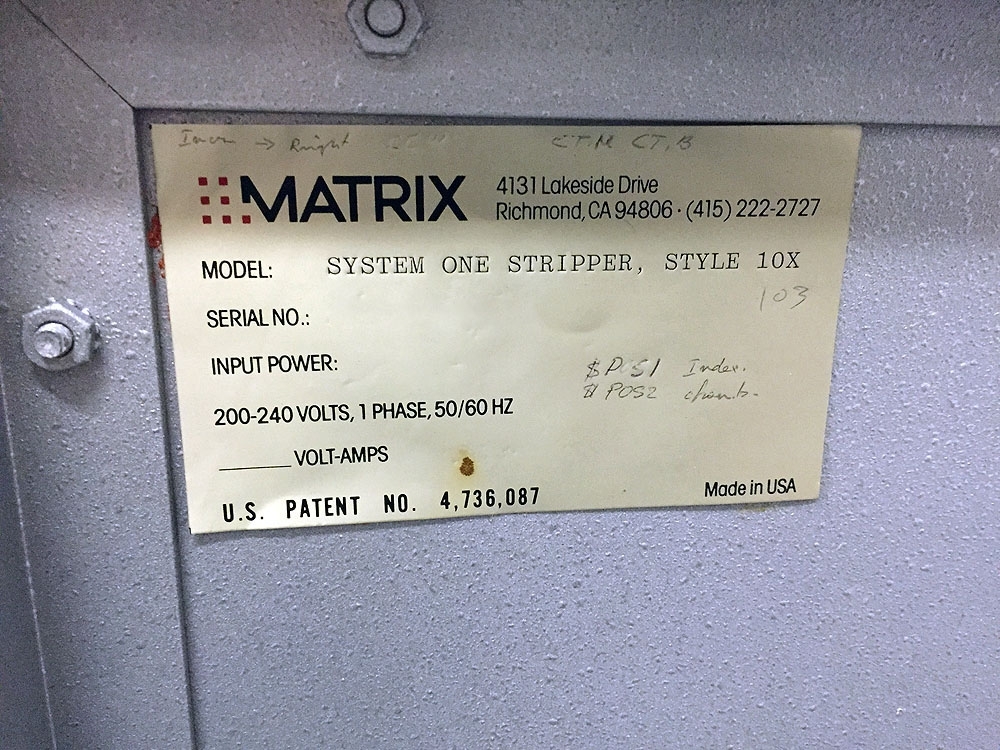

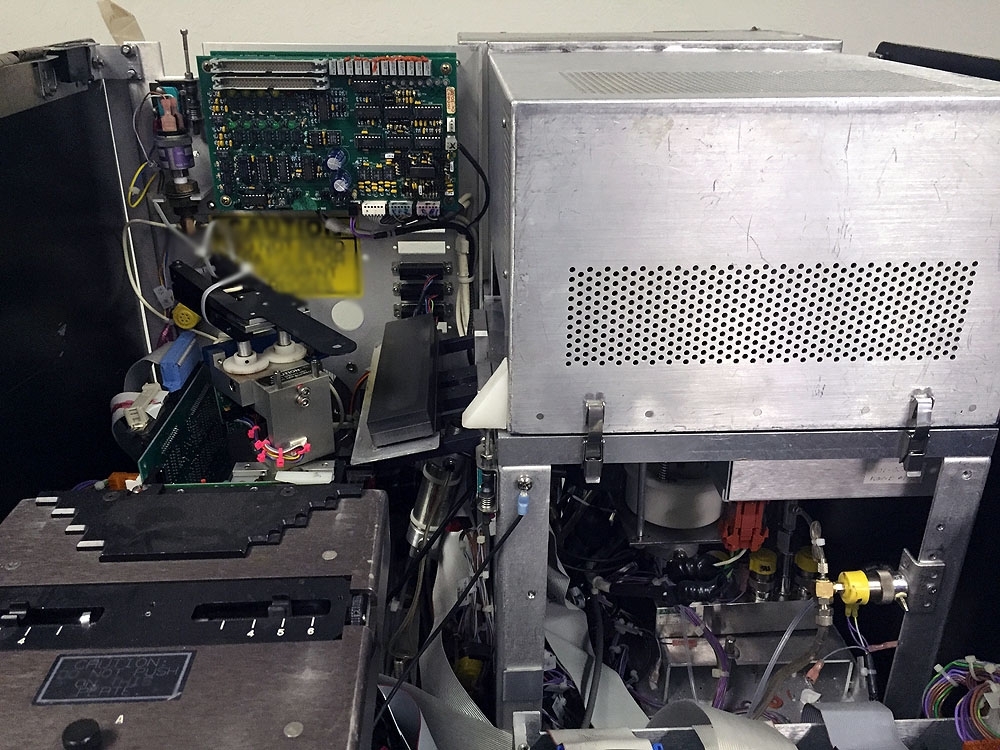

Used MATRIX System One #9201831 for sale

URL successfully copied!

Tap to zoom

ID: 9201831

Wafer Size: 6"

Stripper, 6"

Included ranging:

50mm up to 150mm

The system optimizes vital device parameters:

Enhanced gate oxide integrity

Reduced threshold and capacitance voltage shifts

Reduced contact resistance / Oxidation

Photoresist Stripping:

High dose implant

Post-polysilicon etch

Post-metal etch

Post-oxide etch

Controlled resist removal:

Post-develop descum (pre-etch)

Dry / wet process capability

Uniformity capability (<5% 1σ)

GaAs, InP wafer strip and descum

Thin film head resist cleaning

Opto-electronic devices cleaning

MEMS

Single wafer multi-Step Processing:

Precisely controlled & repeatable stripping of each wafer

(3) programmable steps + overstrip

Capable of long process times for exceptional control

High throughput:

35 WPH on 150mm substrate

Aluminum Wafer Chuck:

Fast

Precise

Uniform removal of resist

Low Particles:

0.1 particles (>0.3μm) added per cm2

Proven System Performance:

700 System ones in use worldwide

95% uptime

Proven Reactor Design:

Closed-loop temperature control

Stable range for strip:

150°C – 250ºC (+/-5°C)

For descum:

70°C – 150ºC .

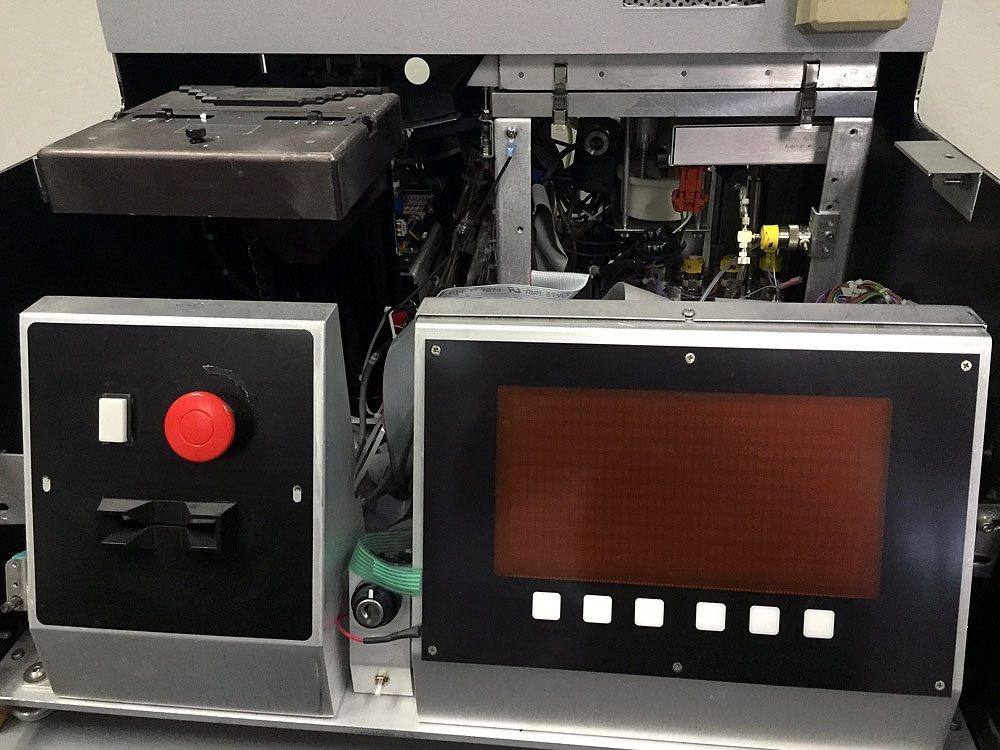

MATRIX Equipment One is a state-of-the-art etcher and asher, used to laser mark components onto metallic surfaces. It is ideal for industrial marking applications, as it is suitable for etching tough materials as well as soft metals, such as aluminum, steel, brass, stainless steel, titanium, and copper. The laser beam that is emitted from the etcher and asher is precise and accurate, allowing for quick and easy marking. The design of System One is compact and durable, and it is easy to use and maintain. Its adjustable base allows for precise control of the laser beam and ensures consistent results. The intuitive control panel makes it easy to control settings, adjust the parameters, and preview designs before committing to the process. The built-in safety features ensure safety and durability, while also allowing for easy cleaning. The unit also includes a fiber optic scanner that reads the desired material and makes sure the laser beam is correctly positioned. This feature ensures accuracy and precise patterns, no matter the material being etched or ashed. The automated software allows for easy customization and accurate reproduction of patterns, and its sophisticated imaging algorithms guarantee precise marking. The machine also works gladly with a variety of graphics and CAD software, allowing for quick and easy design. The speed and precision of the laser marking process make it ideal for multiple industrial and commercial applications. It is ideal for marking inventory parts, serial numbers, product codes, barcodes, and logos onto a variety of materials. The size of the etched or ashed marking is also impressive, allowing for large numbers of high-quality marks to be created in a short amount of time. MATRIX Tool One offers high-speed, precise laser marking. Its features, accuracy, and durability make it the ideal choice for industrial applications, and it is the ideal choice for anyone wanting to produce quality, consistent results. Whether marking metals or other materials, Asset One is the best option available.

There are no reviews yet