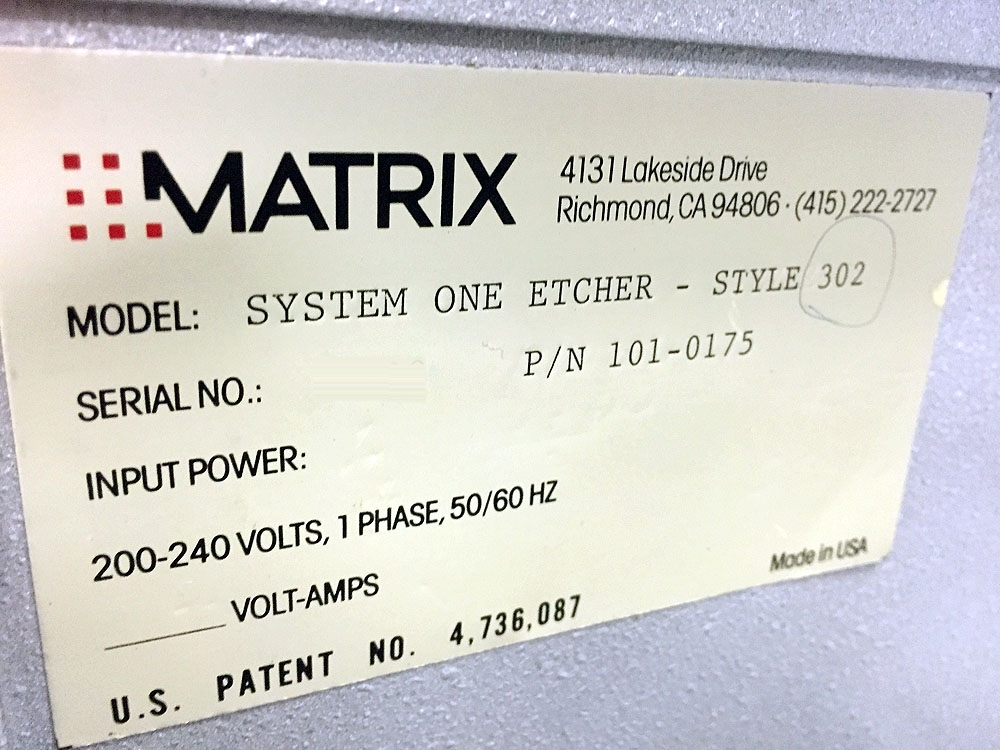

Used MATRIX System One 302 #9201781 for sale

URL successfully copied!

Tap to zoom

ID: 9201781

Wafer Size: 6"

Etchers, 6"

Electro-mechanical production system:

Nitride

Oxide

Polysilicon

Chemical reaction induced by a gas plasma

Etching main console module:

Process

Operator interface

Wafer transport

Card reader

Elevator

Microprocessor control

Etching power supply console:

RF Generator

DC Supply

AC Distribution

Gas distribution panel

Temperature / Pressure control

Physical specifications:

Main console Power supply Console overall

Width 25″ 25″ 25″

Depth 28″ 28″ 28″

Height 22″ 36″ 58″

Weight 100 lbs 310 lbs 410 lbs.

MATRIX Equipment One 302 is an advanced etcher / asher designed for use in the semiconductor industry. It is a fully automated high frequency sputtering tool, capable of producing high-quality deposits of thin film coatings. The 302 mounts to both stand-alone or automated robotic systems, and is controlled by a user-friendly Graphical User Interface (GUI), allowing for flexible customization of the parameters for the etching/ashing process. System One 302 features an internal high frequency generator (HFA) to produce the ionization and bombardment necessary for effective etching/ashing. The unit is capable of delivering an RF power of up to 3KW to the target surface, and features precise control over both pressure and temperature. The ionized plasma density is adjustable, as well as the sputtering yield, creating a highly responsive process. The 302 is equipped with advanced tools for monitoring and analyzing the process. These include a fully programmable Multi-Channel Analyzer (MCA), and an Advanced Array Collector (ACC) for measuring and analyzing the performance of the etching/ashing process. The machine also offers secure data storage and archiving of up to 5GB, allowing for efficient post-processing of the data generated. MATRIX Tool One 302 is designed for use in the semiconductor industry, and boasts a number of advanced features such as high sputtering yield and precise control over the etching/ashing process. This etcher / asher is capable of producing high-quality, consistent thin films of metal particles, and offers superior process control and reliability. The 302 is easy to operate and maintain, making it an ideal choice for demanding semiconductor production environments.

There are no reviews yet