Used MATTSON Paradigm #9222745 for sale

URL successfully copied!

Tap to zoom

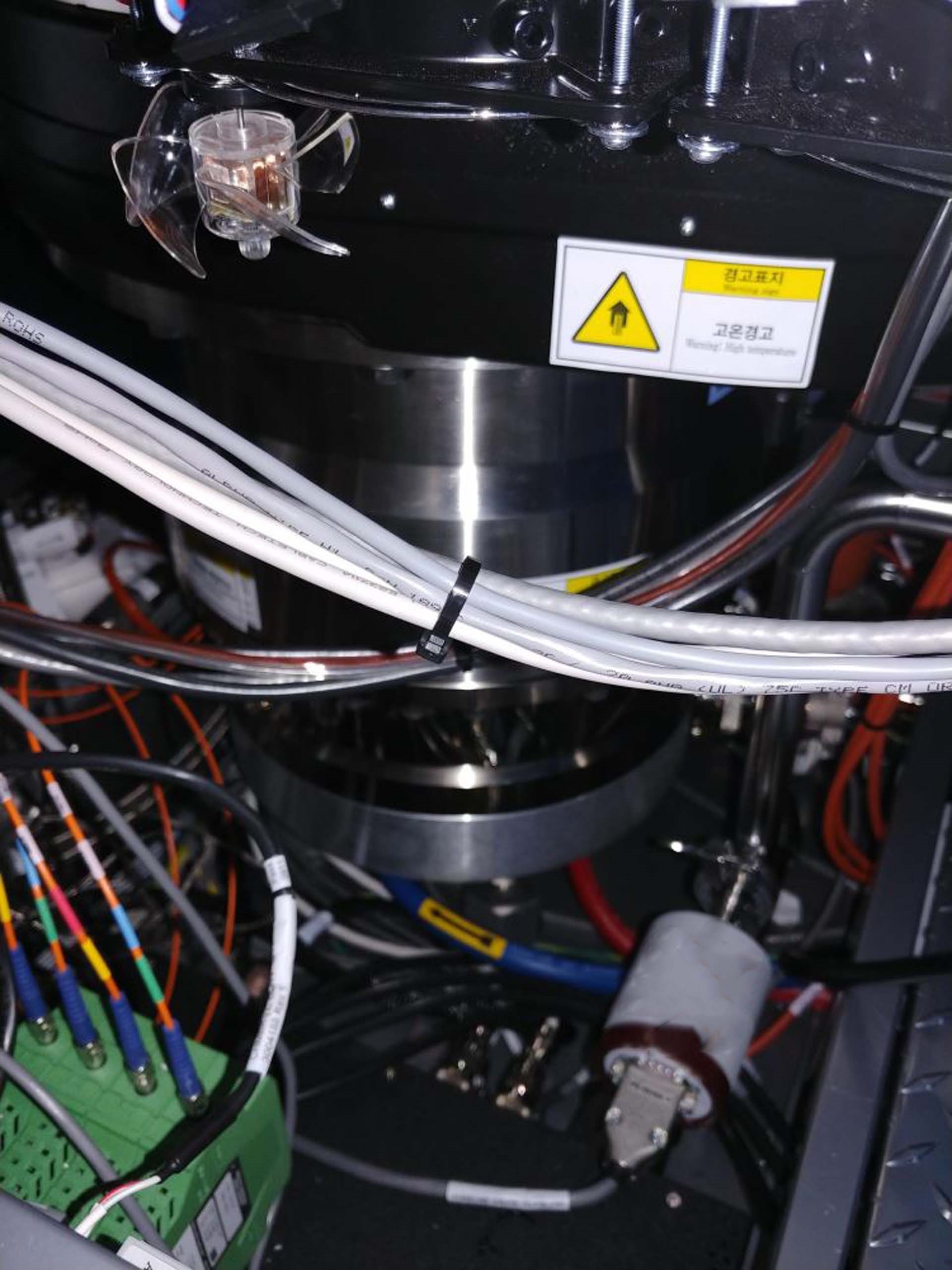

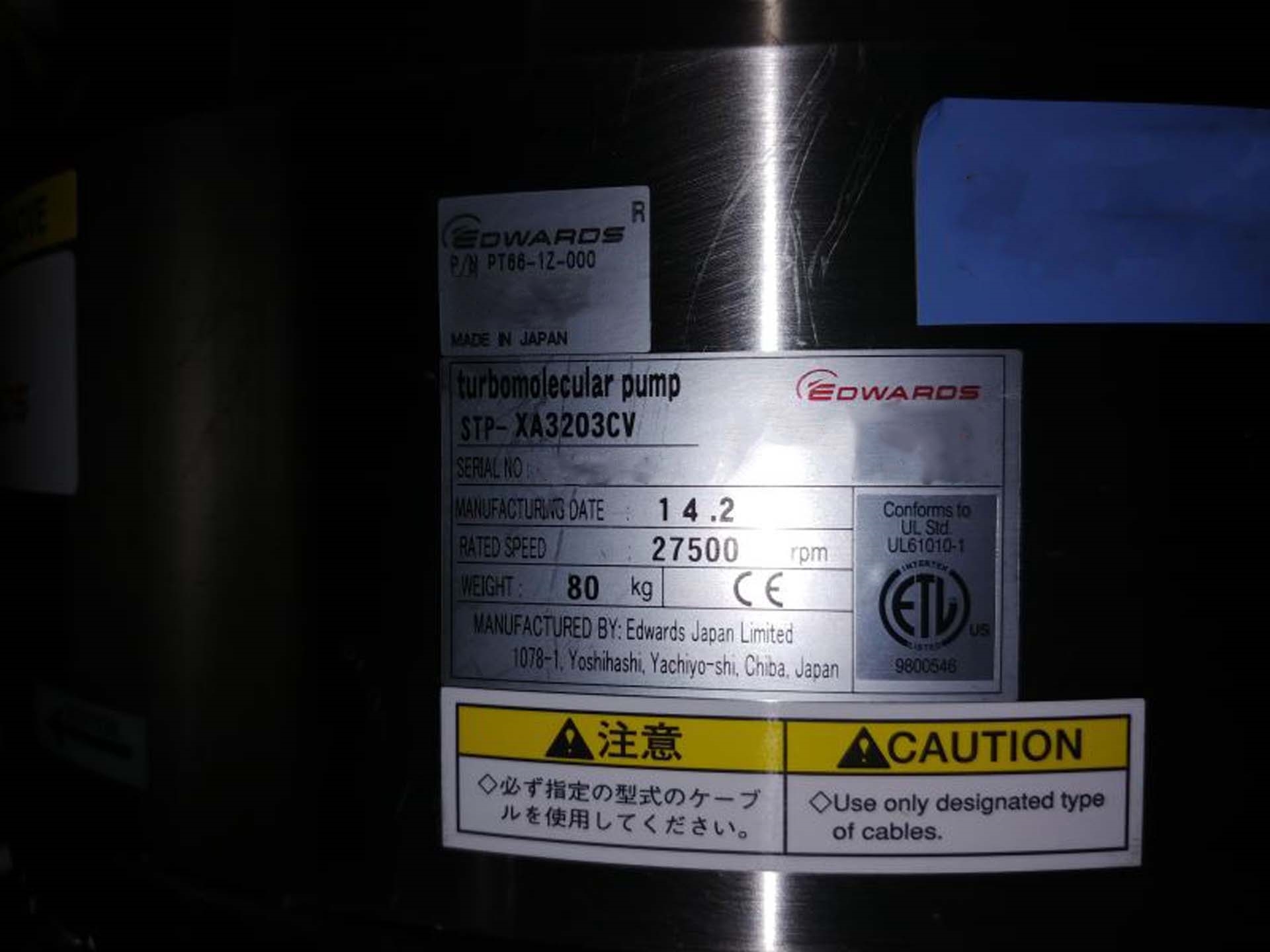

MATTSON Paradigm is a sophisticated and highly reliable asher (or etcher) used in the fabrication of microchips and other components in the electronics industry. It is designed for high-volume production of intricate electronic components and features an automated multi-chamber equipment for etching process control. Paradigm is composed of several interconnected chambers. The EMD (etching chamber) is the primary chamber and features two precision spindles capable of eight-directional movement to achieve the desired micro chip pattern. The ARC (arcing room) is the second chamber and is designed to provide a high-precision environment for thin-film deposition. Lastly, the LE (laser engraving chamber) is designed to achieve high resolution and accuracy during chip pattern design. MATTSON Paradigm also features a process control system with user-editable settings for precision control of etching operations. The etching parameters are further fine-tuned by the operator for optimal efficiency and accuracy. The unit allows for multiple recipes to be stored and easily accessed. This allows for multiple jobs to run from one machine and for simultaneous processing of various materials. To ensure the highest level of precision and accuracy, Paradigm utilizes advanced machine diagnostics. This includes continual monitoring of etching chamber temperature and pressure, spindle position, laser beam power, pattern orientation, and the amount of photoresist remaining. These parameters are also stored with each job and readjusted to maximize chip pattern accuracy and yield. MATTSON also offers a unique thermal soak tool to protect the etching chamber temperature and promote uniformity of the etched film. This extends the life of the etching chamber and allows for higher throughput. Overall, MATTSON Paradigm is an ideal solution for high-volume production of intricate component designs. Its features set it apart as the go-to asset for fast and accurate chip etching. The automated multi-chamber model ensures optimal process control, and its advanced diagnostic equipment ensures the highest level of precision and accuracy, making it an ideal solutions for any application requiring precise microchip etching.

There are no reviews yet