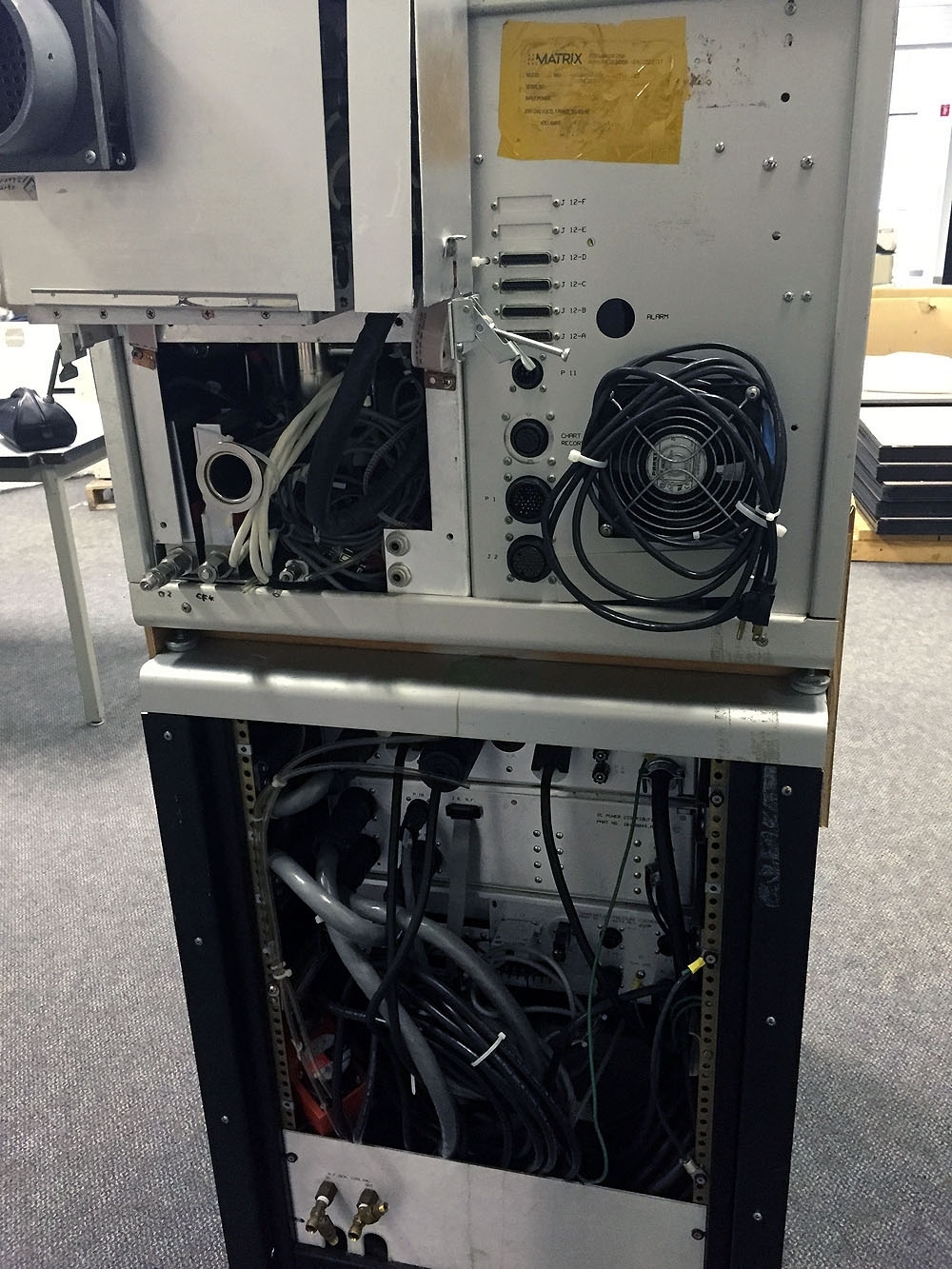

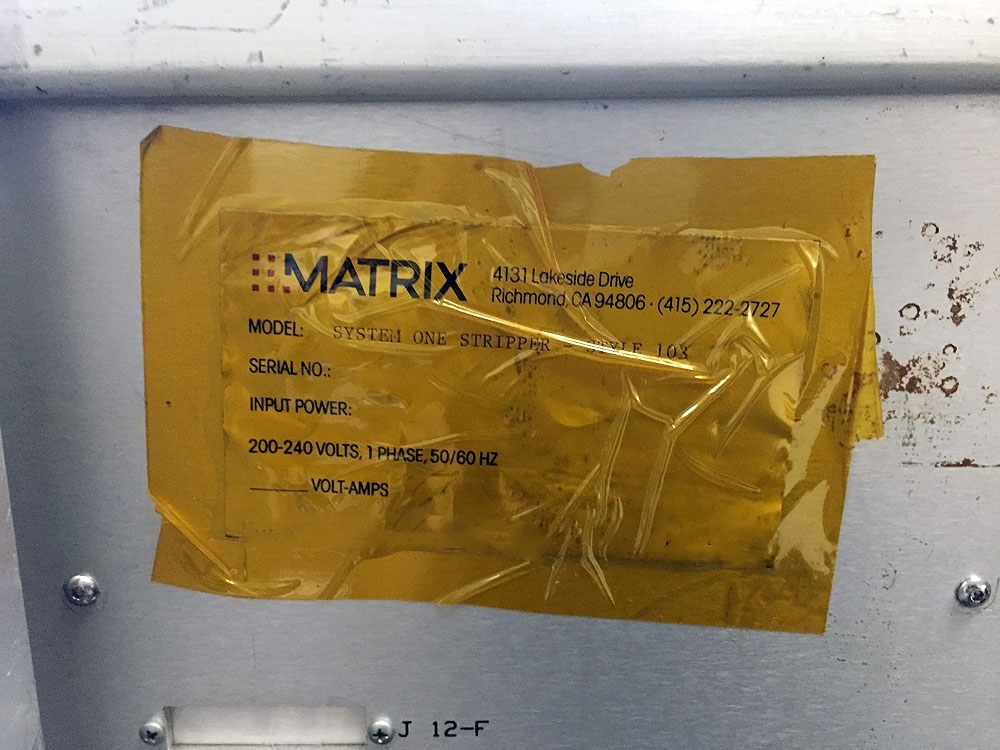

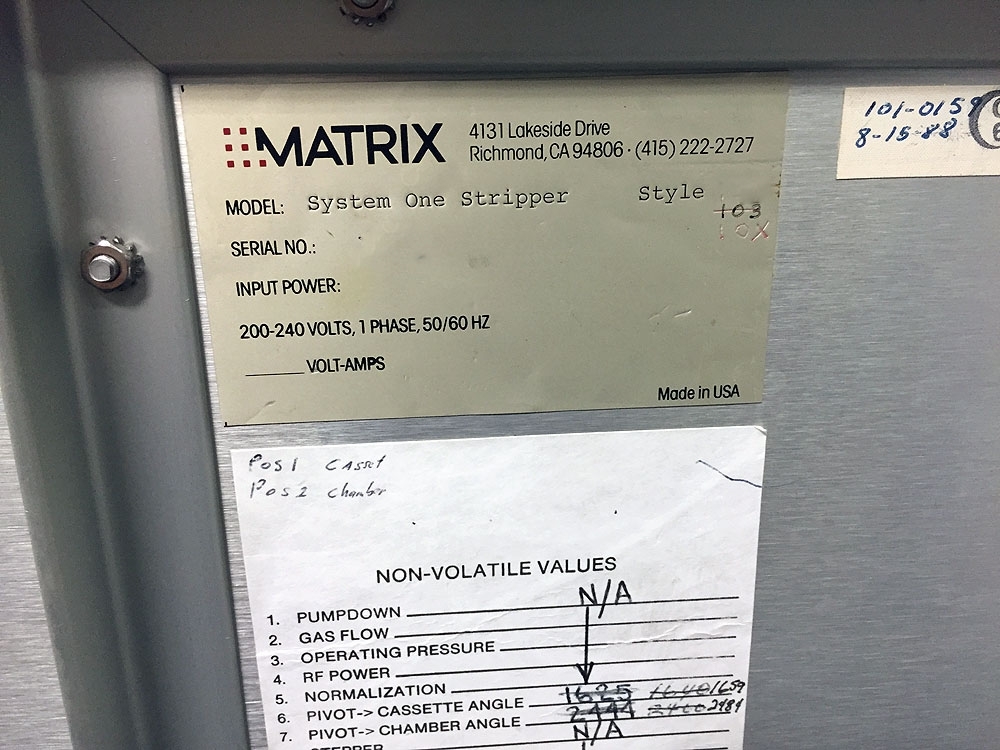

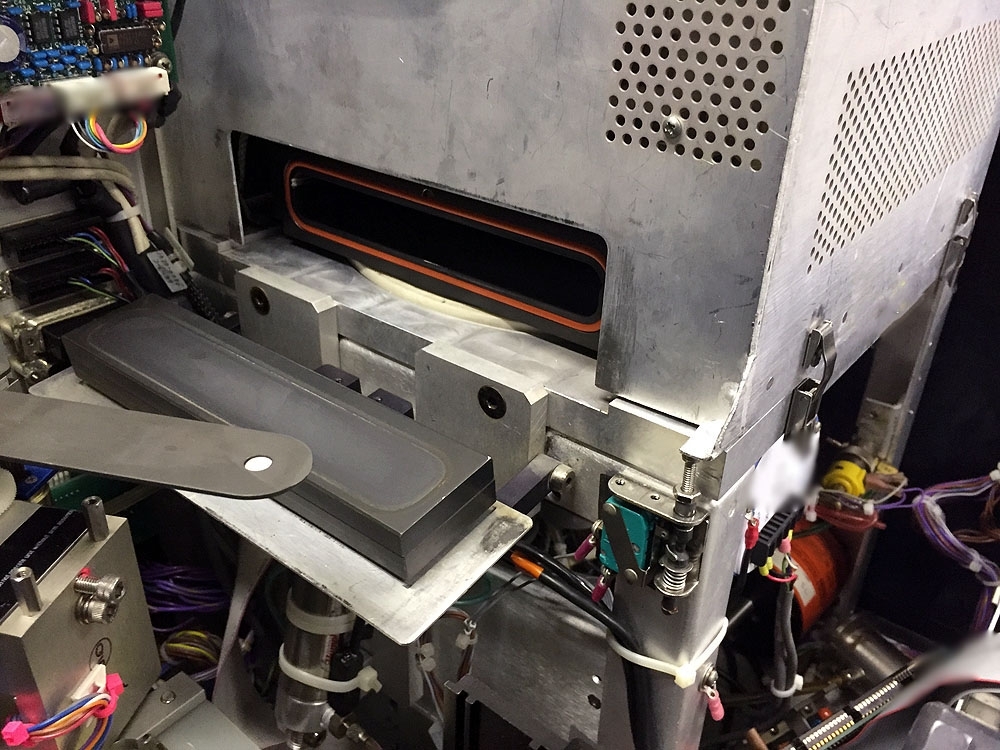

Used MATRIX System One 103 #9201876 for sale

URL successfully copied!

Tap to zoom

ID: 9201876

Wafer Size: 6"

Stripper, 6"

Included ranging:

50mm up to 150mm

The system optimizes vital device parameters:

Enhanced gate oxide integrity

Reduced threshold and capacitance voltage shifts

Reduced contact resistance / Oxidation

Photoresist Stripping:

High dose implant

Post-polysilicon etch

Post-metal etch

Post-oxide etch

Controlled resist removal:

Post-develop descum (pre-etch)

Dry / wet process capability

Uniformity capability (<5% 1σ)

GaAs, InP wafer strip and descum

Thin film head resist cleaning

Opto-electronic devices cleaning

MEMS

Single wafer multi-Step Processing:

Precisely controlled & repeatable stripping of each wafer

(3) programmable steps + overstrip

Capable of long process times for exceptional control

High throughput:

35 WPH on 150mm substrate

Aluminum Wafer Chuck:

Fast

Precise

Uniform removal of resist

Low Particles:

0.1 particles (>0.3μm) added per cm2

Proven System Performance:

700 System ones in use worldwide

95% uptime

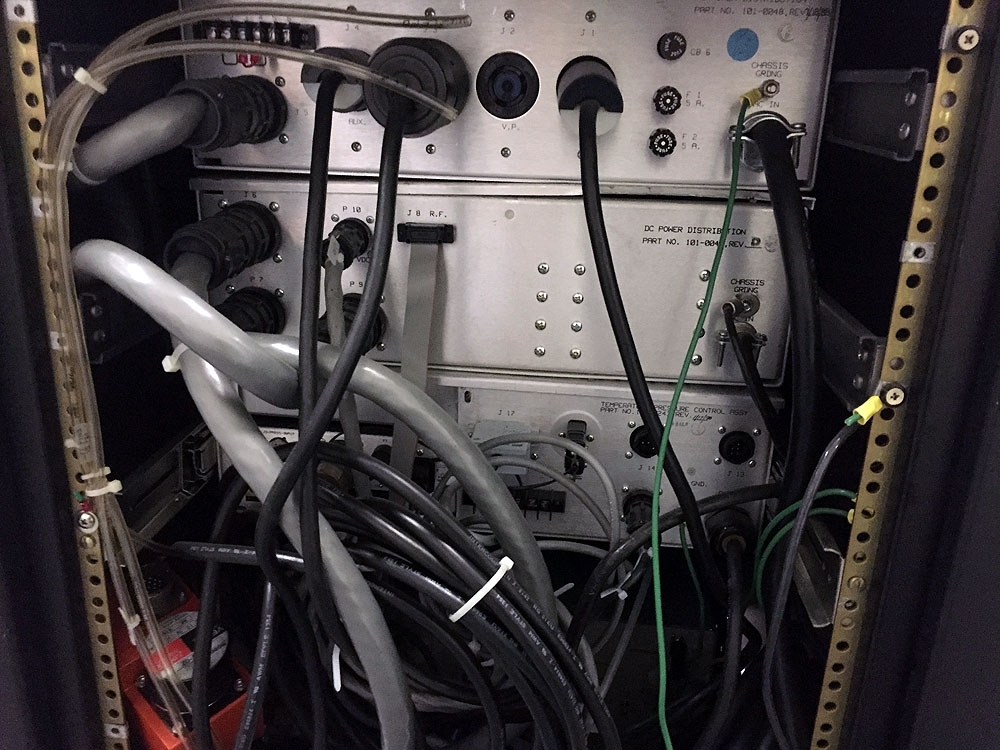

Proven Reactor Design:

Closed-loop temperature control

Stable range for strip:

150°C – 250ºC (+/-5°C)

For descum:

70°C – 150ºC .

MATRIX Equipment One 103 is an advanced etching and ashing system designed to provide efficient, precise, quality control processes for the production of semiconductor devices. Unit One 103 is a Planar Machine with both plasma and wet etching, and is capable of handling various types of substrate materials, including silicon wafers, metal, glass, and many non-metallic and organic materials. MATRIX Tool One 103 has a maximum chamber size of 836mm x 788mm, and is designed to provide a stable etch rate of up to 20 microns/sec, with excellent repeatability and uniformity.Asset One 103 has several features and capabilities that make it an ideal choice for complex etching and ashing applications. The model is highly automated, with an intuitive touchscreen user interface, enabling users to easily input parameters and set up the equipment for the most efficient operation. The system also has a wide variety of control components, including a tablet based controller, a programmable logic controller (PLC), a gas manifold, and an upstream and downstream process monitoring unit. All these components work together to make it possible to customize the process parameters to achieve the desired etching and ashing results. MATRIX Machine One 103 also supports a wide range of process chemistries, including gaseous and liquid chemistries. This tool provides an effective means of controlling and monitoring reaction parameters such as pressure, temperature, gas flows, voltages, and substrate commands. The asset also includes an automatic wafer recognition and substrate loading sub-model for improved manufacturing throughput.Equipment One 103 incorporates a range of advanced safety features, including a nitrogen purge capability to minimize hazardous gases, and an inline filter system to prevent dust particles from entering the chamber. It also has a Programmable Environmentally Assisted Etching (PEAE) unit, which is designed to achieve the optimal etching and ashing conditions, with no need for manual adjustment. The unit also has an advanced monitoring machine, which provides real-time information about the process parameters, such as temperature, pressure, and flows, providing a detailed view of the tool performance. Overall, MATRIX Asset One 103 is designed to provide highly efficient and precise etching and ashing processes with excellent quality control. This model has a wide range of advanced features, enabling it to be customized to specific applications and providing excellent process repeatability and control. It is an ideal choice for modern semiconductor etching and ashing requirements and provides users with the capability to produce the highest quality products quickly and efficiently.

There are no reviews yet