Used MAXIS 300LA #293586670 for sale

URL successfully copied!

Tap to zoom

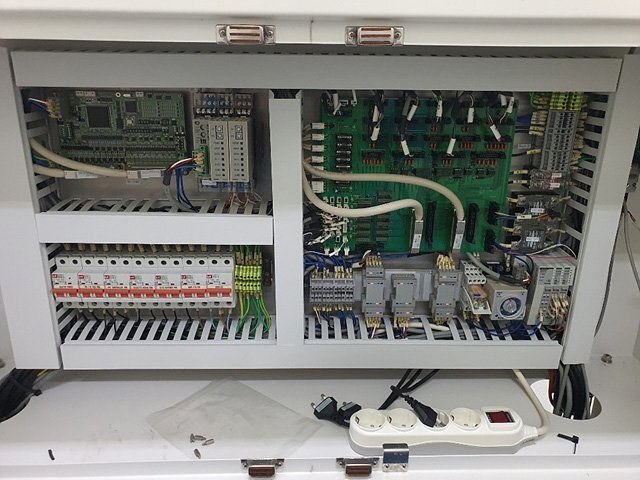

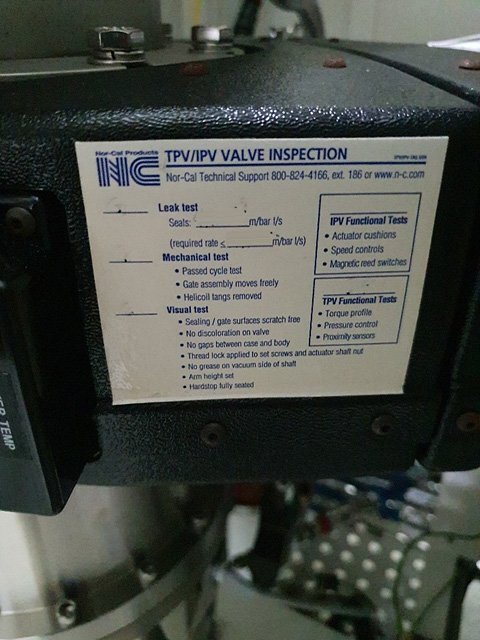

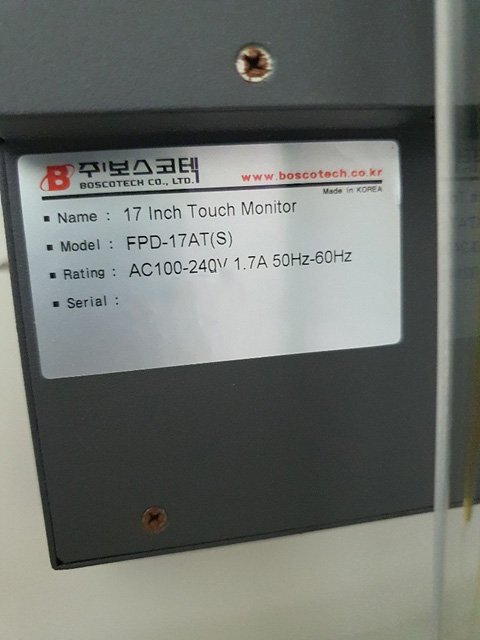

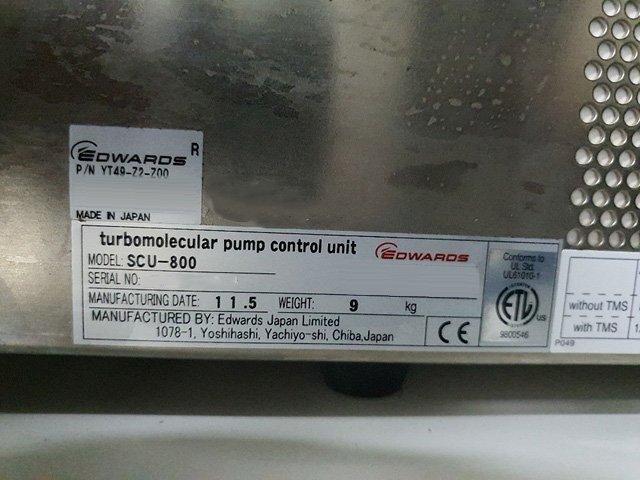

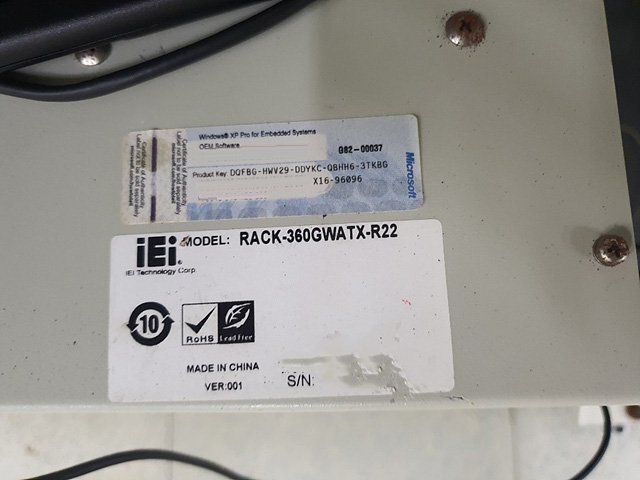

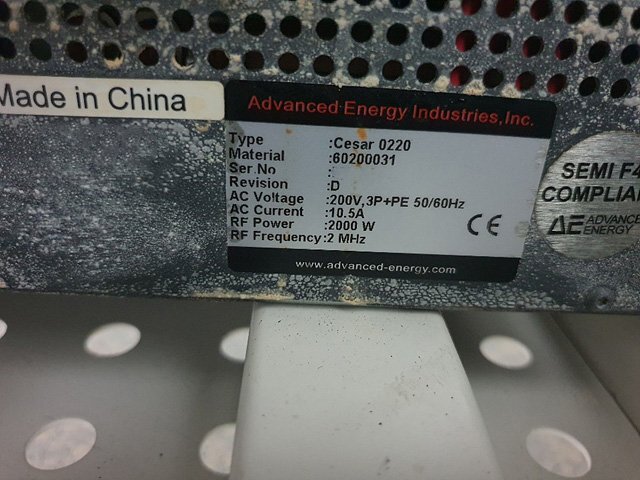

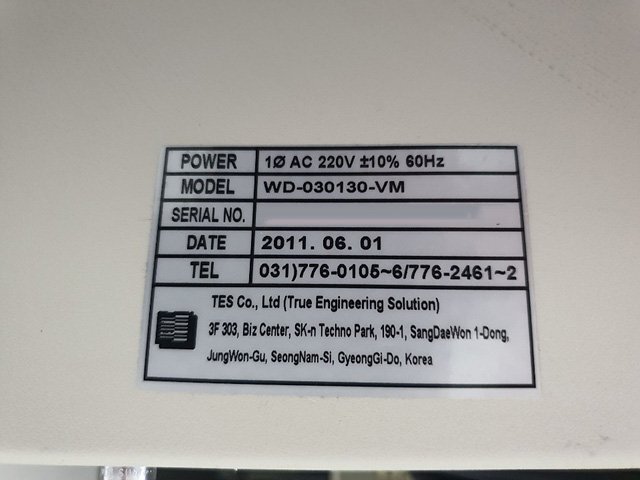

MAXIS 300LA is an etching equipment specifically designed for production, research and product development. It is a horizontal etchant that can process standard semiconductor wafers up to 300mm in diameter. This system features an Automatic Load Port, a main etching cabinet, an exhaust gas unit, ancillary splitter/mixer devices, and an LCD with both options for service monitoring and for intuitive operator control. The Automatic Load Port is an easy to use, robotic-like transporter, equipped with two axes, that helps manage the handling of SC-type (spherical) wafers. It also minimizes the chances of unacceptable wafer misalignment, increases production efficiency, and provides easy noncontact wafer transfer. The main cabinet of 300LA consists of a Vacuum-Isolation chamber, a Static-Bed Pressure Controller, a Thermocouple-Pressure Controller, a Flowswitch-Pressure Controller, and a Gas Monitor. Additionally, the corrosion-proof metallic panel of the chamber is designed to eliminate any communication with the outside environment. This cabinet helps to control pressure, temperature and gas flow rates for accurate etching. The exhaust gas machine is used to direct the exhausted etching byproduct away from the etching chamber and out of MAXIS 300LA. It features an exhaust plate and four pumps, which together ensure the safe evacuation of any generated vapors. 300LA also includes ancillary splitter/mixer devices, a valve array, temperature control, and flow control. These devices allow for the accurate mixing of up to two precursor gases in the etching chamber to achieve more uniform etching results. Finally, the LCD display with both service monitoring options and intuitive operator control allows for comprehensive machine settings, process control, and queuing tool maintenance. This feature ensures maximum wafer production with minimal effort from the operator. In conclusion, MAXIS 300LA etching asset is a reliable, versatile, and powerful tool for the production, research, and development of semiconductor wafers. Its Automatic Load Port ensures easy and accurate wafer handling, its corrosion-proof metallic panel ensures no communication with the outside environment, and its exhaust gas model ensures safe evacuation of any generated vapors. Its ancillary splitter/mixer devices, valve array, temperature and gas flow control, and LCD with both service monitoring and intuitive operator control ensure consistent quality and maximum wafer production with minimal effort from the operator.

There are no reviews yet