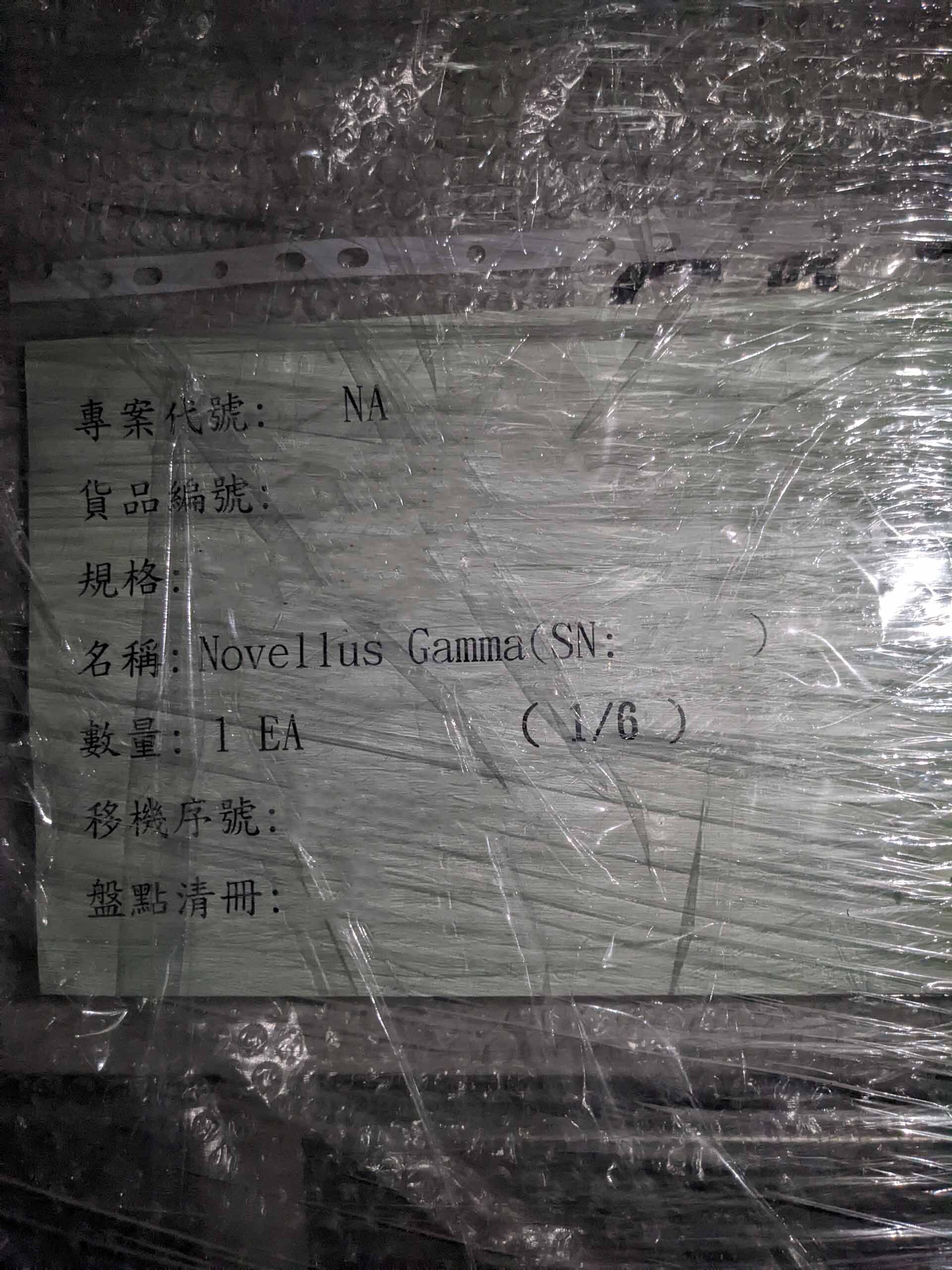

Used NOVELLUS Gamma 2130 #293627328 for sale

URL successfully copied!

Tap to zoom

ID: 293627328

Wafer Size: 12"

Vintage: 2004

PR Stripper, 12"

GXT Chamber

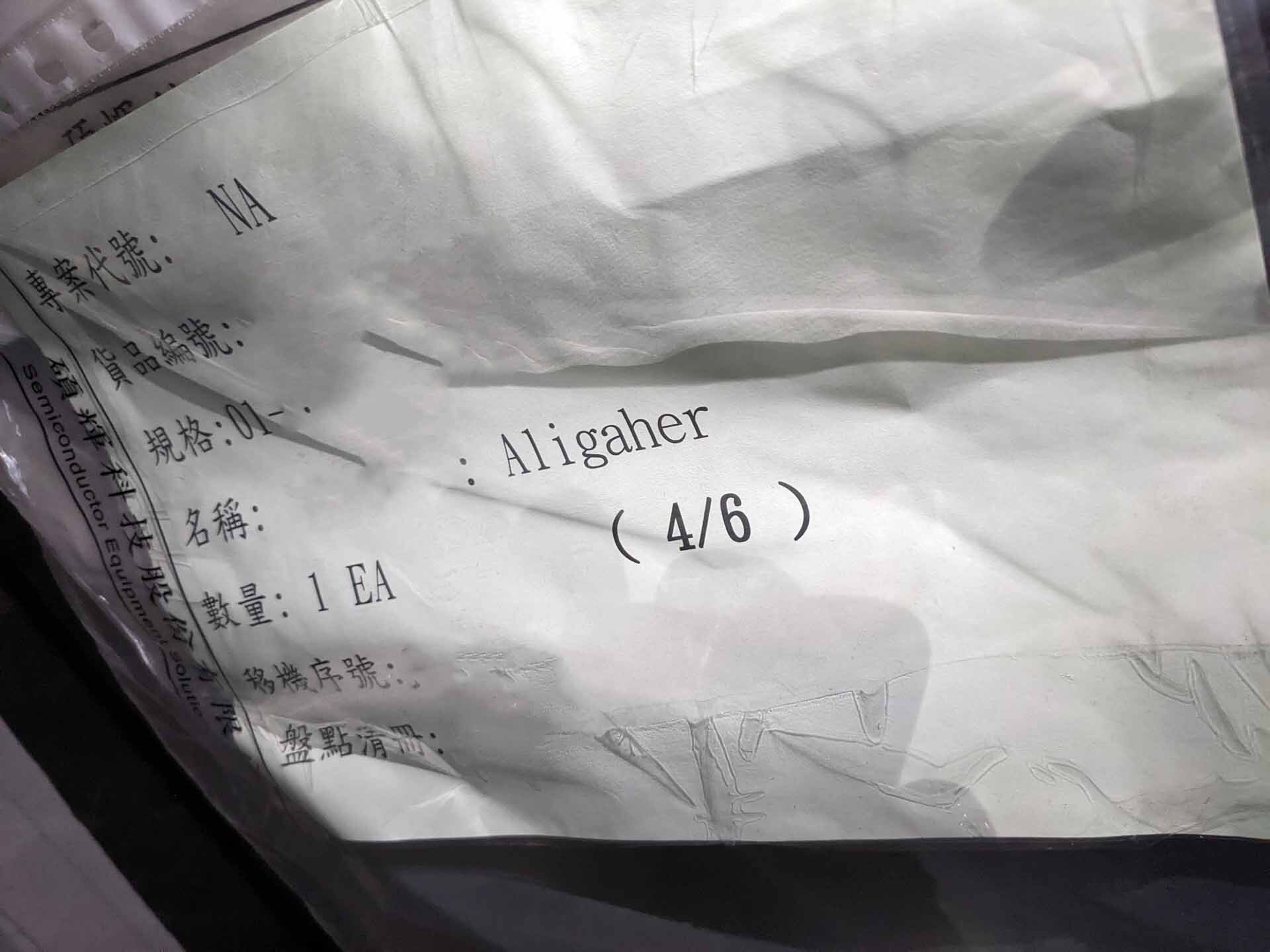

YASKAWA Aligner

KEYENCE Light curtain

(5) ENI GHW-50A-04 RF Rack generators

(2) Generator racks

BROOKS TM V6 Fixload

02-169208-00 EFEM Robot

UI Panel

IU Panel

RF Signal cable

Loadport

Robot station

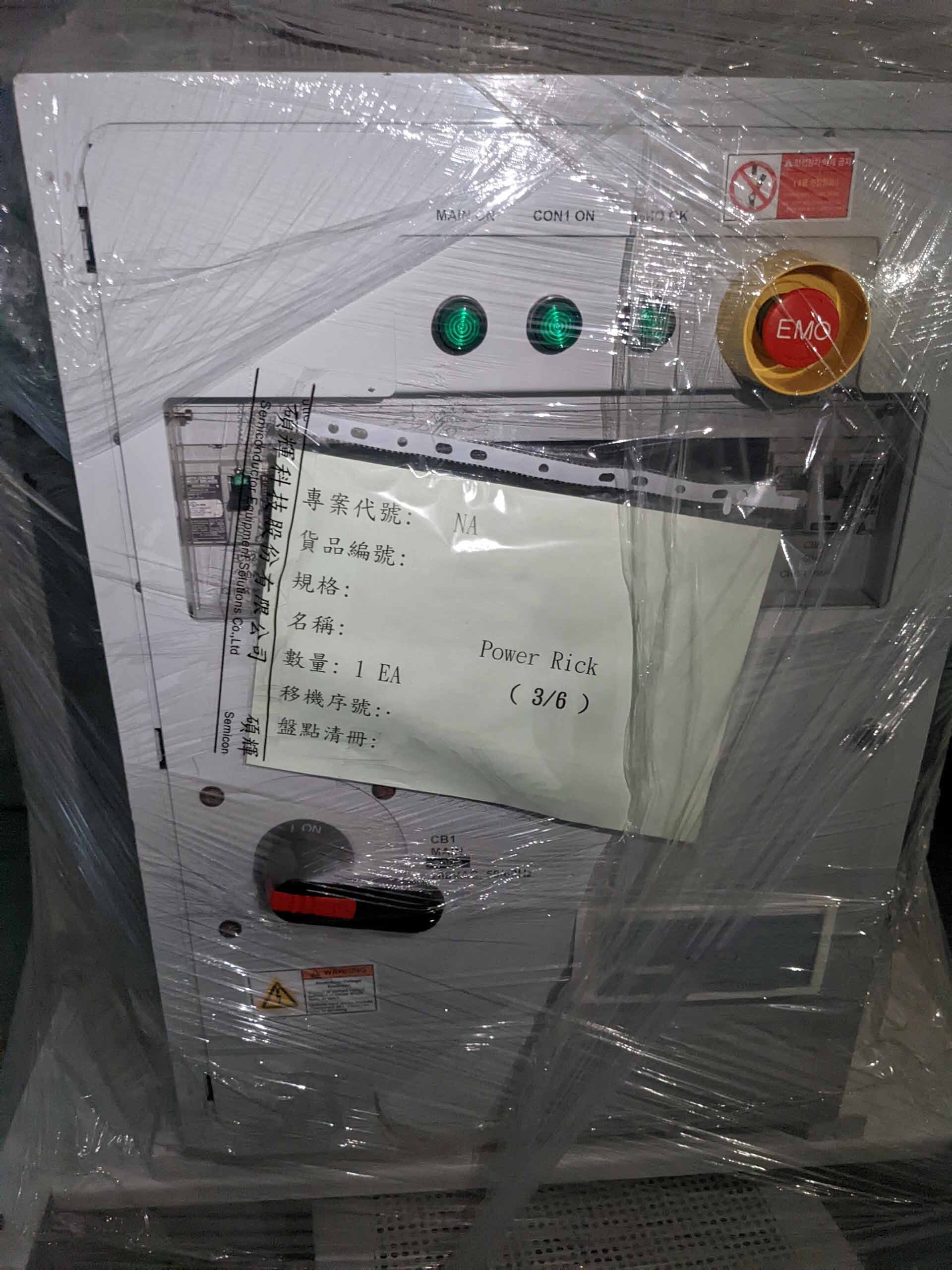

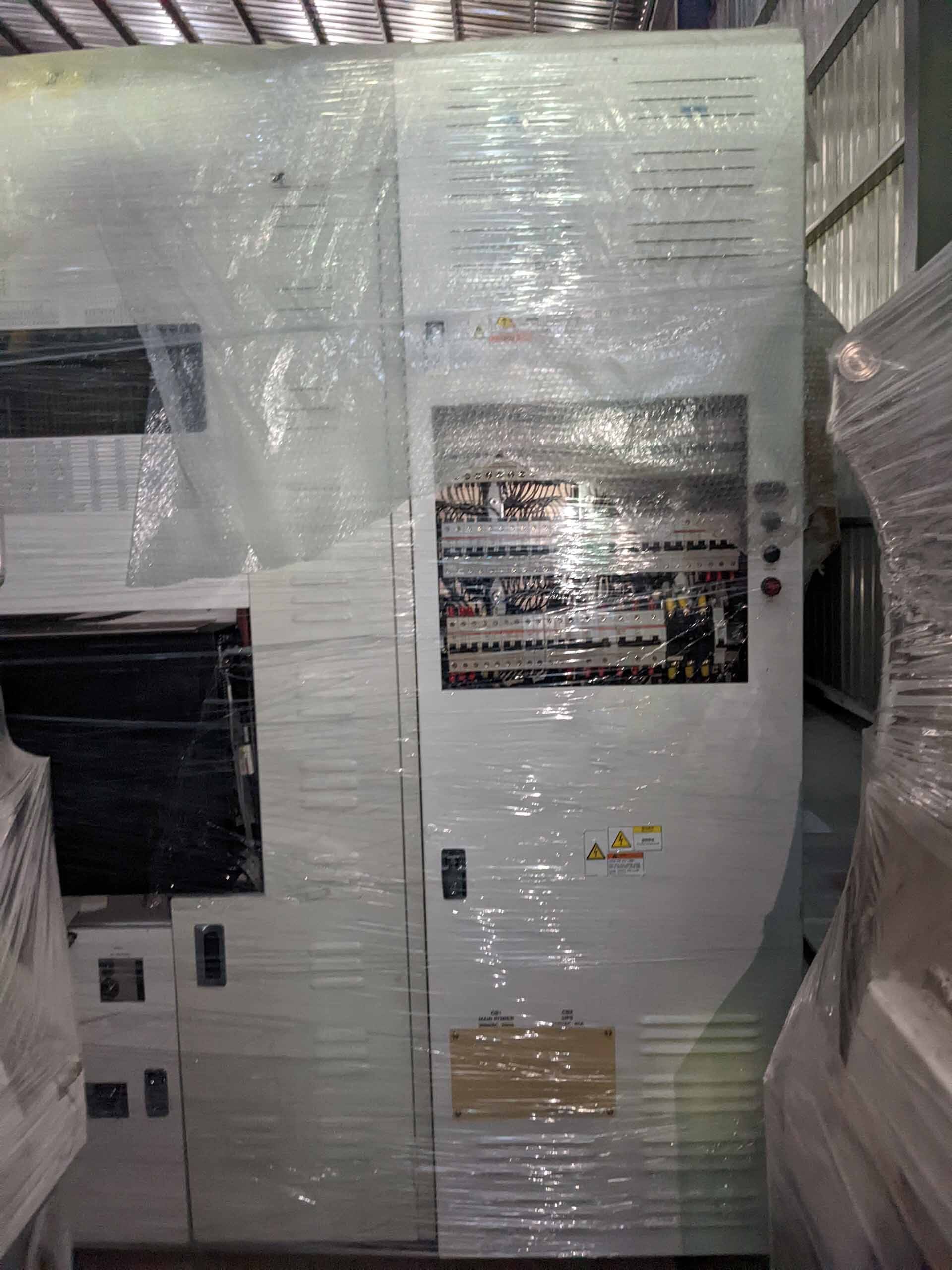

Power rack

Process chamber:

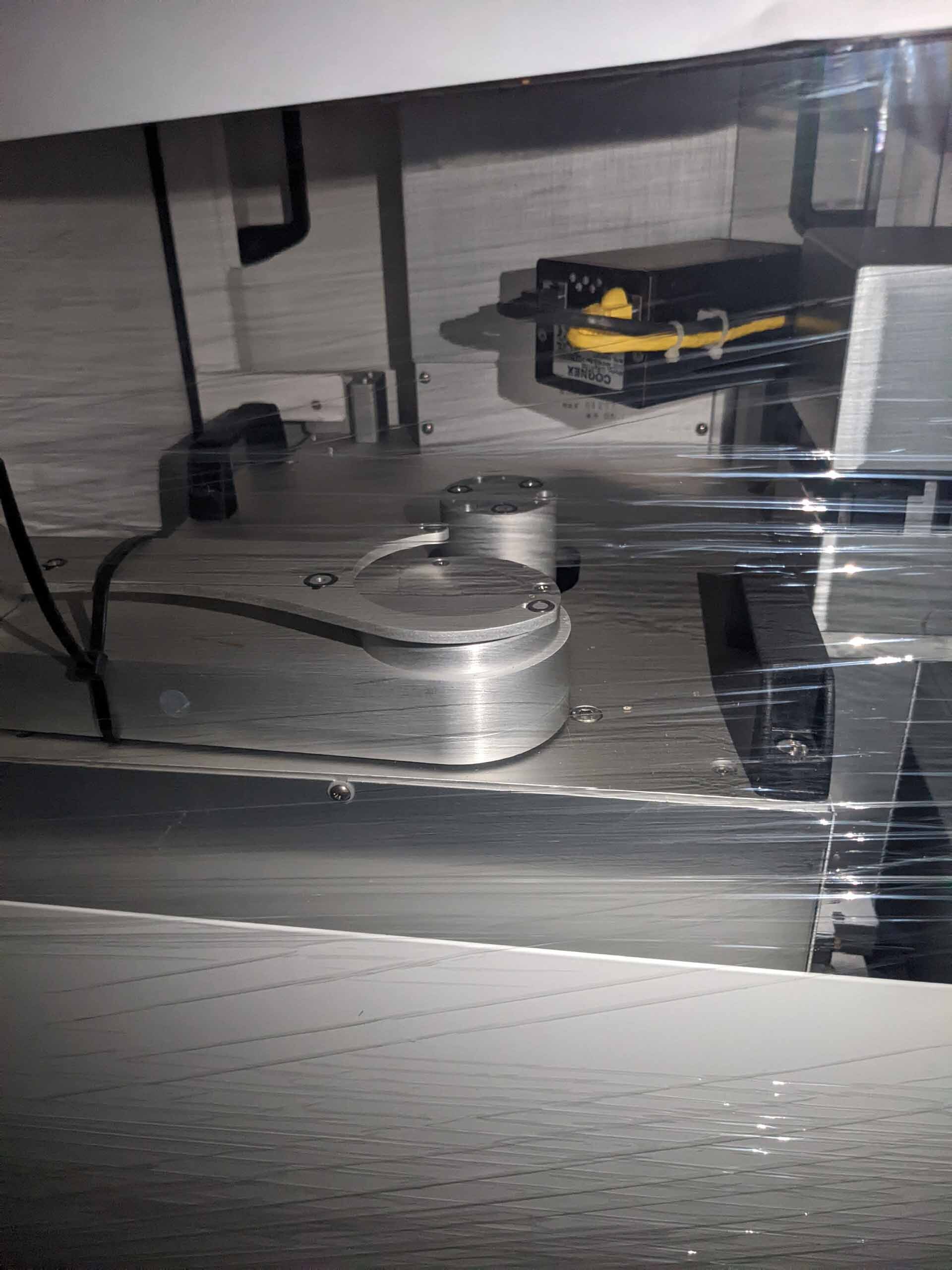

YASKAWA Spindle

Express type: Bell jar and quartz tube upgraded

(4) EPD

(5) CPMX-3000 RF Matchers

(5) 02-352103-00 RF Sources

(4) BROOKS MFC

Load / Unload port

HDIS Pedestal

Fixed pedestal

Stage: Preheat

Athena computer

UI Computer

MDC ISO Gate valve

NC Throttle valve

V-TEX Slit valve

MKS 10 Torr manometer

Gas box: O2, N2, H2N2, CF4

2004 vintage.

NOVELLUS Gamma 2130 is a high-precision etcher/asher designed to meet the needs of the semiconductor industry. It is a fully-automated etcher/asher that offers a full range of process capabilities and enables the production of high-performance devices in a variety of wafer sizes. It is equipped with a state-of-the-art PECVD chamber, capable of producing uniform and high-quality deposits of nitride, oxynitride, and polysilicon films. Gamma 2130 also features a high-resolution imaging and patterning system for layout design and accurate masking for precise etching or ashing. NOVELLUS Gamma 2130 is capable of depositing or etching several layers with different thicknesses and dimensions at a high throughput rate. It has a maximum etch rate of 1000A/min and can achieve repeatable results with uniformity over 50mm wafers. The platform offers unparalleled control over reactive species concentrations and substrate temperature. Moreover, it can be configured with an array of gas delivery and process control systems to support a variety of deposition and etching applications. Gamma 2130 is built using the latest technology and is rated for a pressure of 1000mBar. It is equipped with a high-precision end-point monitoring and control system to ensure exact metrology and process control over a variety of wafer sizes and materials. The advanced imaging systems and software setups allow for improved yields and consistency in coating and etching processes. The system is also designed for performance in high dust and deposition or etch rates. NOVELLUS Gamma 2130 offers the highest possible levels of safety and reliability, due to its in-built safety mechanisms and redundant systems for protection. It is designed to run nonstop for extended periods of time and is easily customizable depending on the needs of the desired application. Gamma 2130 is a robust and advanced etcher/asher that can provide flexible, reliable and cost-effective solutions for any semiconductor process.

There are no reviews yet