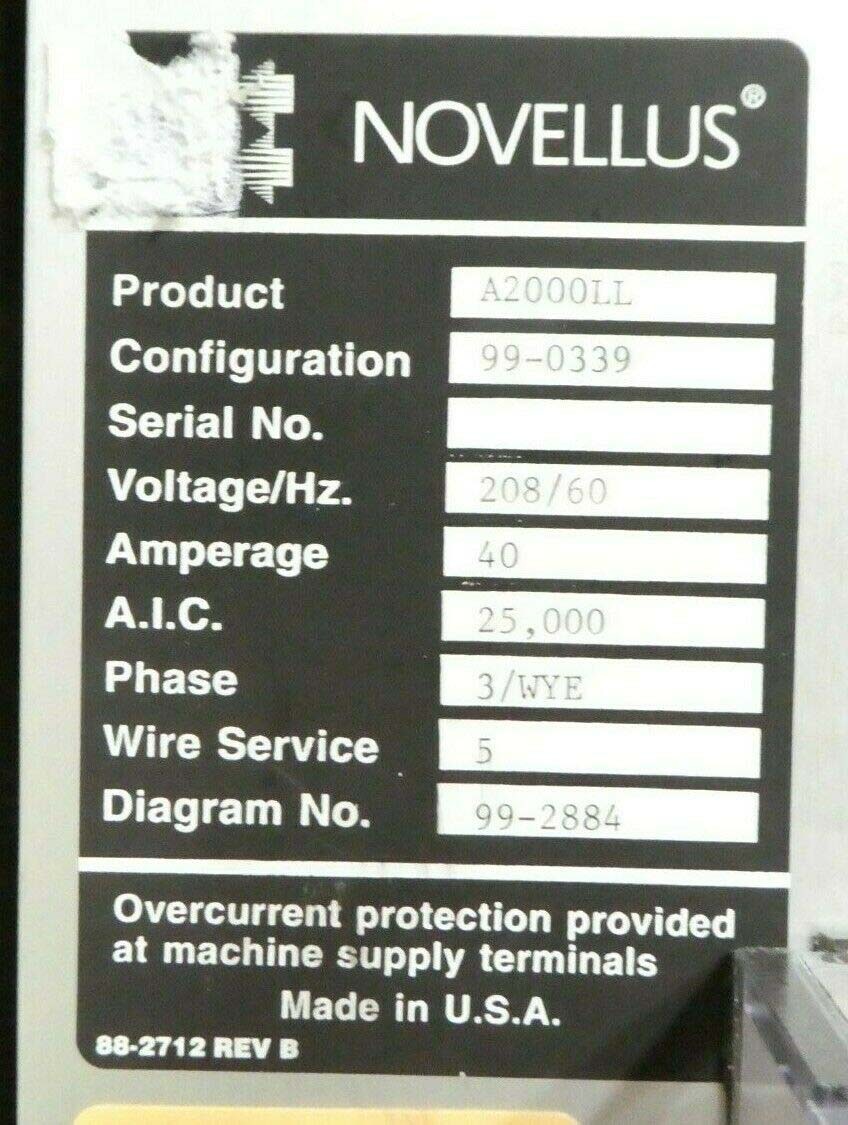

Used NOVELLUS Aura 2000LL #293594774 for sale

URL successfully copied!

Tap to zoom

ID: 293594774

Asher

Part No: 99-0339

Non-copper

Components:

Make / Model / Description / Part number

- / - / Load lock chamber / A01-218-01

GASONICS / 94-1175 / Indexer elevator / 04630-003

GASONICS / 94-1174 / Indexer elevator / 04630-004

GASONICS / 94-1118 / Load lock elevators / 04290-201

GASONICS / 94-1119 / Load lock elevators / 04290-101

DEXON / FFU / - / MS43E-1040

GASONICS / - / Loadlock rear panel display / A95-107-01

MKS INSTRUMENTS / Baratron / - / 622A11TDE

MKS INSTRUMENTS / 150 / Pressure controller / 152H-P0

MKS INSTRUMENTS / - / Valve / 253B-11020

NOVELLUS / - / Waveguide systems / 95-4477

(1) / VARIAN / - / Valve / L6281703

(1) / OMRON / Sysmac C40H / PLC / C40H-060R-DE-V1

PCB:

Make / Model / Description / Part number

GASONICS / - / Plasma / A90-031-03

GASONICS / - / Controller board / 90-2658

GASONICS / - / Display decoder / 90-2609

GASONICS / - / Loadlock interface BD / 90-2608

HINE DESIGN / - / ARM Controller board / 02423-001 / 06764-001

NOVELLUS / A2000 / Interlock BD / 90-2735

Wafer handling robot / arm unit missing

CE Marked.

NOVELLUS Aura 2000LL is a state-of-the-art etcher/asher solution for use in semiconductor fabs. Built from durable materials and advanced technology, Aura 2000LL provides fast and precise processing of substrates in a variety of granular sizes. Its process chamber has an inner diameter of 500mm to accommodate large substrates, and its optimized spatial uniformity of etching/ashing helps ensure excellent process results. The enclosed machine design of NOVELLUS Aura 2000LL functions efficiently via multiple etcher sources, venting out particles, and ventilation systems. It also features low-cost maintenance, in comparison to traditional etching configurations, due to its top-down ashing feature. In addition, the tool offers programmable multi-zone substrate control, allowing for maximum process flexibility. Specifically, the machine is equipped with three etcher sources, a VHF source, a microwave source, and a broad beam source. The VHF source is the most commonly used, and can provide a multi-zone capability to etch small or large substrates without having to reduce the chamber diameter. The versatility of this etcher source allows Aura 2000LL to process a wide range of materials and etch depths accurately. Moreover, its high-frequency, high-power operation assists in maintaining high process uniformities, making it suitable for application in high-volume product moves. Similarly, the microwave source on NOVELLUS Aura 2000LL offers a multi-mode etching approach with high process rates and high-quality results. The broad-beam source, however, is used to rapidly process substrates with the aid of a high-energy electron beam. This beam is capable of inducing undesired charging, ultimately needing to be neutralized and anode plates installed. Finally, Aura 2000LL is set apart from other chemical etching solutions with its reliable CIP (clean in place) operations. This chemical integrated purge process helps remove and prevent contaminants from formation, ensuring that the etch chamber is filled with the most clean environment possible. Such innovative self-maintenance of NOVELLUS Aura 2000LL helps enhance its repeatability and reproducibility for advanced process capabilities. Part of the award-winning NOVELLUS family of products, Aura 2000LL stands apart from other etching systems with its flexibility to accommodate a variety of substrates sizes and high-quality etch depths. Its optimized spatial uniformity of etching/ashing and high-speed operation make it ideal for highly-demanding applications within semiconductor fabs.

There are no reviews yet