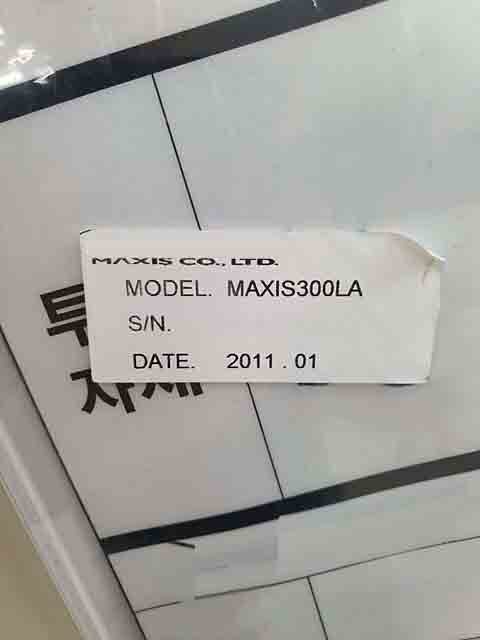

Used MAXIS 300L #293586674 for sale

URL successfully copied!

Tap to zoom

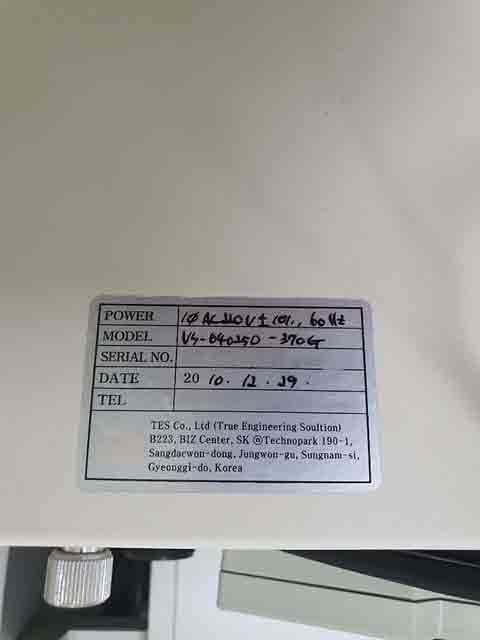

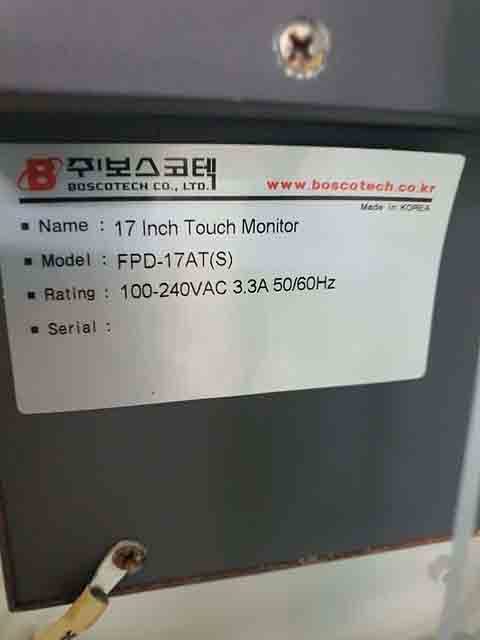

MAXIS 300L is an etcher/asher designed for deep etching and ashing of various materials, including metals, plastics, ceramics, and silicon. This etcher/asher combines two etching technologies - HF (Hydrogen Fluoride) and mp (Metal Plasma) - to achieve deep and uniform etching in a single chamber. MAXIS 300 L features a 15-inch square chamber made of stainless steel with an integrated emitter and receivers, enabling full four-channeled etching/ashing. Its unique process gases—uranium (U2O2) and chlorine-hexafluoride (CF6) both intensify etching effects—are injected directly into the chamber, ensuring uniform process gas distribution throughout. This etcher/asher houses 6 quartz trays, with 3 removable and 3 fixed, for sample handling. Samples can be loaded onto quartz trays and transferred into the chamber with a mechanism called a transfer shuttle. This shuttle is also used to transport sample trays from the etcher/asher to other laboratories for further processing. 300L is equipped with a built-in safety system, including an automatic shut-down and an emergency stop (EN) button. Moreover, it is designed to prevent over-pressure, ensuring safe operation of the etcher/asher. 300 L is a fully automated etcher with two operator modes—full manual and semi-auto—and offers a wide range of process monitoring tools, including step-by-step wafer scanning and pattern compare functions. It also comes with a 3D view function to display data graphically in three dimensions, allowing the user to take a look at the process results. The system is equipped with a programmable logic control (PLC) board which enables synchronized operation of multiple chambers, as well as a user-friendly graphical user interface which provides interactive menus and a step-by-step description of each step necessary for job execution. In addition, its intelligent motion analysis software (IMAS) software enables fast and easy calibration of etching parameters such as speed, pressure, and process time. This software also enables users to control etching processes from a remote location. MAXIS 300L is the perfect tool for deep etching and ashing of various materials. Its dual etching technology and specialized design make it ideal for etching and ashing with high accuracy over a range of materials. It is designed for reliable and repeatable performance, offering enhanced safety and improved process control, thus making it an ideal etcher/asher for high-end applications.

There are no reviews yet