Used MATTSON 165-91000-00 #293671335 for sale

URL successfully copied!

Tap to zoom

ID: 293671335

Vintage: 2022

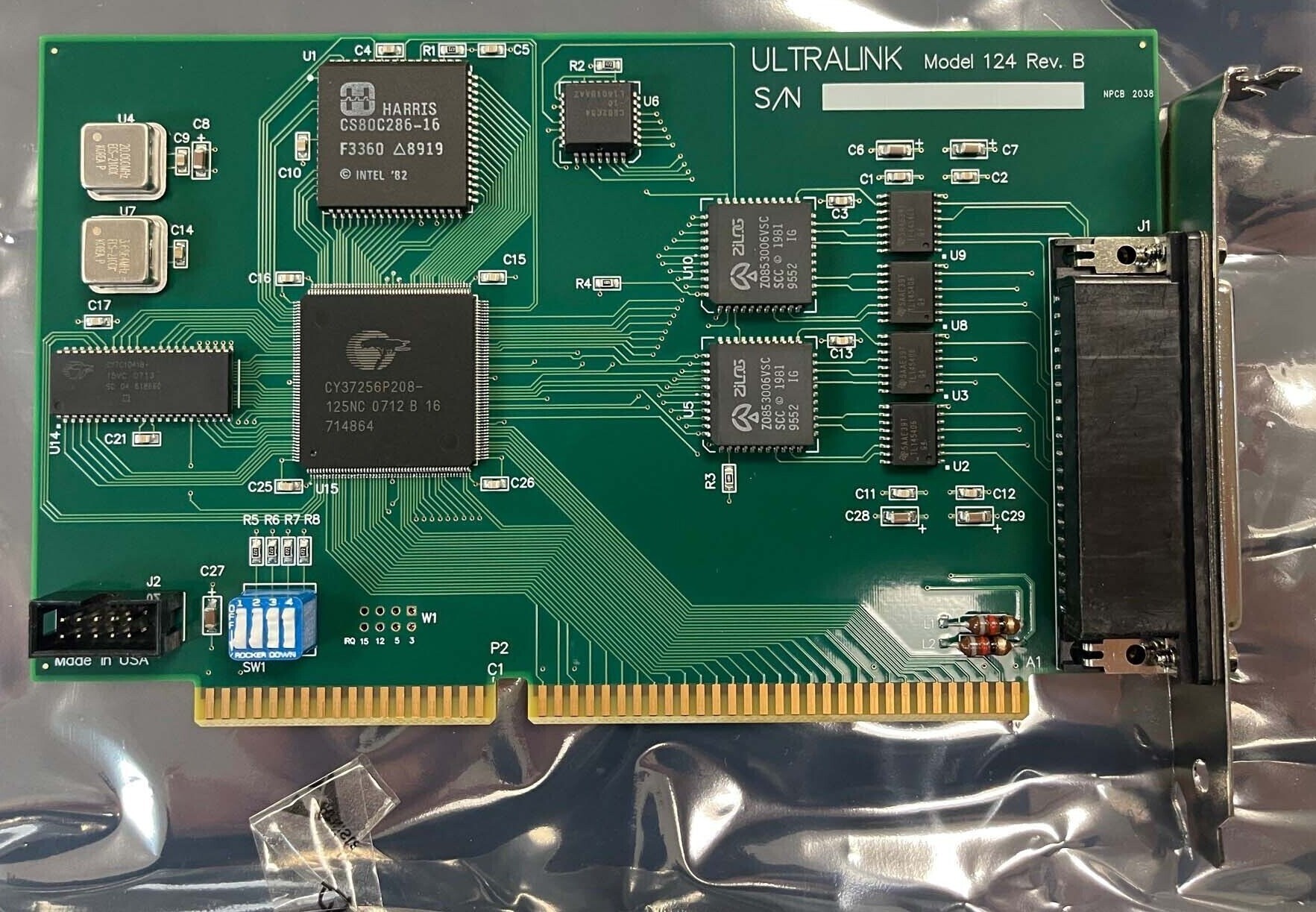

PCB Card assemblies for Aspen II

SECS II

Communication cable

2022 vintage.

MATTSON 165-91000-00 is an advanced etching or asher equipment for photolithography. It has an adjustable gas flow system to optimize process conditions for repeatable results. The etcher utilizes a horizontal ring chuck with a floating finish plate to reduce topography. The gas distribution unit is equipped with valved silica lines with adjustable orifices to provide directional gas flow, for higher repeatability of etching profiles, and uniformity of edge profiles. The machine also includes high-quality quartz substrate heating diffusion furnaces, with precise temperature control for repeatable temperature profiles, and low thermal shock for the substrate. The capacitance end point sensing tool is integrated into the asset, with both manual and automatic operation option. The model can also be interfaced with other process control systems, such as Job Controllers and MES systems for maximization of process control and monitoring. In terms of process capabilities, 165-91000-00 is designed to deliver precision etching of virtually any substrate, including silicon, quartz, ceramic, aluminum, and glass. In addition, the equipment can deposit and etch metals, such as gold, copper, chromium, and palladium, for high-resolution applications. The system has a wide process range, allowing for etching depths from 3 μm to 18 μm. It also features a wide process window to allow tuning of the etch rate for optimum etching results for various applications. MATTSON 165-91000-00 also offers excellent process repeatability and statistical process control tools, such as SPC charts. It also has an onboard process software package with recipes, real-time live monitoring of process parameters, process trend analysis, statistical process control, and process data storage. The unit is constructed of Teflon and stainless steel, making it extremely durable and resistant to corrosion. All glass and silica connections are leak tight, and the machine has a self-cleaning gas lines. Additionally, the tool comes with advanced safety features, as well as venturi loading and 4" wafer handling. Overall, 165-91000-00 is an advanced etching/asher asset that delivers precise etching of virtually any substrate with high resolution. It offers excellent process repeatability and statistical process control tools with advanced safety features and 4" wafer handling. The model is constructed of Teflon and stainless steel, making it extremely durable and resistant to corrosion. The gas distribution equipment provides directional gas flow, ensuring repeatable etching profiles and uniformity of edge profiles.

There are no reviews yet