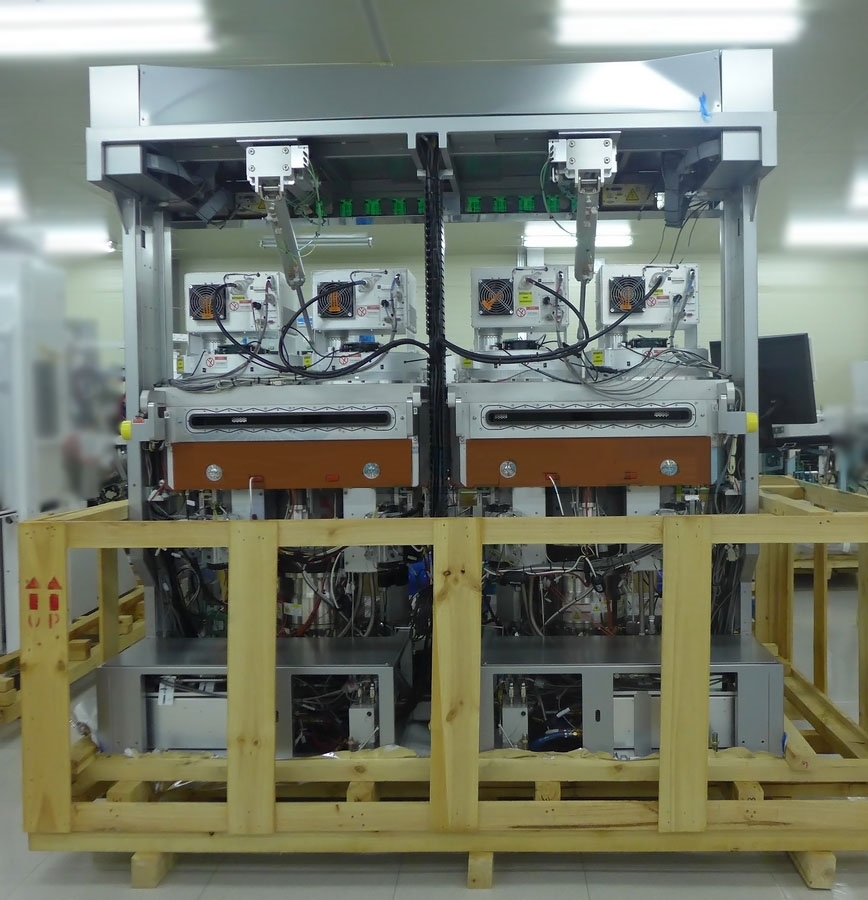

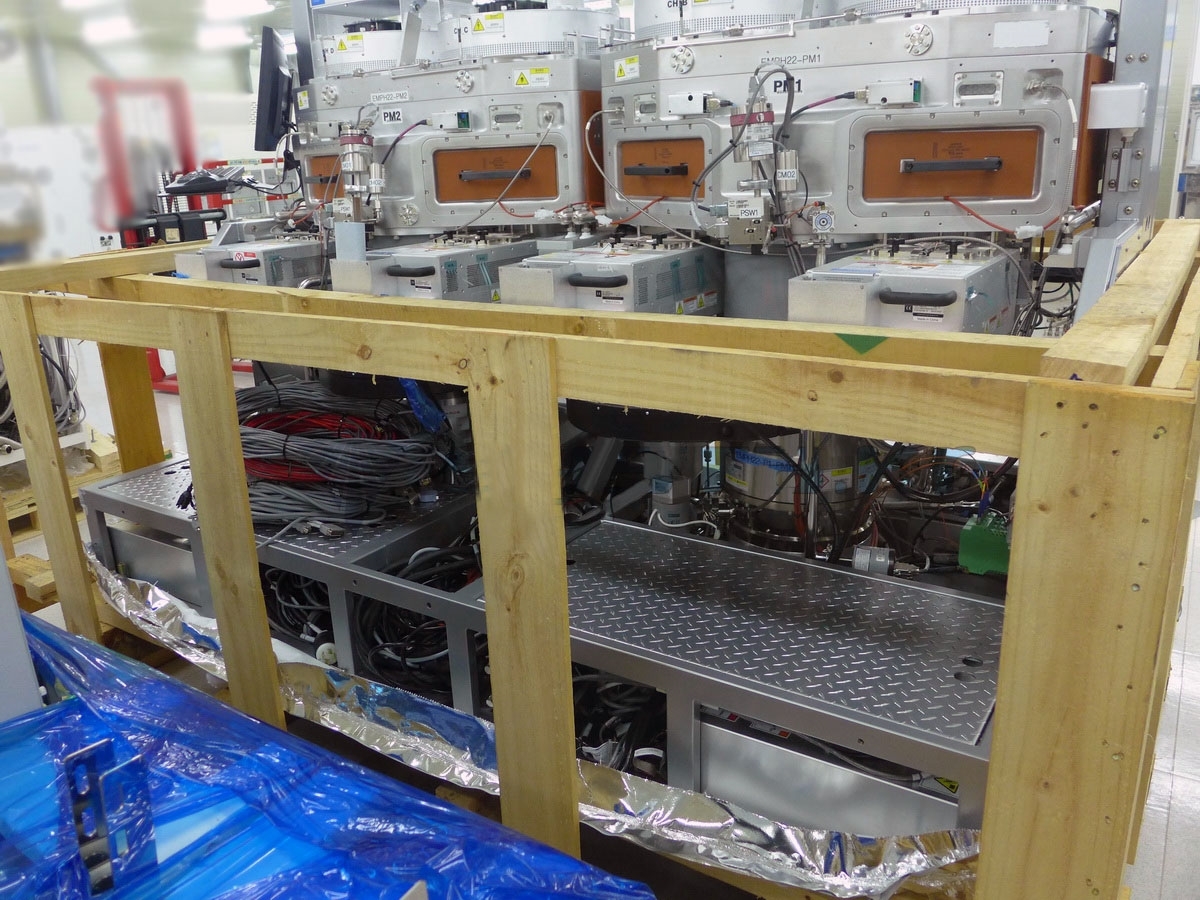

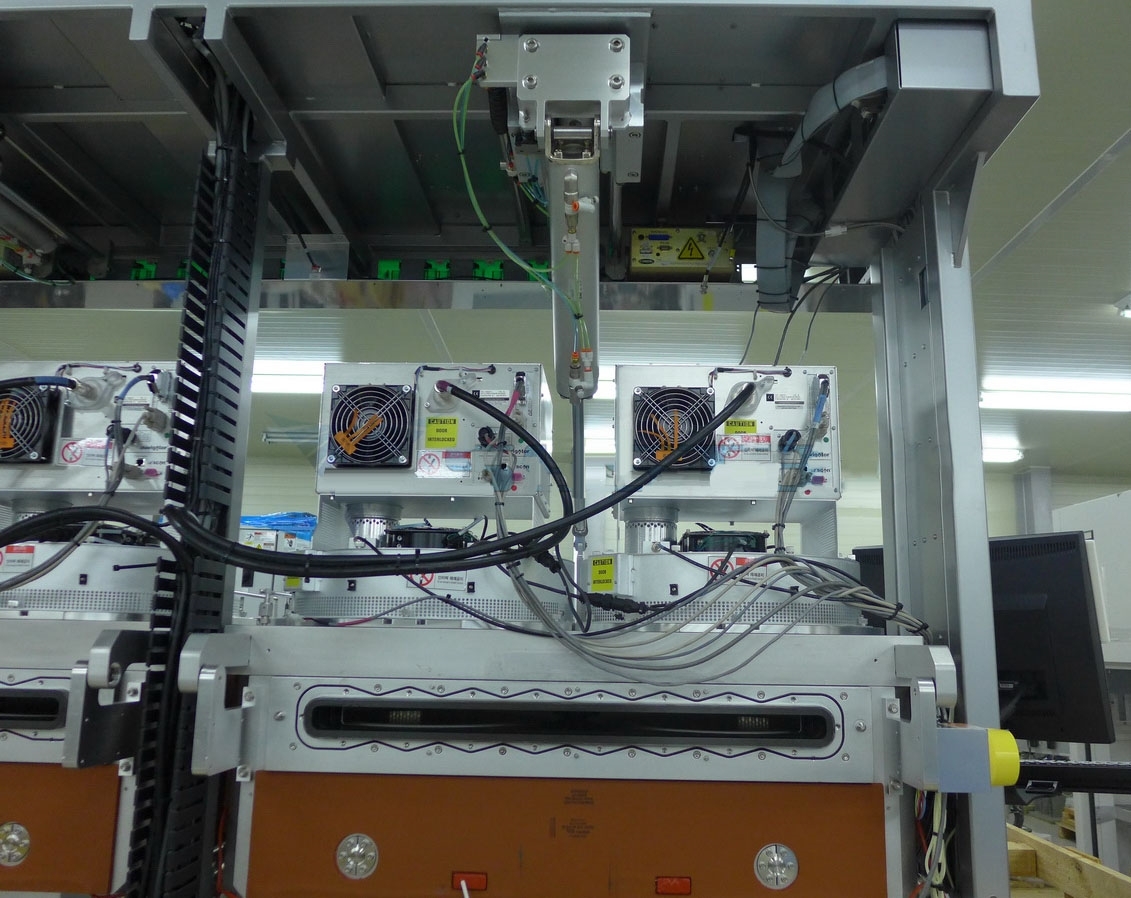

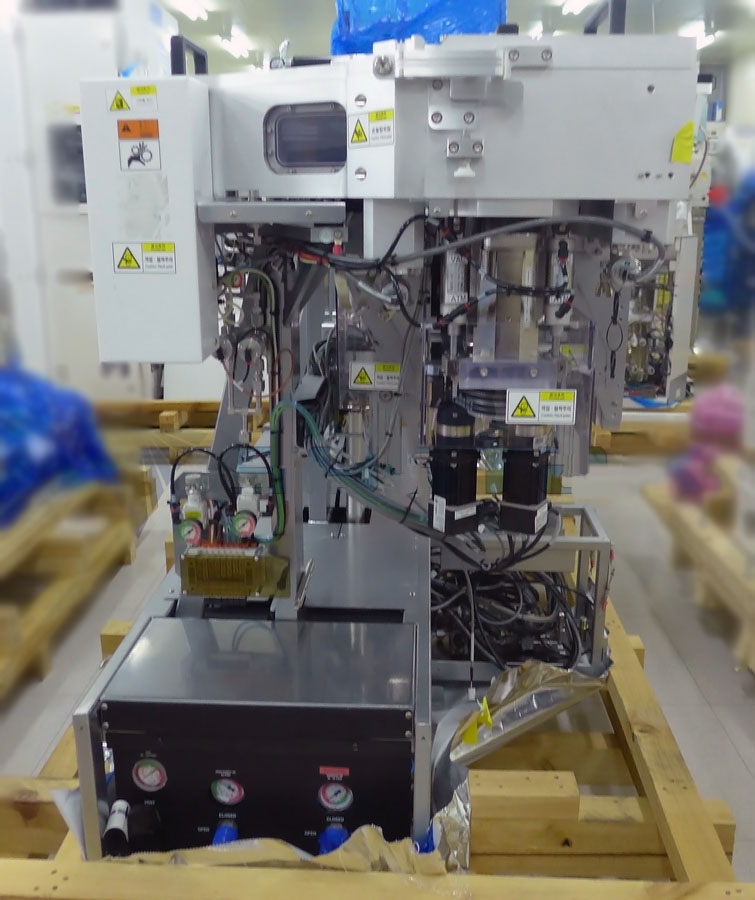

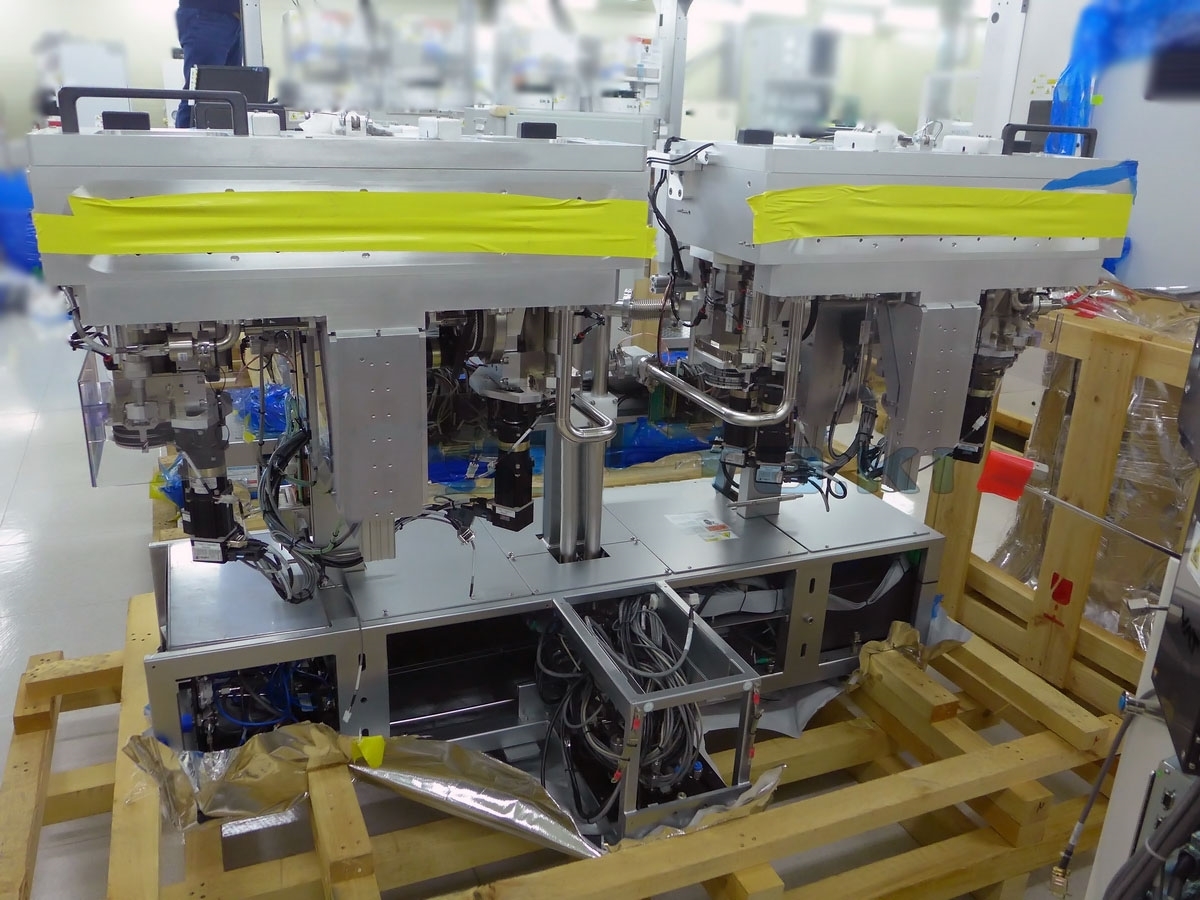

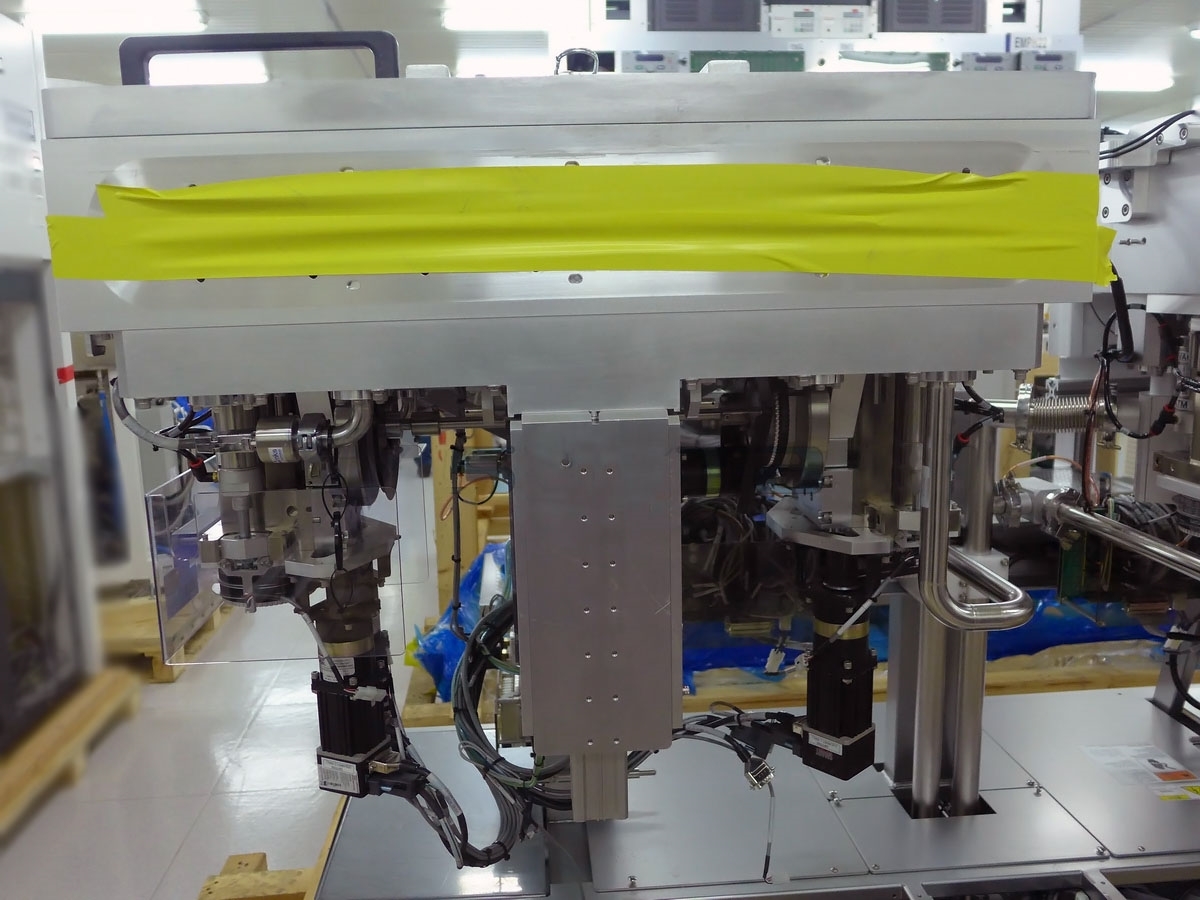

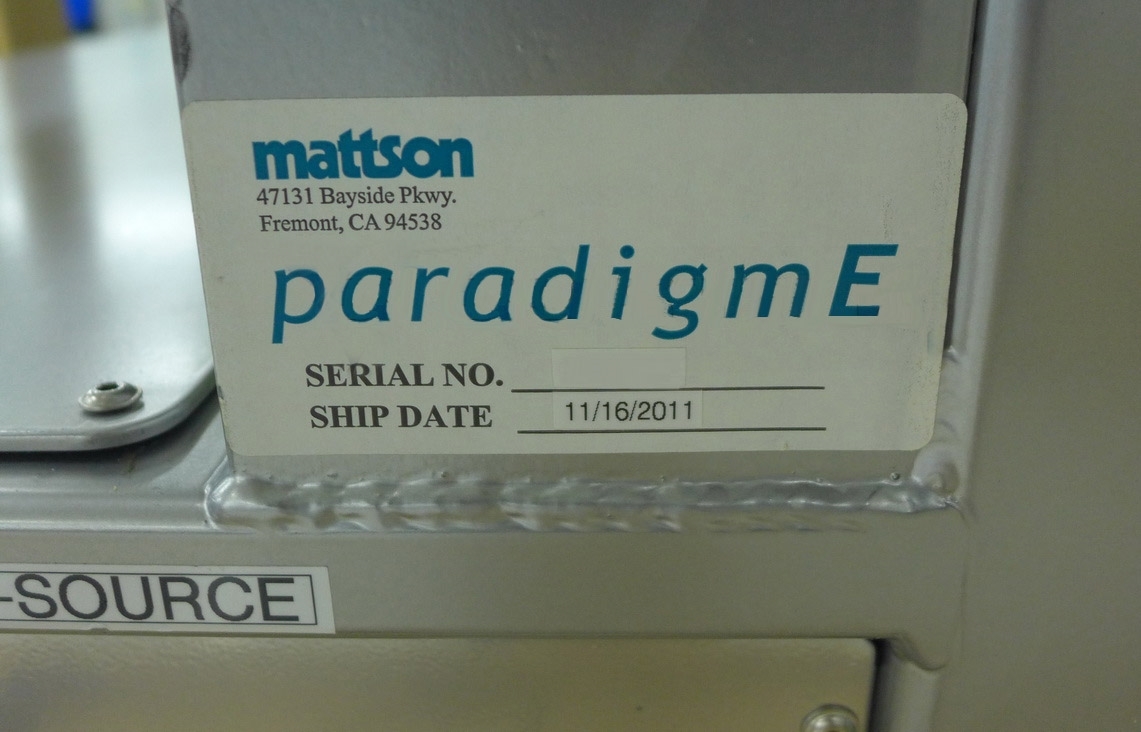

Used MATTSON Paradigme SI #9259601 for sale

URL successfully copied!

Tap to zoom

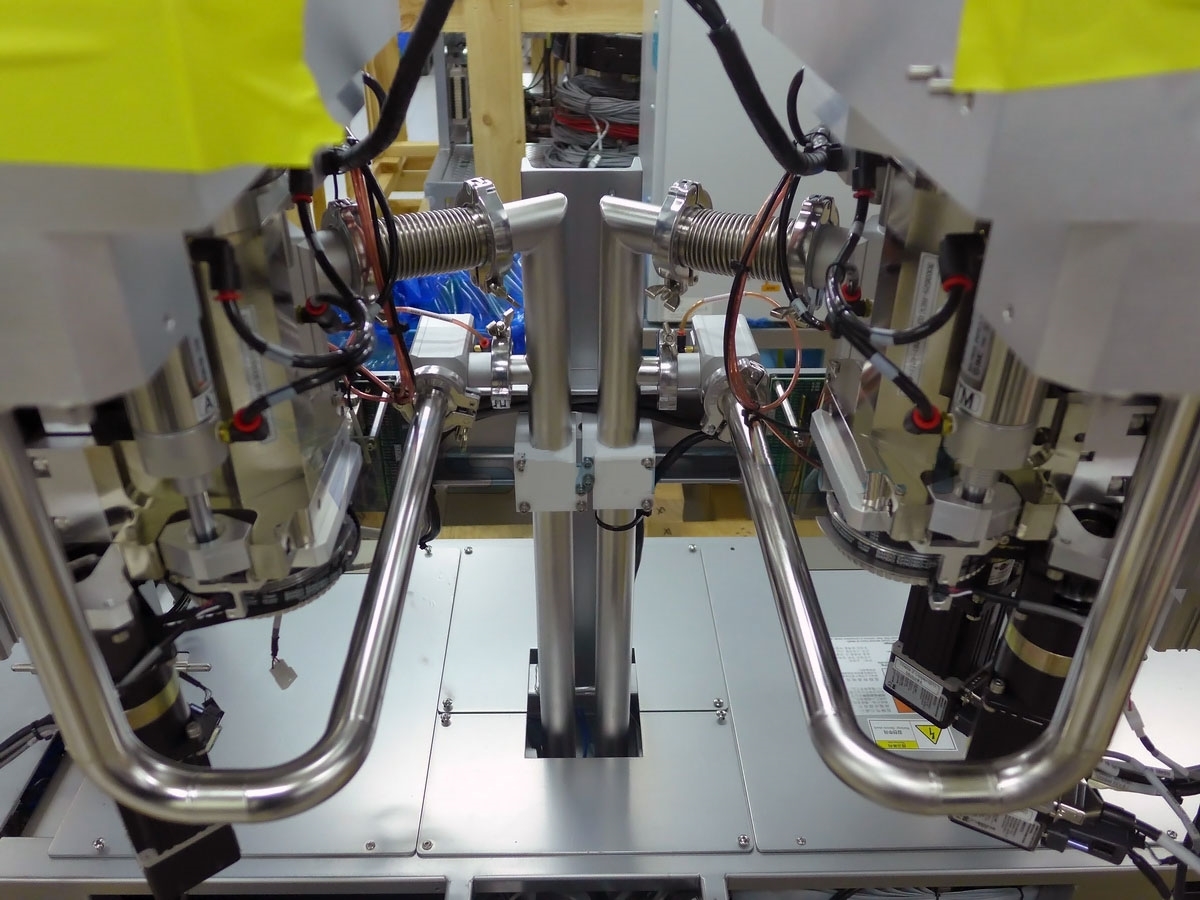

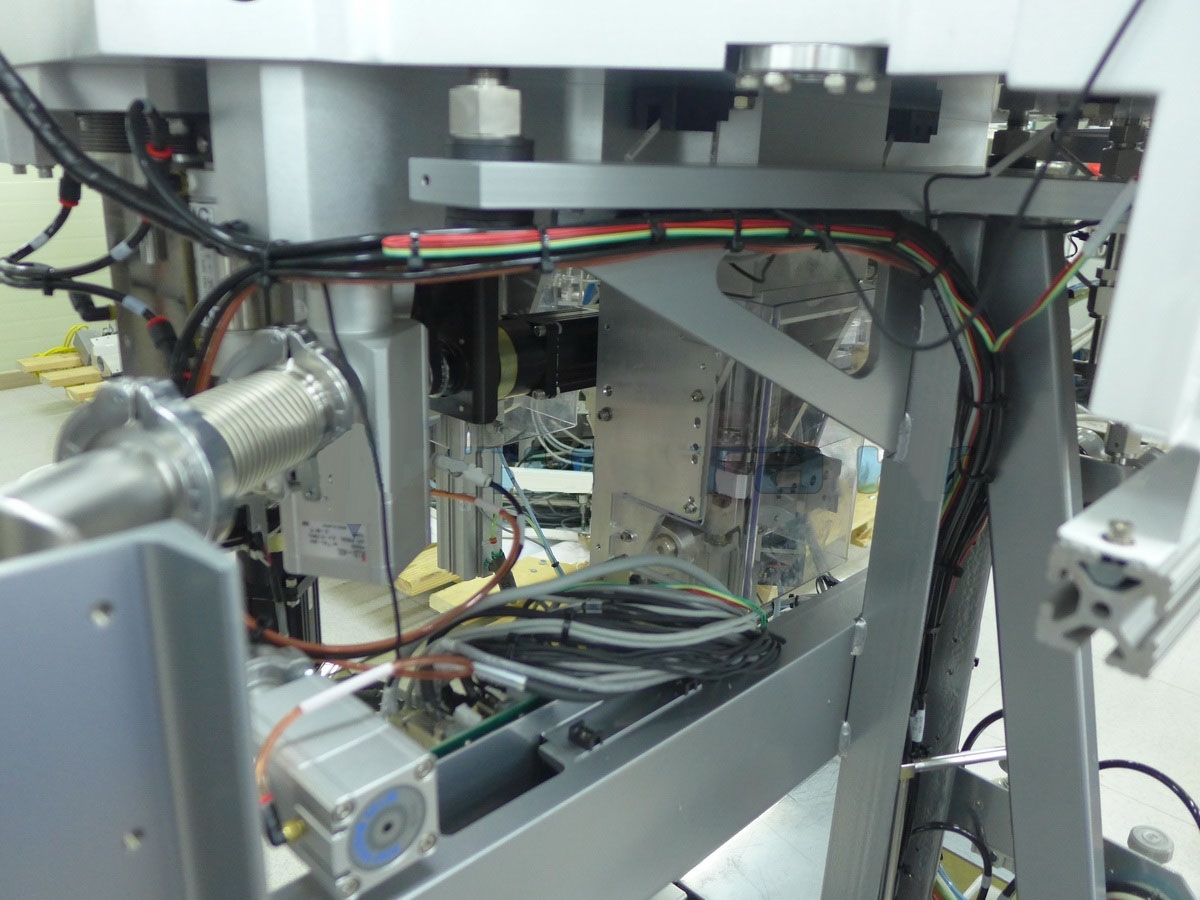

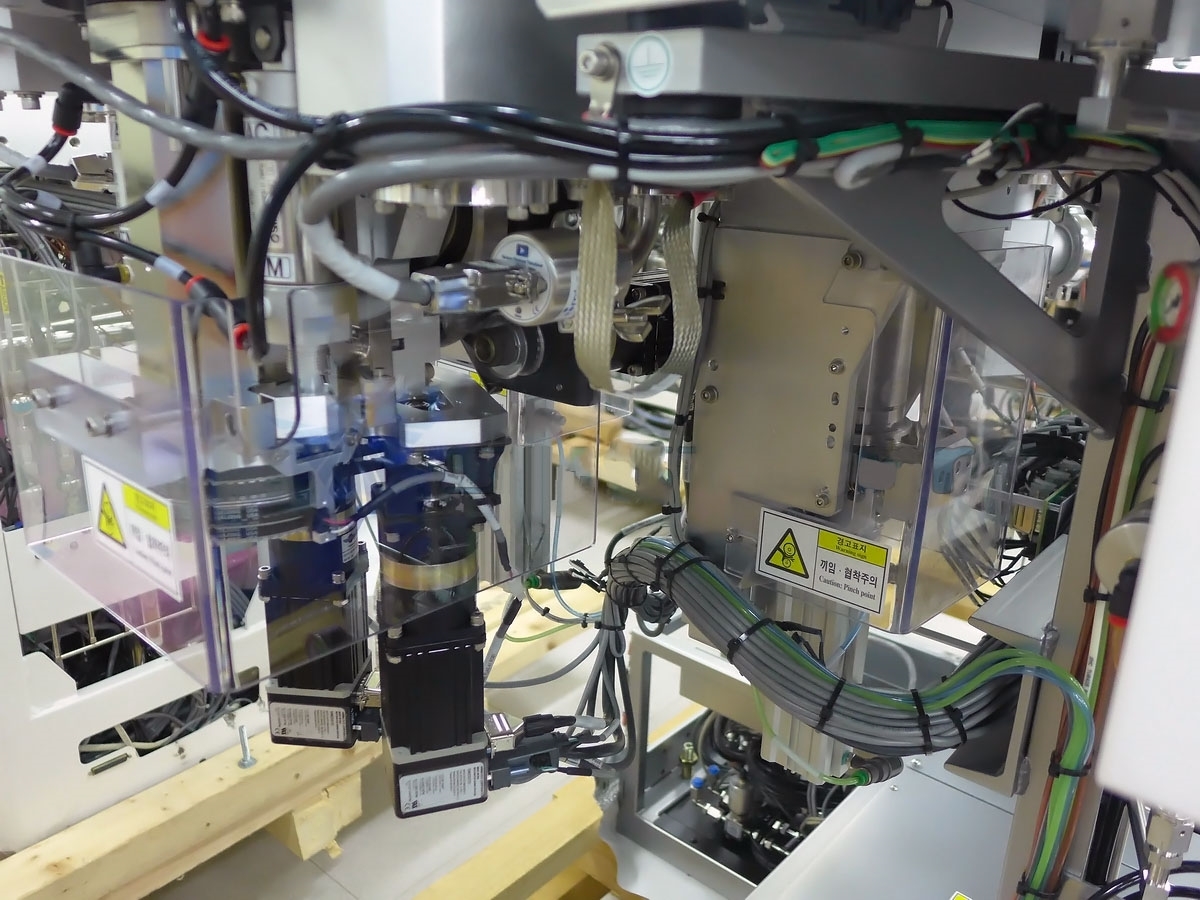

MATTSON Paradigm SI is an advanced etcher/aser equipment designed for precise patterning of a wide variety of materials for use in device fabrication. The system is composed of three main components: an ultra-high resolution scanning unit, a vacuum feed mechanism, and a pressure-controlled gas along with a dedicated patterning chamber. The scanning machine utilizes patented scanning technology which helps to ensure that the substrate is evenly exposed for optimal etching yields. The tool is engineered for the highest possible accuracy and repeatability of patterning process parameters over time. Additionally, the asset uses an advanced software suite which provides users with unprecedented control of the etching process. The vacuum feed mechanism is designed to provide a controlled environment for the etching process. This vacuum feed model eliminates any residual gas within the chamber, helping to ensure that the etching process parameters remain consistent over time. Additionally, this equipment helps to ensure that the pattern patterns are physically aligned with the existing substrate contours. The pressure-controlled gas provides an accurate and even distribution of the etching agent. This system uses a flow of the etching agent to continuously fill the etching chamber. This ensures that the etching process occurs uniformly and with maximum efficiency. Additionally, this unit offers precise control of the etching agent's pressure and concentration as required for optimal patterning. The dedicated patterning chamber is designed to allow for rapid patterning of multiple layers simultaneously, or for full patterns with a single pass. This chamber is capable of accurately and repeatably controlling the etching environment to ensure that each pattern is perfected without the need for extensive post-processing. This helps to reduce overall production time and costs. Overall, MATTSON Paradigm SI is an advanced etcher/aser machine that provides a reliable and cost effective way to produce complex patterns on a wide variety of materials. The combination of ultra-high resolution scan technology, a vacuum feed mechanism, and pressure-controlled gas provide users with unparalleled control of the etching process. Additionally, the dedicated patterning chamber helps to ensure that each pattern is correctly aligned and perfect with minimal post-processing.

There are no reviews yet