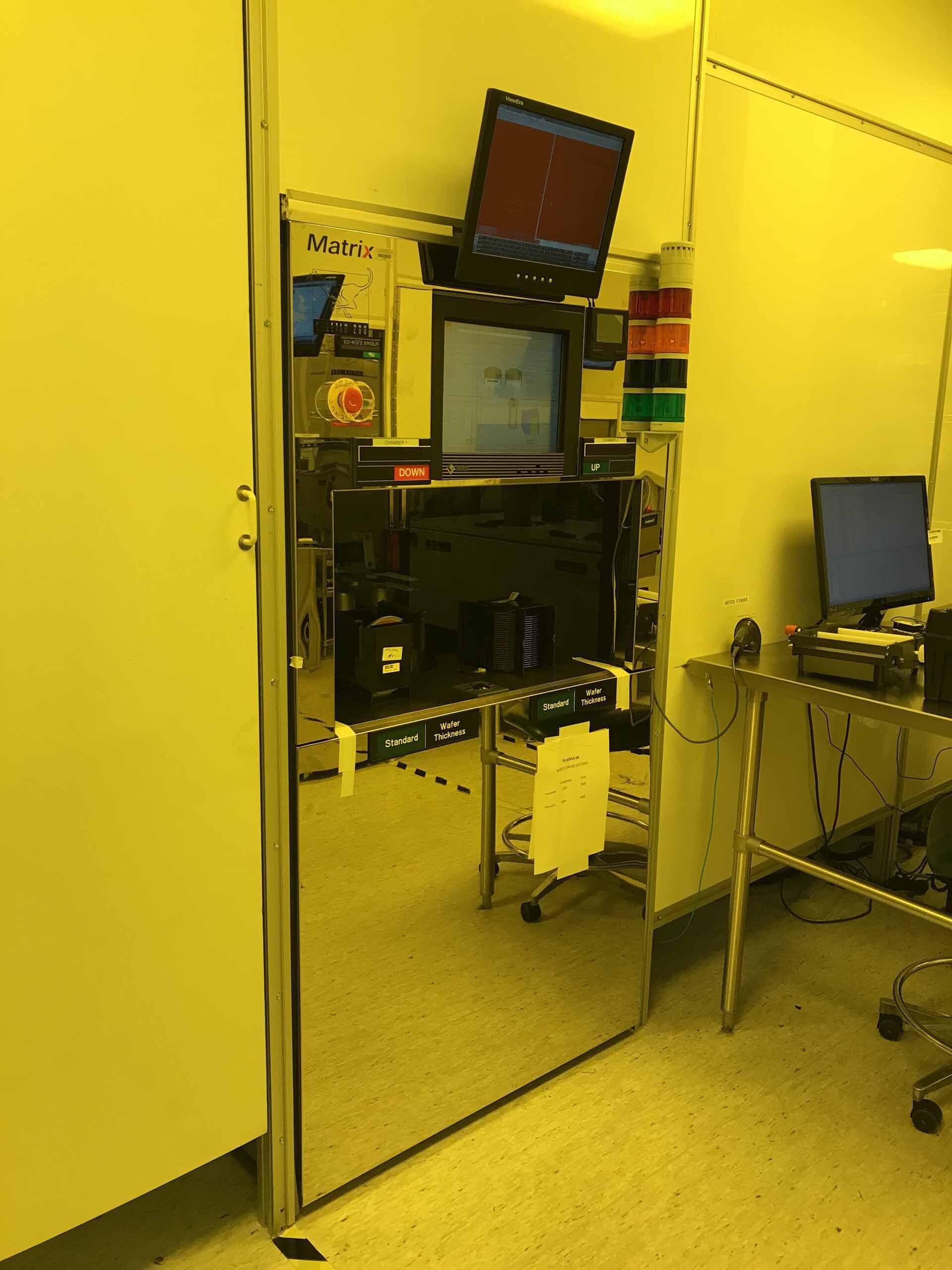

Used MATRIX Cheetah 200 #9400266 for sale

URL successfully copied!

Tap to zoom

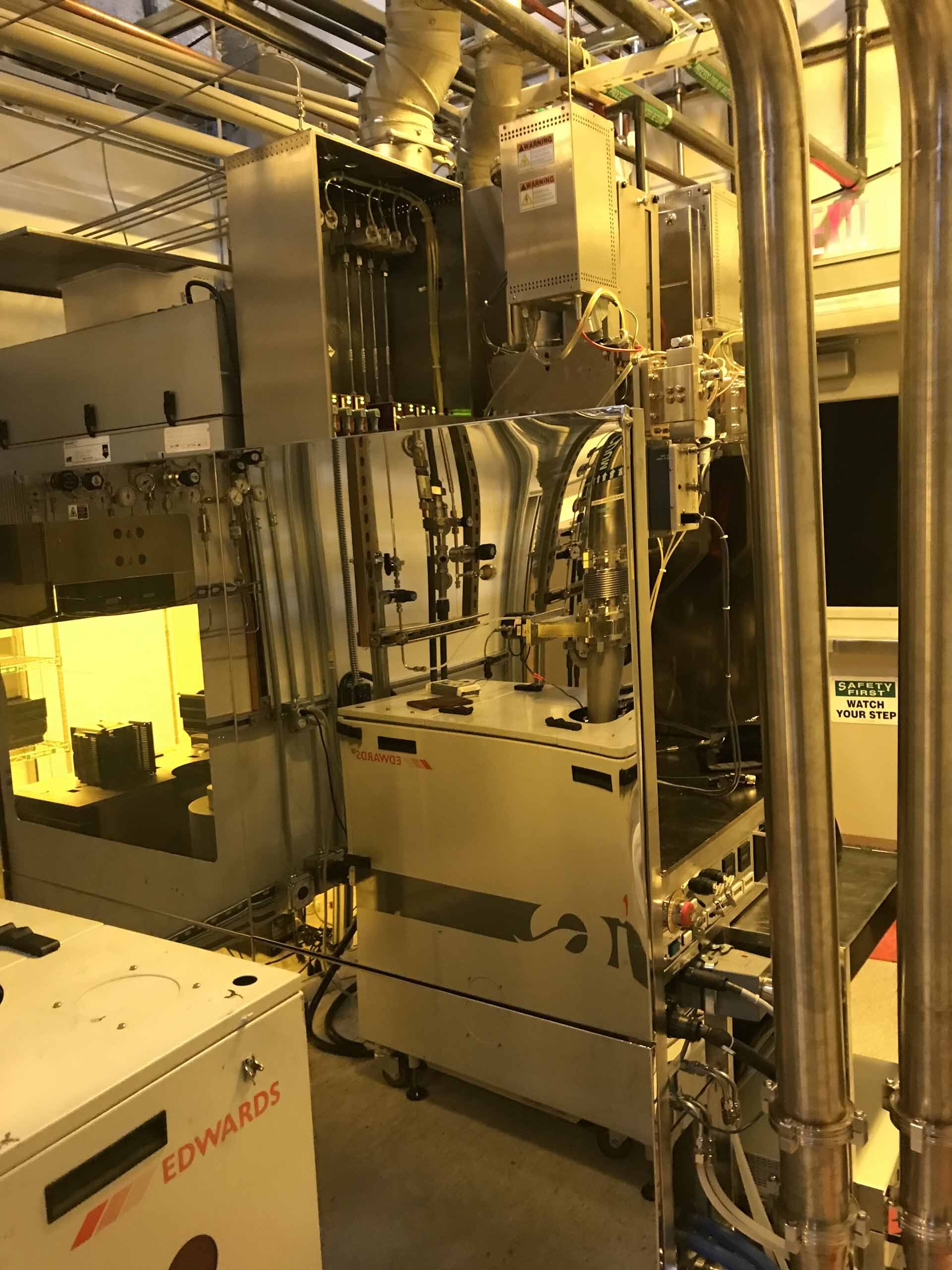

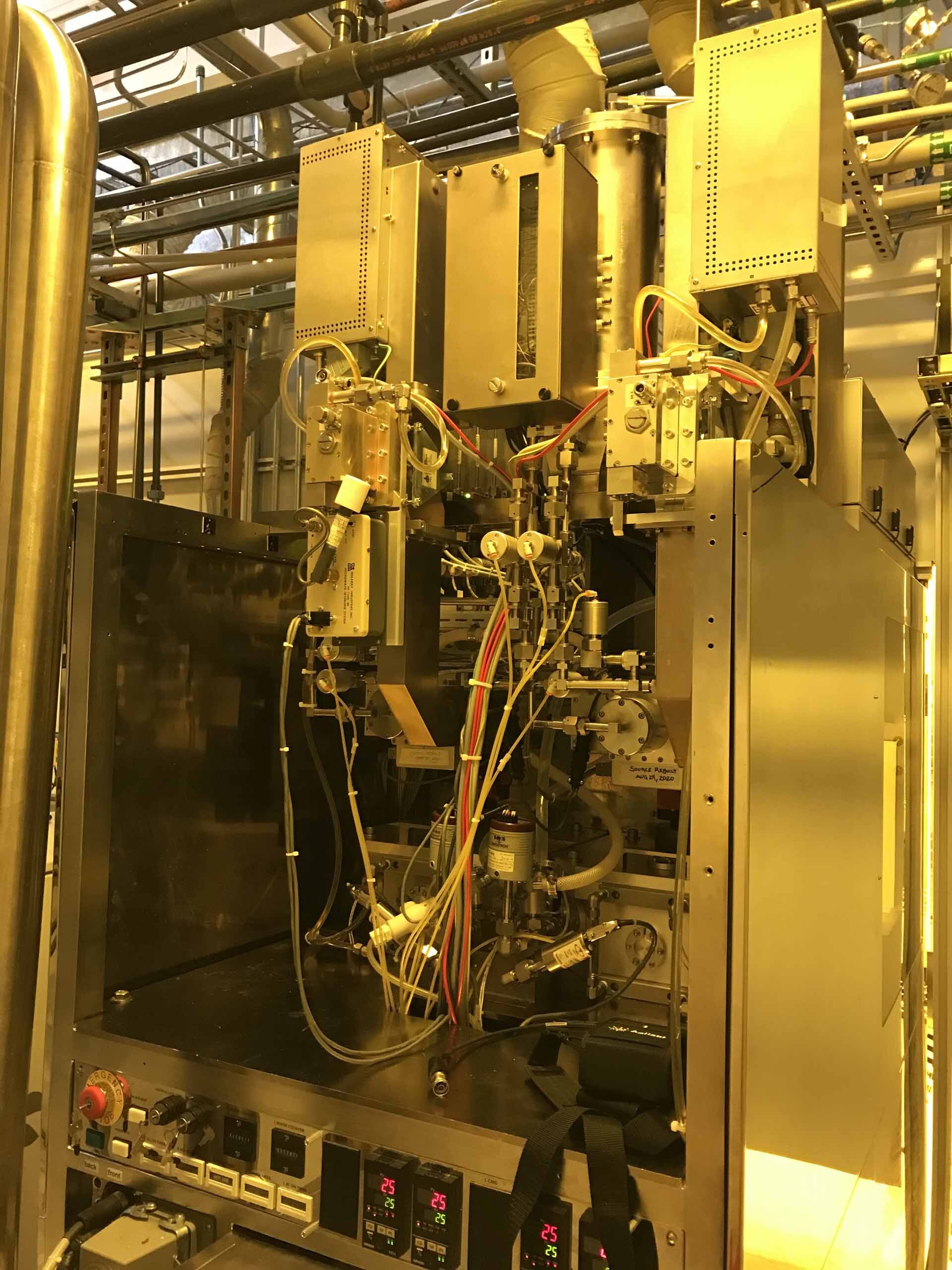

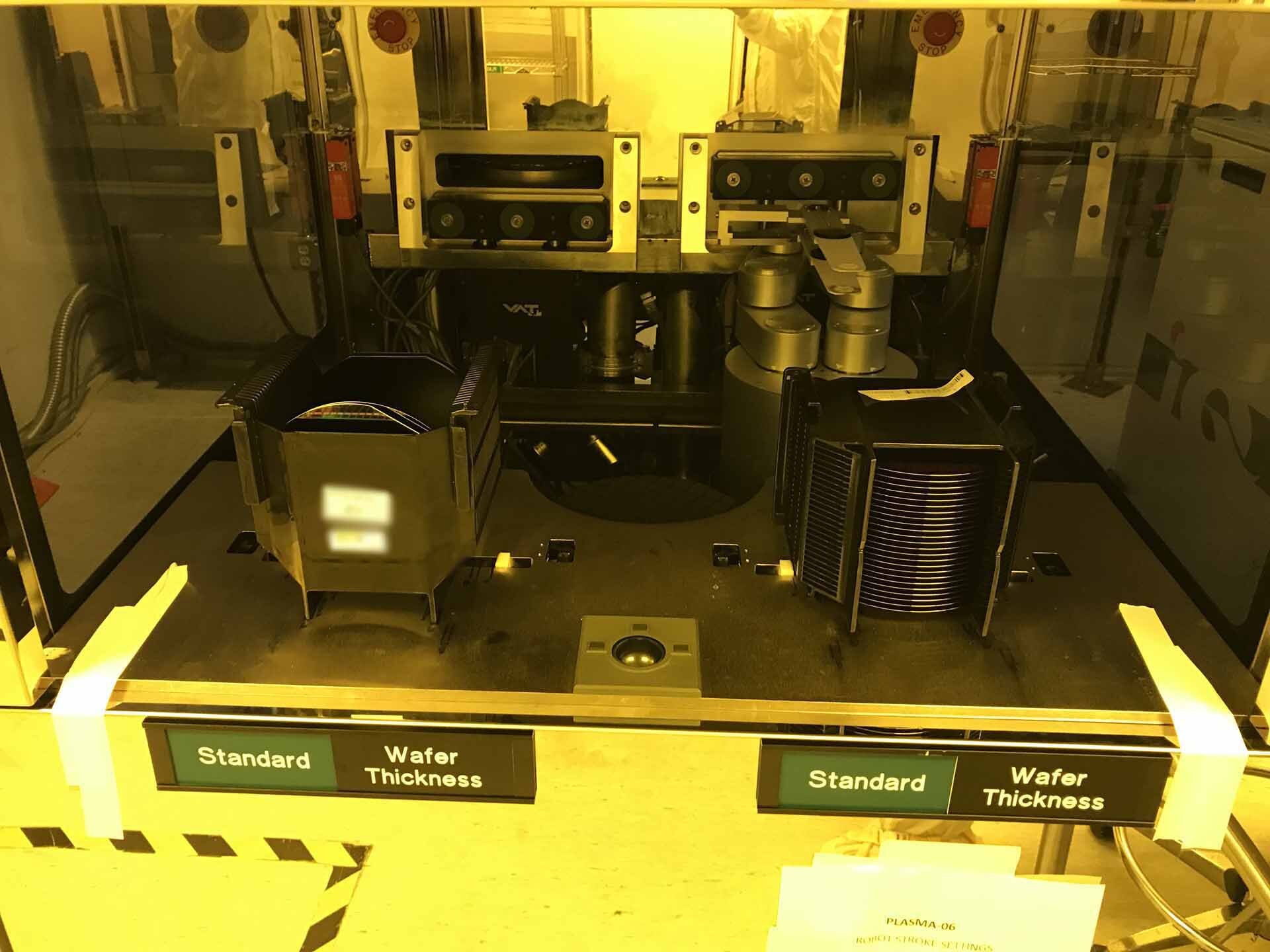

MATRIX Cheetah 200 is an etcher/asher designed for high efficiency, precision etching/ashing applications in both research and industrial settings. It has an overall size of 510mm wide, 690mm deep and 203mm high in a compact design. The construction of Cheetah 200 consists of a reliable non-corrosive stainless steel chamber, handles and housing. The insulated chamber lid is composed of thick, laser-cut aluminum construction, providing external strength and containment while operating at temperature levels of up to 1200°C. The etcher/asher is equipped with a patented gas delivery scrubbing equipment to create clean and reliable chamber atmosphere by filtering ultra-fine particles from the gas before it reaches the chamber. It is also equipped with advanced chamber temperature alarm to maintain a safe working environment. MATRIX Cheetah 200 features a premium Etching/Ashing" process for a precisely-controlled etch/ash. Its easy to use motion control parameter settings provide precise control over the etching/ashing process. It has a maximum etching/ashing time of up to 60 minutes on both top and bottom of the substrate, with a temperature dose range of up to 1200°C. The Matix Cheetah 200 is equipped with a touchpad control interface. It allows access to the etching/ashing parameters, when to stop and the total elapsed time of the process. It also keeps control of the CO 2 feedback which is used to protect the atmosphere of the chamber during the etching/ashing process. The chamber is heated via two halogen quartz lamps, providing precise temperature and uniformity. The temperature is adjustable in 1°C increments and can be monitored via an embedded digital thermocouple. It is also equipped with an isolated cooling system, which supplies cooling air to the chamber to ensure the standard of etching/ashing processes and the overall unit dependability. The etcher/asher also features an automated cassette machine for sample loading and unloading. It allows up to 25 substrates to be mounted at the same time. The samples are loaded and unloaded from the cassette tool with no manual operation required. To ensure that all processes follow the optimal etching/ashing protocol, MATRIX Cheetah 200 is equipped with pre-programmed settings that have been validated and tested to achieve dependable and repeatable results with every etch/ash. The integrated data logging asset allows for easy traceability, as well as the ability to store settings and recipes for future use. The etcher/asher is made to run semi-automatically and continuously, with a minimized cleaning cycle, so it is ready to run at the next etching/ashing job. Cheetah 200 has excellent long term process stability and uniformity, leading to consistently reliable results.

There are no reviews yet