Used MATTSON Aspen II #9155758 for sale

URL successfully copied!

Tap to zoom

ID: 9155758

Wafer Size: 8"

Vintage: 1996

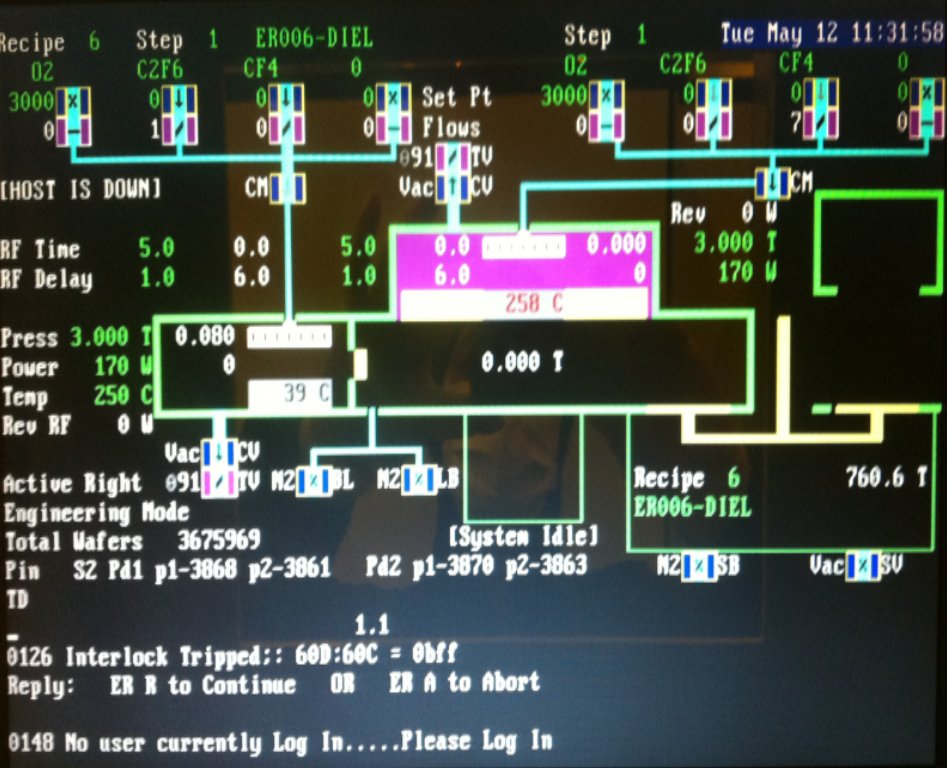

Dual chamber asher, 8"

Configuration:

Cool down: Yes

Process chamber 1: Yes

Process chamber 2: Yes

Load lock manometer: Yes

Chamber manometer: Yes

Settle manometer: Yes

Software version: 5.56E

Software type: QNX

Temp control: Watlow, Uroterm

Chamber Configuration:

Chamber type: Triode

RFPP: RF10S

RF Match: RFS 1000

MFC O2: Yes

MFC C2F6: Yes

MFC CF4: Yes

Heater block: Horizontal vertical and Circular grove

Light tower: Yes

Power: 120/208 VAC, 10A 1PH/3PH 50/60HZ 5 Wire

1996 vintage.

MATTSON Aspen II is an advanced etcher / asher designed for use in a number of processes, ranging from substrate processing through to final pattern formation. It is capable of etching and ashing wafers up to 300mm in diameter on a five-platen non-remote equipment. The system features a fully automated batch cassette loader and aligner, which removes the need for manual loading and alignment. For even greater convenience it can be connected to an industry standard robot loader. Aspen II's unique design allows it to deliver high throughput with minimal process variation and exceptional product uniformity. Its dual-zone process chambers provide independent control of process parameters, allowing the unit to achieve higher process rates. The machine is also equipped with an adjustable wafer temperature control tool, helping to minimize defects caused by substrate temperature fluctuations. In addition to its fast process times, MATTSON Aspen II also provides precise plasma etching and high-quality patterning. The asset is optimised for both etching and ashing applications and uses advanced recipes to ensure high quality etching and ashing processes. This is further aided by optional variable sized openings for minimum-sized features and its high resolution resolution mesh for precise patterning. The model also features several safety features to protect operators from potential hazards. This includes infrared sensors to detect open or damaged cassettes and an auto-disable mechanism for loadlocks and manual loading systems. Aspen II is a versatile device, offering robust performance, precise control, and precise patterning for a range of etching and ashing processes. Its simple, user-friendly design allows for easy setup and operation, making it an ideal choice for research, development, and production.

There are no reviews yet